Full-automatic screening machine for refill capillary tube

A capillary and screening machine technology, applied in sorting and other directions, can solve problems such as uneven refill weight layers, difficult manual screening, and affecting the writing effect of pens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

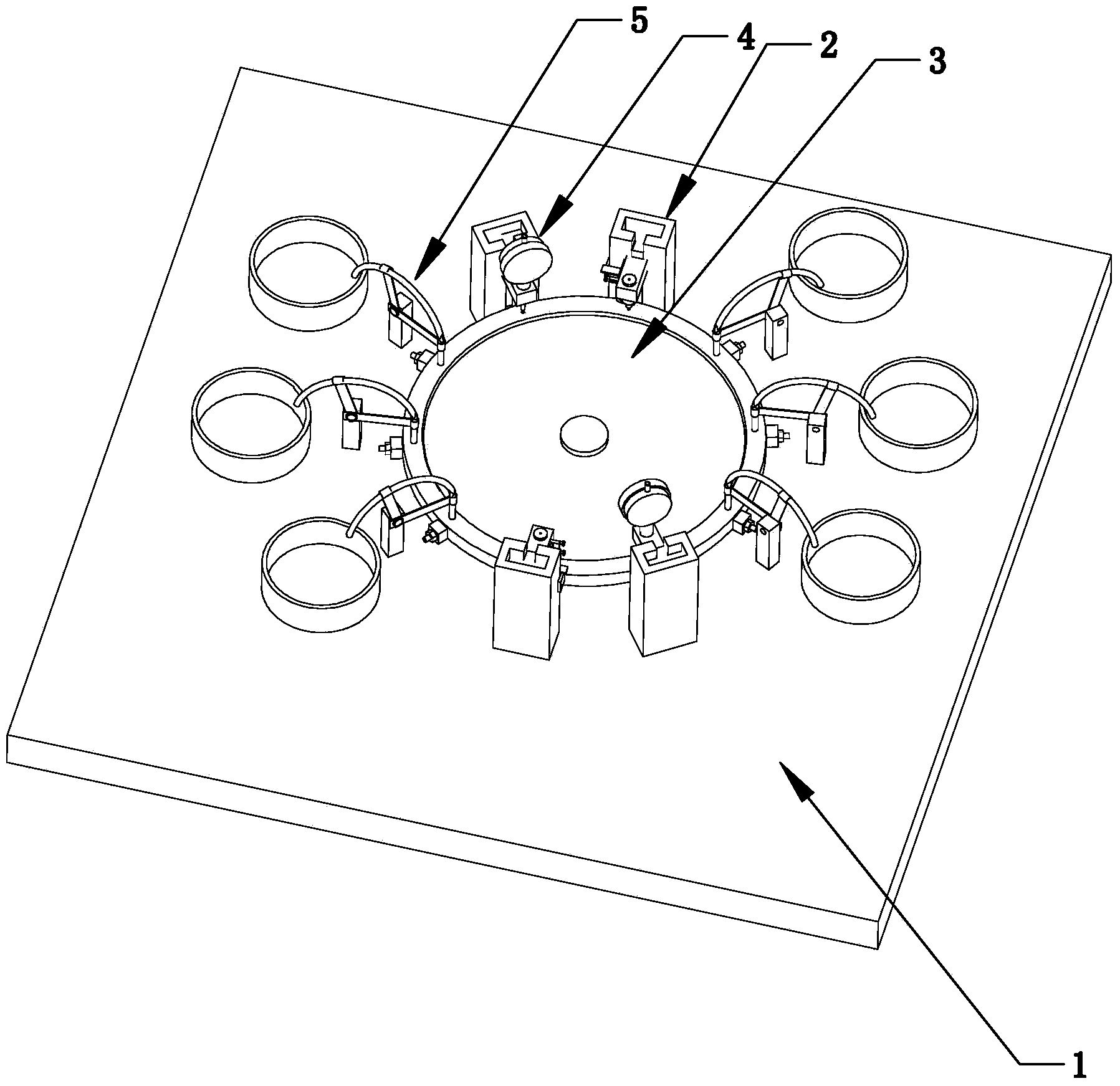

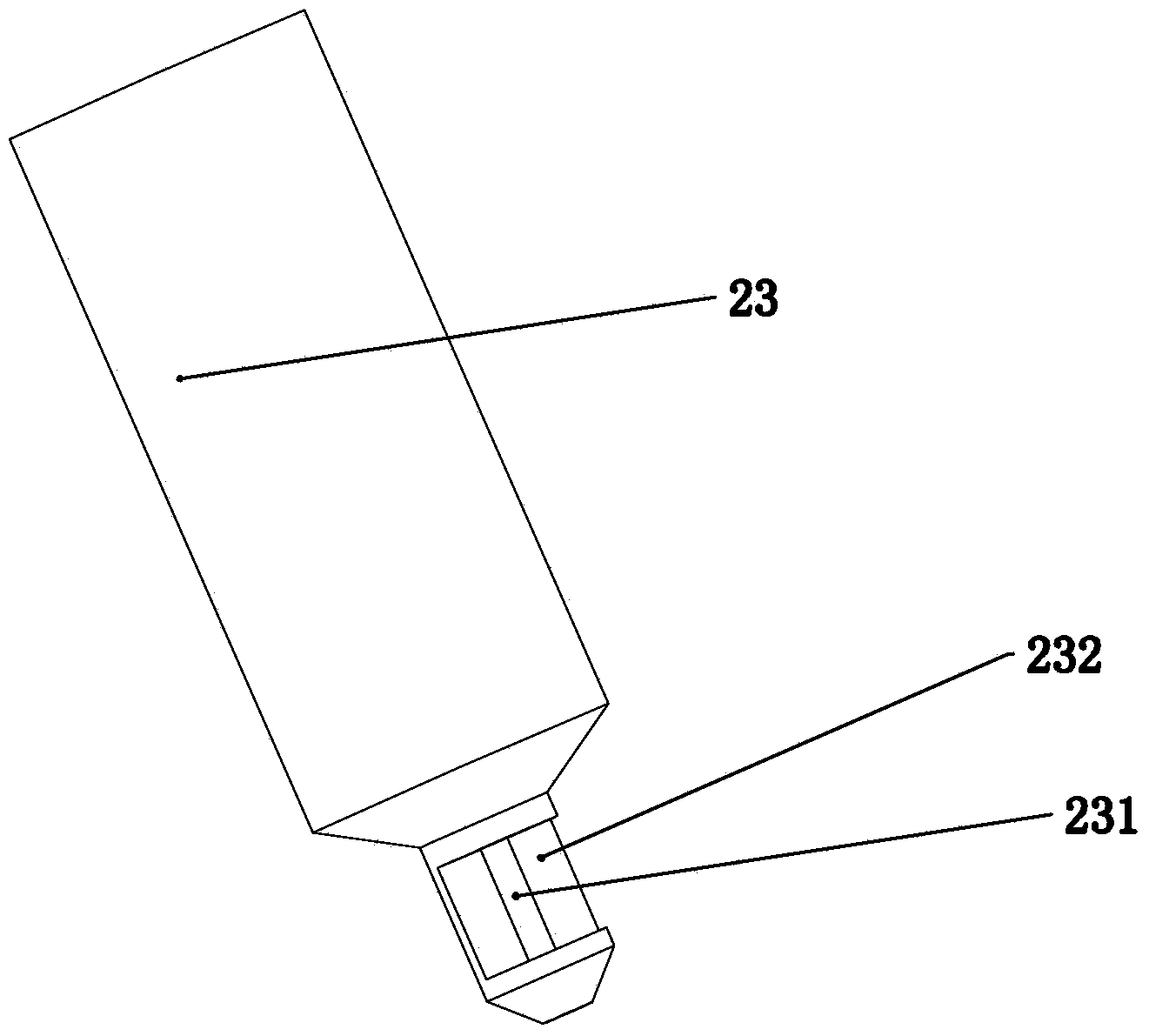

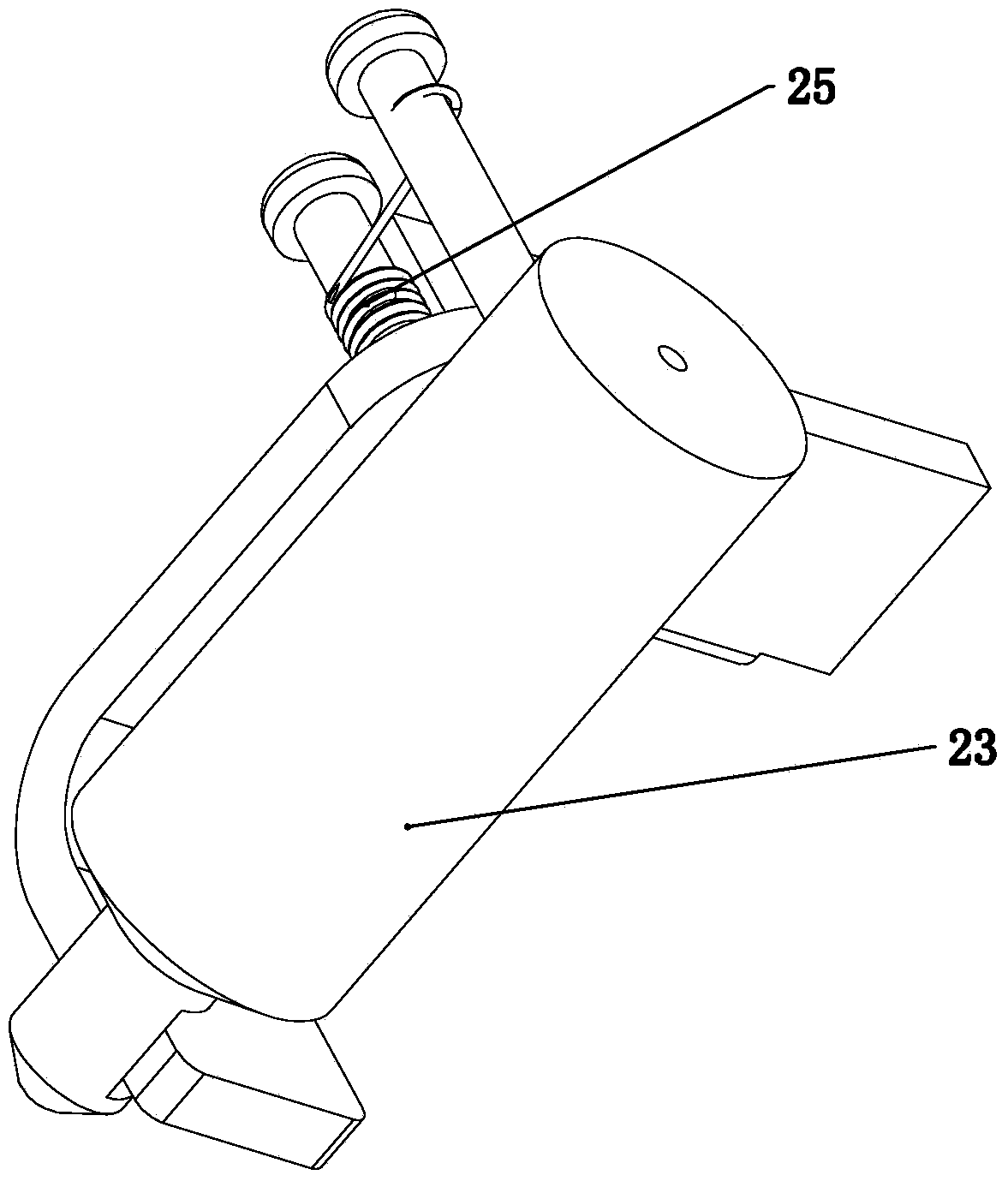

[0017] like figure 1 — Image 6 As shown, a fully automatic screening machine for pen core capillary tubes includes a frame 1, a turntable 3, a pen core capillary tube placement mechanism 2, a pen core capillary tube length detection mechanism 4, a pen core capillary tube screening mechanism 5 and a transmission mechanism, and the turntable 2 Rotation is arranged on the frame 1, and the pen core capillary tube placement hole 31 is evenly arranged on the said turntable 3 around its circumference, and the diameter of the placement hole 31 is slightly larger than the diameter of the pen core capillary tube, and the pen core capillary tube placement mechanism 2, pen The core capillary length detection mechanism 4 and the pen core capillary screening mechanism 5 are sequentially arranged on the periphery of the loading plate 2, and the pen core capillary placement mechanism 2 includes a first bracket 21, a first sliding block 22, a feeding tube 23 and a splint 24, wherein the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com