Method for preparing thermally-sprayed iron-based powder porous surface heat exchange tube

A technology of iron-based powder and porous surface, which is applied in coating, fusion spraying, metal material coating process, etc., can solve the problems of deterioration of matrix pipe structure, difficulty in meeting heat exchange tubes, and reduction of mechanical properties, etc., to achieve lower temperature , low cost, and the effect of increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

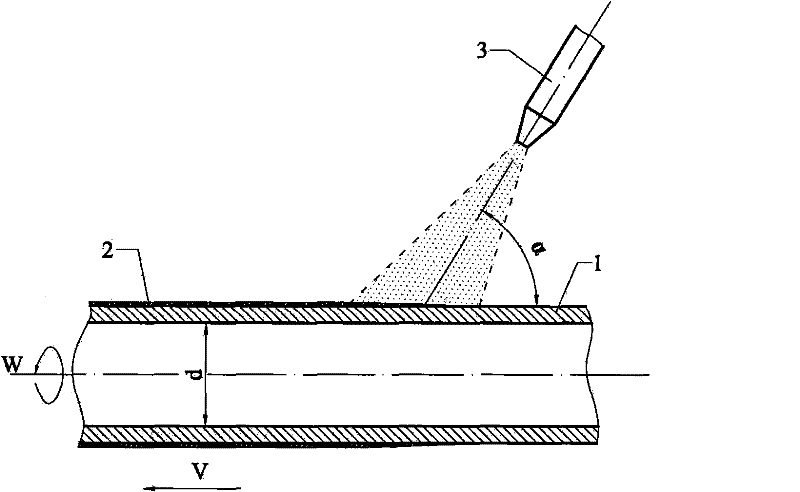

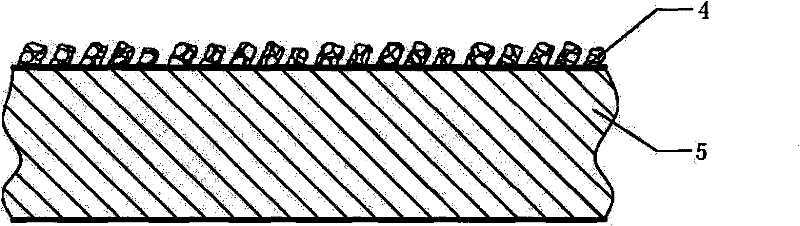

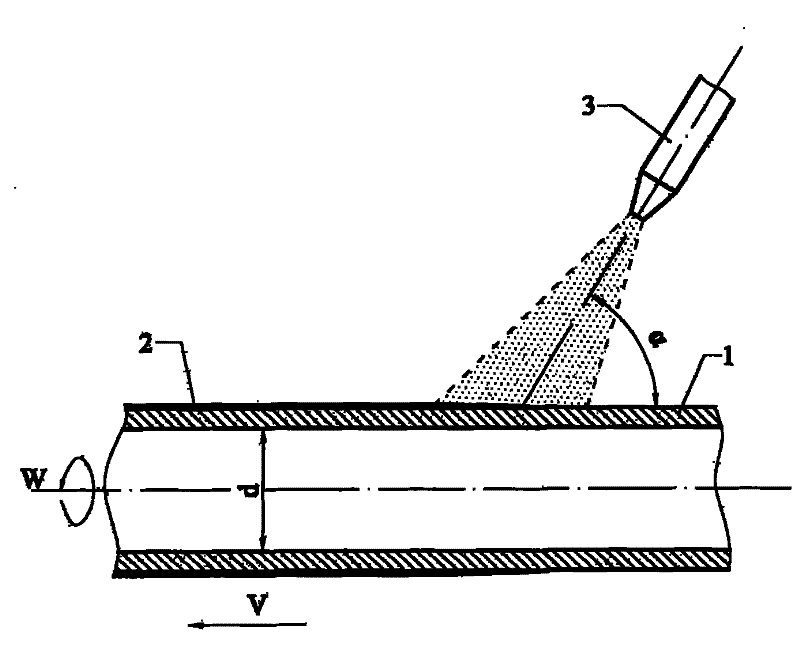

[0028] The particle size of the iron-based alloy powder is 140-200 mesh, and the particle size of the nickel-coated aluminum powder is 140-250 mesh. The iron-based alloy powder, nickel-coated aluminum powder and spraying additive are uniformly mixed in a weight ratio of 6:1:3 to form a mechanized alloy powder. First rotate the tube substrate horizontally at a speed of 400 rpm; preheat the tube substrate with a micro-carbonization flame, and control the preheating temperature at 90-110°C. Then spray nickel-clad aluminum powder on the preheated pipe substrate to form a base layer with a thickness of 0.12mm, and finally use a micro-carbonization flame at 750-900°C to spray mechanized alloy powder. (Strictly control various operating parameters during the spraying process. The pipe substrate must not exceed 200°C, and the thickness of each spraying must not exceed 0.09mm. The final thickness of the coating is determined by the number of sprayings.) Finally, a porous surface coatin...

Embodiment 2

[0032] The particle size of the iron-based alloy powder is 250-300 mesh, and the particle size of the nickel-coated aluminum powder is 250-325 mesh. The iron-based alloy powder, nickel-coated aluminum powder and spraying additive are uniformly mixed in a weight ratio of 7:1:3 to form a mechanized alloy powder. First rotate the tube substrate horizontally at a speed of 500 rpm; preheat the tube substrate with a micro-carbonization flame, and control the preheating temperature at 90-100°C. Then spray nickel-clad aluminum powder on the preheated pipe substrate to form a base layer with a thickness of 0.10mm, and finally spray the mixed powder with a micro-carbonization flame at 650-900°C. (Strictly control various operating parameters during the spraying process. The pipe substrate must not exceed 180°C, and the thickness of each spraying must not exceed 0.08mm. The final thickness of the coating is determined by the number of sprayings.) Finally, a porous surface coating with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com