Surface preparation method capable of preparing various nanowire structures

A technology of nanowires and red copper, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effects of improving boiling heat transfer, diversifying structural forms, and strengthening condensation heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

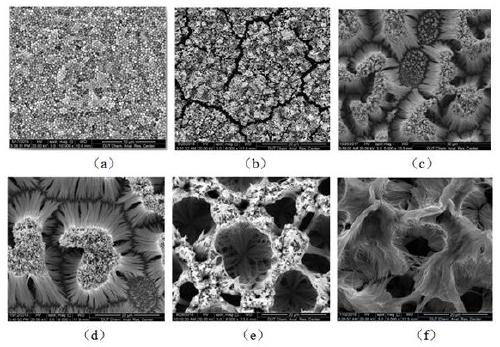

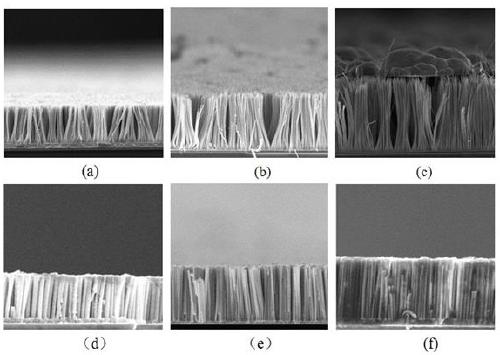

[0018] Surface preparation of vertical, agglomerated, and pit-shaped copper nanowire structures

[0019] A. Take the copper block and polish it with sandpaper, put it in acetone, ethanol, and deionized water for 10 minutes, and then take it out and blow it dry with nitrogen.

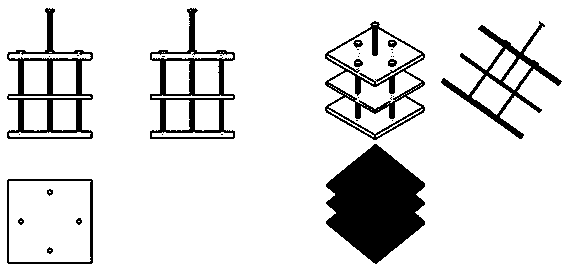

[0020] B. In the fixture, put the plexiglass block, the copper block connected to the working electrode, the porous anodized aluminum template, the filter paper dripped with the electroplating solution, the copper block connected to the counter electrode, and the plexiglass block from bottom to top, and fully clamp Tight, template models 450-360, 450-280, 450-200, 450-110, 125-30, 65-10. The voltage setting of the electrochemical workstation is -0.8V, and the time setting is 900s.

[0021]D. The working selection of the three-electrode system: the distance between the copper block covered with the template and another copper block is 20mm, and the distance between the reference electrode and the two ele...

Embodiment 2

[0025] Surface preparation of vertical and agglomerated copper nanowires with different heights

[0026] A. Take the copper block and polish it with sandpaper, put it in acetone, ethanol, and deionized water for 10 minutes, and then take it out and blow it dry with nitrogen.

[0027] B. In the two-electrode system provided by the fixture, put in order from bottom to top the plexiglass block, the copper block connected to the working electrode, the porous anodized aluminum template, the filter paper dripped with electroplating solution, the copper block connected to the counter electrode, and the plexiglass Block, and fully clamped, the template model is 450-360, 450-200. The voltage setting of the electrochemical workstation is -0.8V, and the time setting is 900s.

[0028] C. In the three-electrode system provided by the electroplating pool, the distance between the cathode copper block and the anode copper block is 20mm, and the distance between the reference electrode and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com