Method for calculating simulated leakage rate

A calculation method and leakage technology, applied in the calculation field of simulated leakage, can solve the problems of expensive aircraft equipment, lack of airtightness, large volume and other problems, and achieve the effect of reducing the test cost and test difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

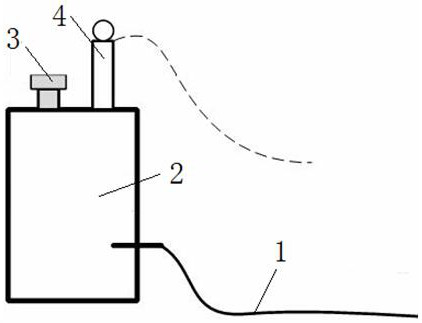

[0037] Such as figure 1 As shown, a calculation method of simulated leakage includes the following steps:

[0038] a. Insert one end of the capillary 1 into the simulation chamber 2, and the other end extends outside the simulation chamber 2, and fill the simulation chamber 2 with pressure gas through the inlet 3;

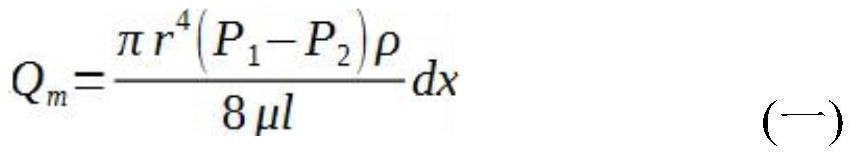

[0039] b. Calculate the capillary length required for leakage according to the mass flow rate of the capillary, the formula is as follows:

[0040]

[0041] Among them, P1 and P2 are the pressures at the two ports of the capillary (pa); ρ is the flow density (kg / m 3 ); μ is the dynamic viscosity coefficient (pa s); l is the capillary length (m); r is the capillary radius (m), Q m is the set leakage rate;

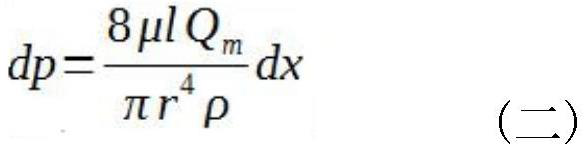

[0042] c. Set dx as any length (m) on the capillary, and the pressure difference at both ends is dp=p1-p2, and the following formula can be obtained from formula (1):

[0043]

[0044] d. The following formula is obtained from the gas state formula P=ρR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com