Automobile hub die cooling system

A technology for mold cooling and automobile hubs, applied in the field of machinery, can solve problems such as difficult to control the solidification and molding sequence of cast blanks, reduce the pass rate of casting products, and easily produce defects in products, and achieve faster solidification speed, higher production efficiency, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

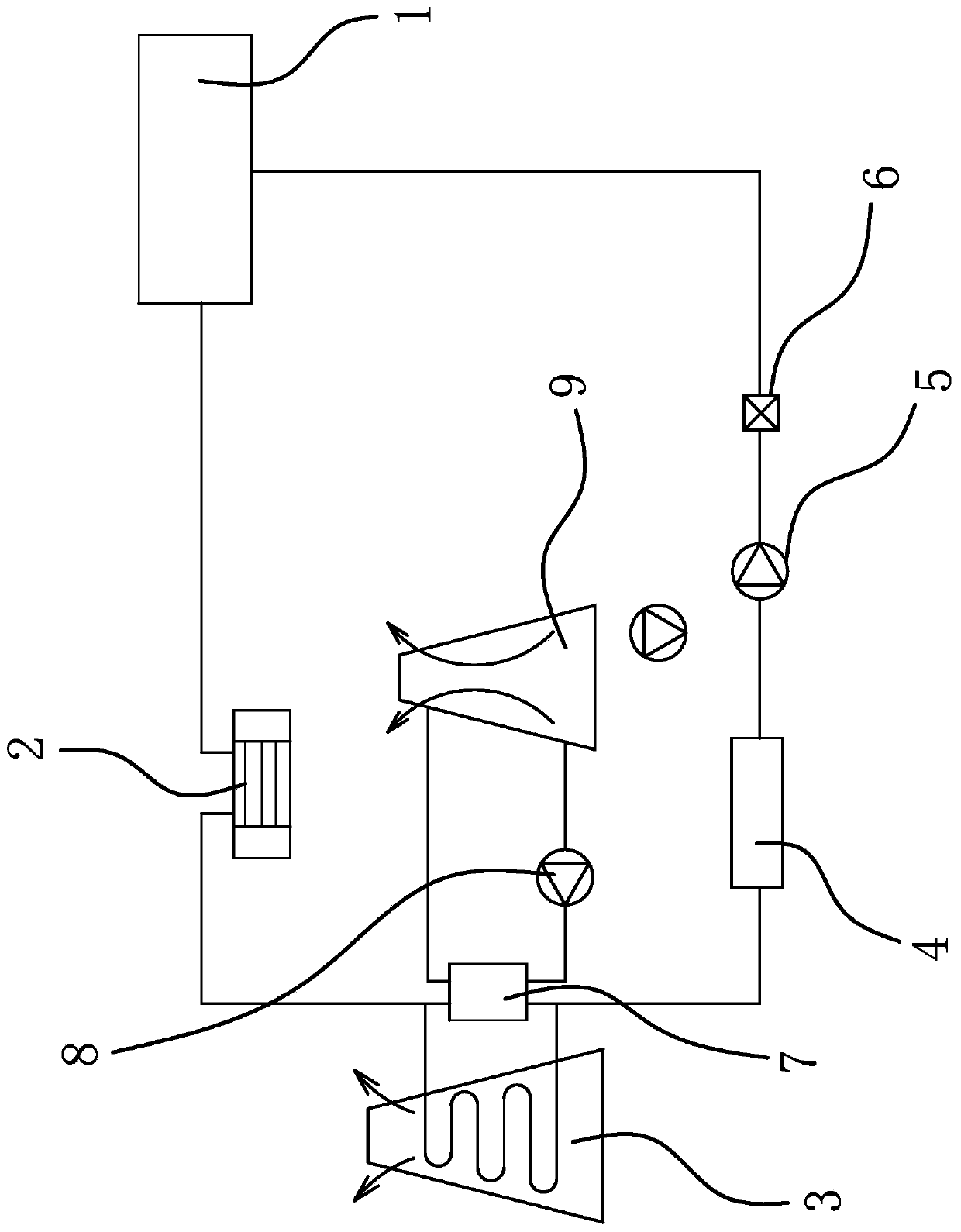

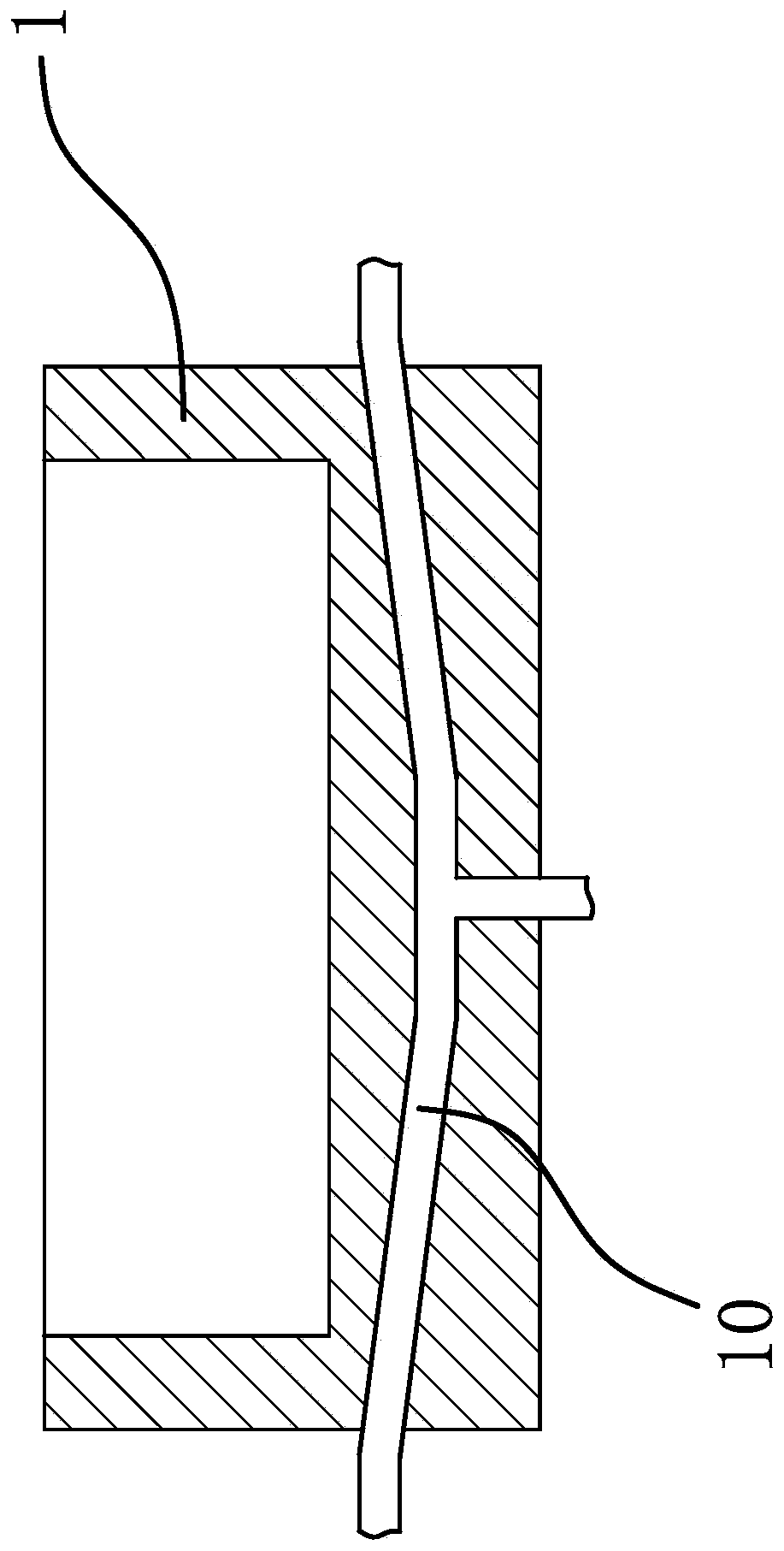

[0018] Such as figure 1 with figure 2 As shown, the cooling system of the automobile wheel hub mold includes a working fluid circulation system, a cooling water circulation and a direct air cooling system.

[0019] The working fluid circulation system consists of a hub mold 1, a compressor 2, a liquid storage tank 4, a working fluid circulation pump 5, an expansion valve 6, an evaporation channel 10, a water-cooled condenser 7 or an air-cooled condenser 3 and pipelines. The outlet of the evaporation channel 10 in the hub mold 1 is connected to the inlet of the compressor 2 through a pipe, and the outlet of the compressor 2 is divided into two ways: one way is connected to the hot fluid side inlet of the water-cooled condenser 7 through the pipe, and the hot fluid side outlet of the water-cooled condenser 7 Connected to the inlet of the liquid storage tank 4 through a pipeline; one way is connected to the hot fluid side inlet of the air-cooled condenser 3 through a pipeline, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com