Air conditioner debugging system and method for confirming capillary tube length

A debugging system and capillary technology, applied in space heating and ventilation details, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve problems such as long time-consuming and cumbersome capillary process, and achieve short time-consuming and labor-saving , the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

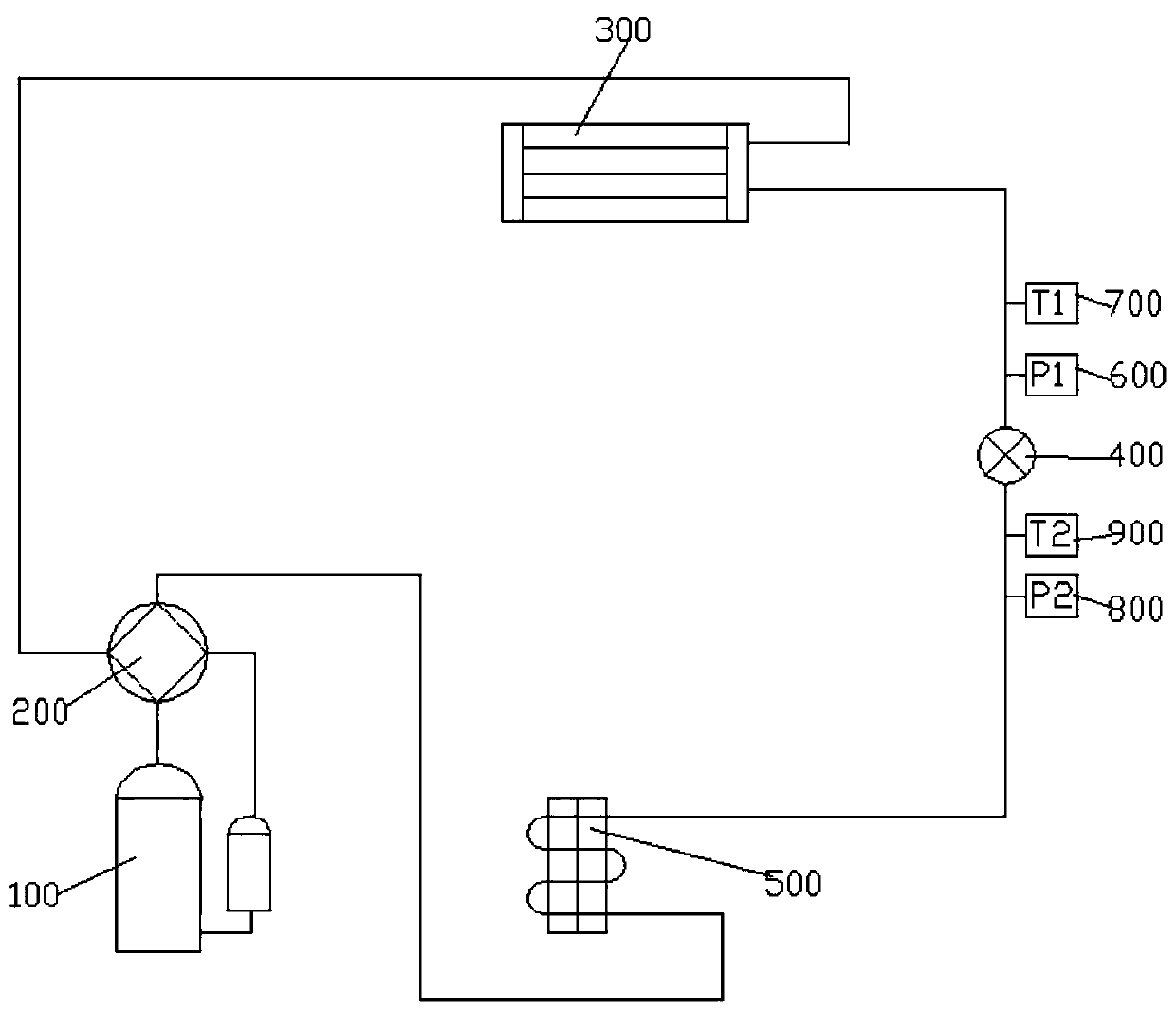

[0060] This embodiment discloses an air conditioner debugging system, which is used to determine the capillary length, such as figure 1As shown, the air conditioning debugging system includes a compressor 100, a four-way valve 200, a condenser 300, and an evaporator 400 connected in sequence, and an electronic expansion valve 500 is arranged between the condenser 300 and the evaporator 400, and the inlet of the electronic expansion valve 500 A first pressure sensor 600 and a first temperature sensor 700 are installed, and an outlet of the electronic expansion valve 500 is installed with a second pressure sensor 800 and a second temperature sensor 900 .

[0061] In this embodiment, preferably, the air conditioning debugging system includes a controller, and the controller is respectively connected to the compressor 100, the electronic expansion valve 500, the first pressure sensor 600, the first temperature sensor 700, the second pressure sensor 800 and the second temperature se...

Embodiment 2

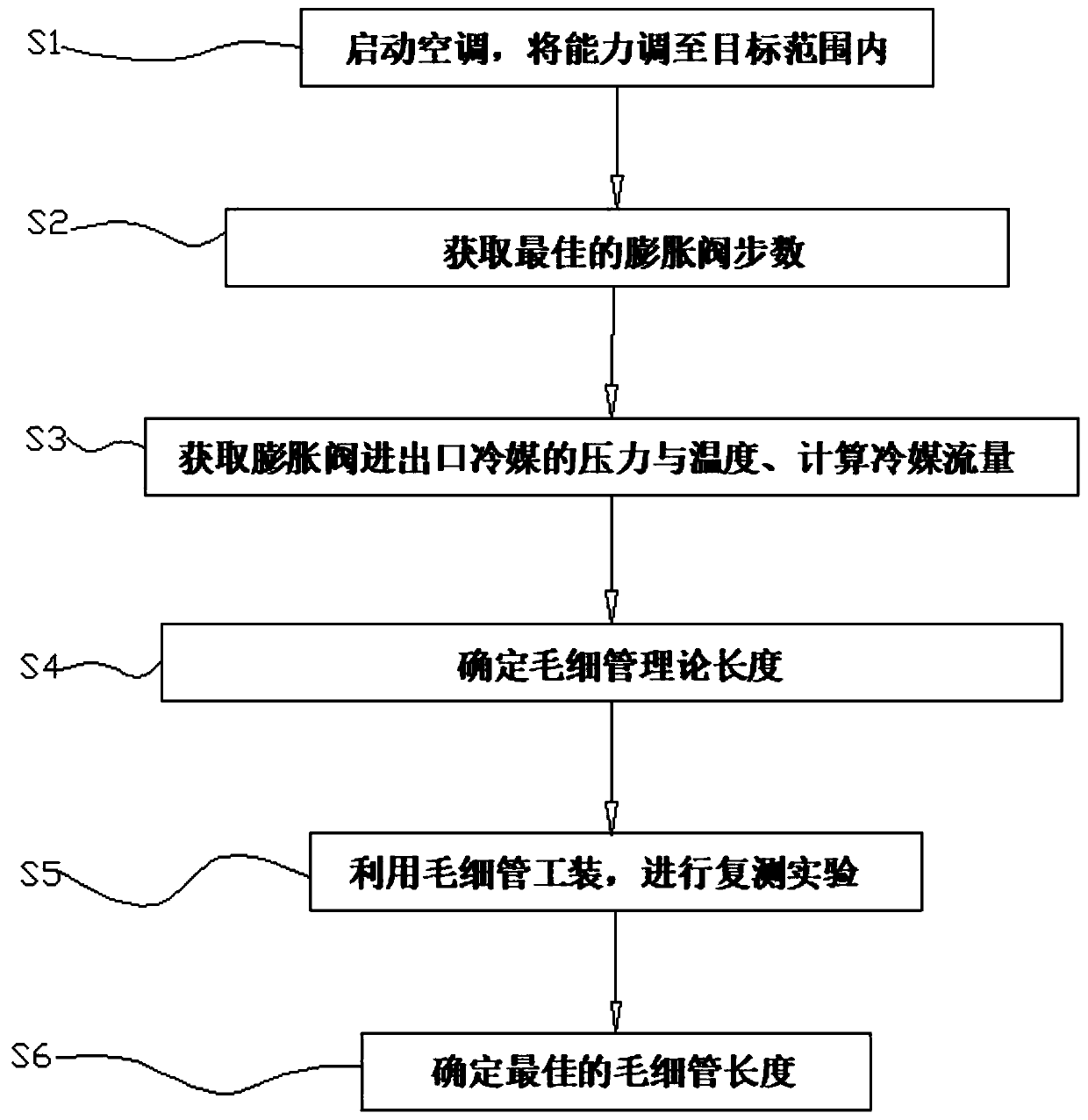

[0064] This embodiment discloses a method for determining the length of the capillary, using the air conditioning debugging system in Embodiment 1, such as figure 2 As shown, methods for determining capillary length include:

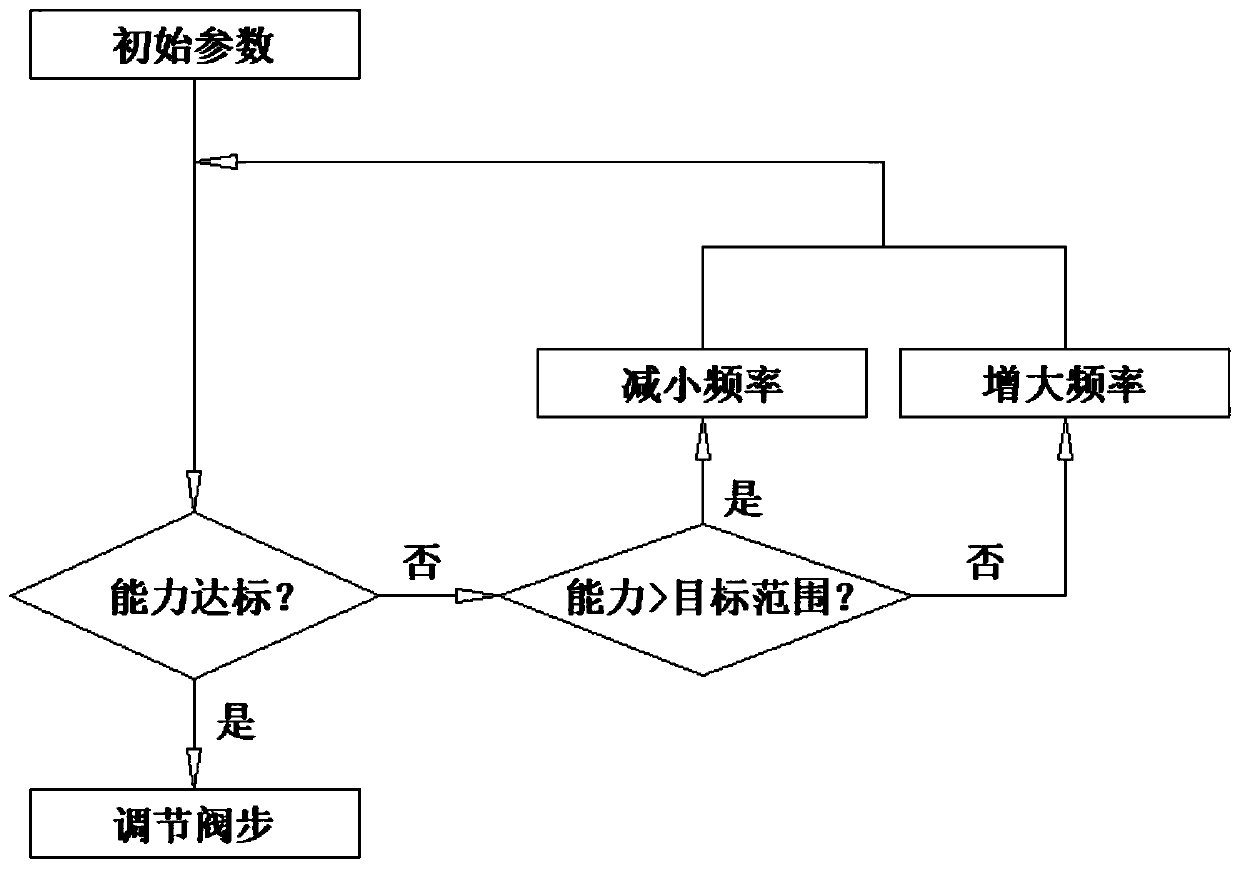

[0065] S1. Start the air conditioning debugging system, set the parameters according to the experience value, adjust the frequency of the compressor, and adjust the capacity to the target range;

[0066] S2. With the best energy efficiency as the goal, adjust the valve step of the electronic expansion valve to obtain the number of steps of the electronic expansion valve when the energy efficiency is the best;

[0067] S3. Obtain the pressure and temperature at the inlet and outlet of the electronic expansion valve 500 when the energy efficiency is the best, and calculate the refrigerant flow rate in the air conditioning debugging system;

[0068] S4. According to the pressure and temperature at the inlet and outlet of the electronic expansion valve 500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com