Auxiliary cooling system for reaction core of passive reactor

An auxiliary cooling system and reactor technology, which is applied in the directions of reactors, cooling devices, nuclear power generation, etc., can solve the problems of low flow rate of passive cooling water and low boundary heat flux density on the wall of the reactor melt retention device, so as to improve safety and improve Critical heat flux to ensure effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

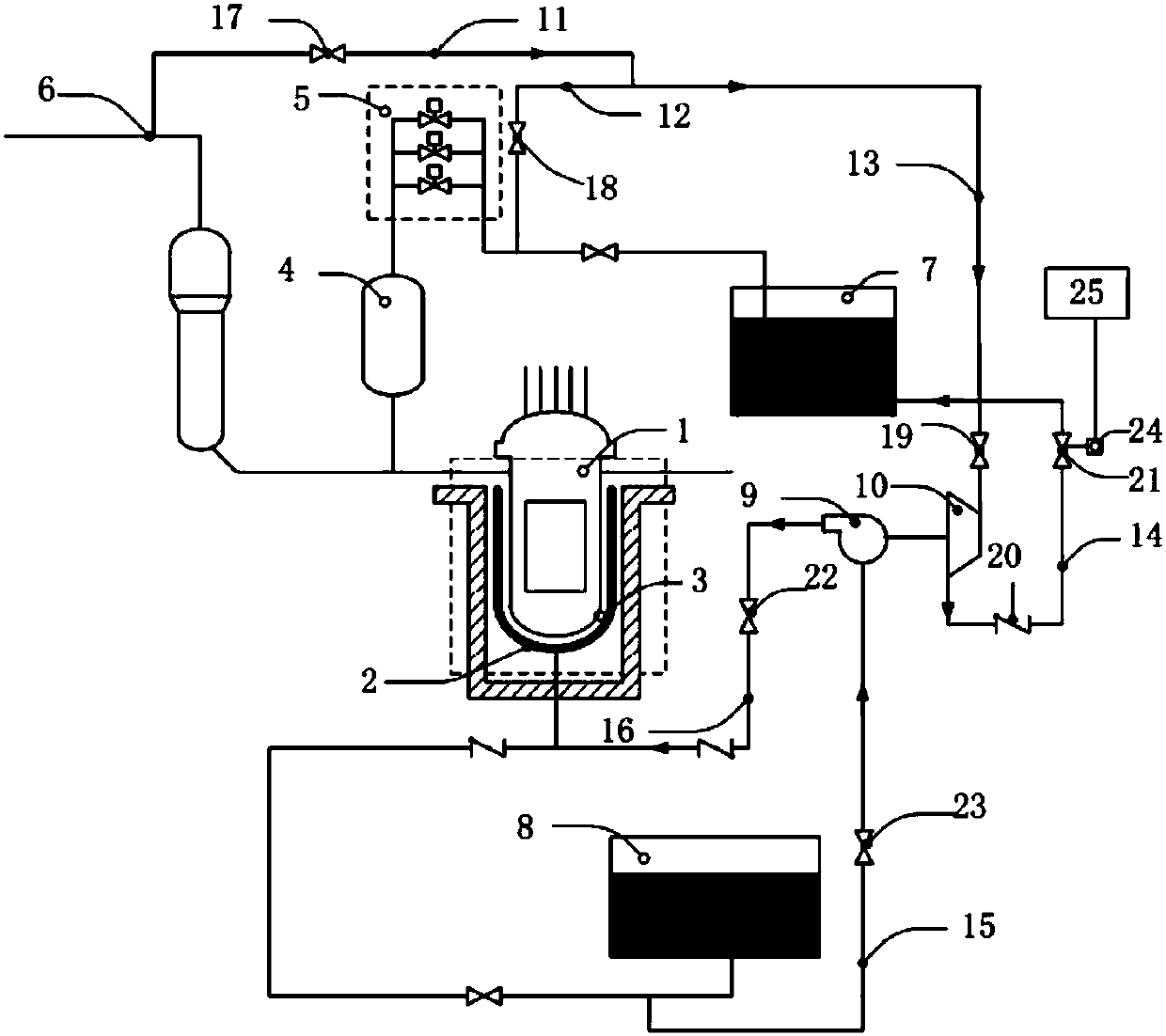

[0022] The composition of exemplary passive reactor core auxiliary cooling system of the present invention is as follows: figure 1 As shown, it includes a pressure vessel 1, an insulation layer 2, an annular space 3, a pressurizer 4, an automatic pressure relief system 5 (connected to the pressure vessel 1 through the pressurizer 4 through the pipeline), the main steam pipeline 6 of the steam generator, Pressure relief tank 7, built-in refueling water tank 8, feed water pump 9, steam turbine 10, steam generator branch steam pipeline 11, automatic pressure relief system branch pipeline 12, steam injection pipeline 13, exhaust pipeline 14, water supply pipeline 15, Drain pipeline 16 , first valve 17 , second valve 18 , third valve 19 , check valve 20 , fifth valve 22 , sixth valve 23 , fourth valve 21 , valve opening trigger switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com