A kind of glass capillary and preparation method thereof

A glass capillary and glass tube technology, used in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of demanding mold performance, internal air lines, and high precision of processing equipment, avoiding quality defects, good shrinkage bonding, and groove size. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

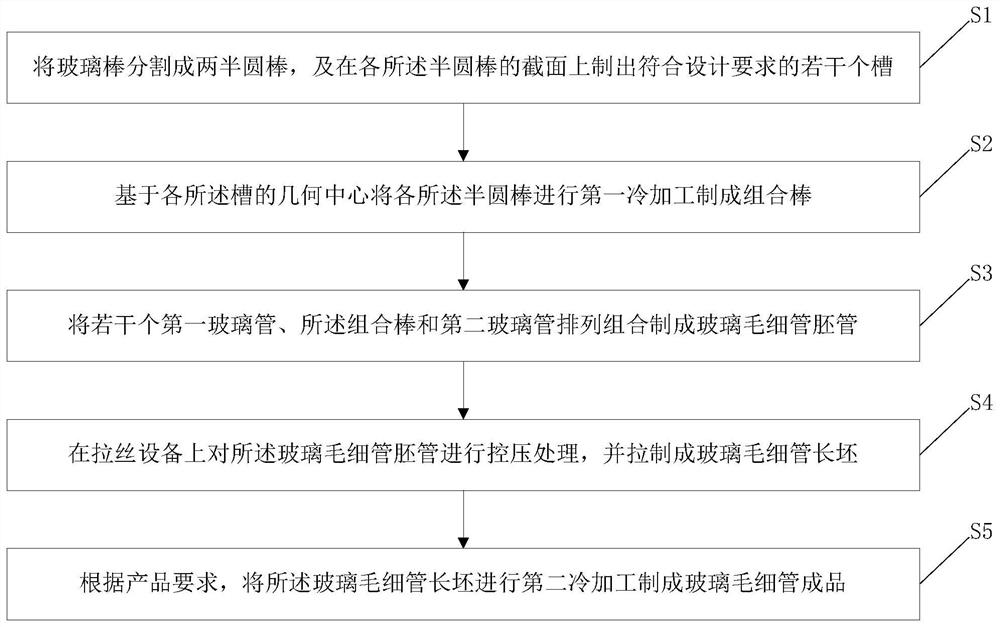

[0055] like figure 1 As shown, one aspect of the present invention provides a method for preparing a glass capillary, comprising the following steps:

[0056] S1. Divide the glass rod into two semicircular rods, and make several grooves that meet the design requirements on the section of each of the semicircular rods;

[0057] S2, performing first cold working on each of the semicircular bars based on the geometric center of each of the grooves to form a composite bar;

[0058] S3, arrange and combine several first glass tubes, described combined rods and second glass tubes to make glass capillary embryo tubes;

[0059] S4, performing pressure-controlled treatment on the glass capillary embryo tube on the wire drawing equipment, and drawing it into a long glass capillary tube blank;

[0060] S5. According to product requirements, the glass capillary long blank is subjected to a second cold working to obtain a finished glass capillary tube.

[0061] In this embodiment, the o...

Embodiment 2

[0090] Another aspect of the present invention provides a glass capillary tube, the glass capillary tube is manufactured by the method described in the first embodiment.

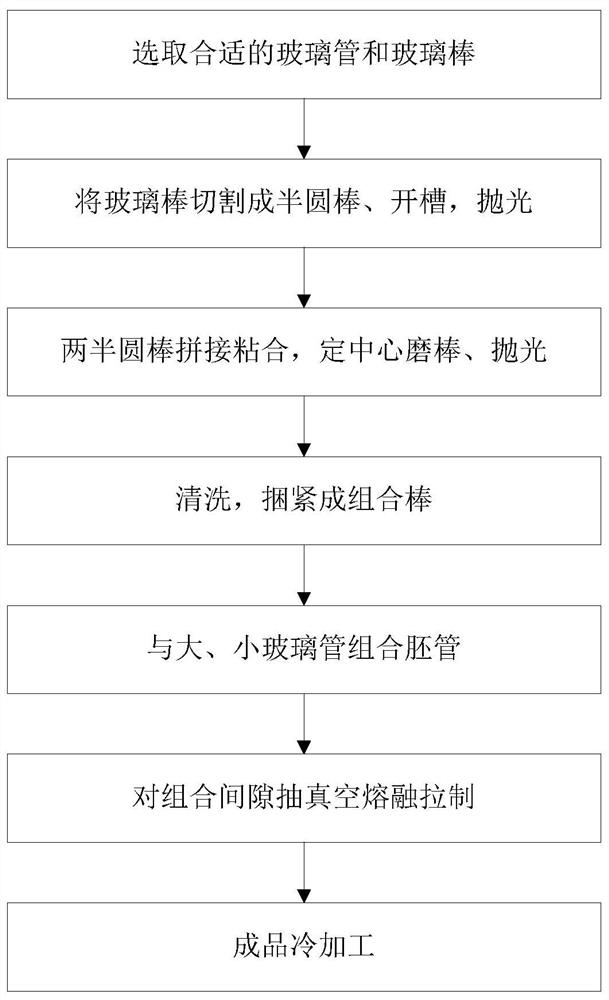

[0091] like figure 2 As shown, a process flow chart for preparing a glass capillary tube of the present invention specifically includes the following:

[0092] (1) According to the needs of the product, select a large glass tube (second glass tube), a small glass tube (first glass tube) and a glass rod of appropriate size.

[0093] (2) The glass rod is cut from the middle into two semi-circular rods of the same size by the optical precision machining method, and the required single or double grooves are processed on the plane of the semi-circular rod, and the plane and groove surface are polished.

[0094] (3) Splicing and bonding the two semi-circular rods to ensure the alignment of the grooves, centering and grinding the rod with the center of the single groove or the symmetrical center of the double gro...

specific Embodiment 1

[0099] like Figure 3 to Figure 5 As shown, a preparation method of a single-hole circular grooved glass capillary specifically includes the following steps:

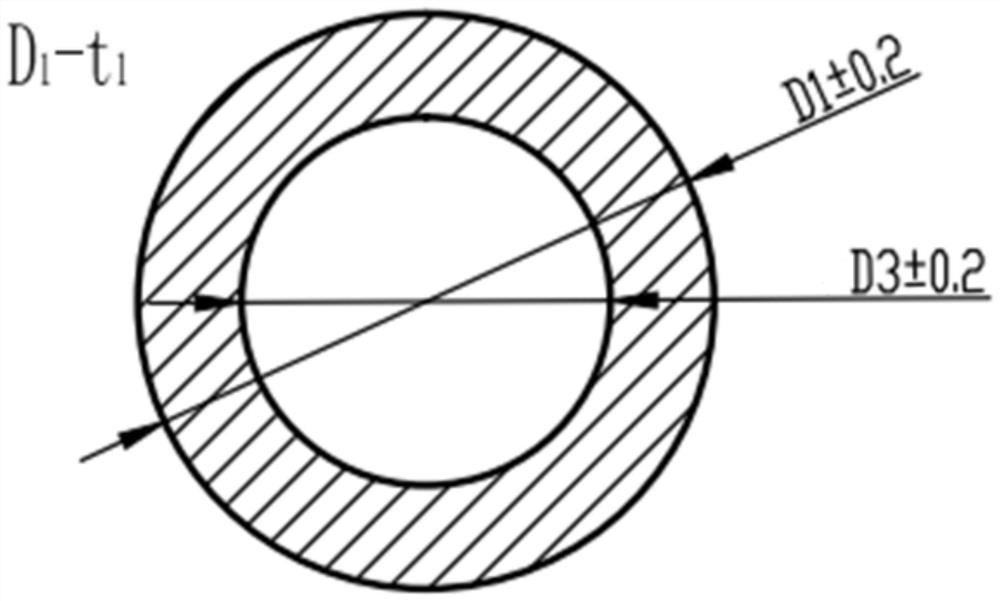

[0100] (1) Select a glass tube with a length of 500 mm and a diameter of D1-t1 (the second glass tube), a glass tube with a length of 550 mm and a diameter of D7 (the first glass tube), and a glass rod with a length of 450 mm and a diameter of D2.

[0101] (2) The glass rod is cut from the middle into two semi-circular rods of the same size by the precision optical processing method, and a precision grinding machine equipped with a special forming grinding wheel is used to process the diameter of D9±0.05mm in the center on the plane of the semi-circular rod. (like Figure 4 shown) with a semicircular groove, and the flat and groove surfaces are polished.

[0102] (3) Use wax to splice and bond the two semi-circular rods to ensure that the grooves are aligned, center the rod with the center of the splicing slot as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com