Patents

Literature

32results about How to "Good conductor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photovoltaic cells

InactiveUS20150083206A1Increase signal strengthLow costMaterial nanotechnologySemiconductor/solid-state device manufacturingOptoelectronicsGraphene

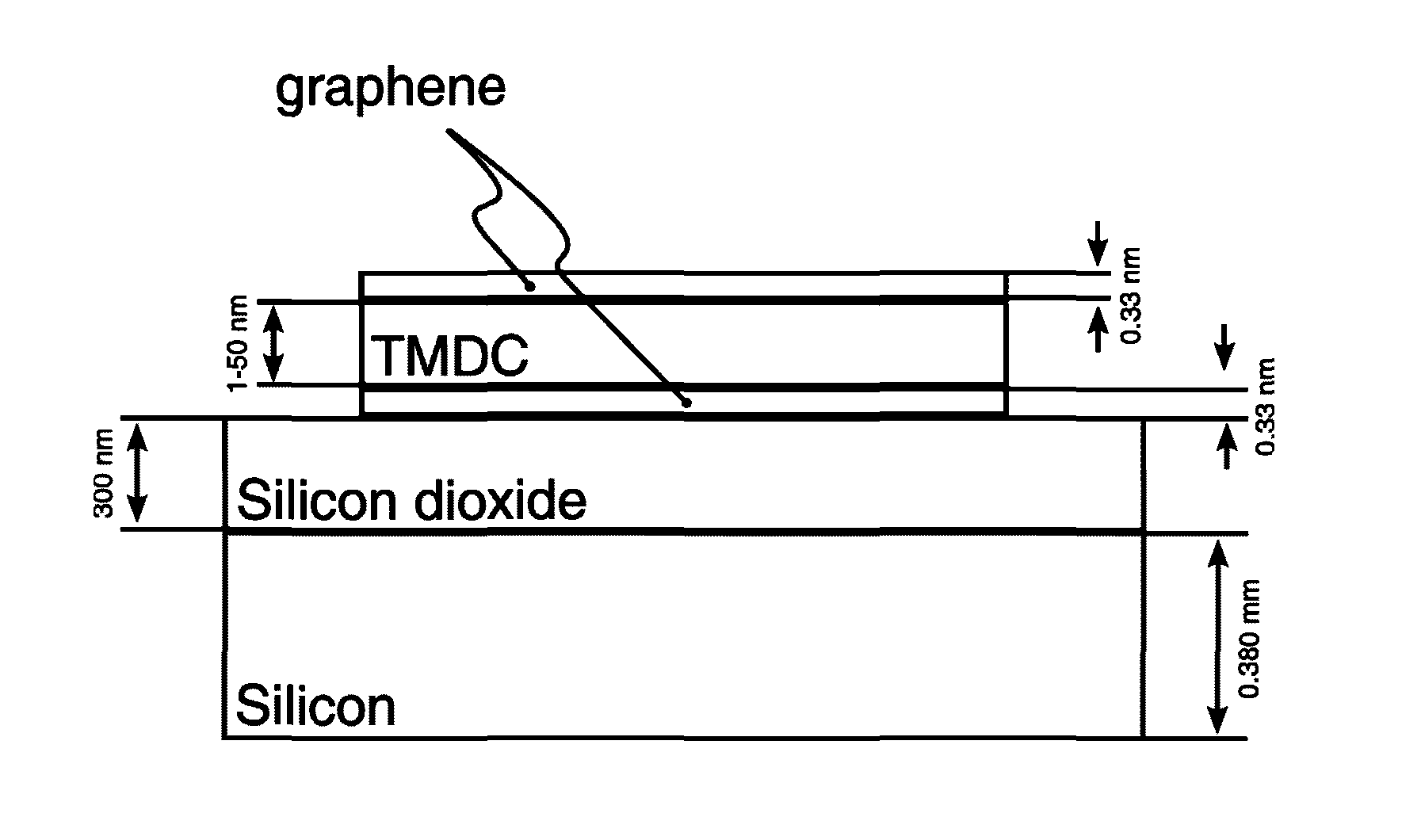

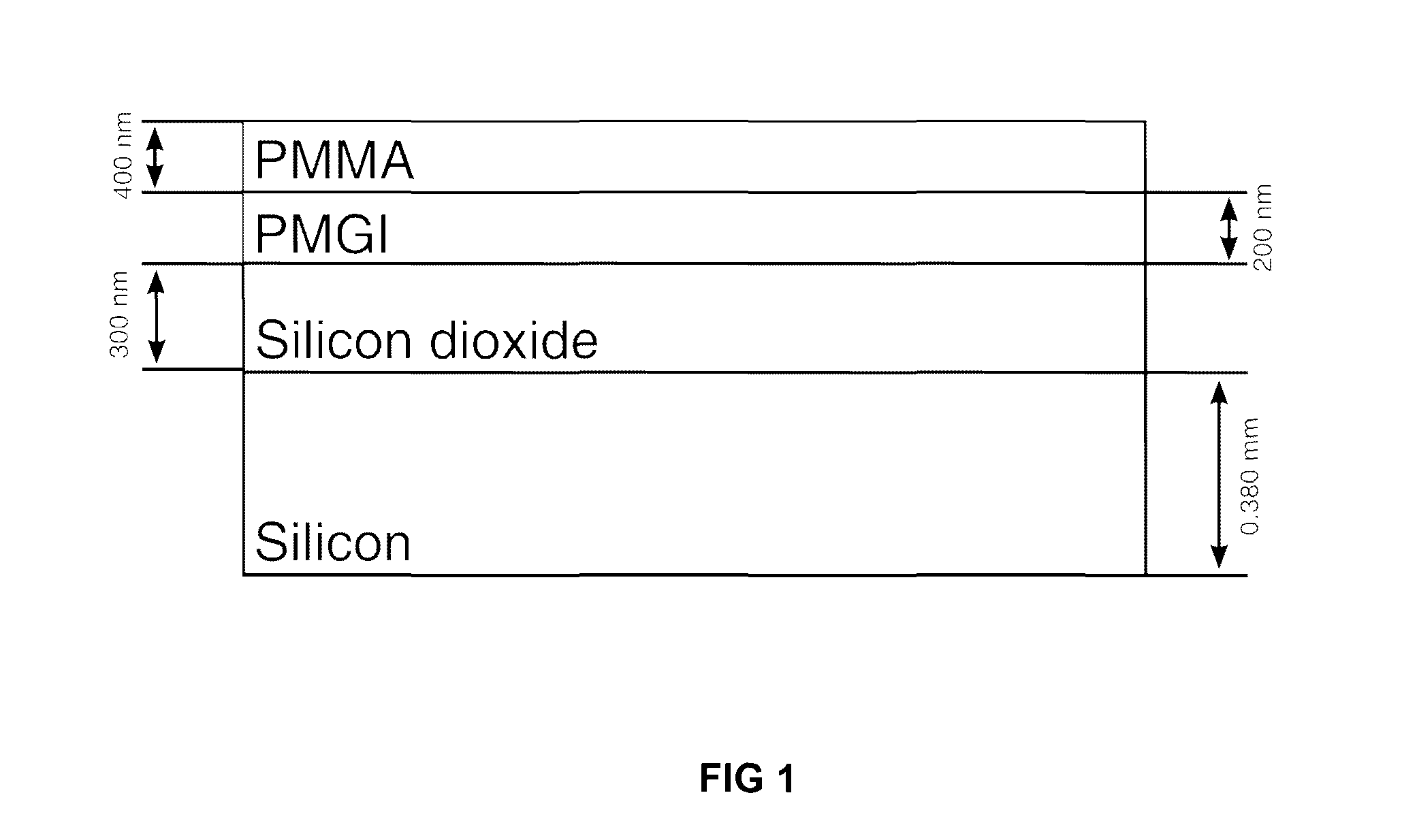

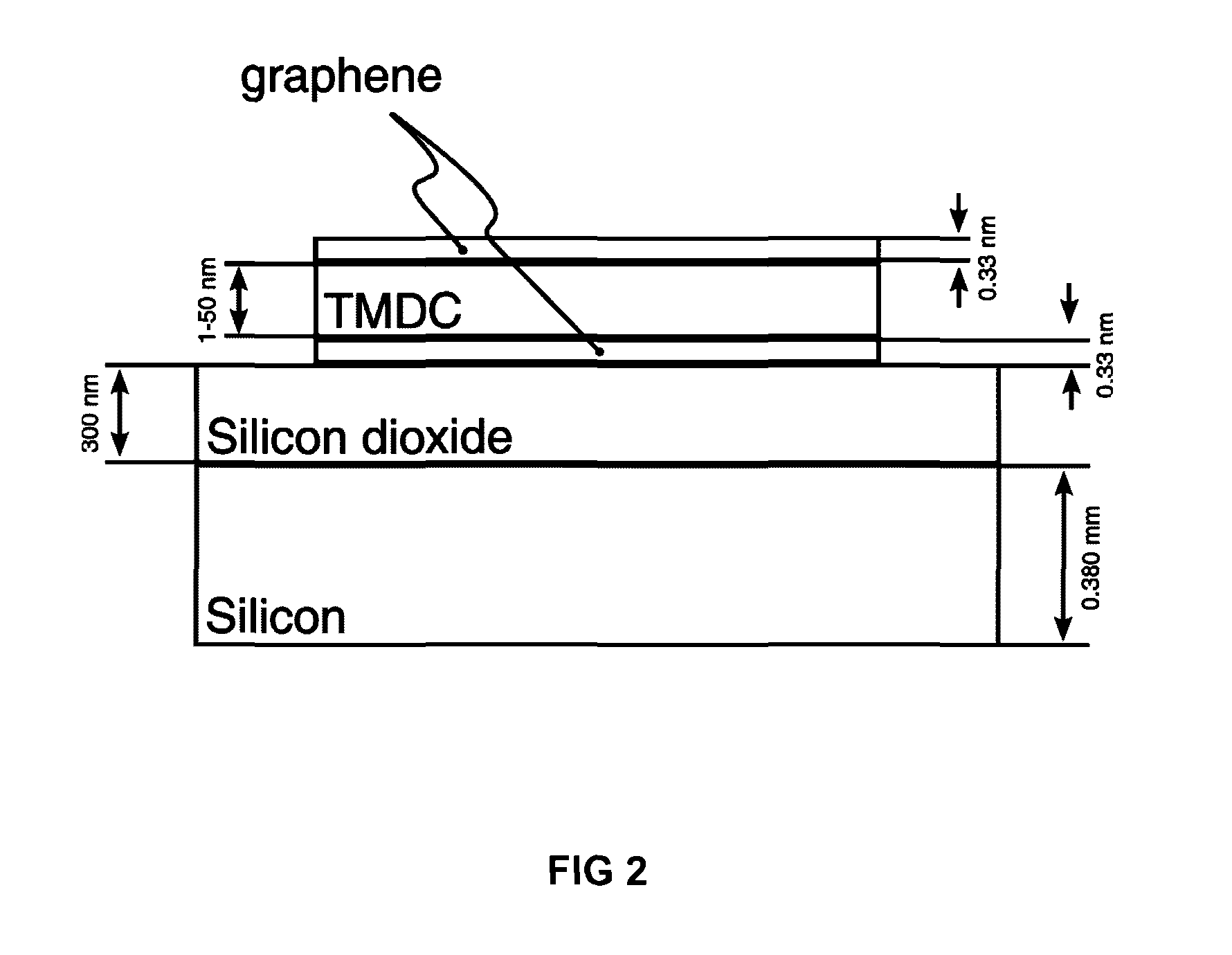

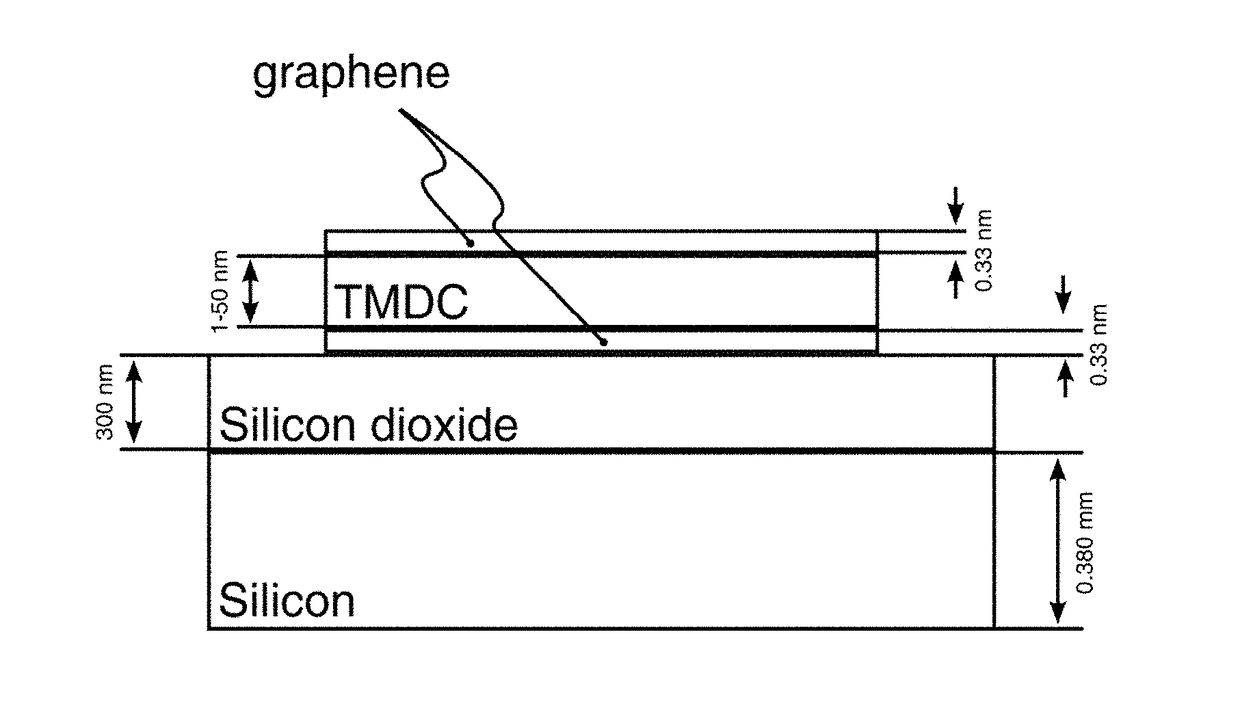

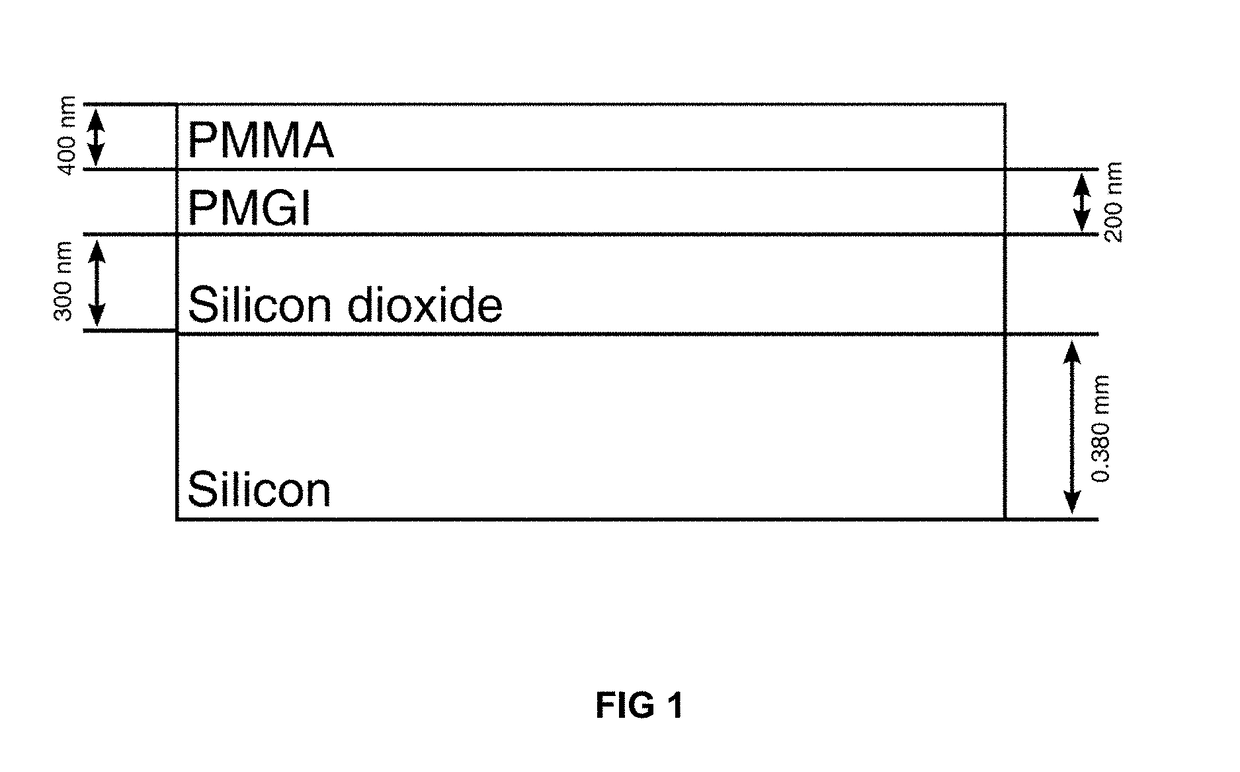

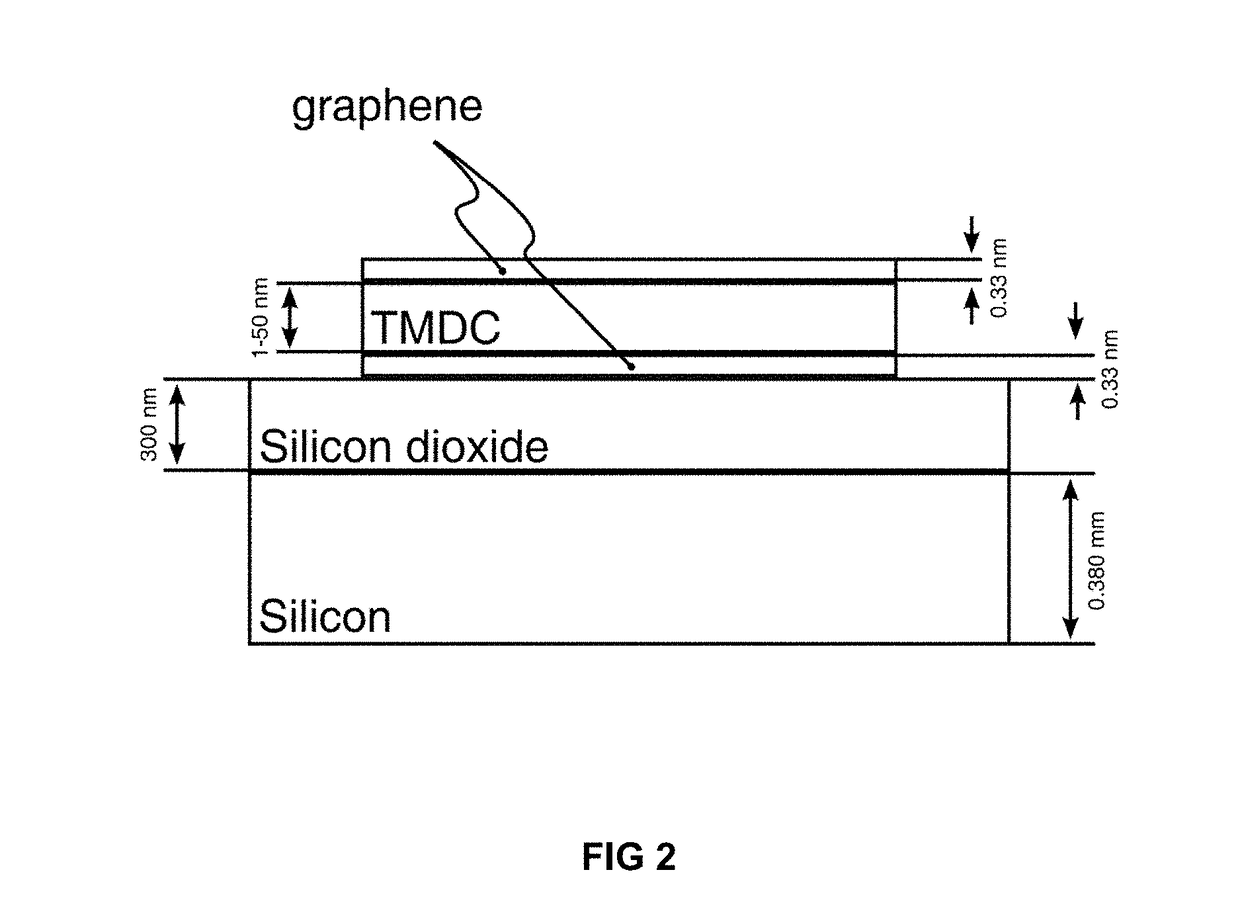

This invention relates to cells and devices for harvesting light. Specifically the cell comprises at least one electrode which comprises graphene or modified graphene and layer of a transition metal dichalcogenide in a vertical heterostructure. The cell may be part of a light harvesting device. The invention also relates to materials and methods for making such cells and devices.

Owner:UNIV OF MANCHESTER

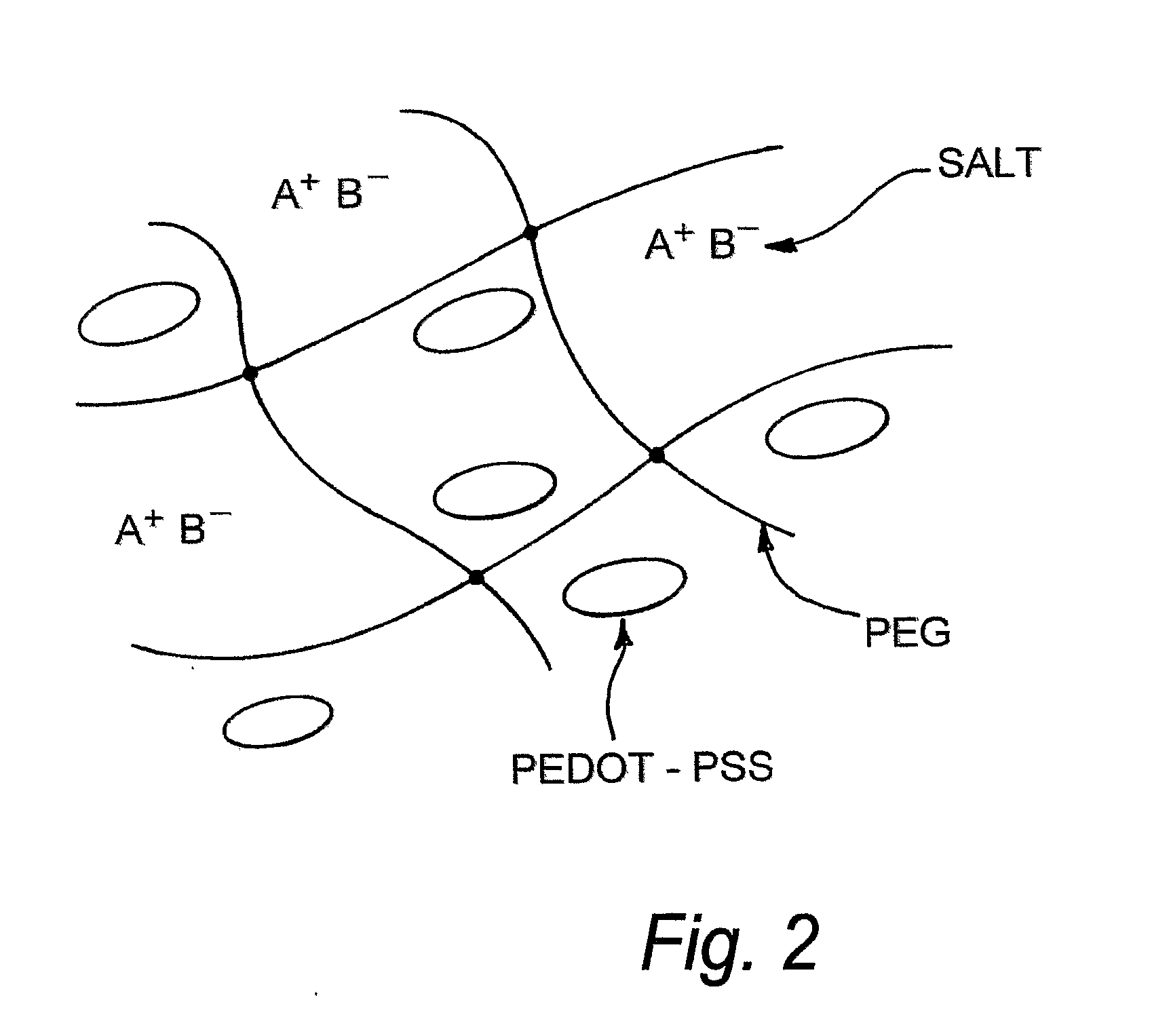

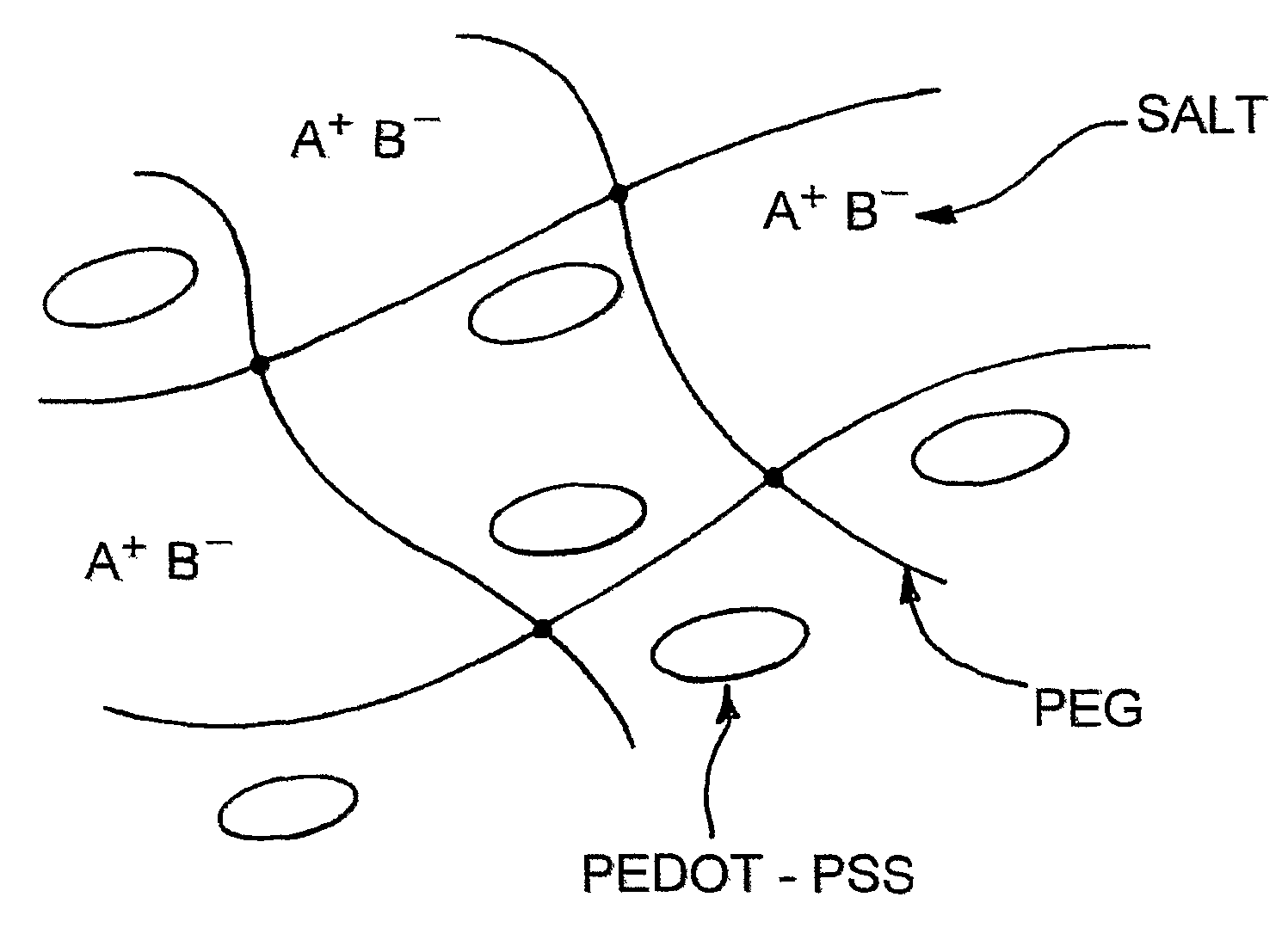

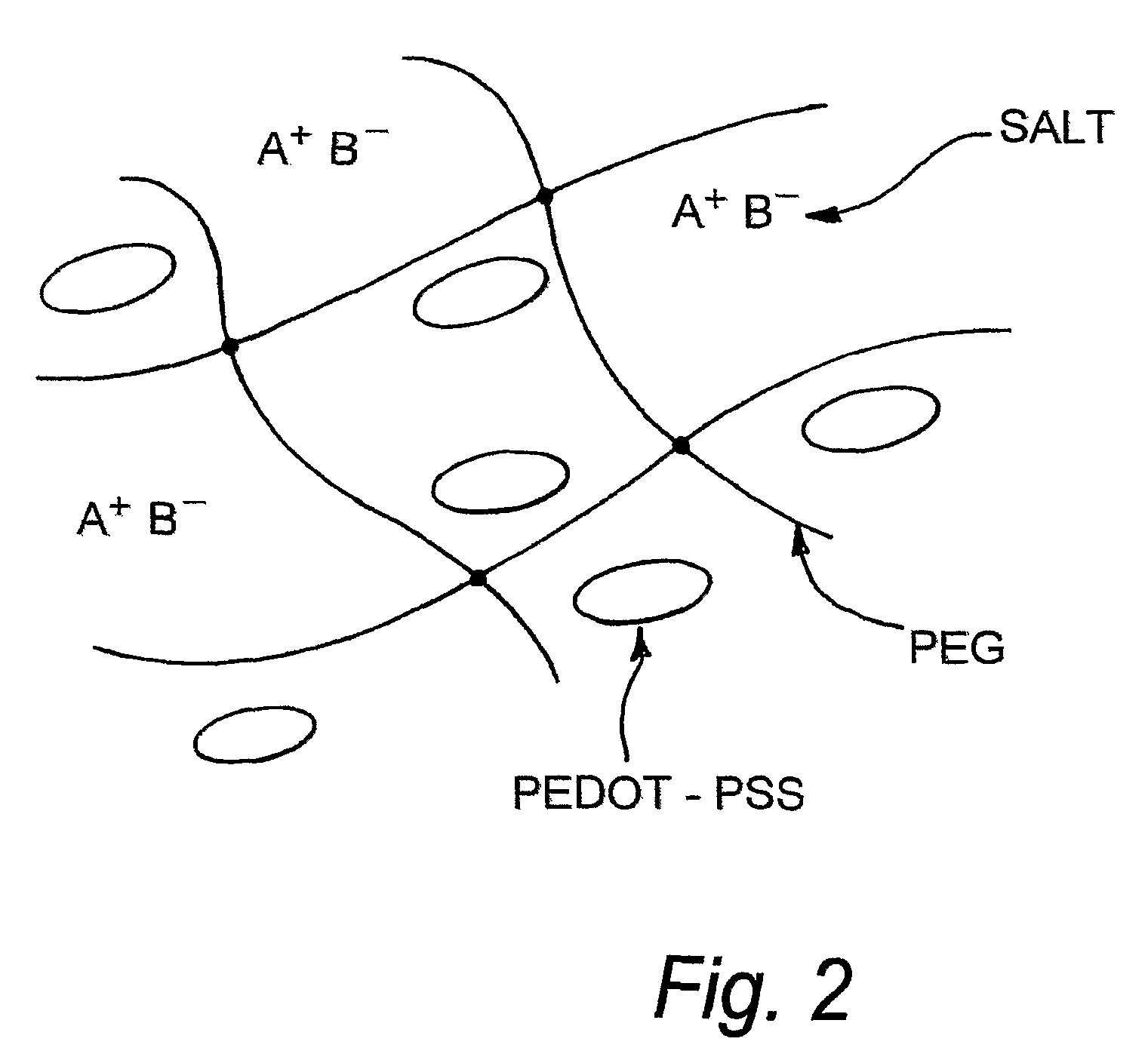

Conductive Polymer Compositions in Opto-Electrical Devices

InactiveUS20100025703A1Good conductorConductive materialSolid-state devicesPolyelectrolytePolymer science

Owner:CAMBRIDGE DISPLAY TECH LTD +1

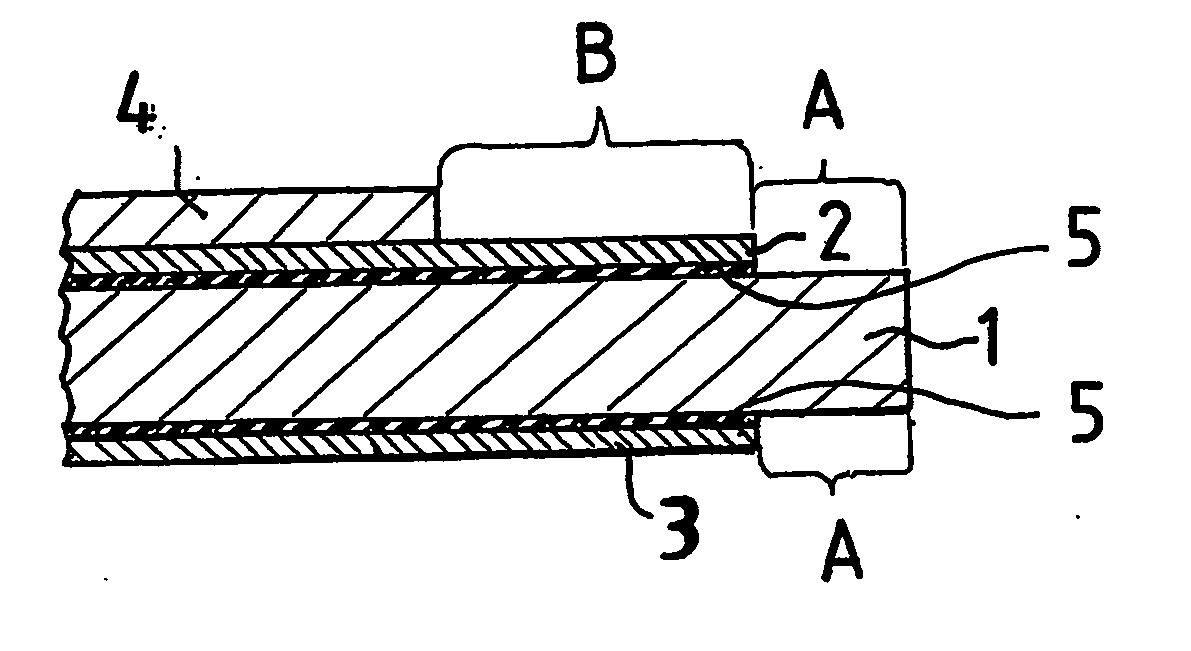

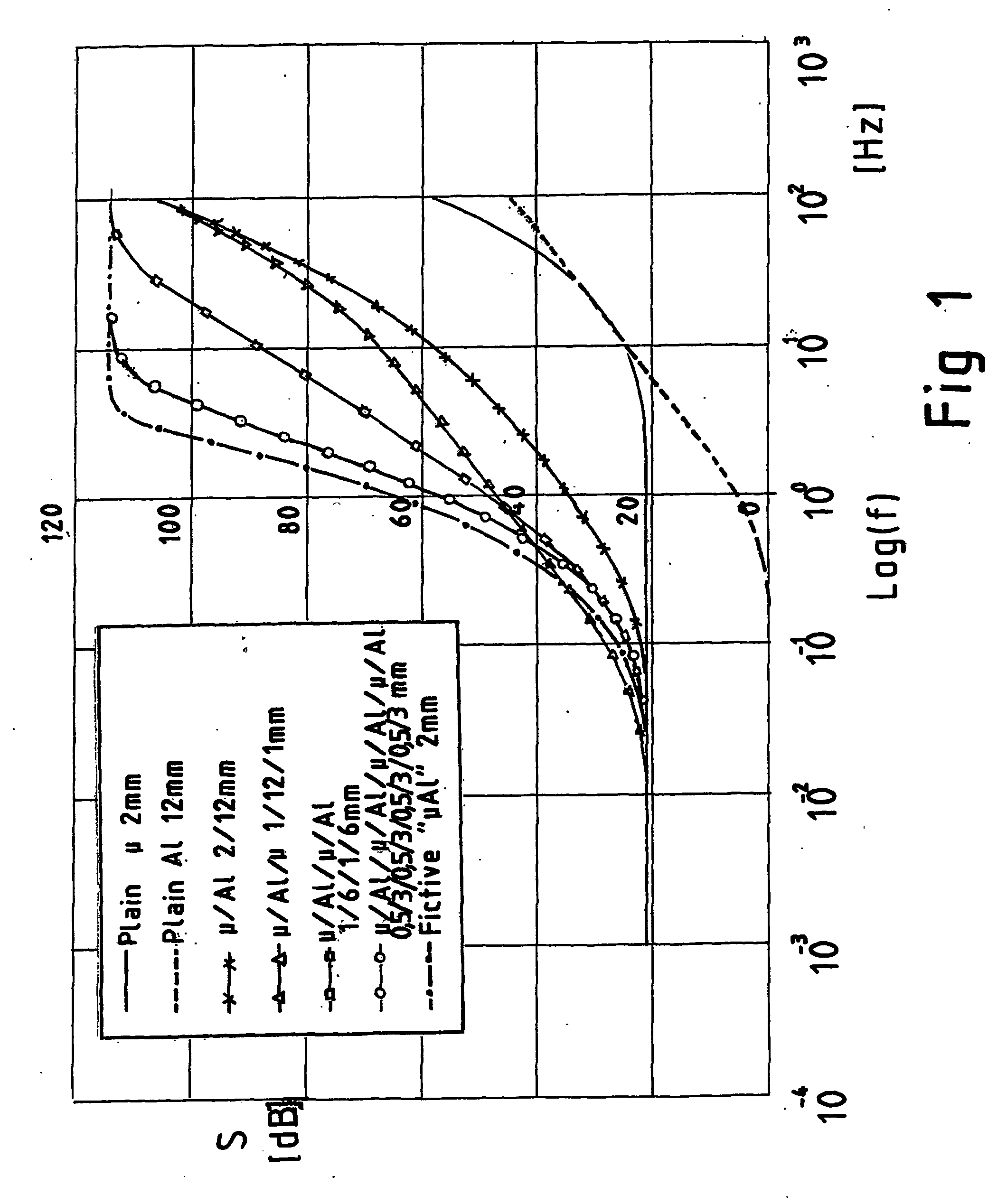

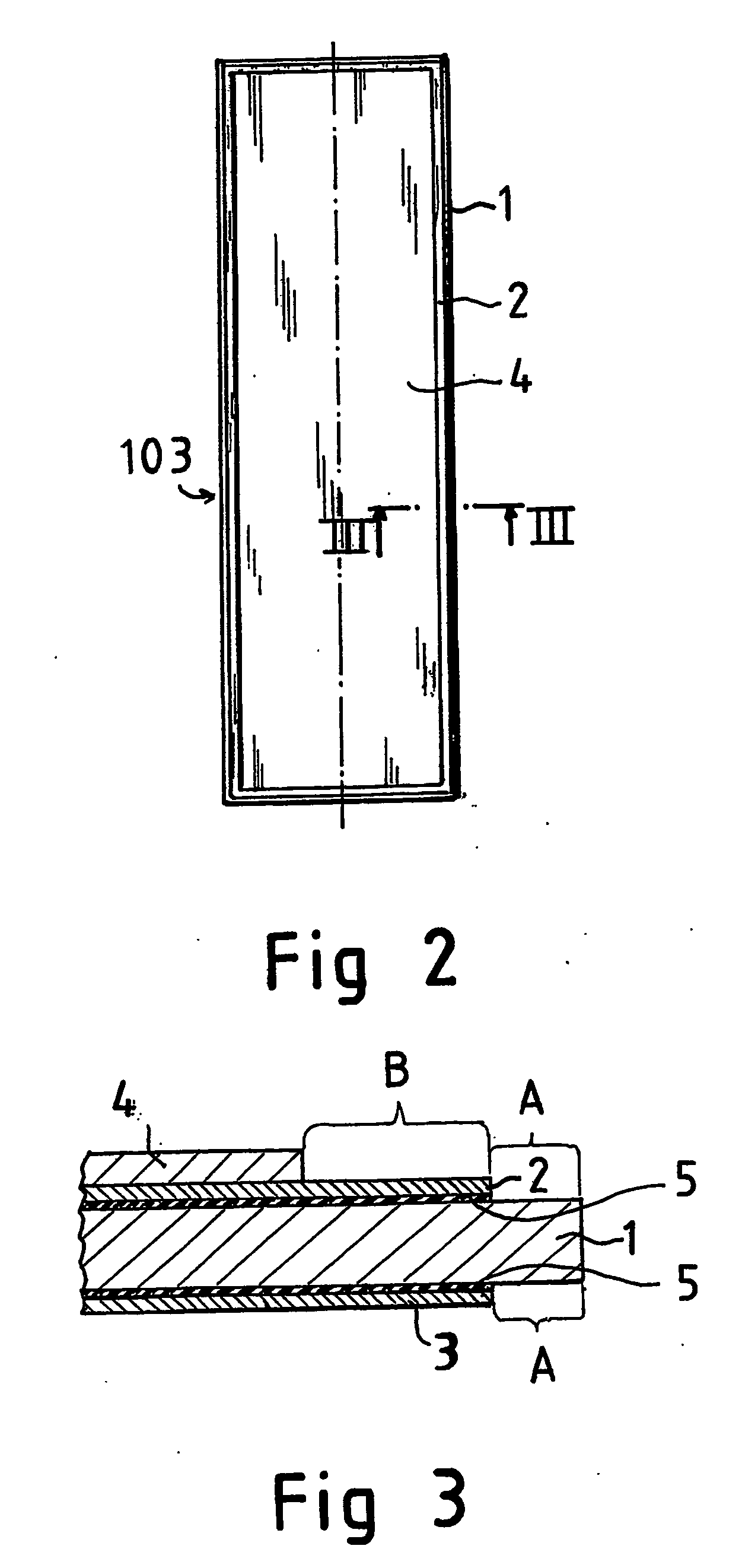

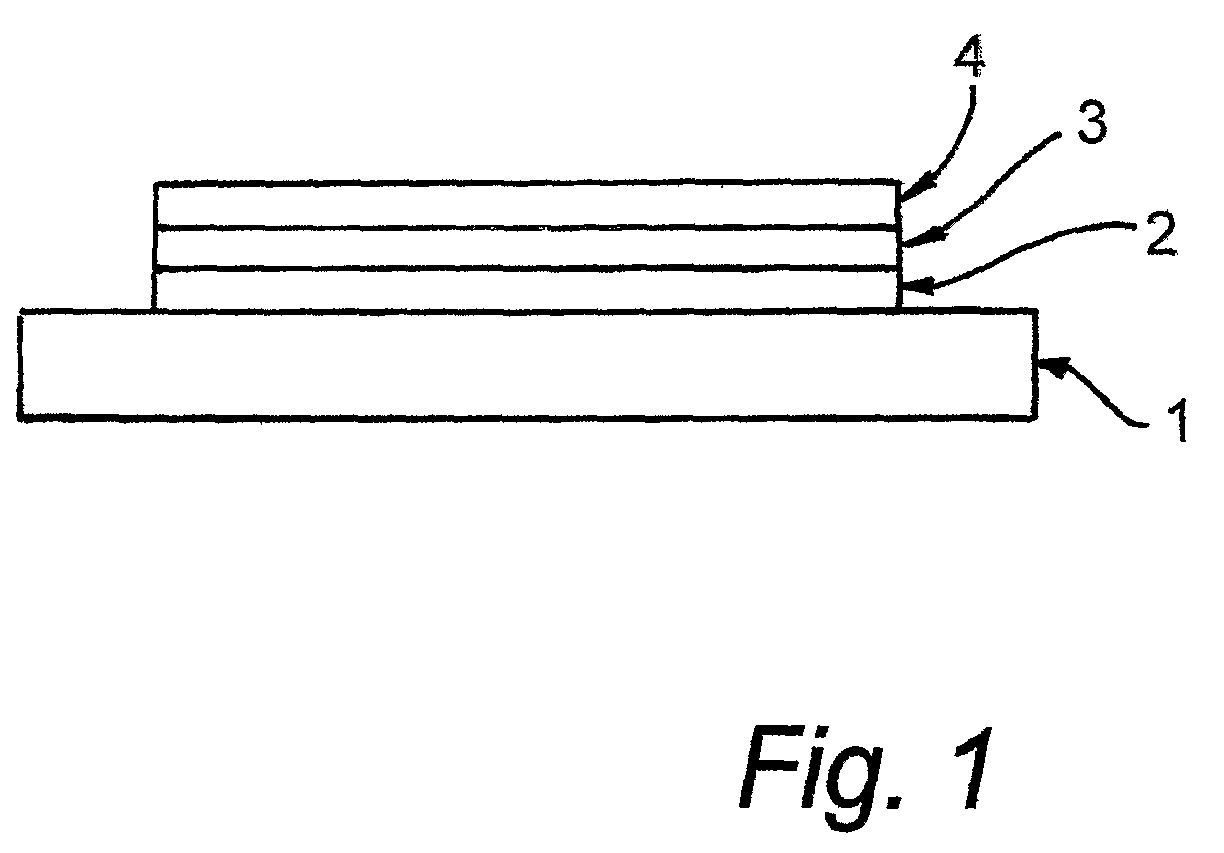

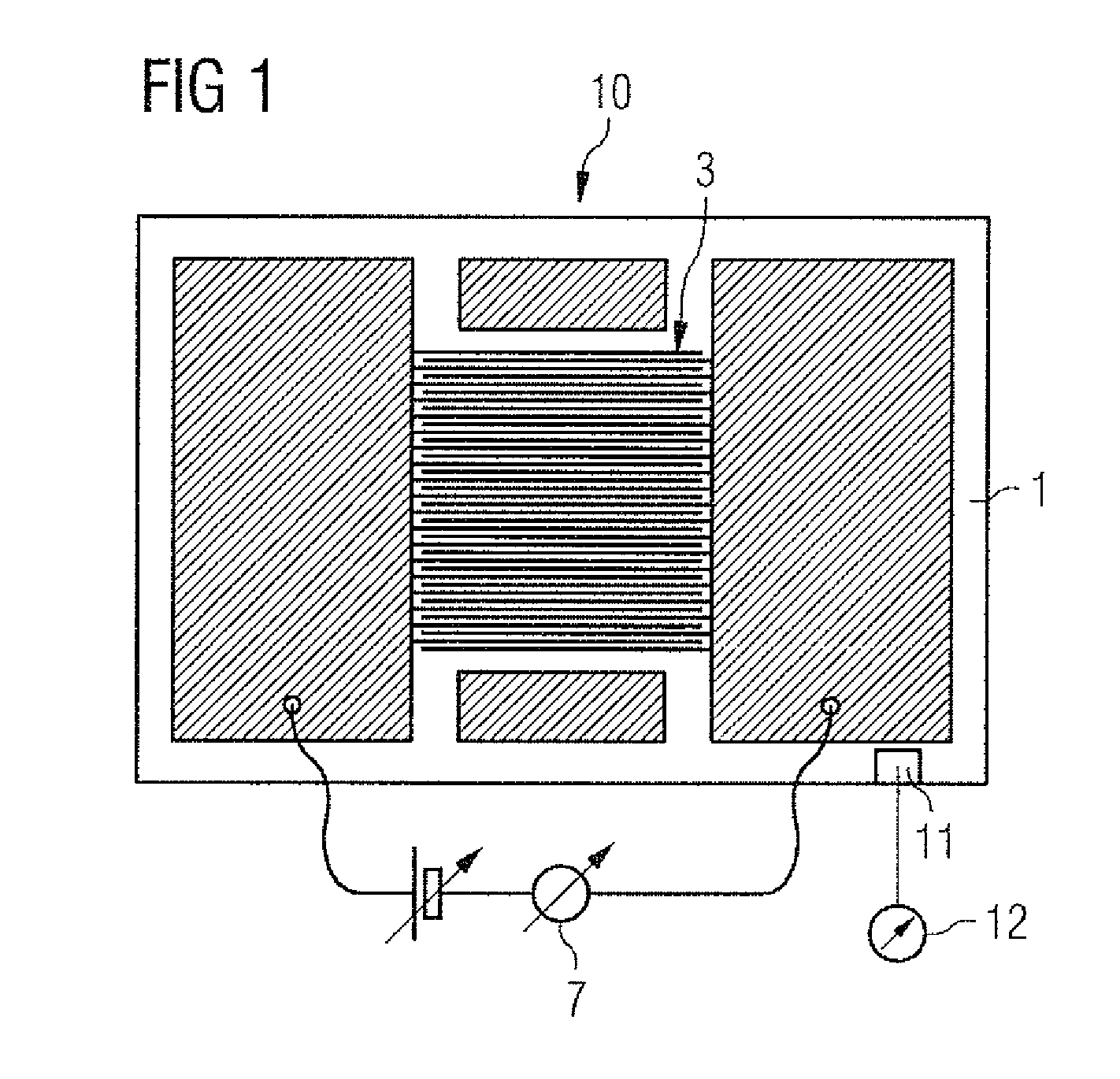

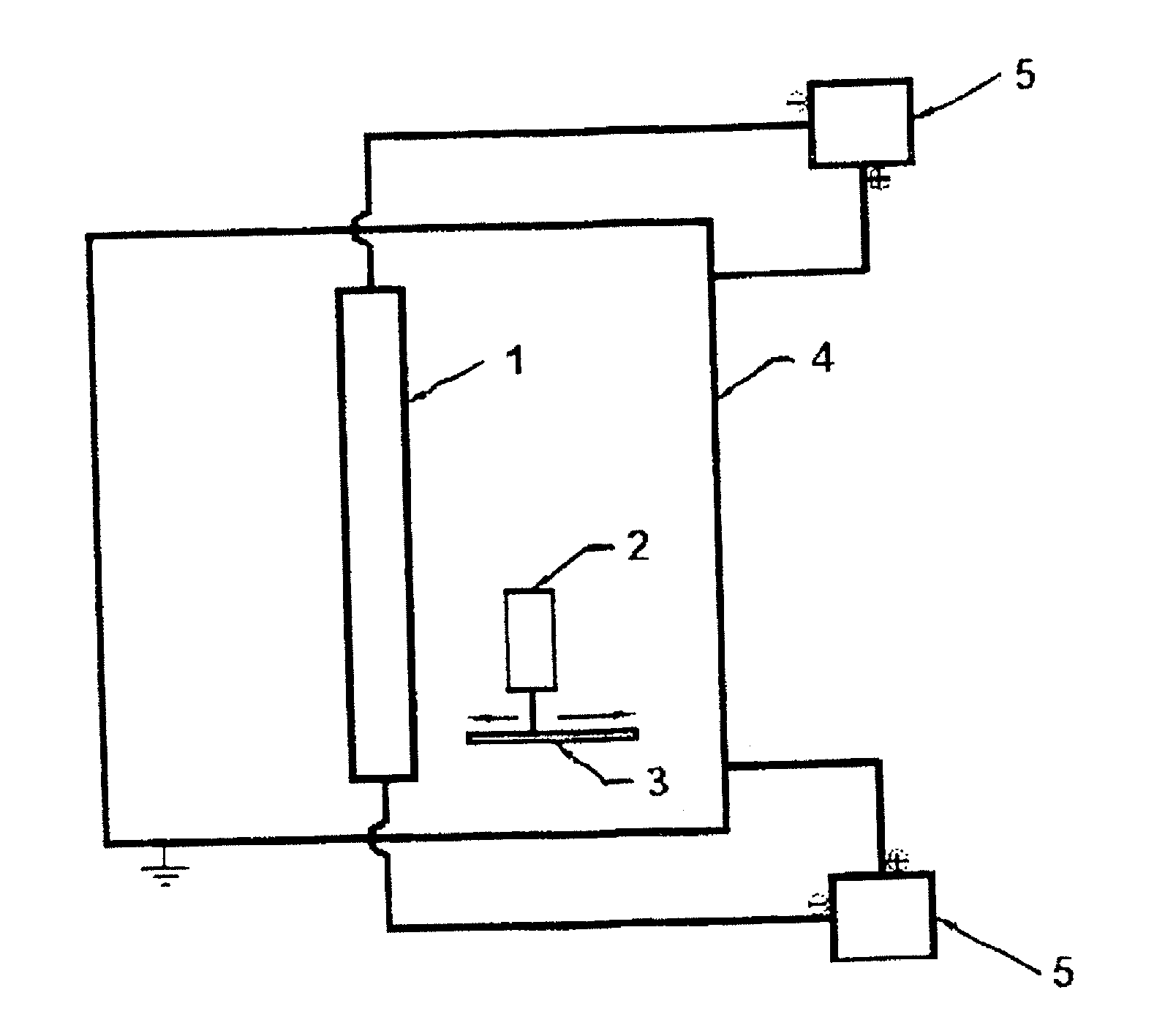

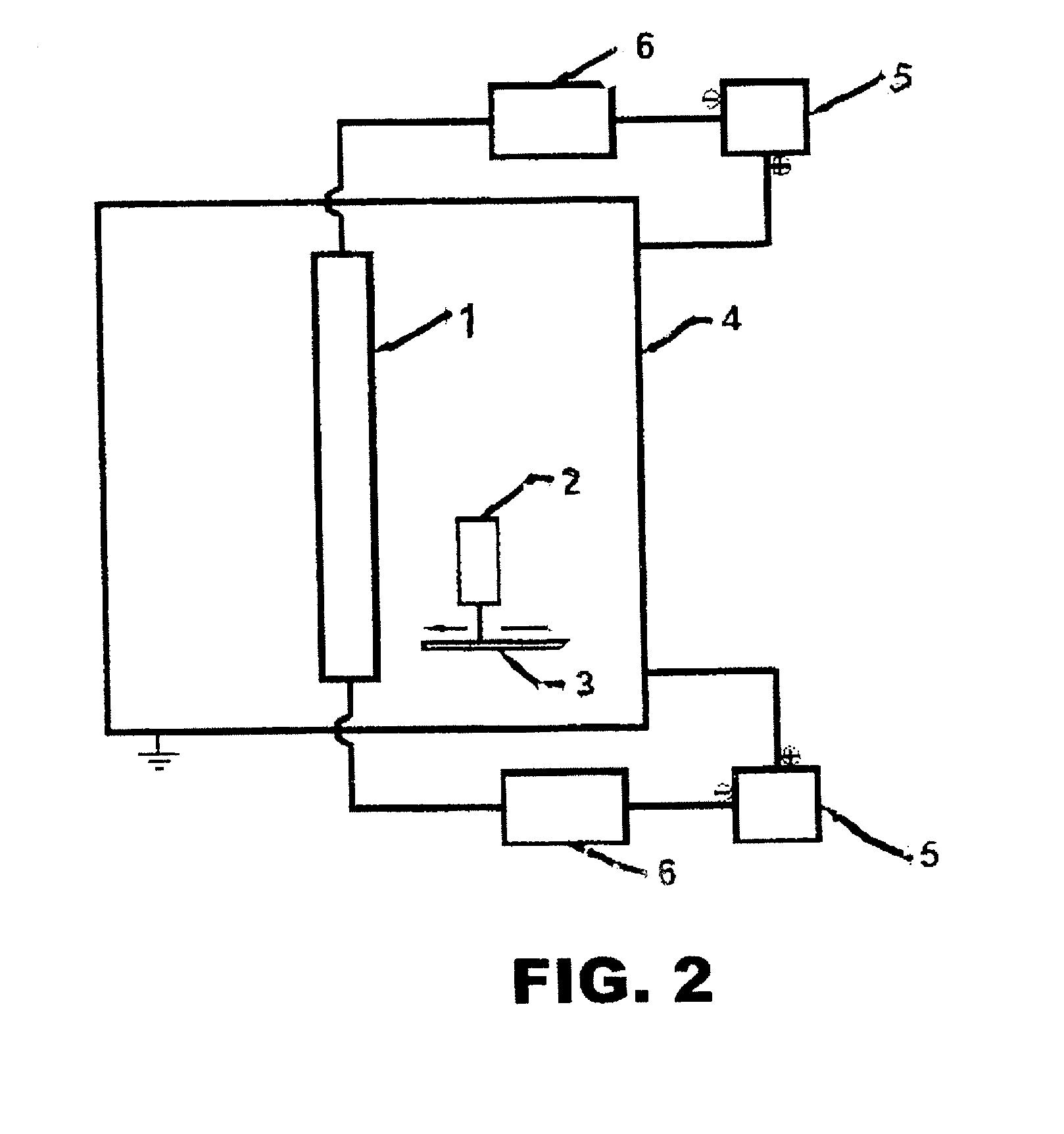

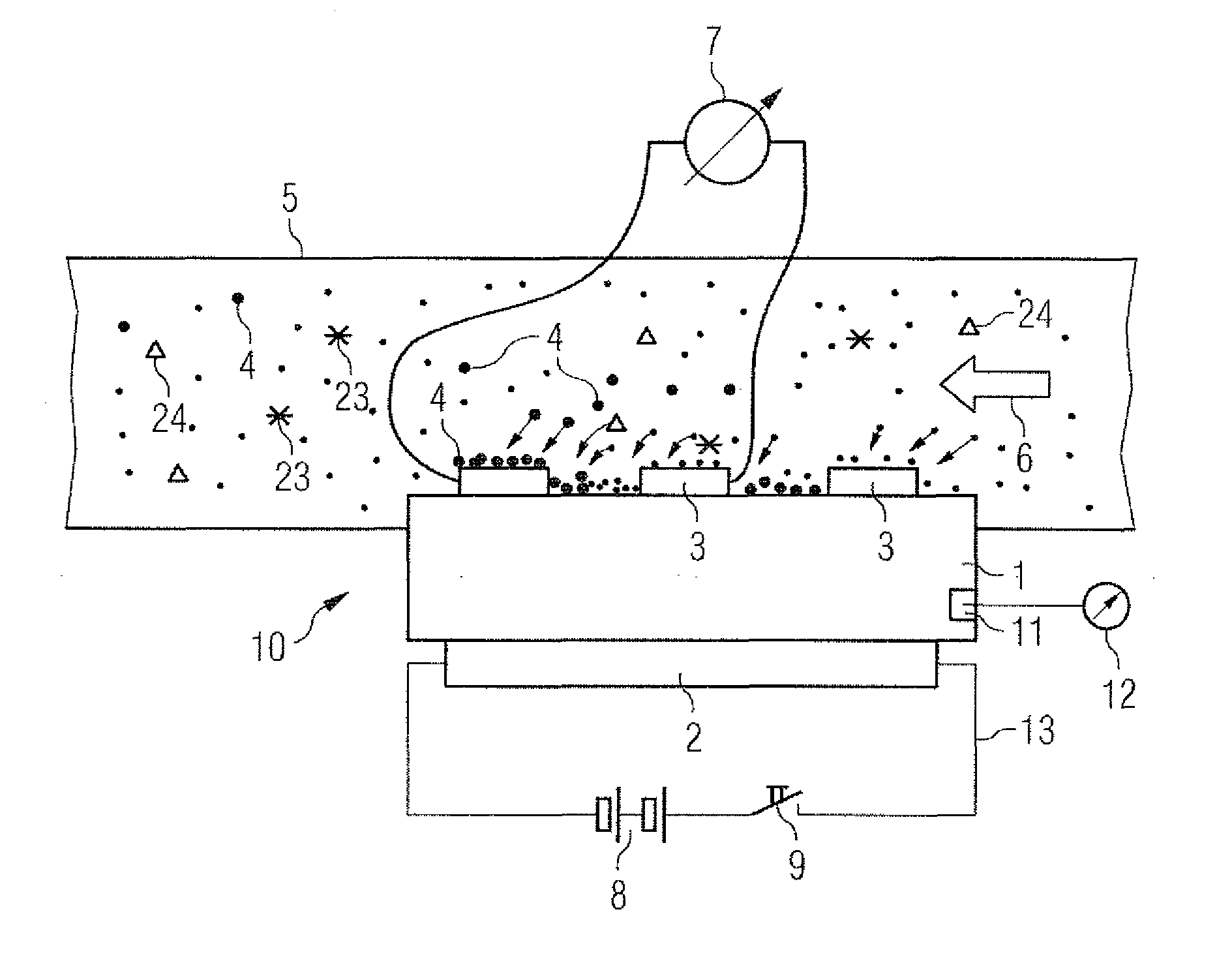

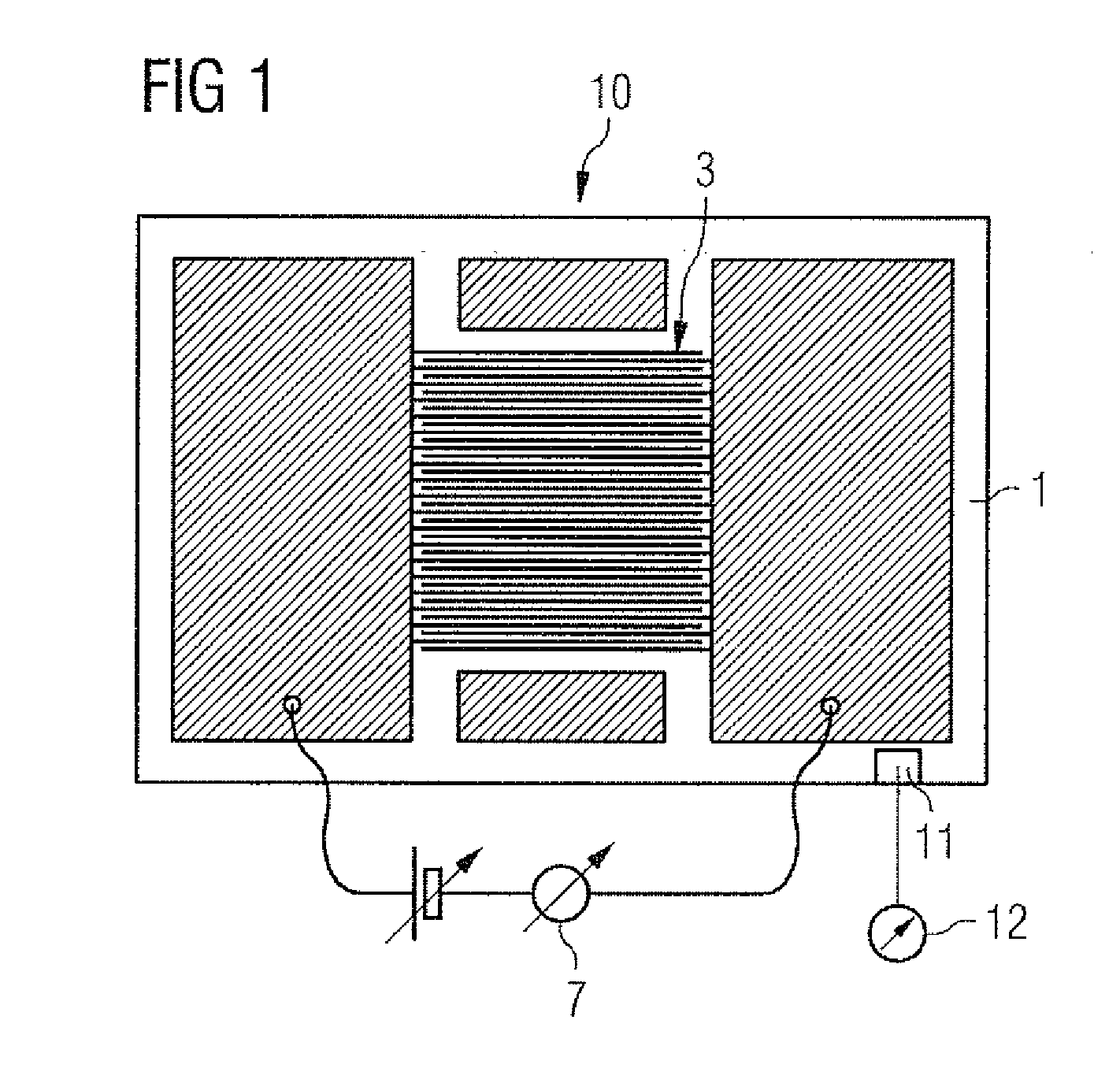

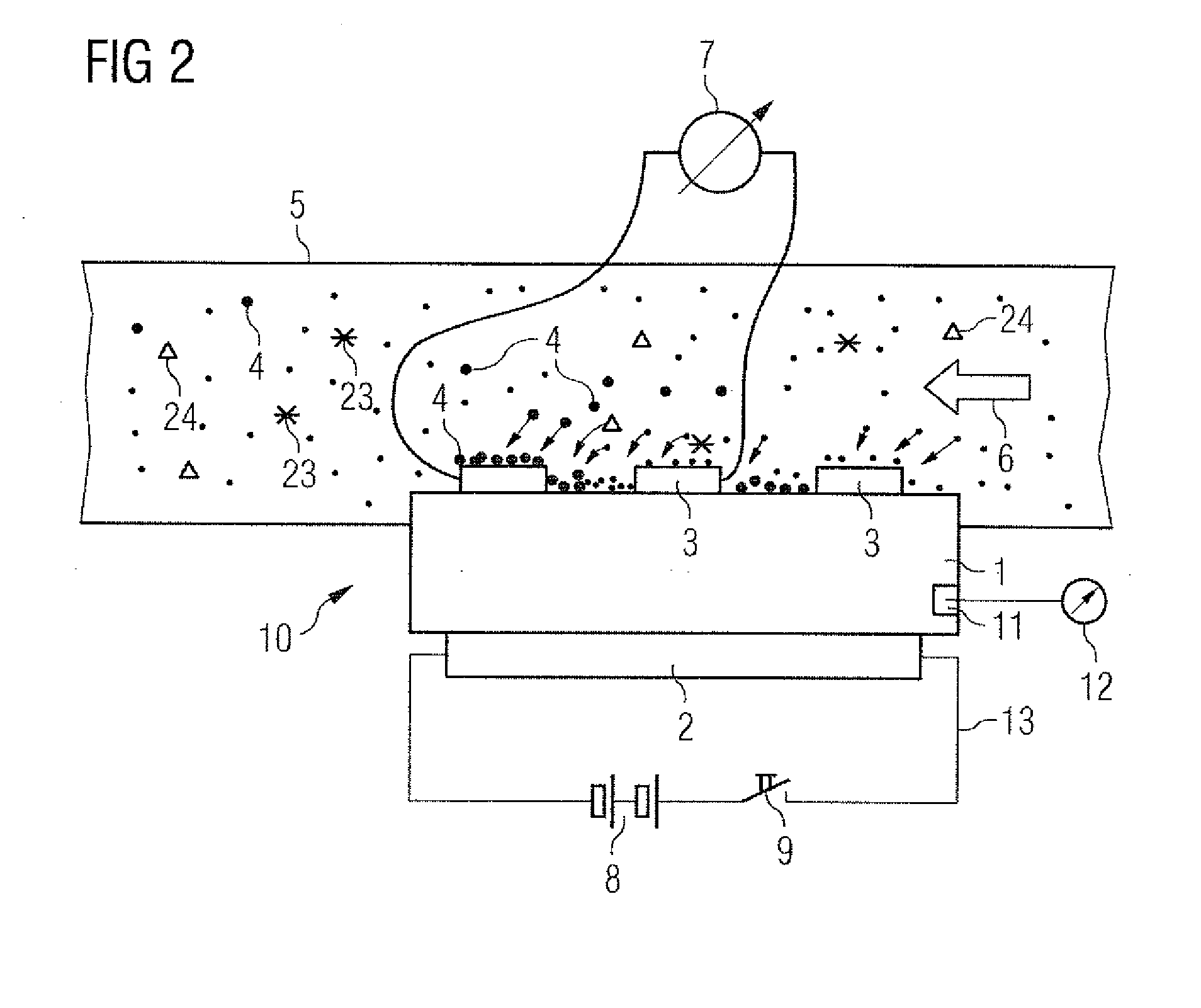

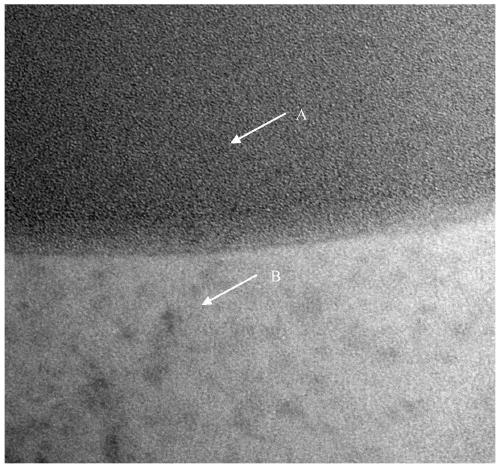

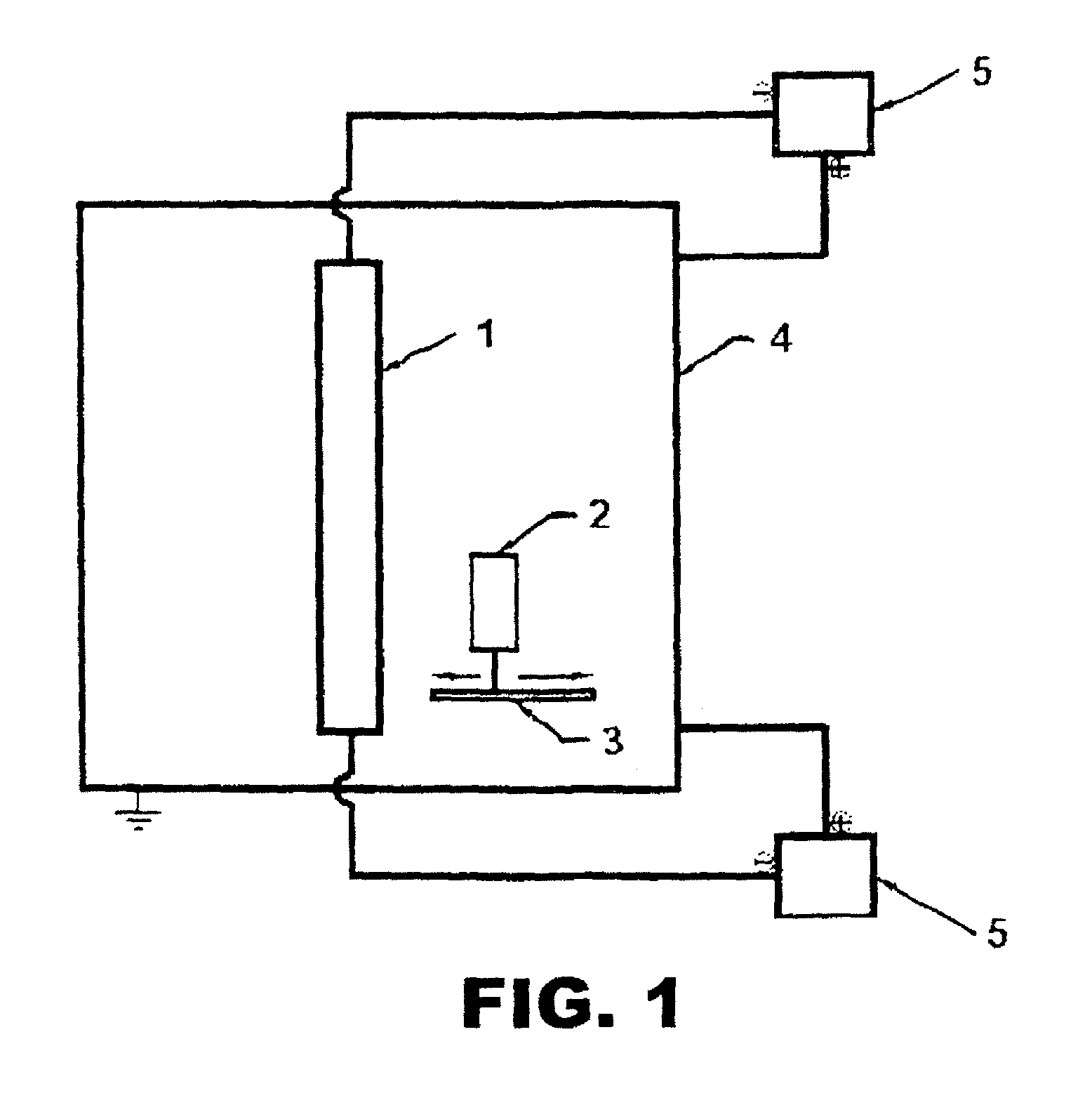

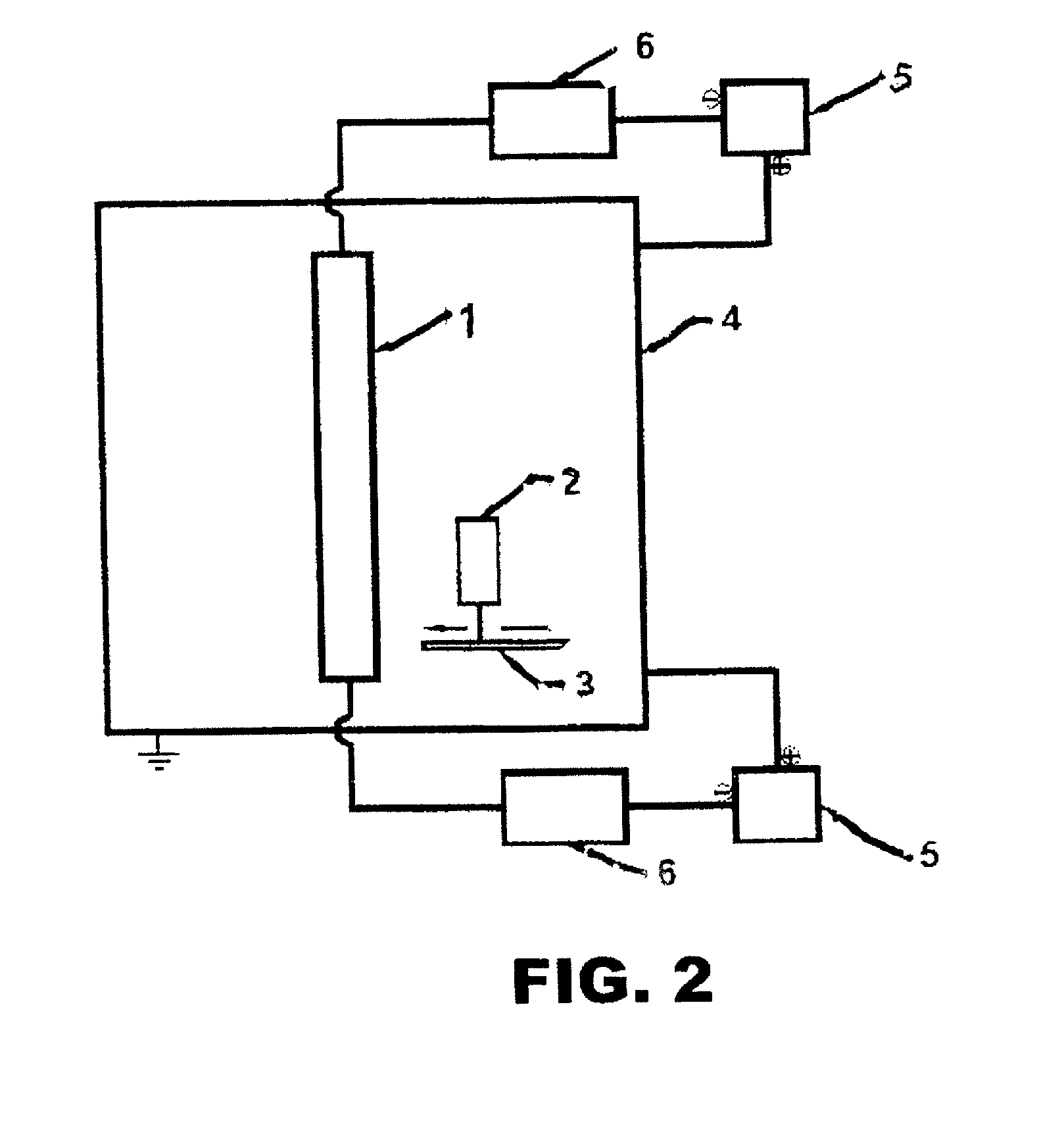

Wall element for magnetically shielded room and magnetically shielded room

ActiveUS20050162249A1Improve shielding effectGood effectScreening rooms/chambersMagnetsEngineeringElectrical resistivity and conductivity

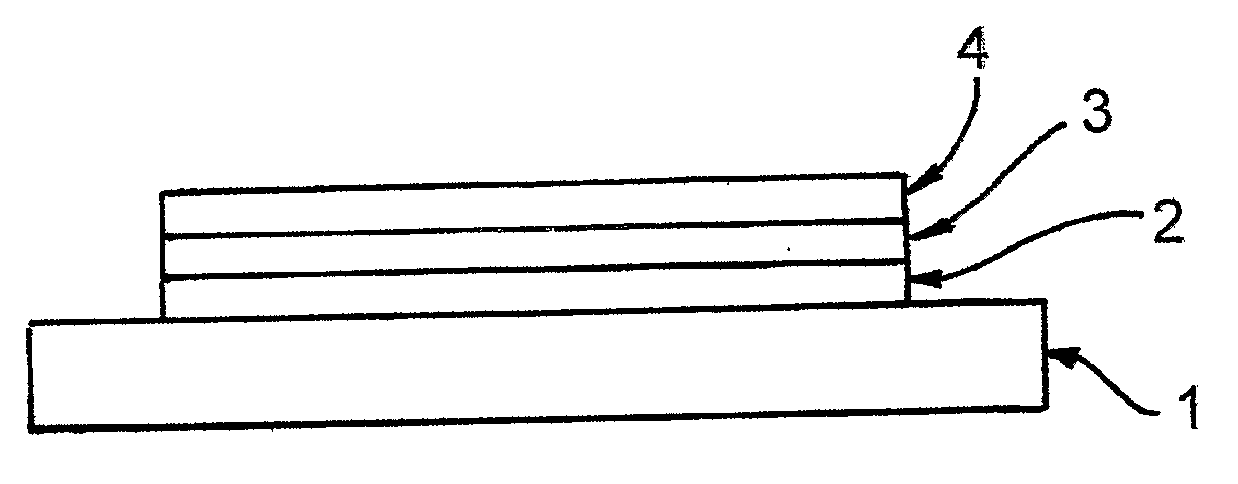

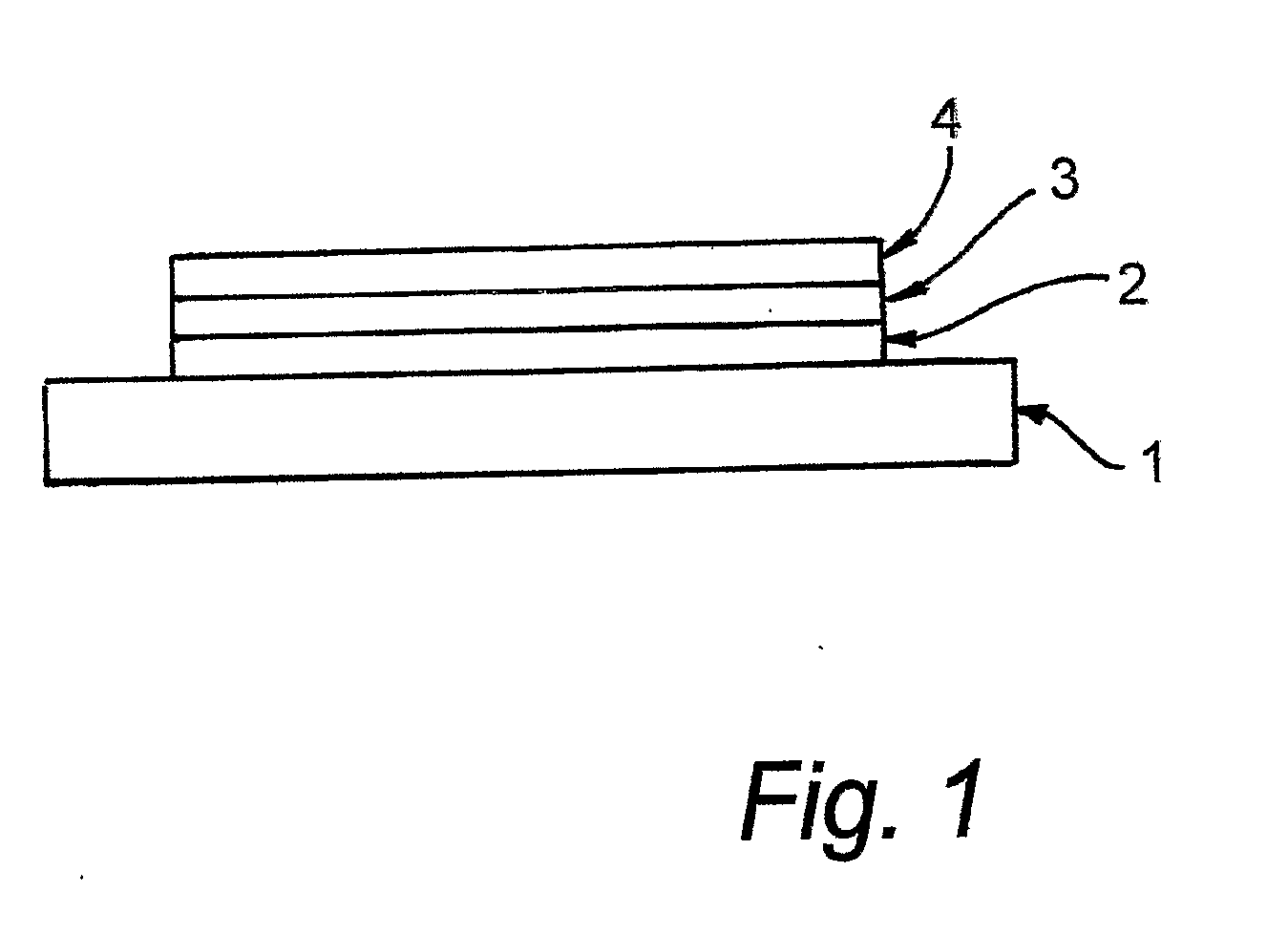

The invention relates to a wall element for a magnetically shielded room and to a magnetically shielded room. The wall element comprises at least one first layer (1) which is formed of metal plate having a high electrical conductivity, and at least two layers, a second layer (2) and a third layer (3), which consist of metal plates having a high magnetic permeability. The layers (1, 2, 3) are superimposed one on top of another in surface contact with each other without any separating air gaps, so that each first layer (1) having a high electrical conductivity lies between each second (2) and third layers (3) having a high permeability substantially in surface contact with the second and third layers, the layers together forming a compact structure in which the product (σ×μ) of electrical conductivity (σ) and permeability (μ) is maximized so as to minimize the penetration depth of magnetic interference.

Owner:ELEKTA NEUROMAG

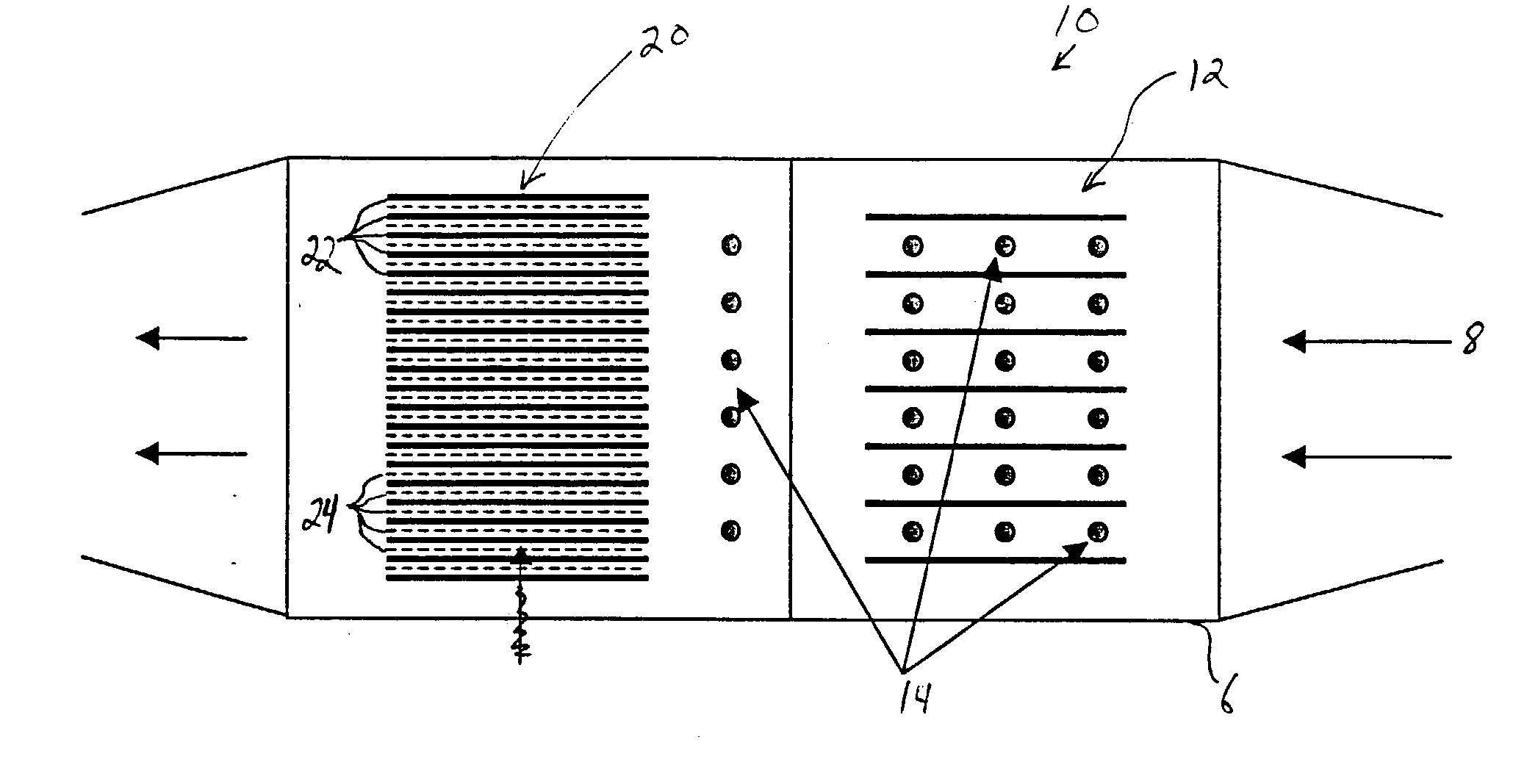

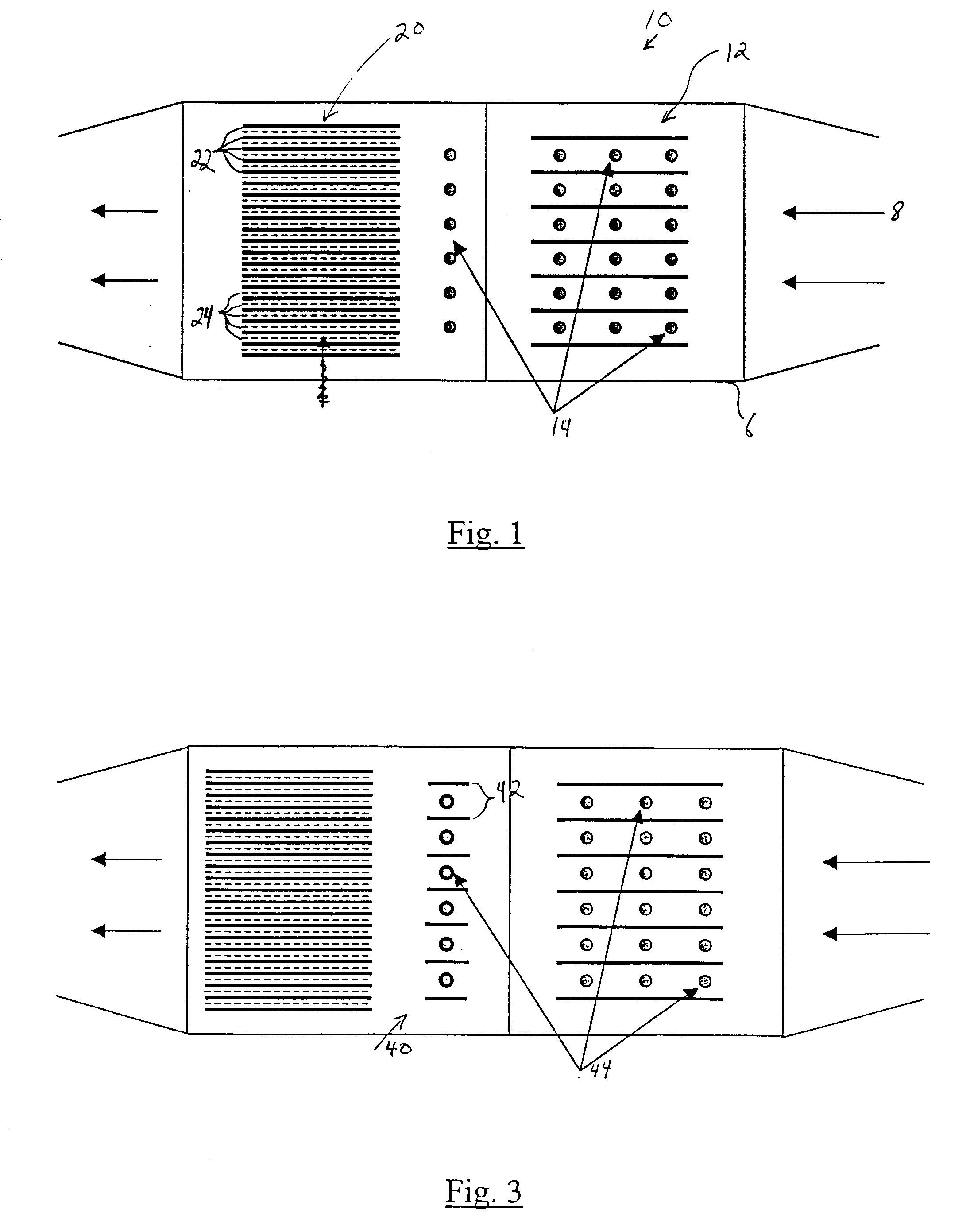

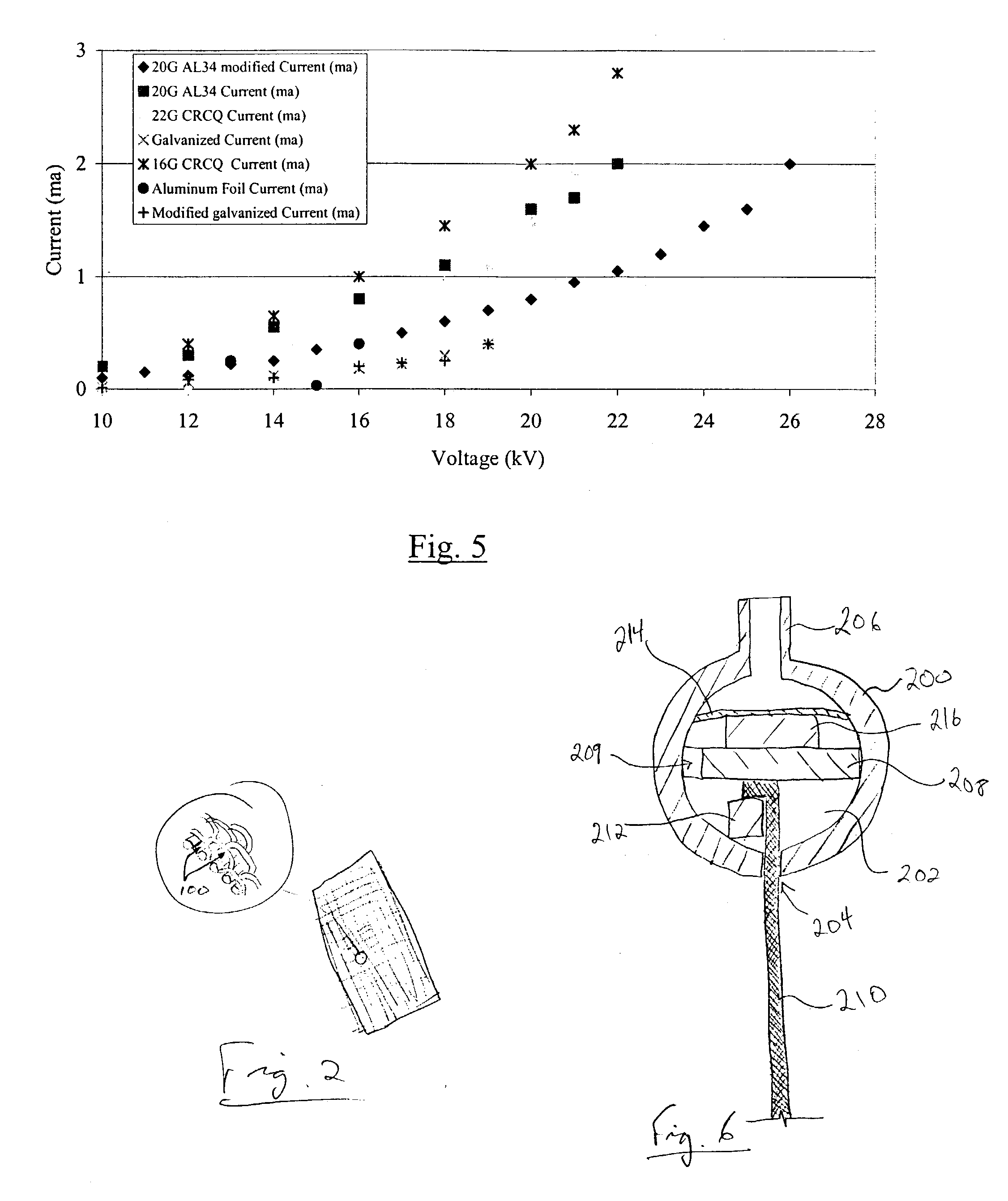

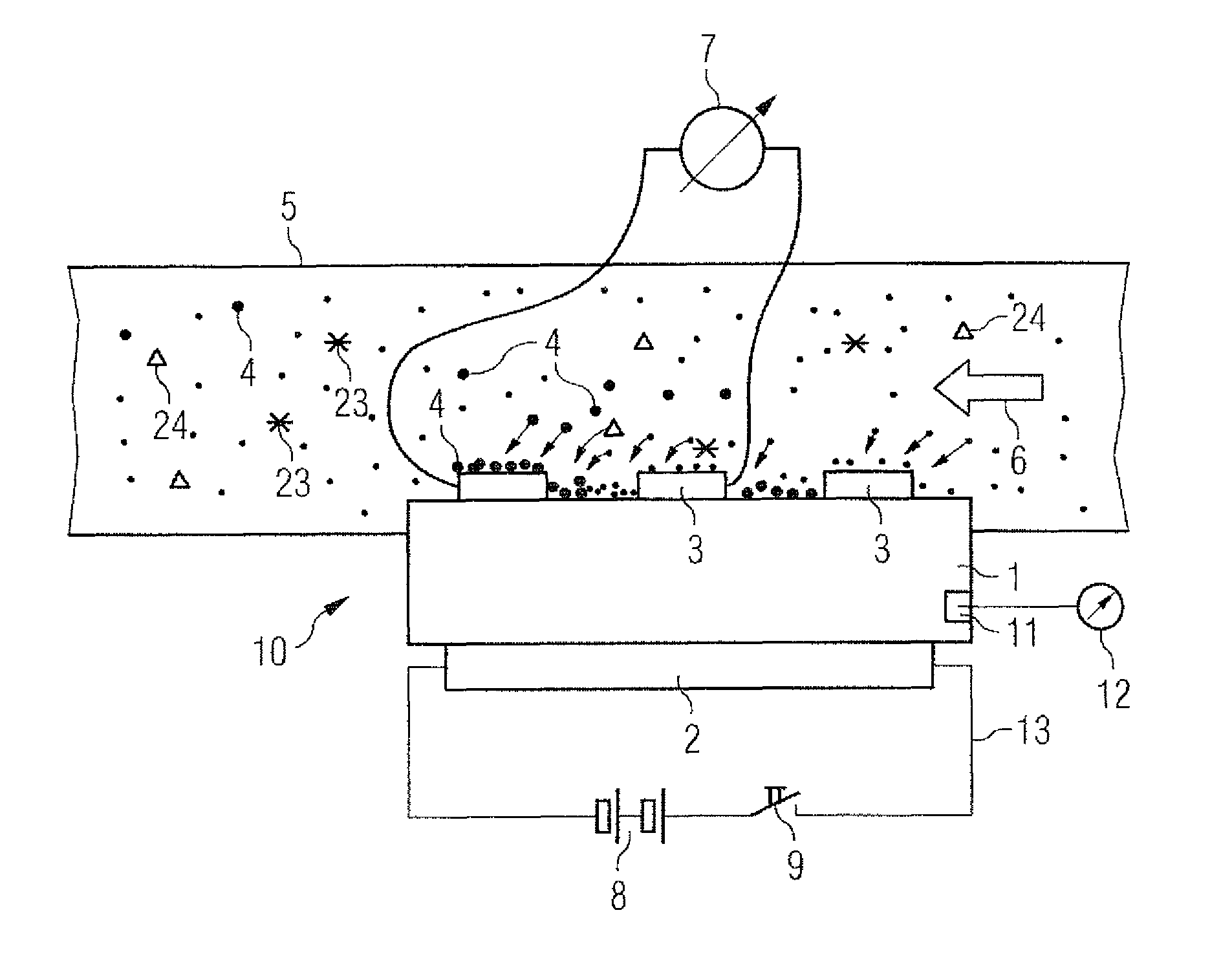

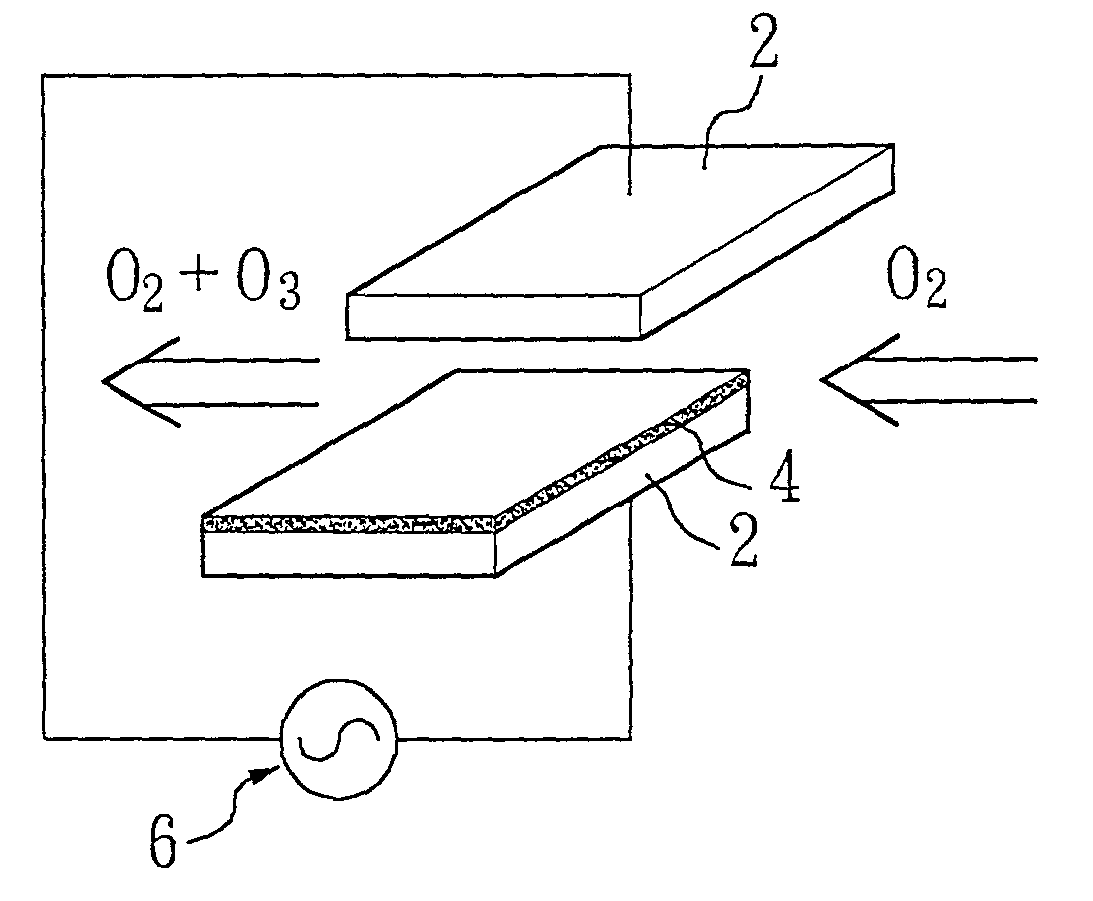

Membrane laminar wet electrostatic precipitator

InactiveUS20030217642A1Minimize formationGood conductorExternal electric electrostatic seperatorElectrode constructionsParticulatesEnvironmental engineering

A laminar flow, wet electrostatic precipitator (ESP) with planar collecting electrodes preferably made of membranes, such as a woven silica fiber. The collecting electrodes are spaced close to planar discharge electrodes to promote laminar flow (Re<2300). Charging electrodes are positioned upstream of the wet ESP to charge the particulate entering the wet ESP to promote collection. The wet ESP is preferably downstream from a conventional turbulent dry ESP for collecting a substantial portion of the larger particulate in the gas stream prior to the gas stream entering the wet ESP.

Owner:OHIO UNIV

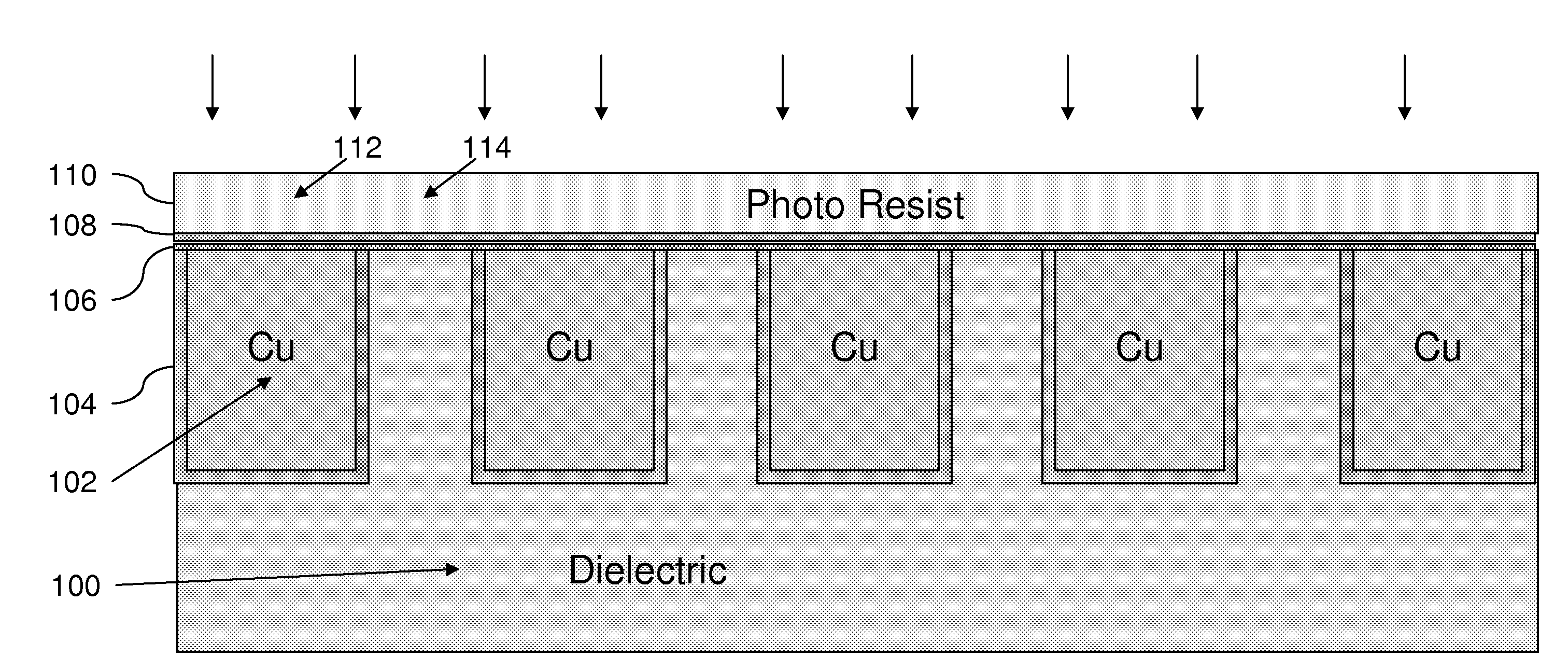

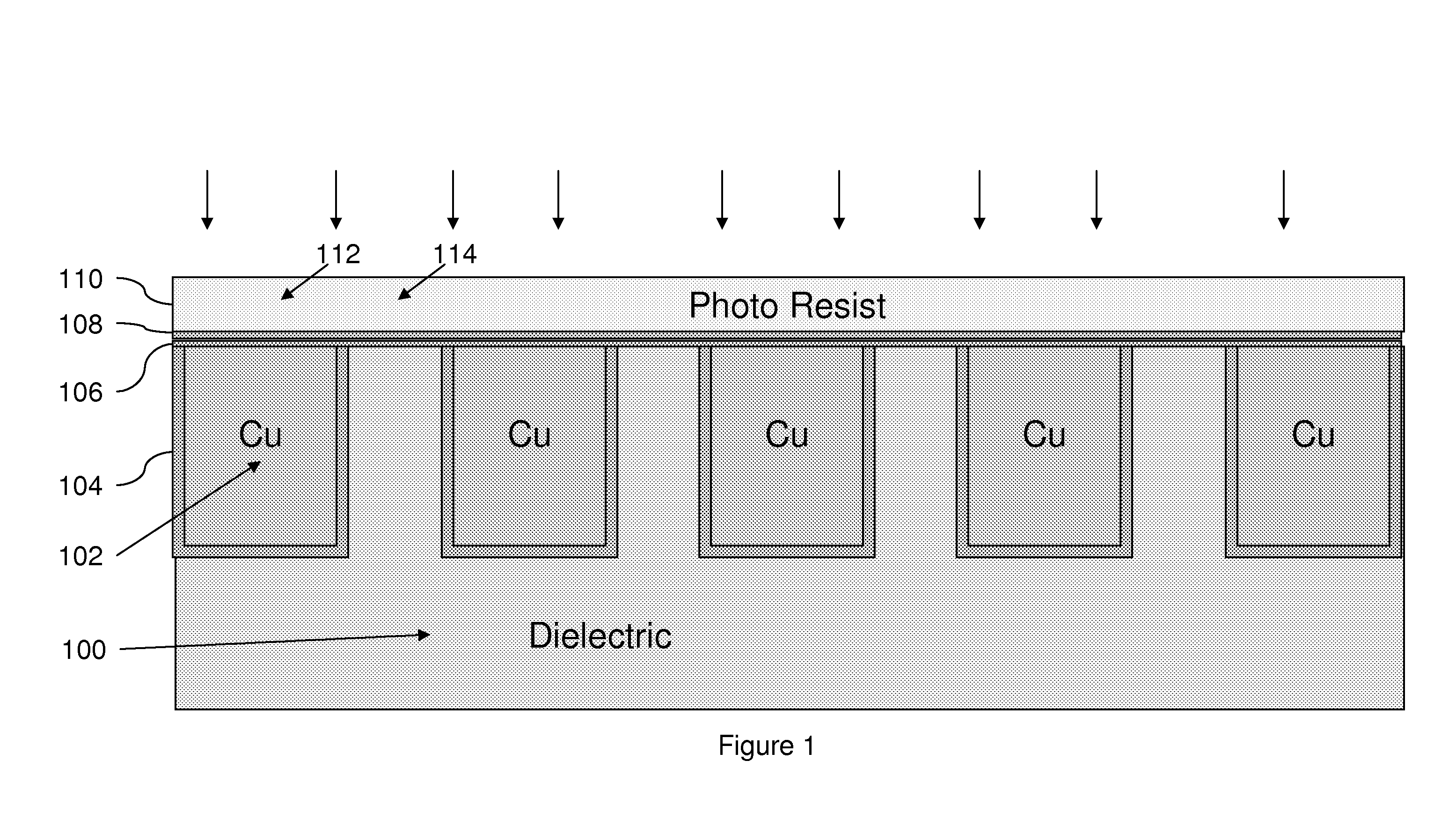

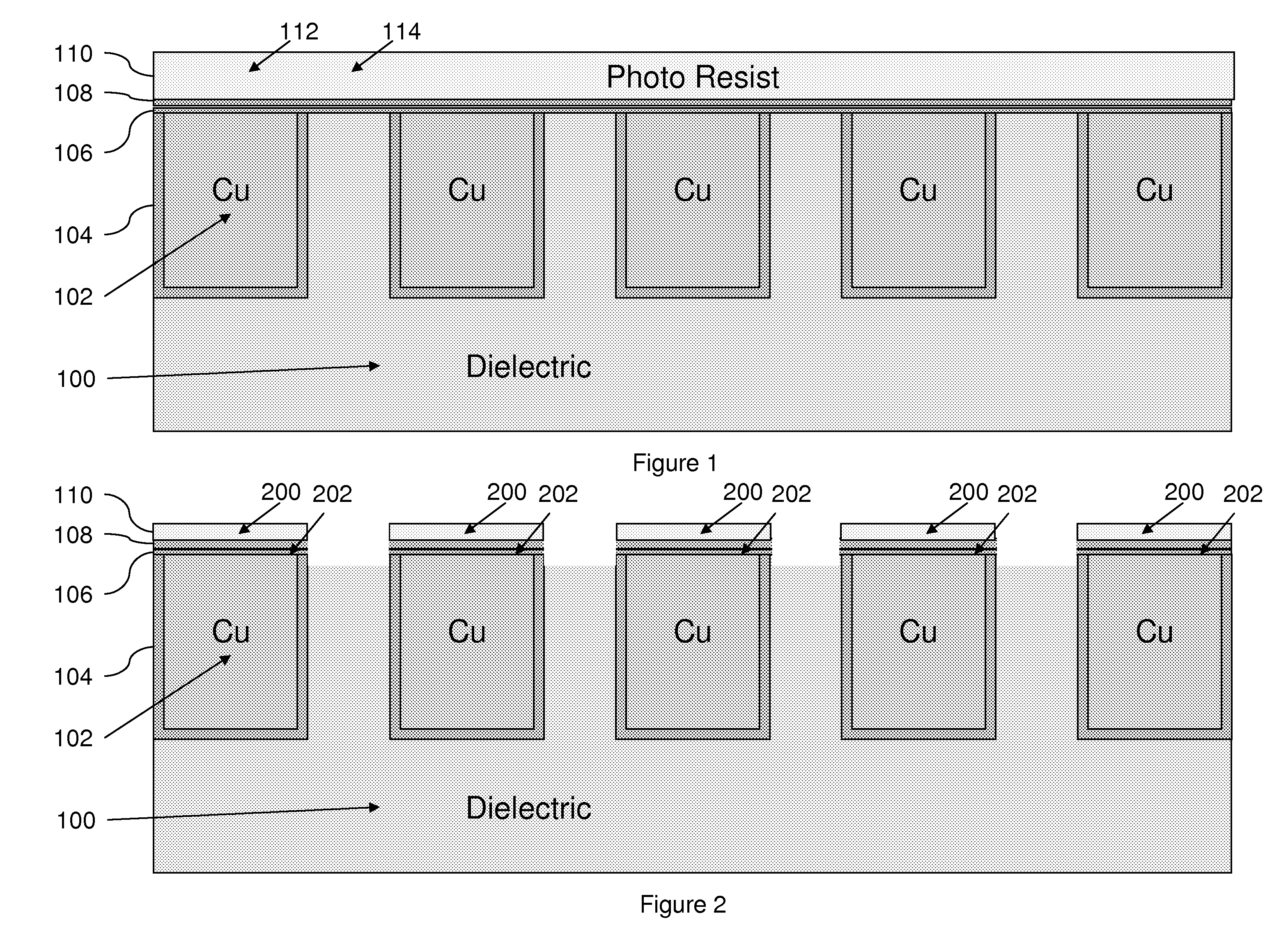

Selective thin metal cap process

ActiveUS20090053890A1Electrical conductivity of the wiring material becomes increasingly more importantGood conductorSemiconductor/solid-state device manufacturingThin metalResist

A method of creating metal caps on copper lines within an inter-line dielectric (ILD) deposits a thin (e.g., 5 nm) metal blanket film (e.g., Ta / TaN) on top the copper lines and dielectric, after the wafer has been planarized. Further a thin dielectric cap is formed over the metal blanket film. A photoresist coating is deposited over the thin dielectric cap and a lithographic exposure process is performed, but without a lithographic mask. A mask is not needed in this situation, because due to the reflectivity difference between copper and the ILD lying under the two thin layers, a mask pattern is automatically formed for etching away the Ta / TaN metal cap between copper lines. Thus, this mask pattern is self-aligned above the copper lines.

Owner:TAIWAN SEMICON MFG CO LTD

Conductive polymer compositions in opto-electrical devices

InactiveUS8945432B2Good conductorNon-aqueous electrolyte cellsDecorative surface effectsPolyelectrolytePolymer science

Owner:CAMBRIDGE DISPLAY TECH LTD +1

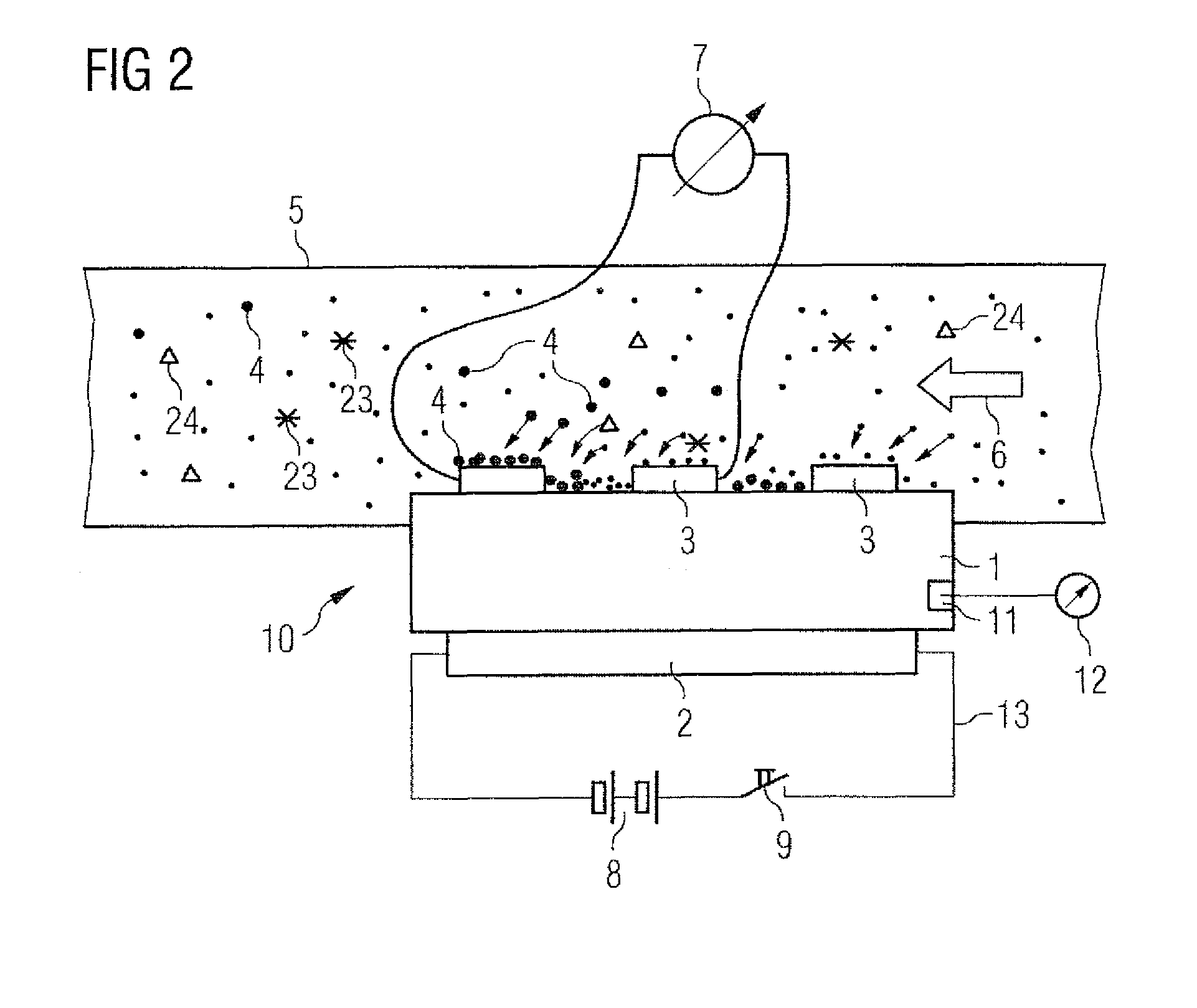

Method for the on-board functional diagnosis of a soot sensor in a motor vehicle and/or for the detection of further constituents in the soot

InactiveUS8490465B2Good conductorFacilitate conductionAnalysing fluids using sonic/ultrasonic/infrasonic wavesElectrical controlElectricityOn board

Owner:CONTINENTAL AUTOMOTIVE GMBH

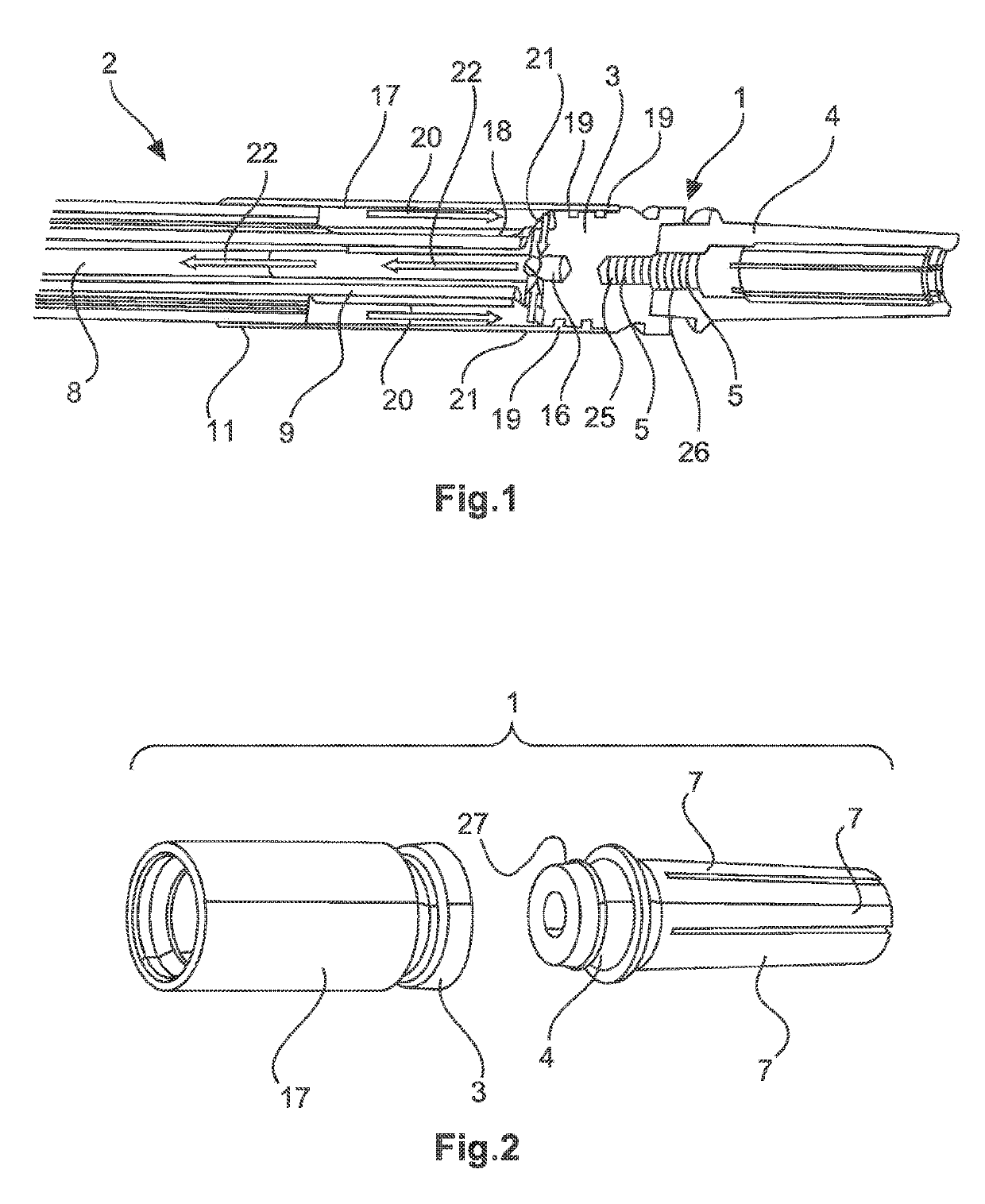

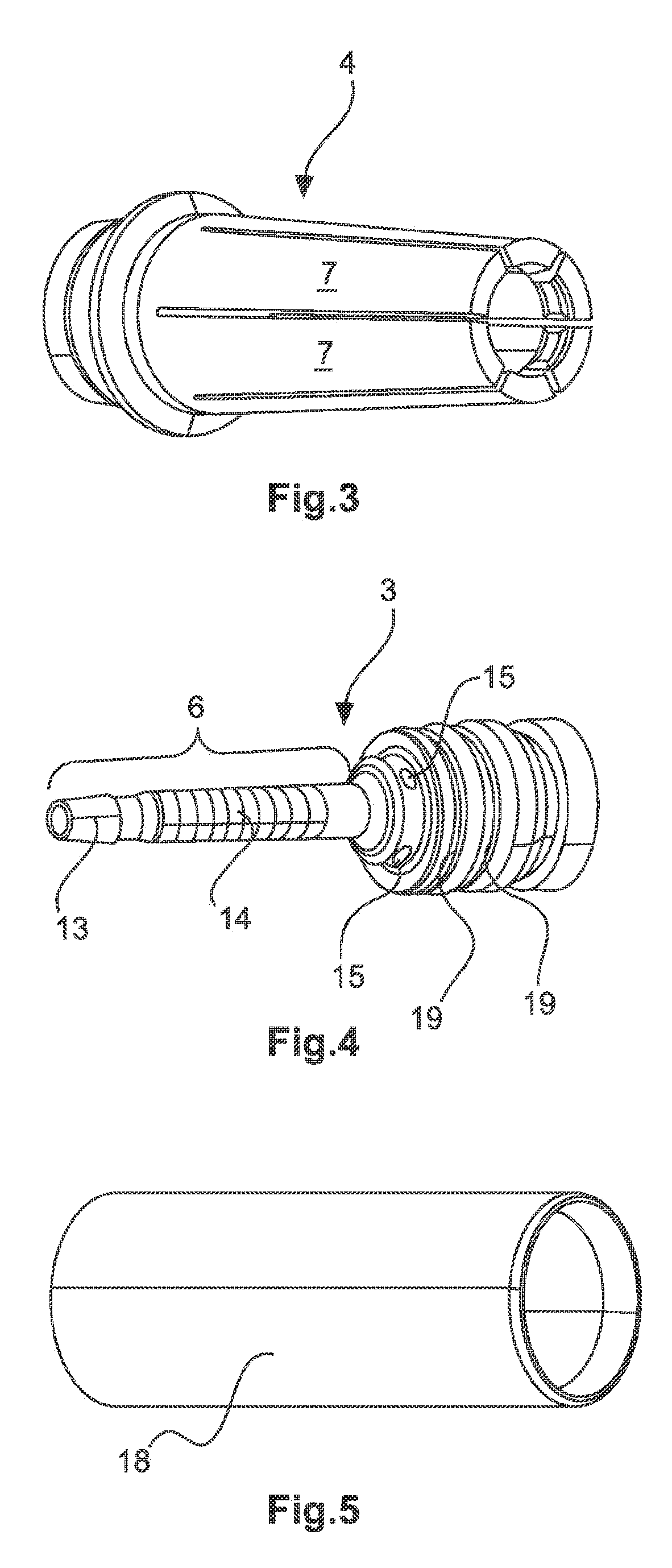

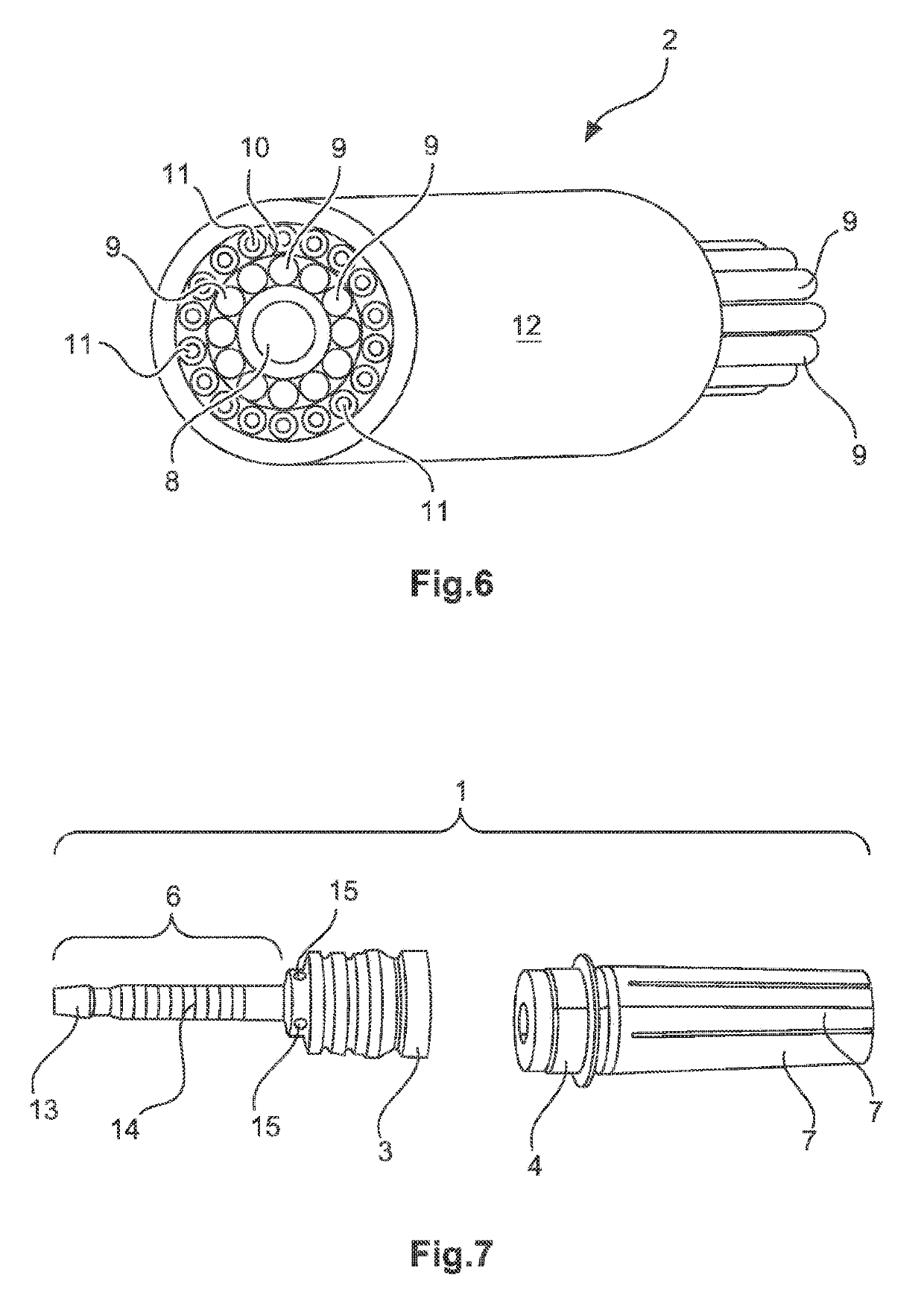

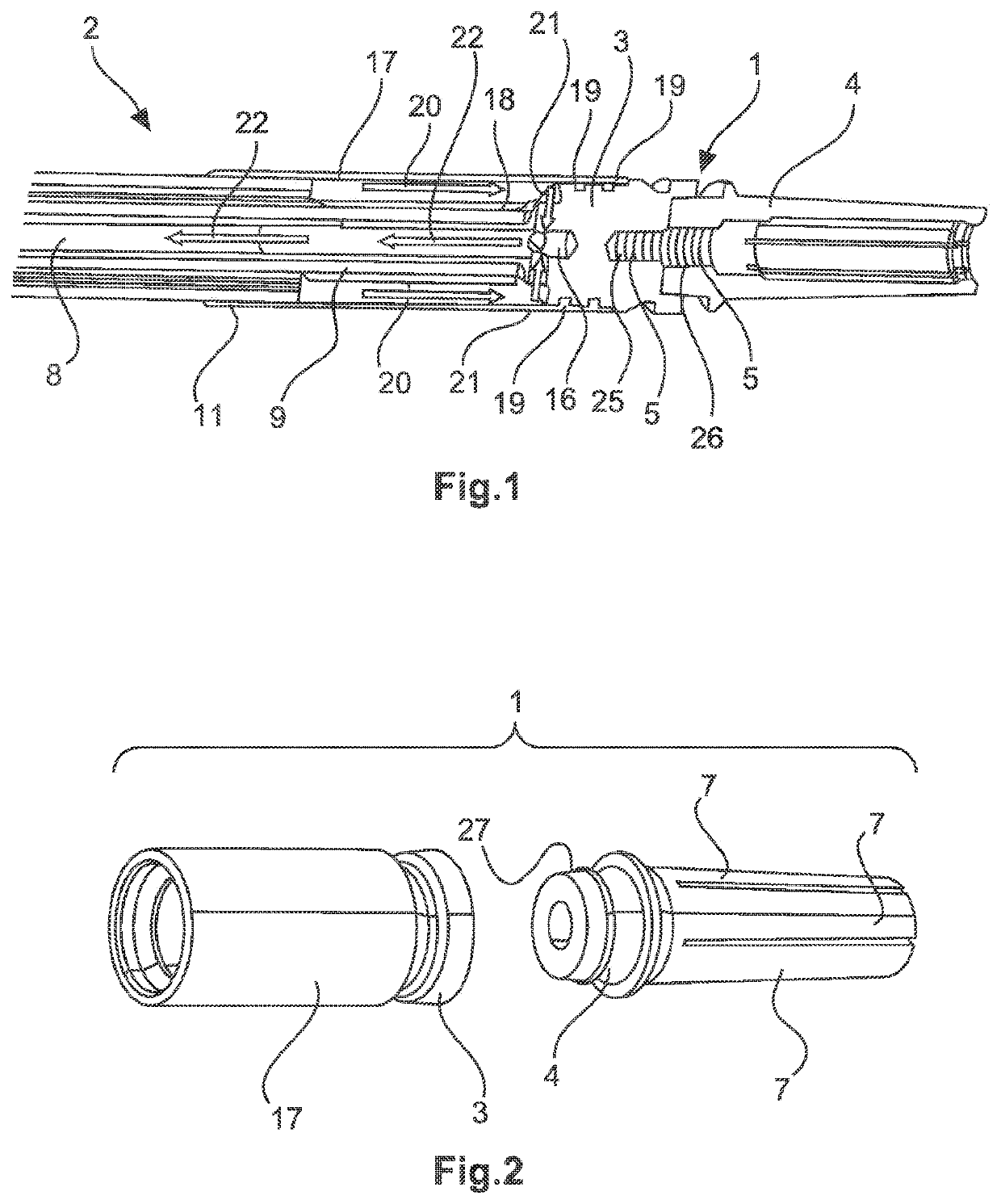

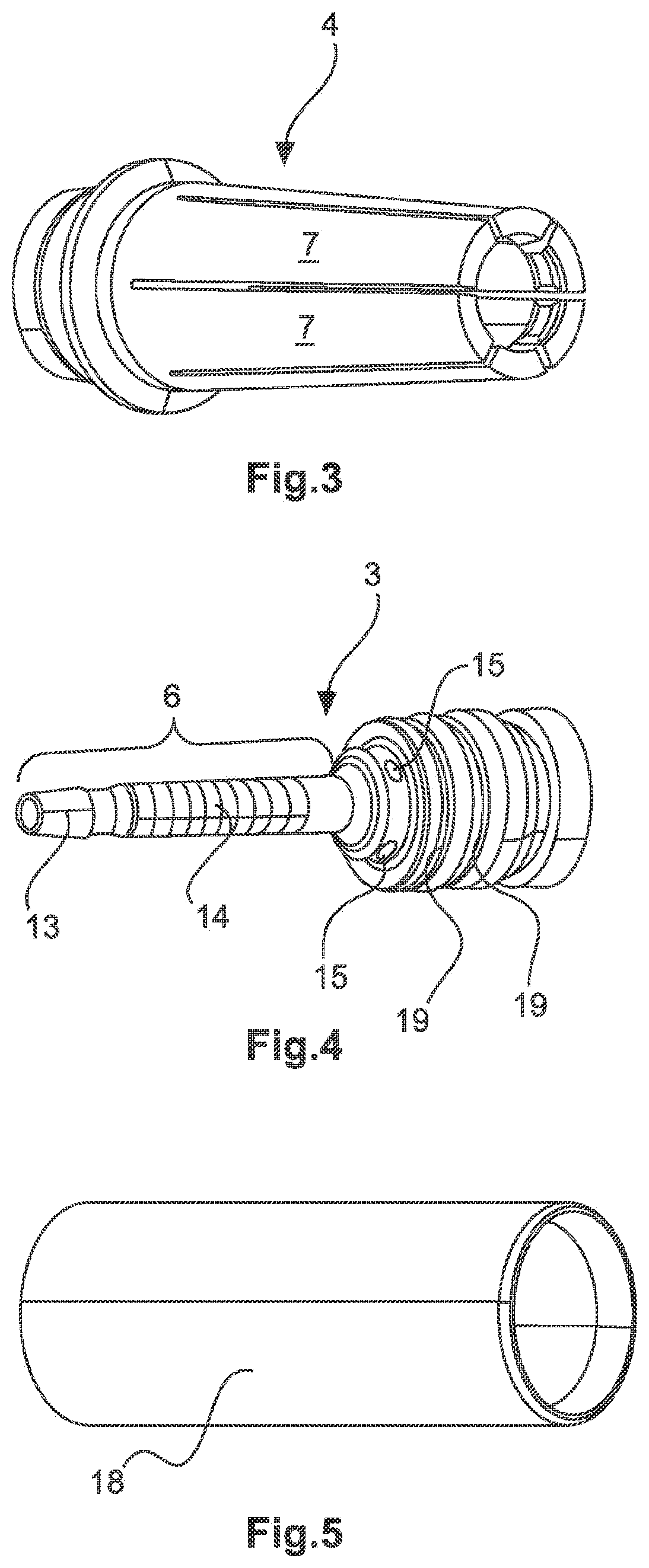

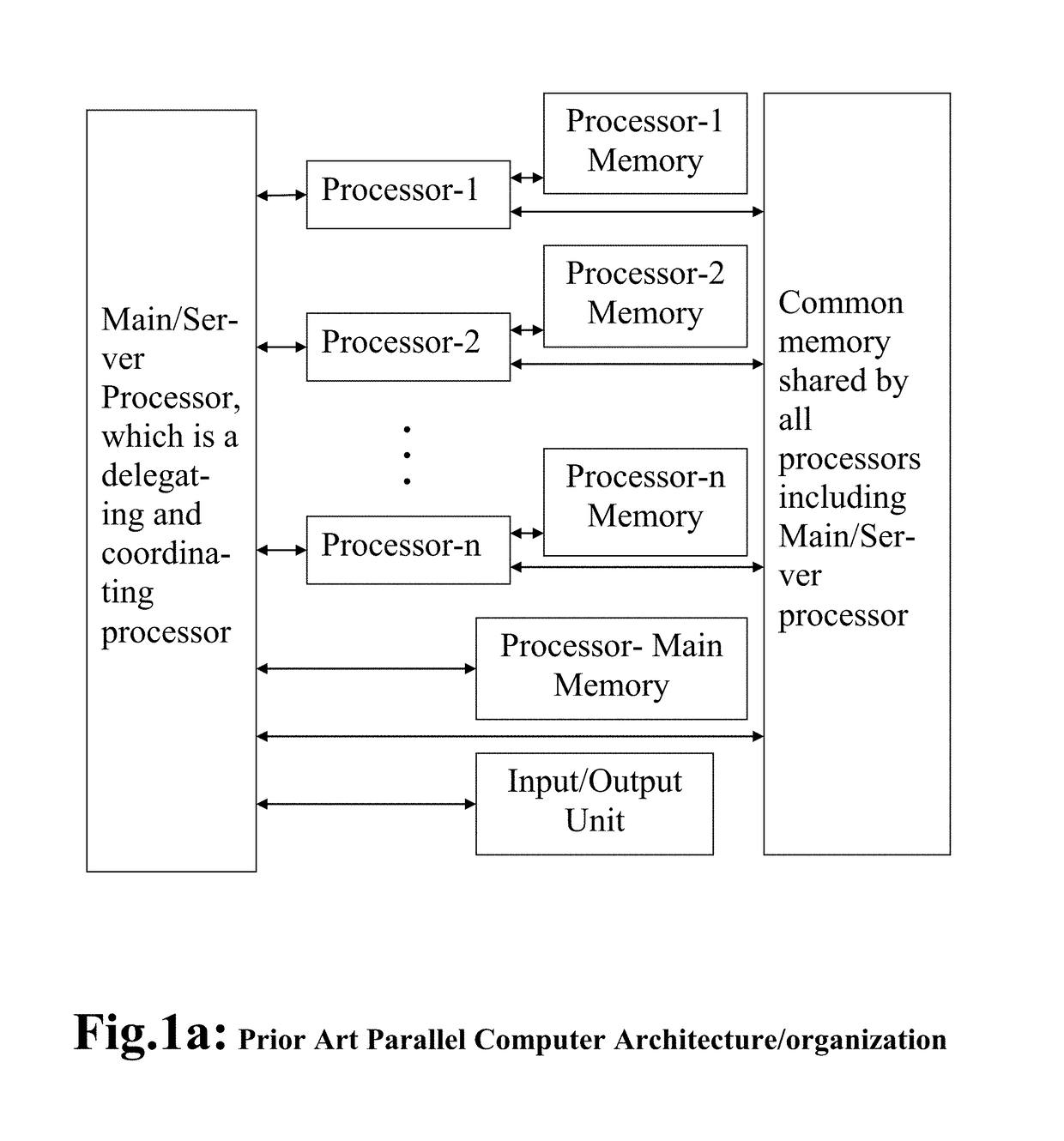

Liquid-cooled contact element

ActiveUS20190315239A1Quick reuseGood conductorOne pole connectionsVehicle connectorsElectricityElectrical conductor

An electrical contact element for a car charging plug connector is disclosed, which electrical contact element has a contact part and a connection part, wherein the connection part can be connected to an electrical conductor of a cable. Cooling liquid can be delivered to the contact element. As a result, the heat produced on the contact element is extracted directly. Therefore higher currents can be transmitted by such a contact element than by known contact elements.

Owner:HARTING AUTOMOTIVE

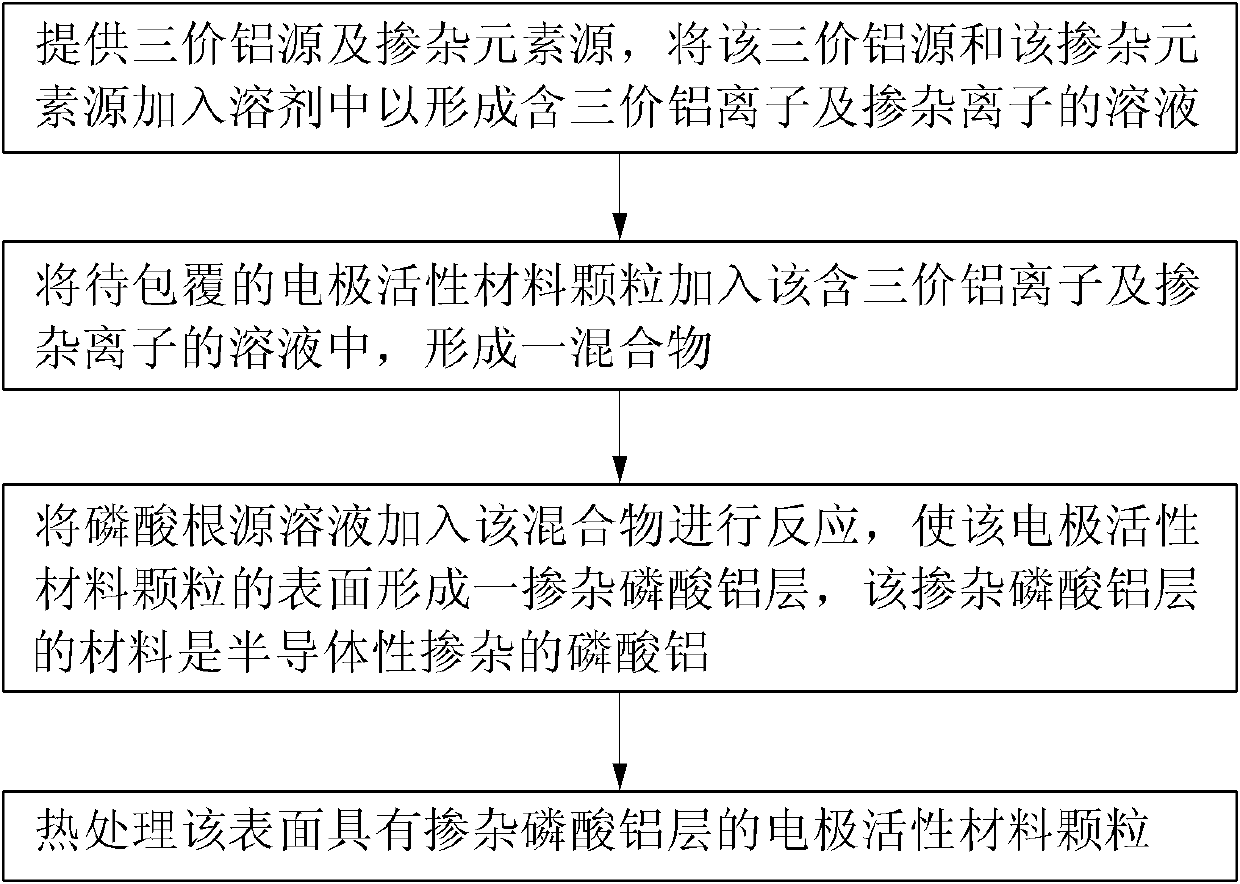

Anode composite material, preparation method thereof and lithium ion battery

ActiveCN102569789AImprove conductivityGood conductorCell electrodesSecondary cellsPhosphoric acidALUMINUM PHOSPHATE

Owner:TSINGHUA UNIV +1

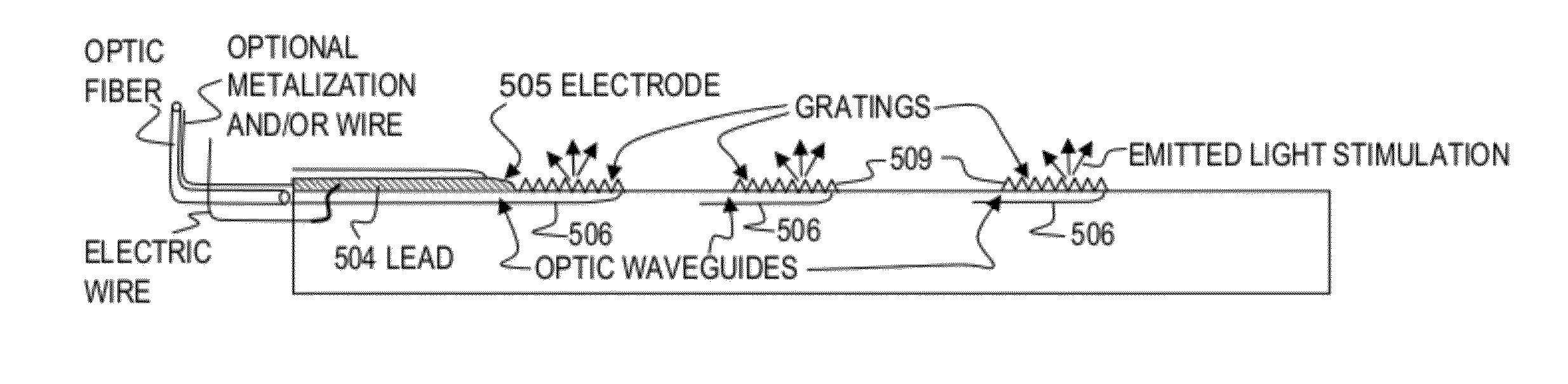

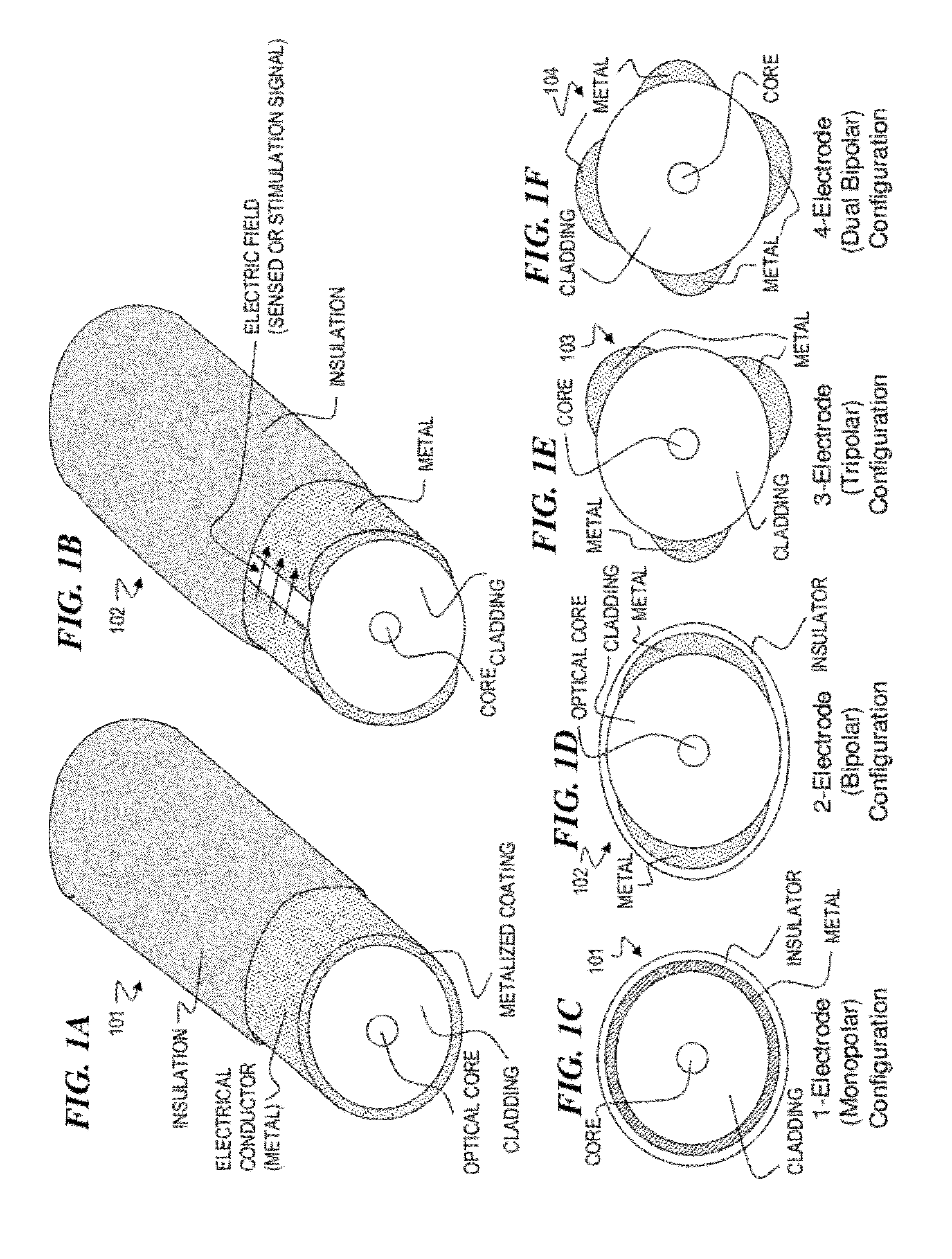

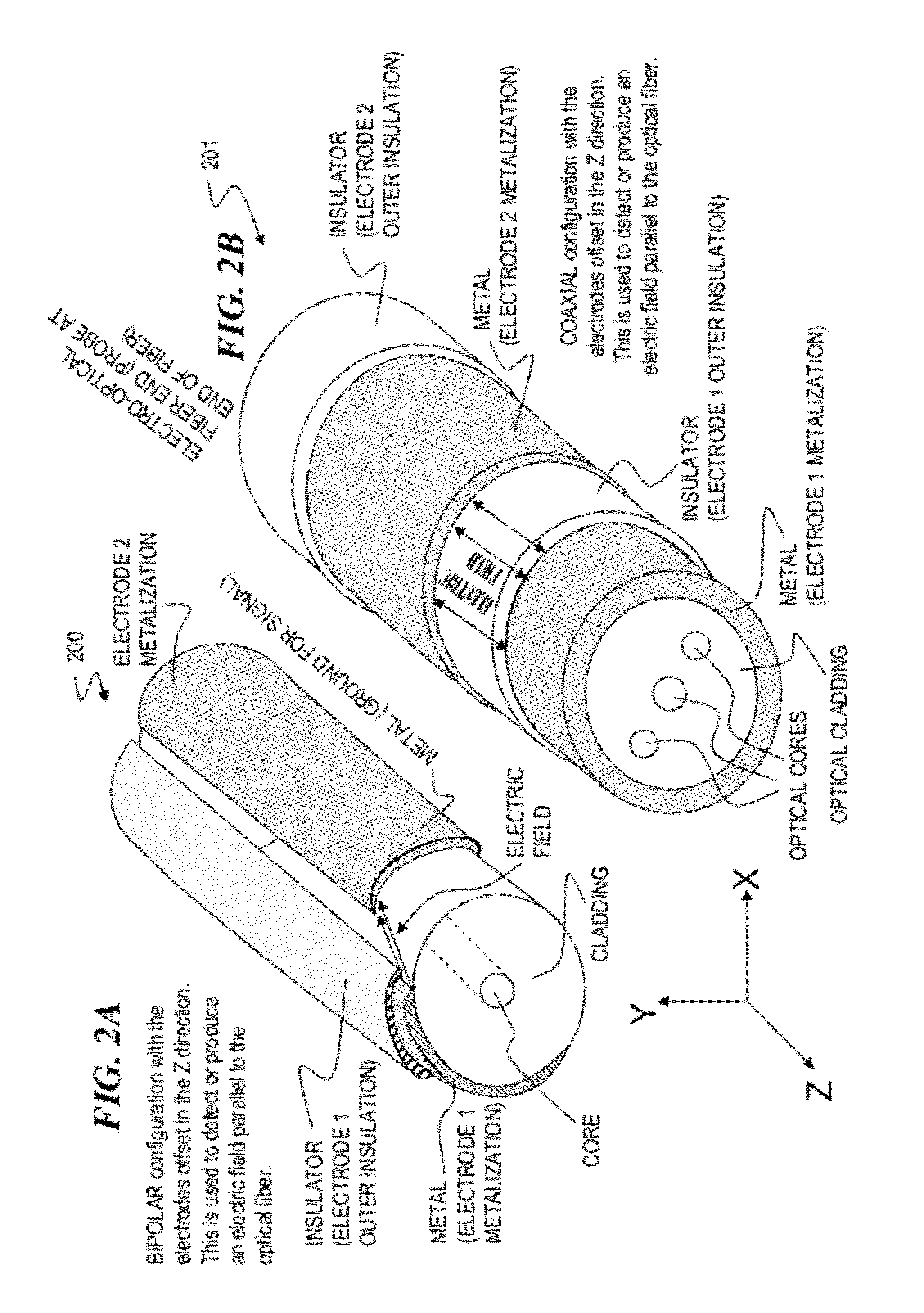

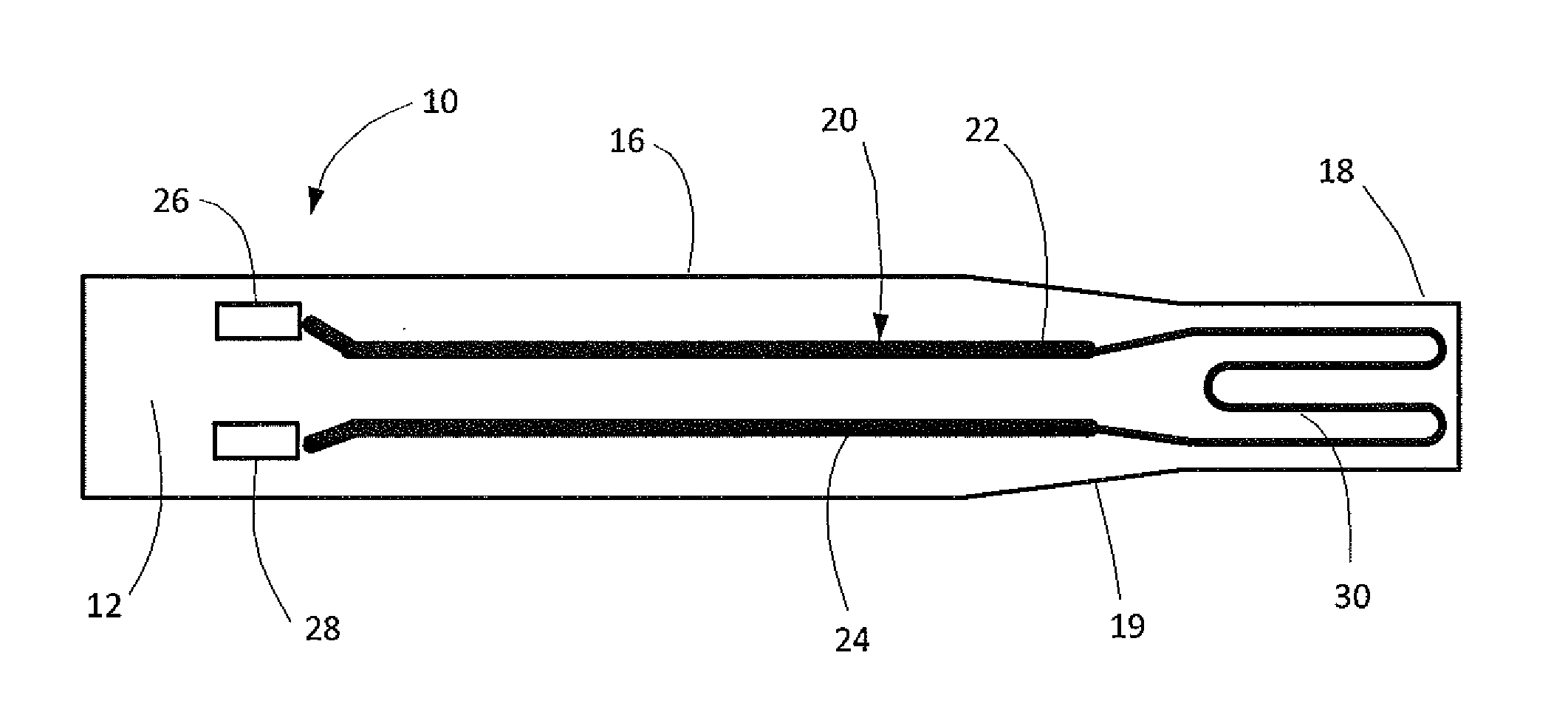

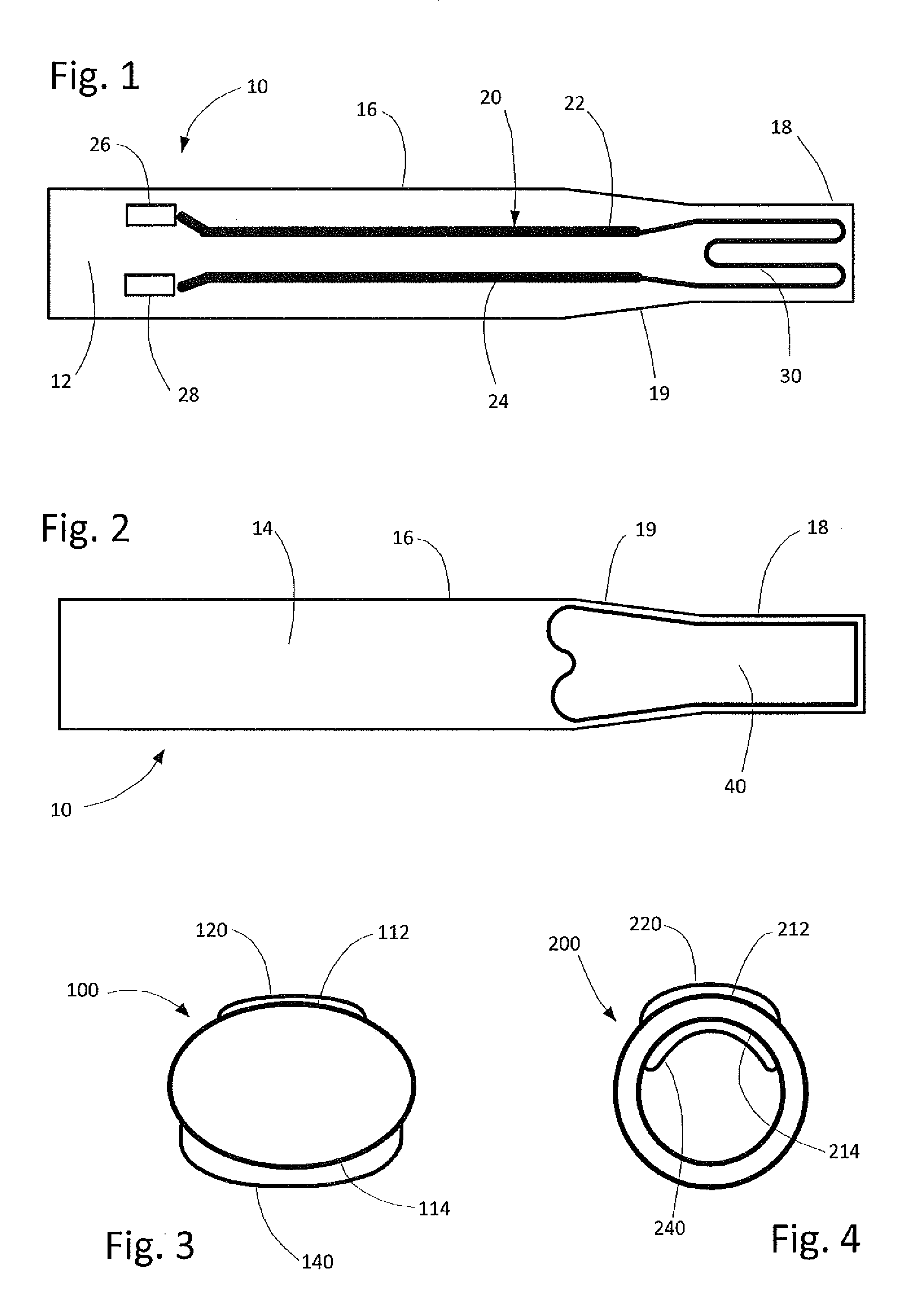

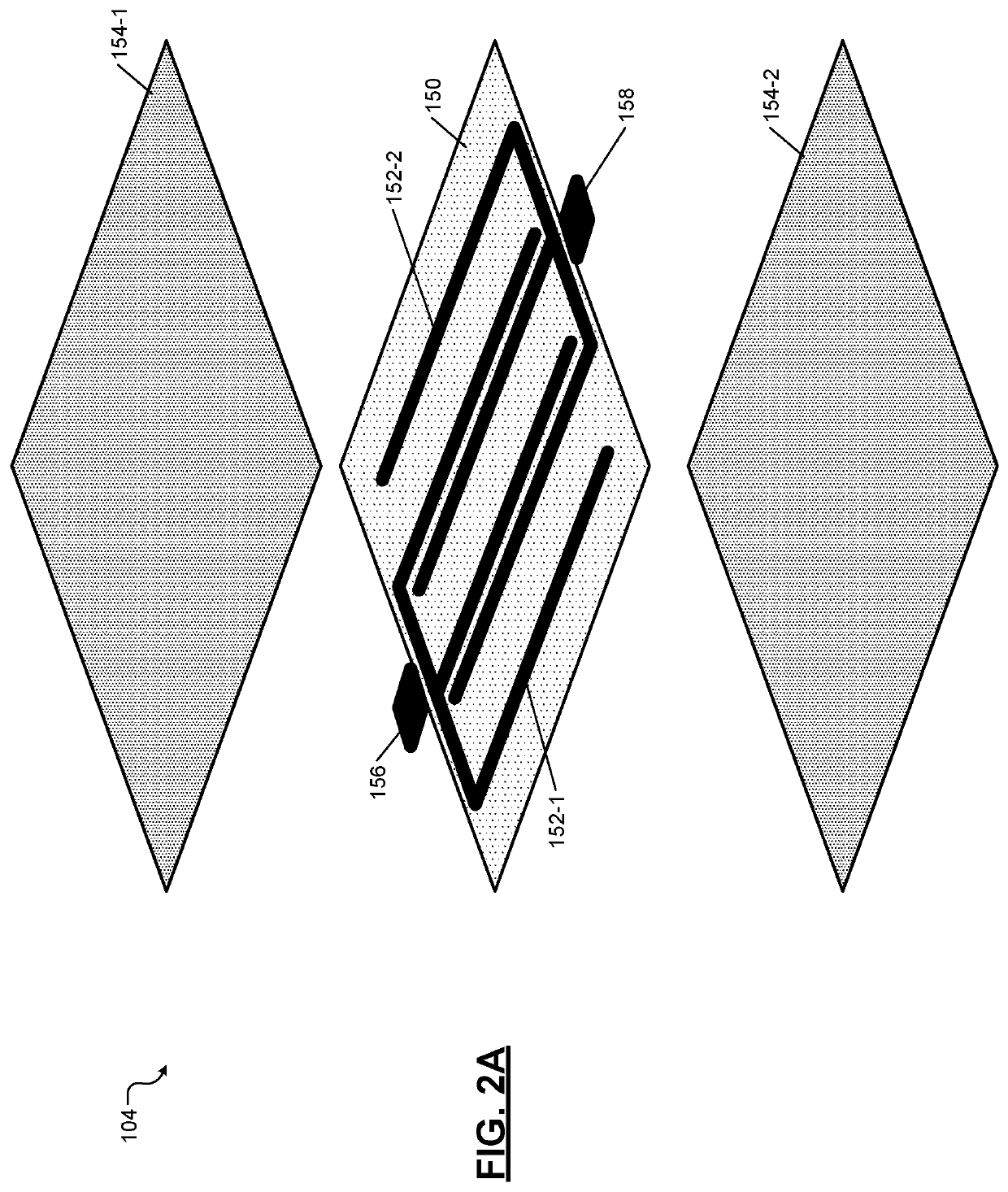

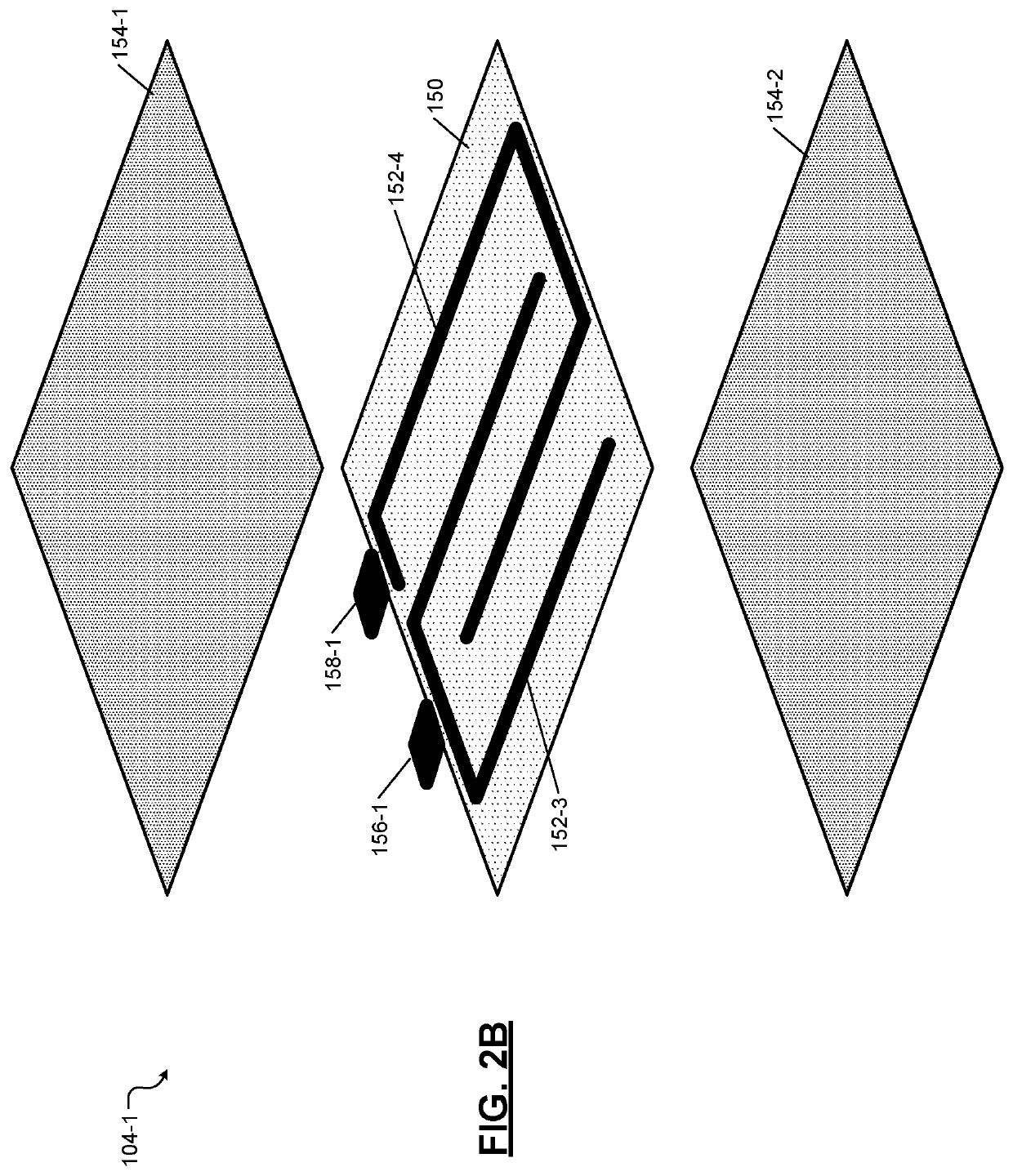

Hybrid optical-electrical probes for stimulation of nerve or other animal tissue

InactiveUS8357187B1Without and damaging tissueEasy to controlInternal electrodesLight therapyImplanted deviceVestibular nerve

An optical-signal vestibular-nerve stimulation device and method that provides different nerve stimulation signals to a plurality of different vestibular nerves, including at least some of the three semicircular canal nerves and the two otolith organ nerves. In some embodiments, balance conditions of the person are sensed by the implanted device, and based on the sensed balance conditions, varying infrared (IR) nerve-stimulation signals are sent to a plurality of the different vestibular nerves.

Owner:LOCKHEED MARTIN ACULIGHT CORP

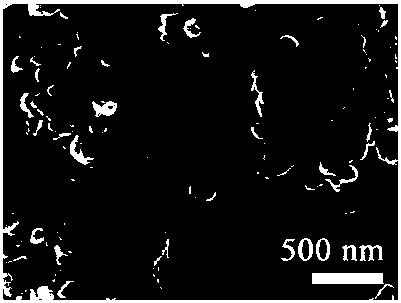

Flexible conductive single wire

ActiveUS20130046368A1Improve radiopacityShort processing timeConductive layers on insulating-supportsElectric discharge tubesCell adhesionIn vivo

Thin conductive metal coatings suitable for flexible nonmetal fine wires and leads are described. Polymer clad silica fiber cores are produced by plasma coating with single or dual layers of metals such as silver, gold or titanium to provide micro thin leads such as those used for pacemakers and fracture resistant aircraft wires that are both conductive and resistant to flexing breakage. The metal surfaces can be used to transmit analog signals while the nonmetal cores can be designed to transmit digital signals. Select deposition conditions can produce nanorough metal coating surfaces which promote cell adhesion so that tissue scarring in vivo is greatly reduced.

Owner:SURFATEK

Method for the on-board functional diagnosis of a soot sensor in a motor vehicle and/or for the detection of further constituents in the soot

InactiveUS20110011154A1Good conductorFacilitate conductionAnalysing fluids using sonic/ultrasonic/infrasonic wavesInternal-combustion engine testingTemperature coefficientElectricity

A method for on-vehicle functional diagnosis of a soot sensor and / or for detecting further components in the soot in a motor vehicle having an internal combustion engine, the soot sensor connected electrically to an evaluation circuit. To specify a method for functional diagnosis of a soot sensor and / or for detecting further components in the soot, by which it is possible to detect a faulty soot sensor and / or further components in the soot in an economical manner, the evaluation circuit measures a temperature coefficient of the soot sensor and detects the faultiness of the soot sensor and / or the presence of further components in the soot from the temperature coefficient of the soot sensor.

Owner:CONTINENTAL AUTOMOTIVE GMBH

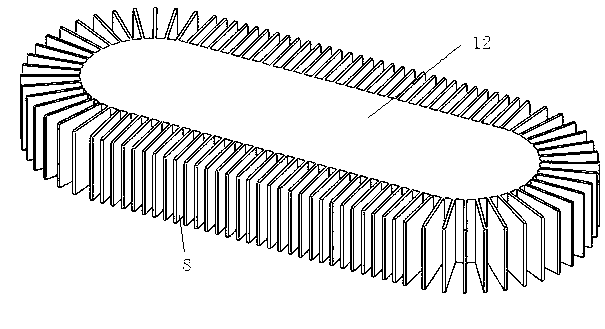

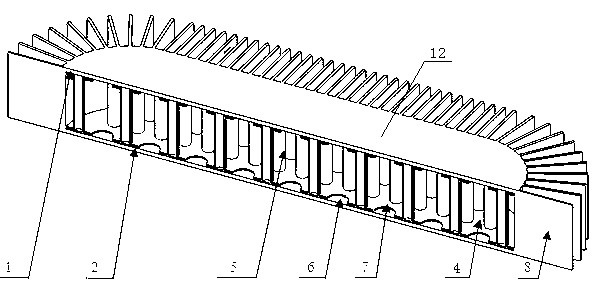

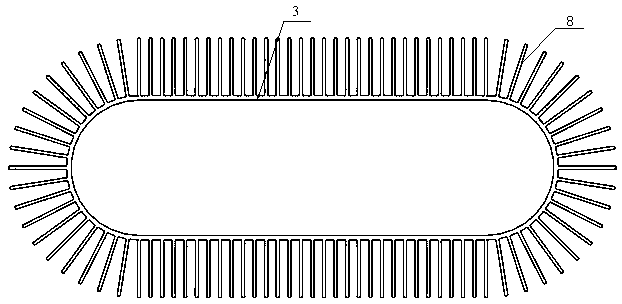

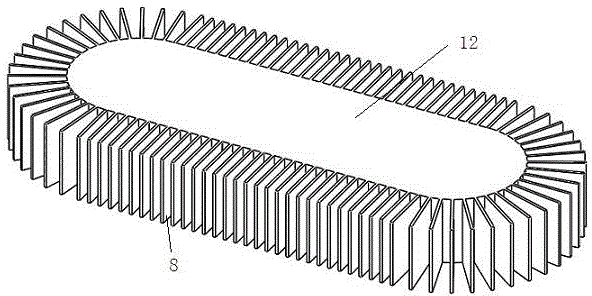

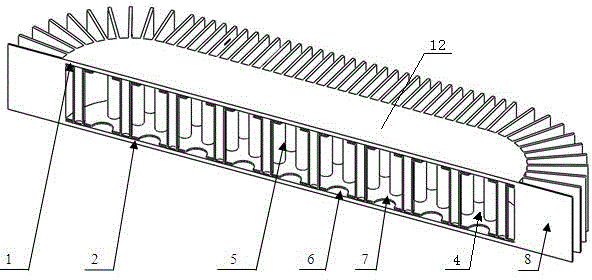

Microgroove group composite phase change radiator

InactiveCN103165547ASuperconductivity hasImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesCooling energyPhase change

The invention discloses a microgroove group composite phase change radiator. The radiator comprises a radiating surface and a condensing surface which are opposite to each other, wherein the radiating surface is connected with the condensing surface by a side surrounding plate to form a closed inner cavity, and a plurality of conveying pipelines for connecting the radiating surface with the condensing surface are arranged in the inner cavity; a microgroove group structure consisting of a plurality of microgrooves on micro level is arranged on the radiating surface in the inner cavity and used for accommodating a heat removal medium; a porous core material is filled in gaps between the conveying pipelines in the inner cavity; and a plurality of gaps are formed at one end of each conveying pipeline, which is in contact with the condensing surface, and the liquefied heat removal medium capable of being accommodated on the condensing surface flows out of the conveying pipelines and enters the porous core material. The radiator has heat superconducting capacity, and the heat of a power electronic equipment chip can be timely transferred to the radiating fin part by the microgroove group composite phase change technology; and the radiator is strong in cooling capacity, does not have cooling energy consumption, runs without power, saves energy, and is light in overall weight, small in size, stable in work, high in reliability, low in cost and environment-friendly.

Owner:HOHAI UNIV CHANGZHOU

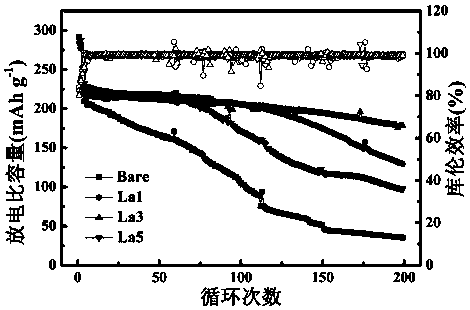

Preparation method of lanthanum oxide/lithium lanthanite-coated lithium-rich manganese-based anode material

InactiveCN110061211AImprove cycle stabilityReduce moistureSecondary cellsPositive electrodesLithiumManganese

The invention discloses a preparation method of a lanthanum oxide / lithium lanthanite-coated lithium-rich manganese-based anode material; the preparation method comprises the following steps of (1) mixing a lithium-rich manganese-based precursor with a lithium source, calcining for one time, and cooling to obtain a lithium-rich manganese-based anode material; (2) dissolving a lanthanum source intoa solvent to prepare a solution A, and dispersing the obtained lithium-rich manganese-based anode material into a solvent to prepare a solution B, dropwise adding the solution A into the solution B under a stirring condition, carrying out a co-precipitation reaction, evaporating the solution to a gel shape after the reaction is completed, and obtaining a lanthanum oxide / lithium lanthanite-coated lithium-rich manganese-based anode material precursor; and (3) carrying out secondary sintering on the obtained lanthanum oxide / lithium lanthanite-coated lithium-rich manganese-based anode material precursor, and cooling to obtain the lanthanum oxide / lithium lanthanite-coated lithium-rich manganese-based anode material. The preparation process is simple, easy to operate and low in cost; and moreover, the synthesized composite material is excellent in electrochemical performance and stable in cycling performance.

Owner:CENT SOUTH UNIV

Photovoltaic cells

InactiveUS20170179314A1Easy to changeGood conductorMaterial nanotechnologyPhotovoltaic energy generationOptoelectronicsGraphene

This invention relates to cells and devices for harvesting light. Specifically the cell comprises at least one electrode which comprises graphene or modified graphene and layer of a transition metal dichalcogenide in a vertical heterostructure. The cell may be part of a light harvesting device. The invention also relates to materials and methods for making such cells and devices.

Owner:UNIV OF MANCHESTER

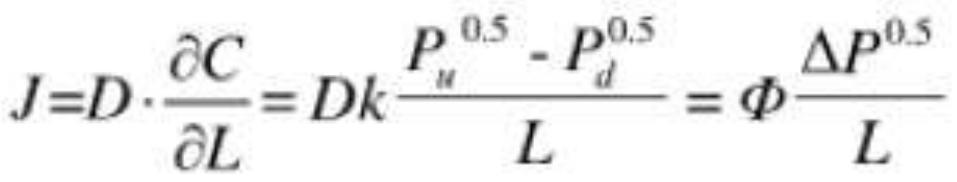

Fuel cell bipolar plate based on carbon nanotube film composite material and preparation method and application thereof

ActiveCN112242533AAccelerated corrosionImprove air tightnessFinal product manufactureFlat articlesFuel cellsCarbon nanotube

The invention provides a fuel cell bipolar plate based on a carbon nanotube film composite material and a preparation method and application thereof. The fuel cell bipolar plate is the carbon nanotubefilm composite material containing a carbon nanotube film and a resin matrix, and the weight ratio of the carbon nanotube film to the resin matrix is 1.5: 1-3: 1, wherein the conductivity of the carbon nanotube film composite material is greater than or equal to 103S / cm. The fuel cell bipolar plate provided by the invention has high conductivity and mechanical strength, and has excellent corrosion resistance.

Owner:BEIJING NEW ENERGY VEHICLE TECH INNOVATION CENT CO LTD

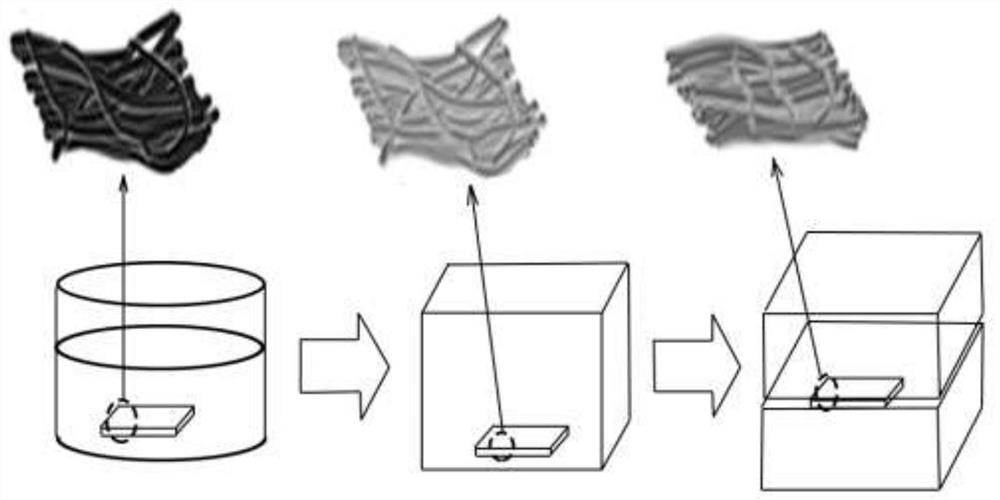

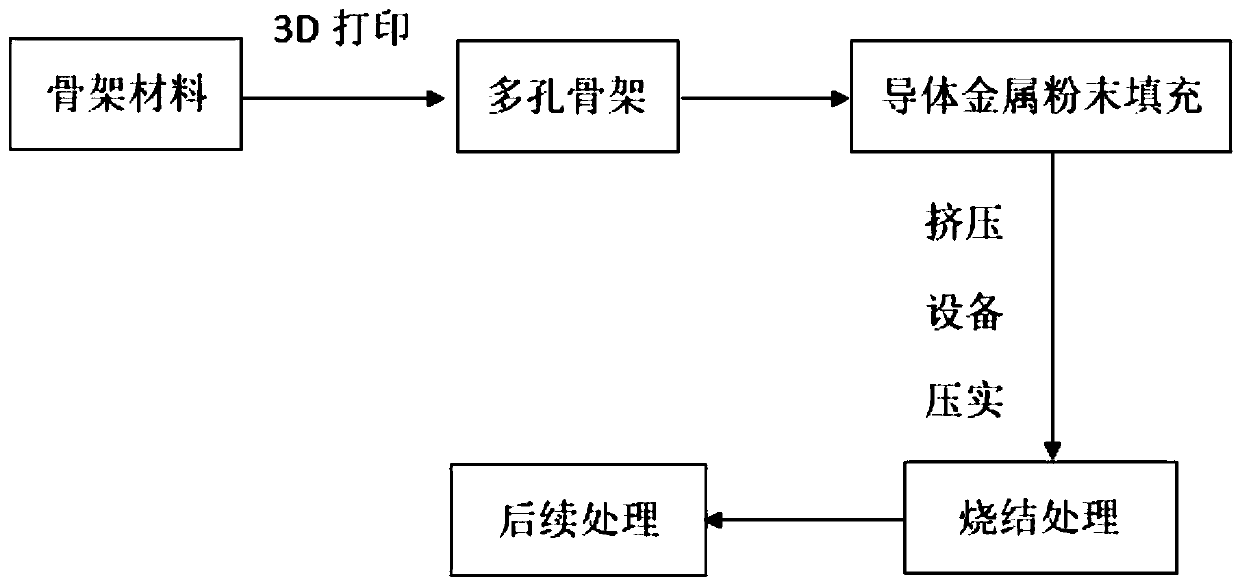

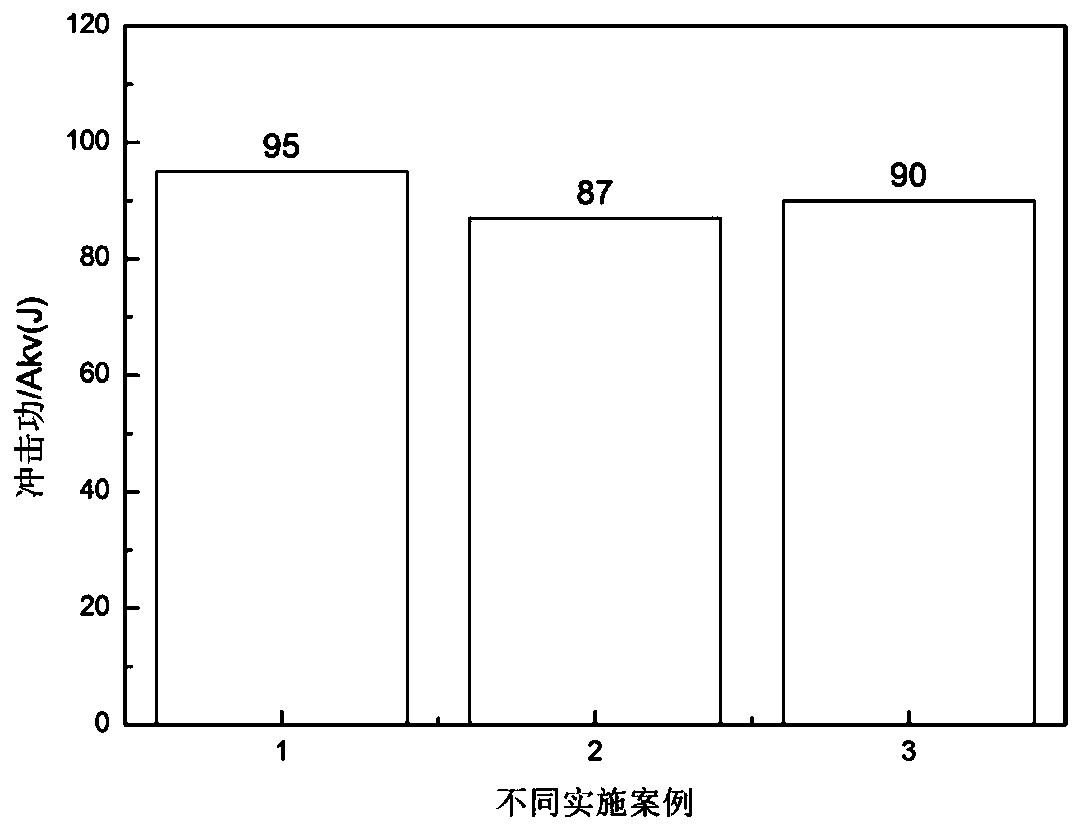

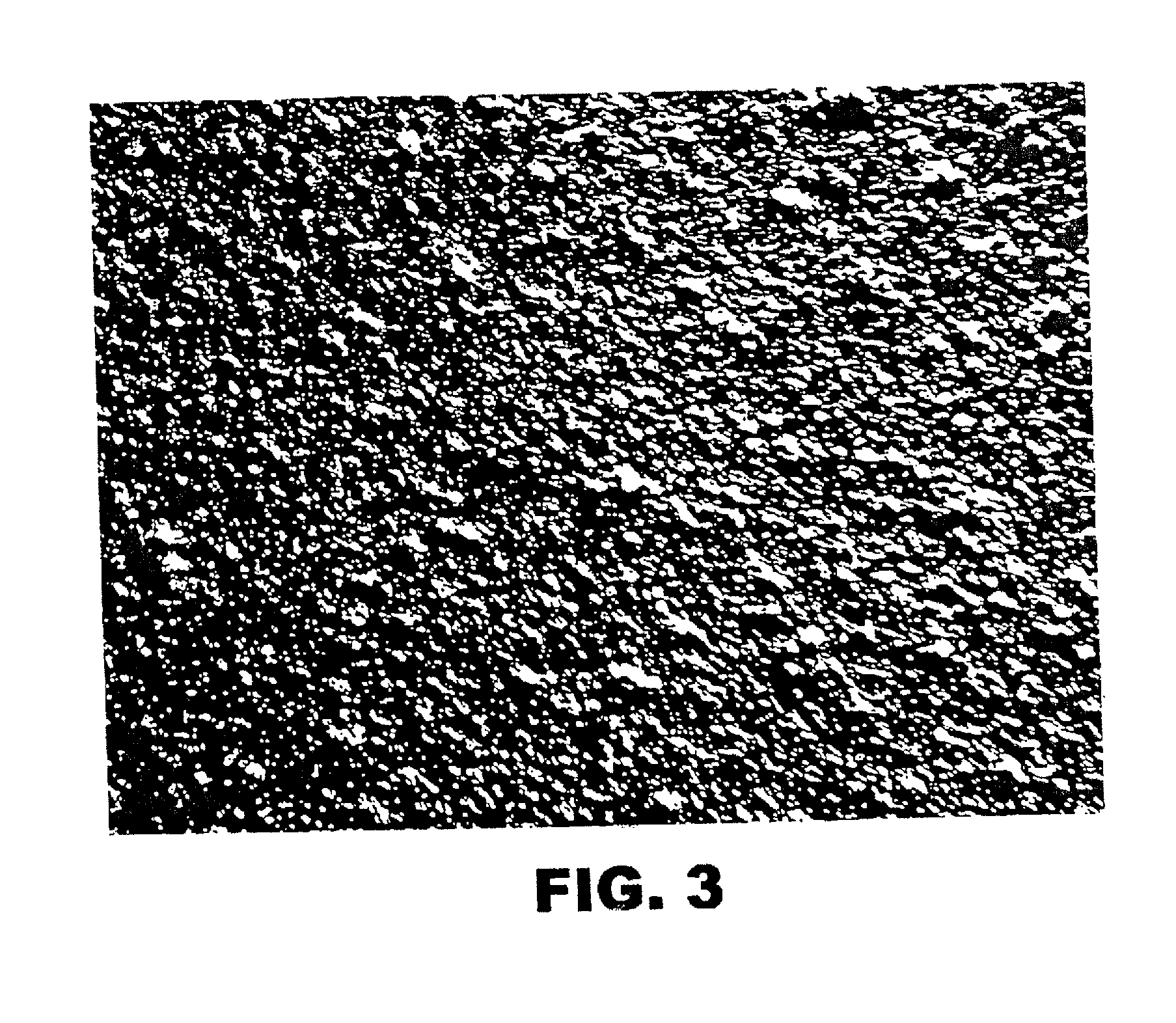

Preparation method of high-performance contact material

InactiveCN111515402AUniform and dense internal structureHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyShock resistanceUltimate tensile strength

The invention discloses a preparation method of a high-performance contact material. The contact material is prepared from nickel, tungsten and other alloys with high strength and excellent wear resistance as a porous framework, a copper alloy which fills holes and has excellent electrical conductivity and the like. The specific preparation method comprises steps as follows: firstly, the porous framework of nickel, tungsten and other alloys is prepared with a laser 3D printing technology; then the framework is filled with copper alloy powder, and a product is compacted on extrusion equipment;and finally, a sample filled with the copper alloy powder is subjected to vacuum sintering. The prepared electric contact material is more wear-resisting, has excellent shock resistance and long service life and is applicable to a high-voltage electrical contact.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Flexible conductive single wire

ActiveUS9422622B2Good conductorRetain flexibilityConductive layers on insulating-supportsElectric discharge tubesCell adhesionTissue scar

Thin conductive metal coatings suitable for flexible nonmetal fine wires and leads are described. Polymer clad silica fiber cores are produced by plasma coating with single or dual layers of metals such as silver, gold or titanium to provide micro thin leads such as those used for pacemakers and fracture resistant aircraft wires that are both conductive and resistant to flexing breakage. The metal surfaces can be used to transmit analog signals while the nonmetal cores can be designed to transmit digital signals. Select deposition conditions can produce nanorough metal coating surfaces which promote cell adhesion so that tissue scarring in vivo is greatly reduced.

Owner:SURFATEK

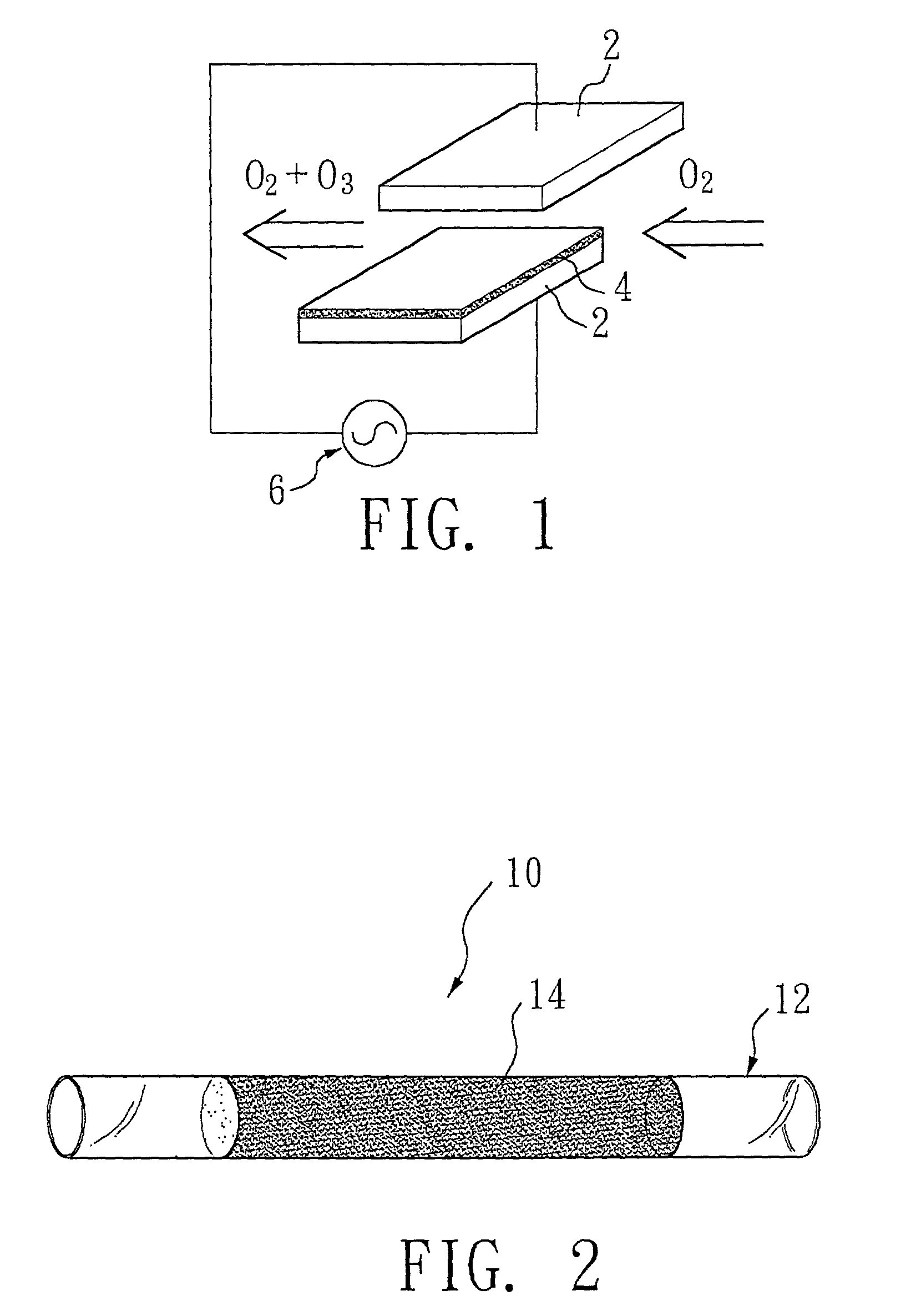

Method of gilding quartz or high aluminum-oxide-containing tube durable under high temperature and high voltage, and gilded quartz or high aluminum-oxide-containing tube applied in ozone generator

InactiveUS20020061403A1Good conductorMaintain stable propertiesPretreated surfacesElectrical discharge ozone preparationOxideHigh pressure

The present invention relates to a method for metal coating on a tube, particularly a tube for ozone generators which have been widely used for commercial and industrial purposes. Quartz or high aluminum-oxide-containing is a preferred material for the tube for an ozone generator. According to the present method, the tube is coated with a film of gold by putting the tube in a stove wherein the temperature and baking time is controlled. The present method for coating improves the durability of tubes operated at high temperature brought forth by micro-discharge, and thus extends the service life of the tube as used in an ozone generator.

Owner:LIOU HUEI TARNG +1

Conductor of electric cable for wiring, electric cable for wiring, and methods of producing them

InactiveUS7560649B2Improve bending resistanceGood conductorNon-insulated conductorsLine/current collector detailsElectrical conductorImpurity

Owner:FURUKAWA ELECTRIC CO LTD

Liquid-cooled contact element

ActiveUS10632861B2Quick reuseGood conductorOne pole connectionsVehicle connectorsElectrical conductorContact element

Owner:HARTING AUTOMOTIVE

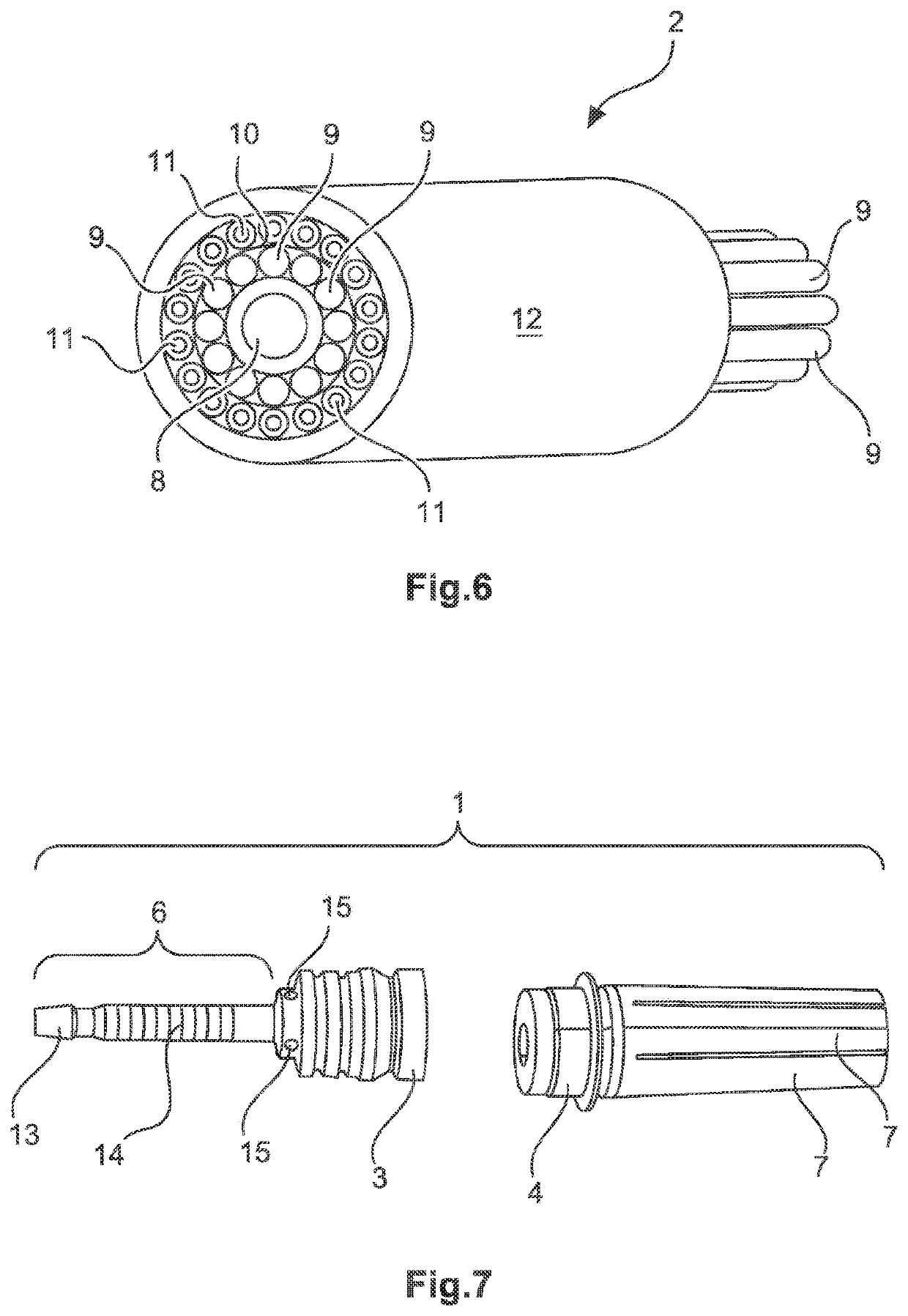

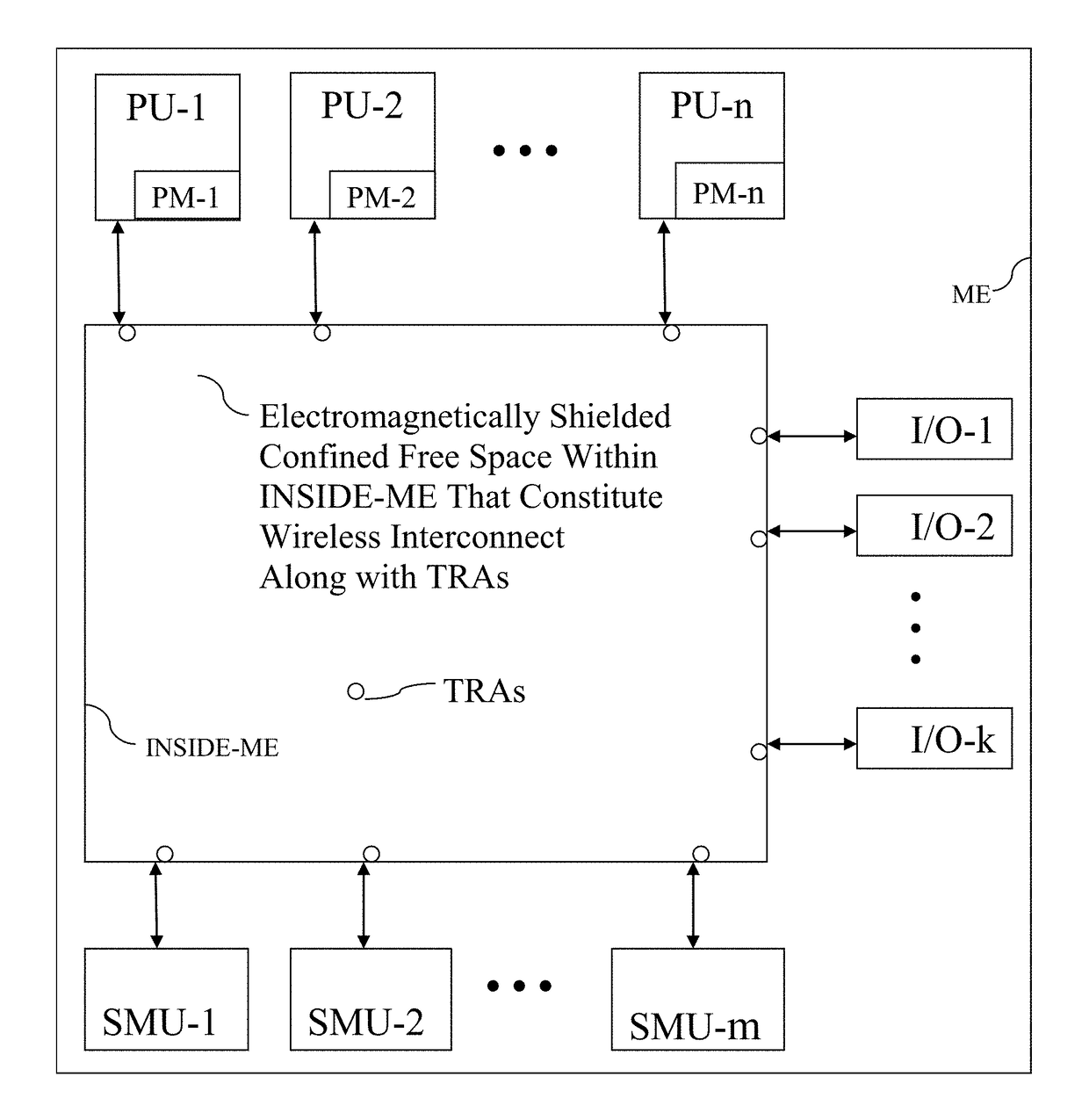

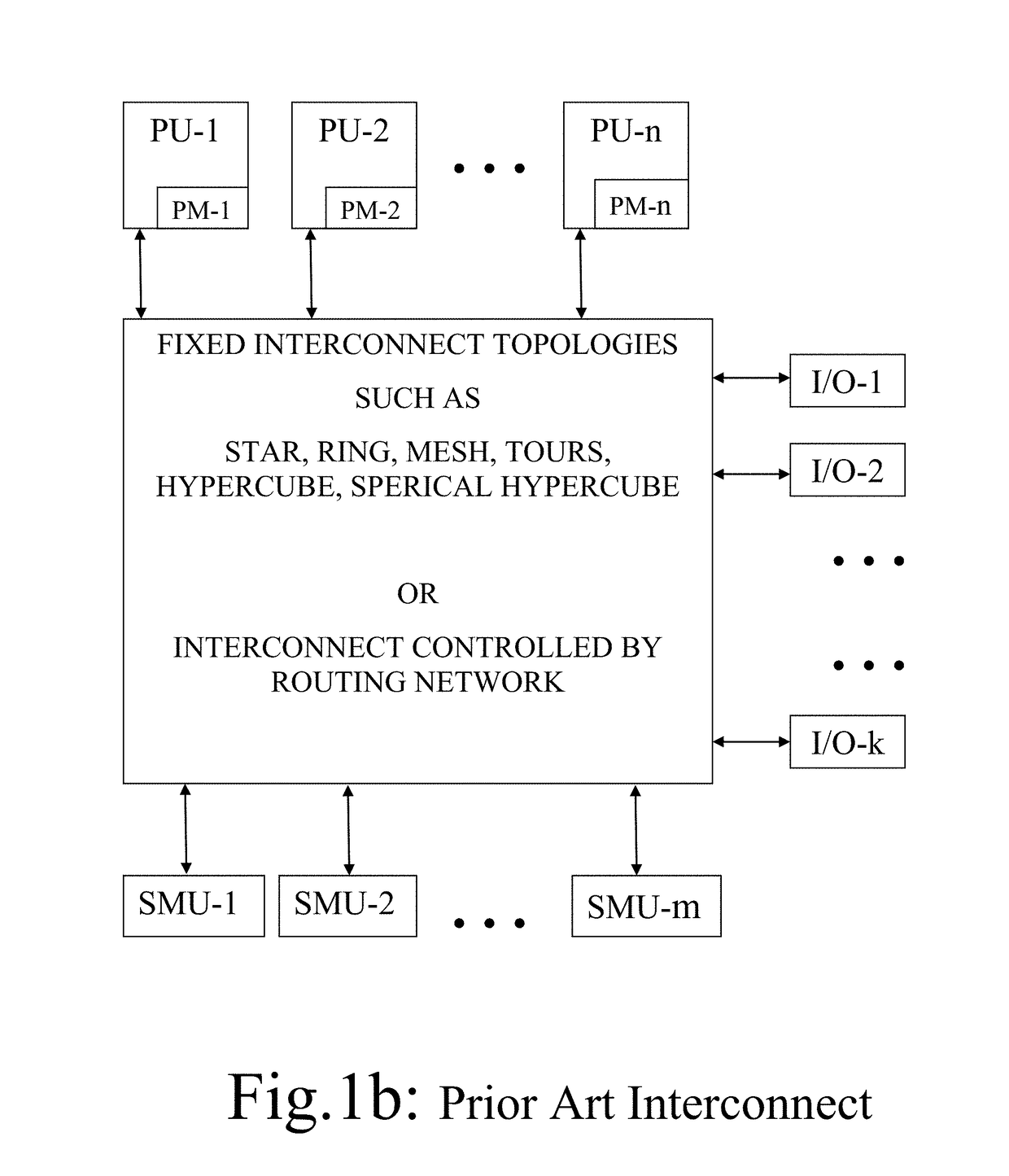

Multiprocessor computing apparatus with wireless interconnect and non-volatile random access memory

ActiveUS9891827B2Increase clock frequencyReduce contentionLocalised screeningInput/output to record carriersMetallic enclosureStatic random-access memory

A fan-less Multiprocessor-Computing-Apparatus (MCA) housed in a Metallic-Enclosure (ME) acting as an electromagnetic-Shield for wireless-communications / interconnects (WLI) among components of MCA enabling the whole-range-frequencies from lows of 10-HZs to highs of GHZ and beyond to be able to address almost unlimited Shared-Memory-Units (SMUs) by each processor with each SMU permanently tuned to send / receive data at a particular frequency. The ME is dust-proofed and filled with clean-air / vacuum for efficient-and-reliable WLI. The ME also acts as a heat-sink with the components of MCA placed on Circuit-Boards are mounted on inside in a plane parallel to the respective side of the ME of any required size and shape and heat producing components are firmly attached to the ME, which is waterproofed and placed-under-water for cooling. The SMUs are made up of static non-volatile Random Access Memory that can be read-from and written-to optically.

Owner:PATEL SURESHCHANDRA B

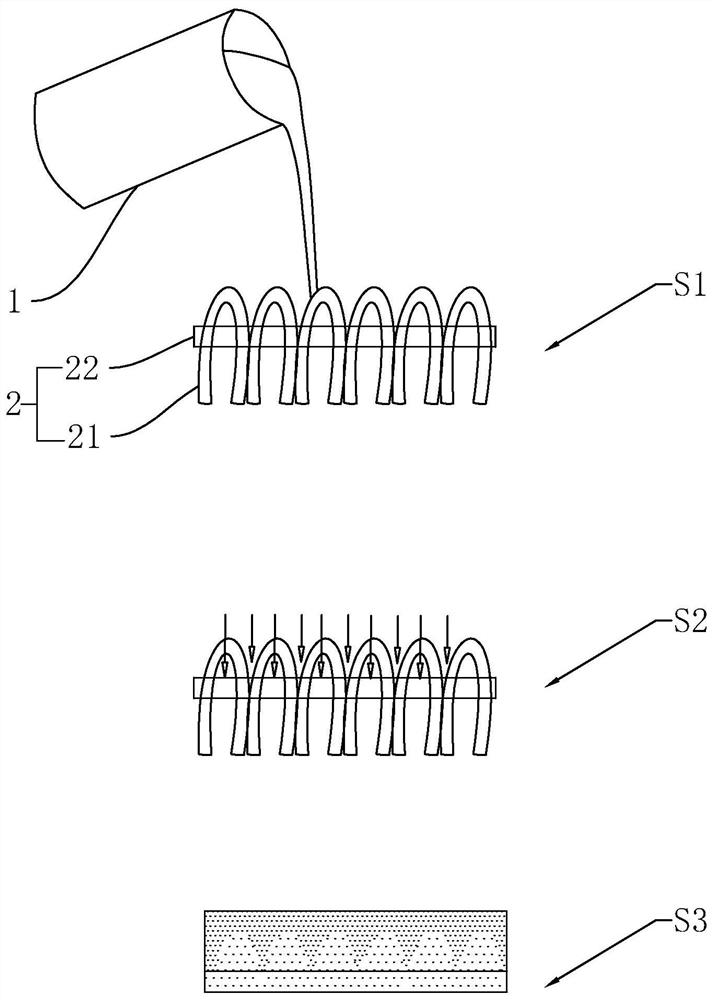

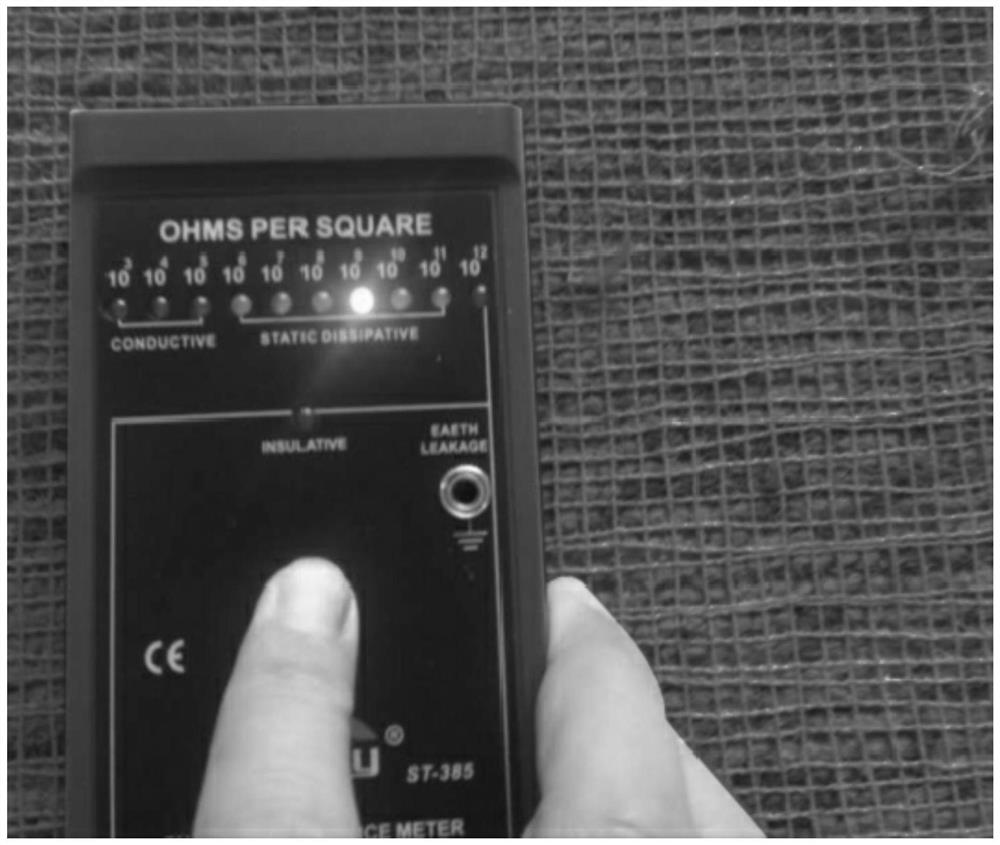

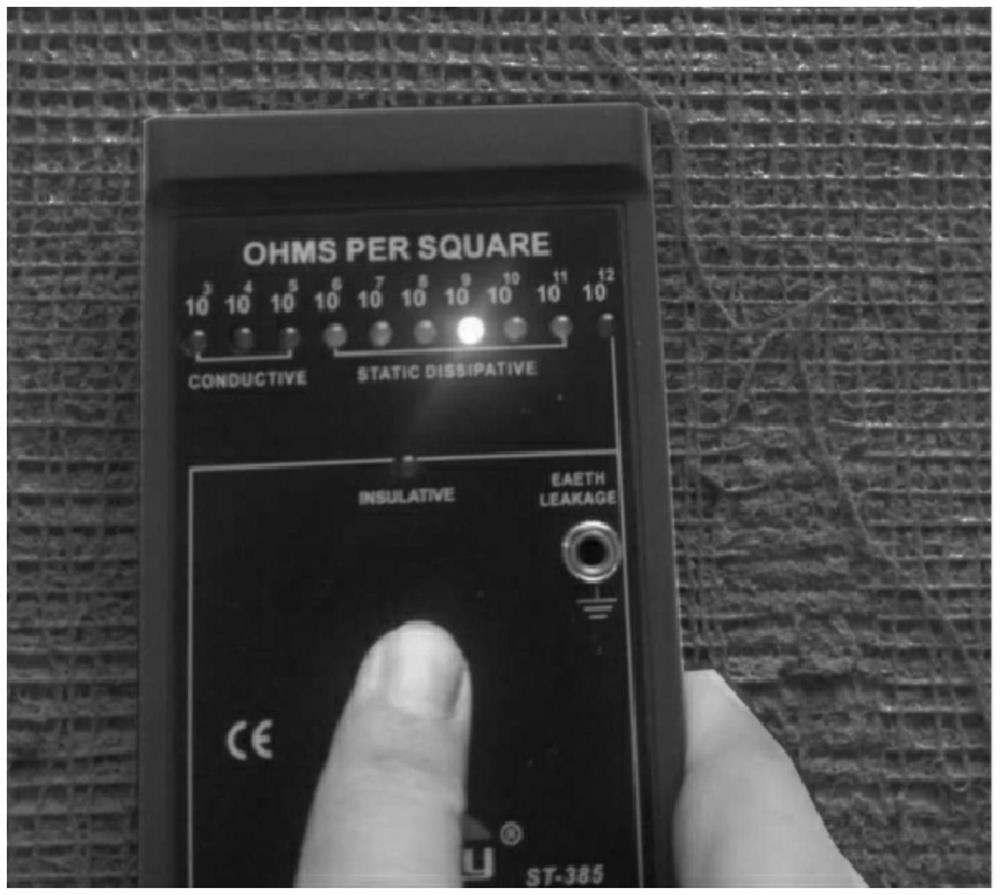

Odorless anti-static carpet gum composition, gum, preparation method thereof and carpet

ActiveCN113736392AImprove conductivityImprove anti-static performanceNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceCarbon nanotube

The invention relates to the technical field of carpet gum, and discloses an odorless anti-static carpet gum composition, gum, a preparation method thereof and a carpet, the odorless anti-static carpet gum composition comprises the following raw materials: a latex part, an auxiliary part and a functional additive part; the latex part is prepared from the following components in parts by weight: 200-300 parts of synthetic latex and 200-300 parts of vulcanized latex; the auxiliary part comprises the following components in parts by weight: 5-10 parts of a silane coupling agent, 2-5 parts of a defoaming agent and 2-5 parts of a water repellent agent; the functional additive part comprises the following components in parts by weight: 5-10 parts of graphite, 5-10 parts of conductive carbon black and 0.5-1 part of carbon nanotubes. The obtained carpet gum composition has better conductivity, and is beneficial to conductivity of the carpet after being used on the carpet so that the carpet has better anti-static performance.

Owner:深圳市准能新材料有限公司

Heated sensor element for mixed gas and liquid environments

InactiveUS20130161311A1Good conductorPreventing overly rapid heatingMaterial analysis by electric/magnetic meansOhmic-resistance heating detailsHeating elementMetal

A heated substrate element for a gas sensor includes a ceramic substrate element having a first surface and a second surface opposite the first surface, a heating element formed on the first surface and, a passive heat conducting metallic layer formed on the second surface. The element is able to resist cracking stresses from sudden local changes in temperature, such as occur when a liquid drop strikes the element.

Owner:MACK TRUCKS

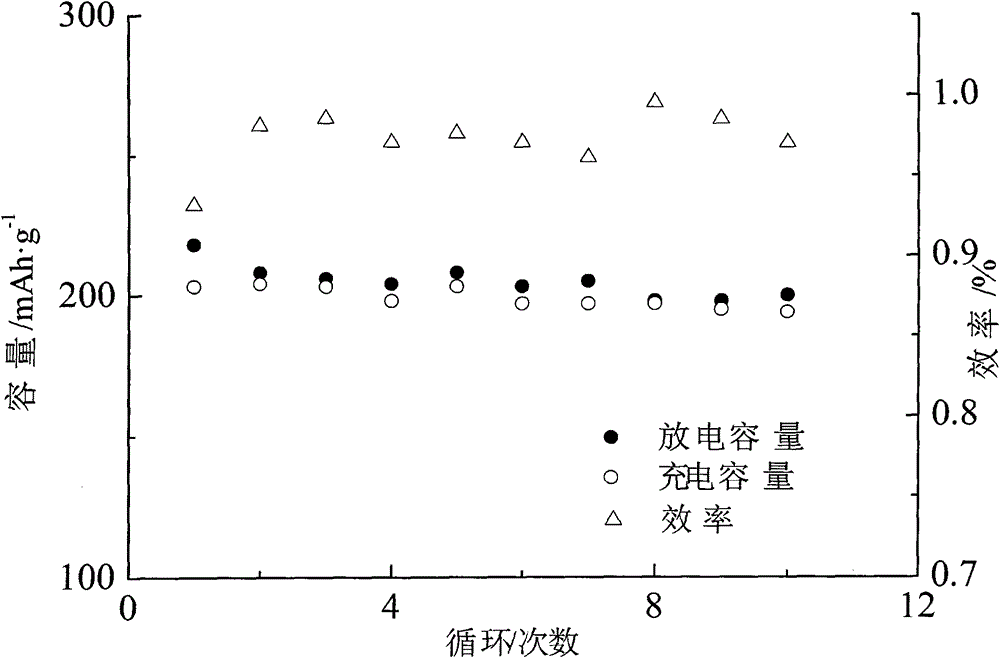

A borate-doped titanium lithium phosphate two-component surface-modified iron fluoride positive electrode material and preparation method thereof

InactiveCN103500834BIncrease contactGood conductorCell electrodesSecondary cellsElectrical conductorHigh energy

The invention provides a borate doped lithium titanium phosphate two-component surface modified ferric fluoride anode material and a preparation method. The preparation method is characterized by ball-milling borate, silicon and aluminium doped lithium titanium phosphate Li1.3Al0.1Ti1.9Si0.2P2.8O12 and synthetic raw materials in a high energy ball mill for a period of time and carrying out heat treatment, thus obtaining the FeF3 anode material. The anode material and the preparation method have the advantages that reactive groups of borate, namely amino groups on borate, are subjected to coordination bonding with fluorine ions on FeF3 material particle surfaces and meanwhile specific groups in borate strongly interact with surface hydroxyl on Li1.3Al0.1Ti1.9Si0.2P2.8O12 and then are subjected to polycondensation; therefore under the action of borate, doped lithium titanium phosphate Li1.3Al0.1Ti1.9Si0.2P2.8O12 is bonded on the surfaces of FeF3 anode particles, so that the particles of doped lithium titanium phosphate Li1.3Al0.1Ti1.9Si0.2P2.8O12 and the FeF3 anode form good contact, and Li1.3Al0.1Ti1.9Si0.2P2.8O12 is a good lithium ion conductor and has ionic conductivity 103-104 times that of lithium cobalt oxide; therefore the defect that the ionic conductivity of the FeF3 anode material is extremely low can be overcome and the electrochemical performance of the FeF3 material can be improved.

Owner:NINGBO UNIV

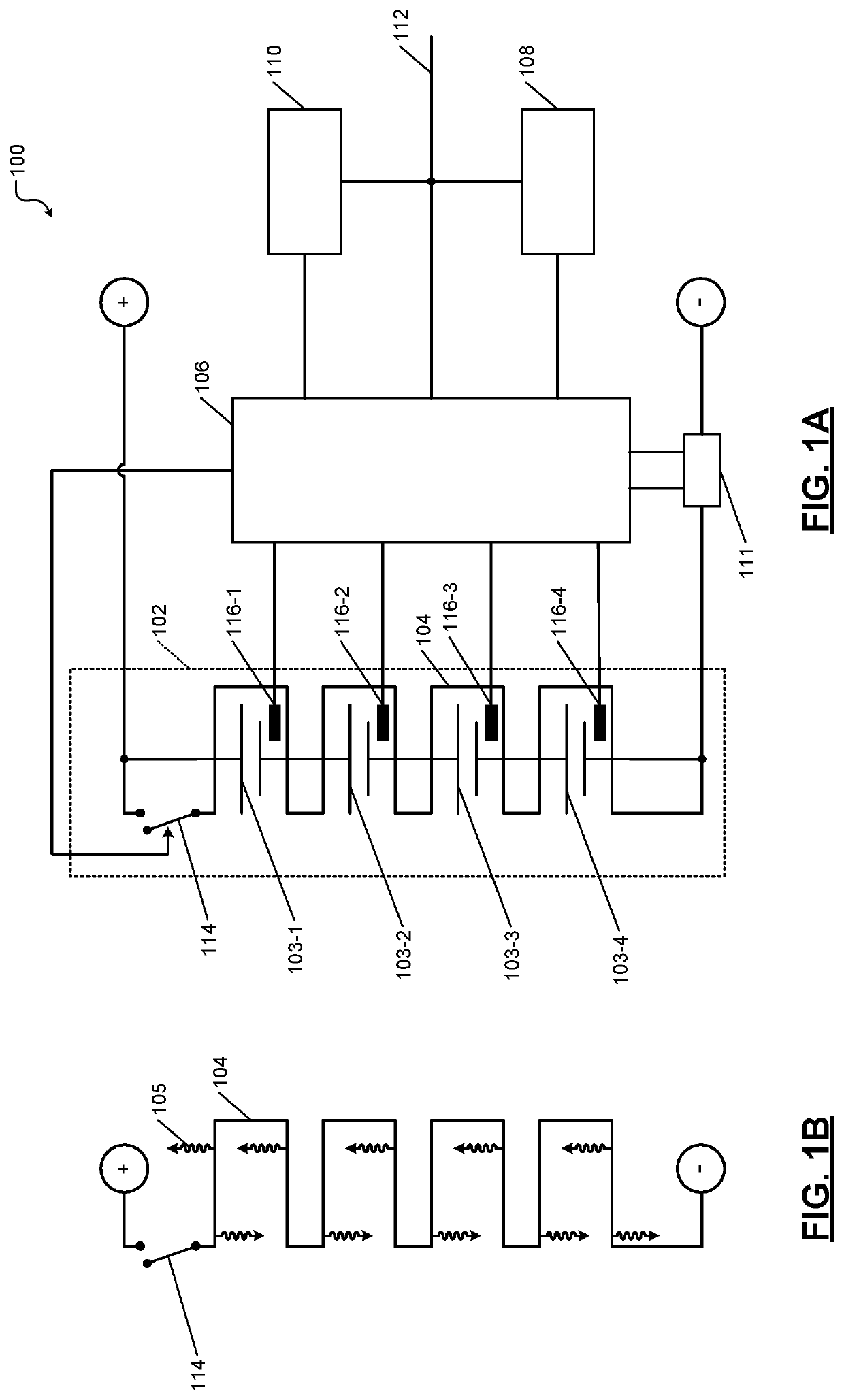

Thermal device for heating and cooling battery modules

PendingUS20220021044A1Good conductorBetter heat conductorCell temperature controlElectric powerElectrical conductorElectrical battery

A thermal device comprises a first layer of a non-metallic material that is a good conductor of heat and electricity, that includes a first terminal and a second terminal, and that has a first surface and a second surface; a metallic material disposed on the first surface of the first layer; a first plastic layer disposed on the metallic material; and a second plastic layer disposed on the second surface of the first layer. The first plastic layer and the second plastic layer include a plastic material that is a good conductor of heat.

Owner:GM GLOBAL TECH OPERATIONS LLC

Composite phase change heat sink with micro-groove group

InactiveCN103165547BSuperconductivity hasHas super thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesPhase changeCooling energy

The invention discloses a microgroove group composite phase change radiator. The radiator comprises a radiating surface and a condensing surface which are opposite to each other, wherein the radiating surface is connected with the condensing surface by a side surrounding plate to form a closed inner cavity, and a plurality of conveying pipelines for connecting the radiating surface with the condensing surface are arranged in the inner cavity; a microgroove group structure consisting of a plurality of microgrooves on micro level is arranged on the radiating surface in the inner cavity and used for accommodating a heat removal medium; a porous core material is filled in gaps between the conveying pipelines in the inner cavity; and a plurality of gaps are formed at one end of each conveying pipeline, which is in contact with the condensing surface, and the liquefied heat removal medium capable of being accommodated on the condensing surface flows out of the conveying pipelines and enters the porous core material. The radiator has heat superconducting capacity, and the heat of a power electronic equipment chip can be timely transferred to the radiating fin part by the microgroove group composite phase change technology; and the radiator is strong in cooling capacity, does not have cooling energy consumption, runs without power, saves energy, and is light in overall weight, small in size, stable in work, high in reliability, low in cost and environment-friendly.

Owner:HOHAI UNIV CHANGZHOU

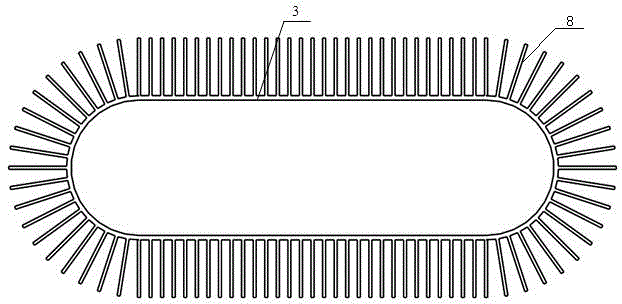

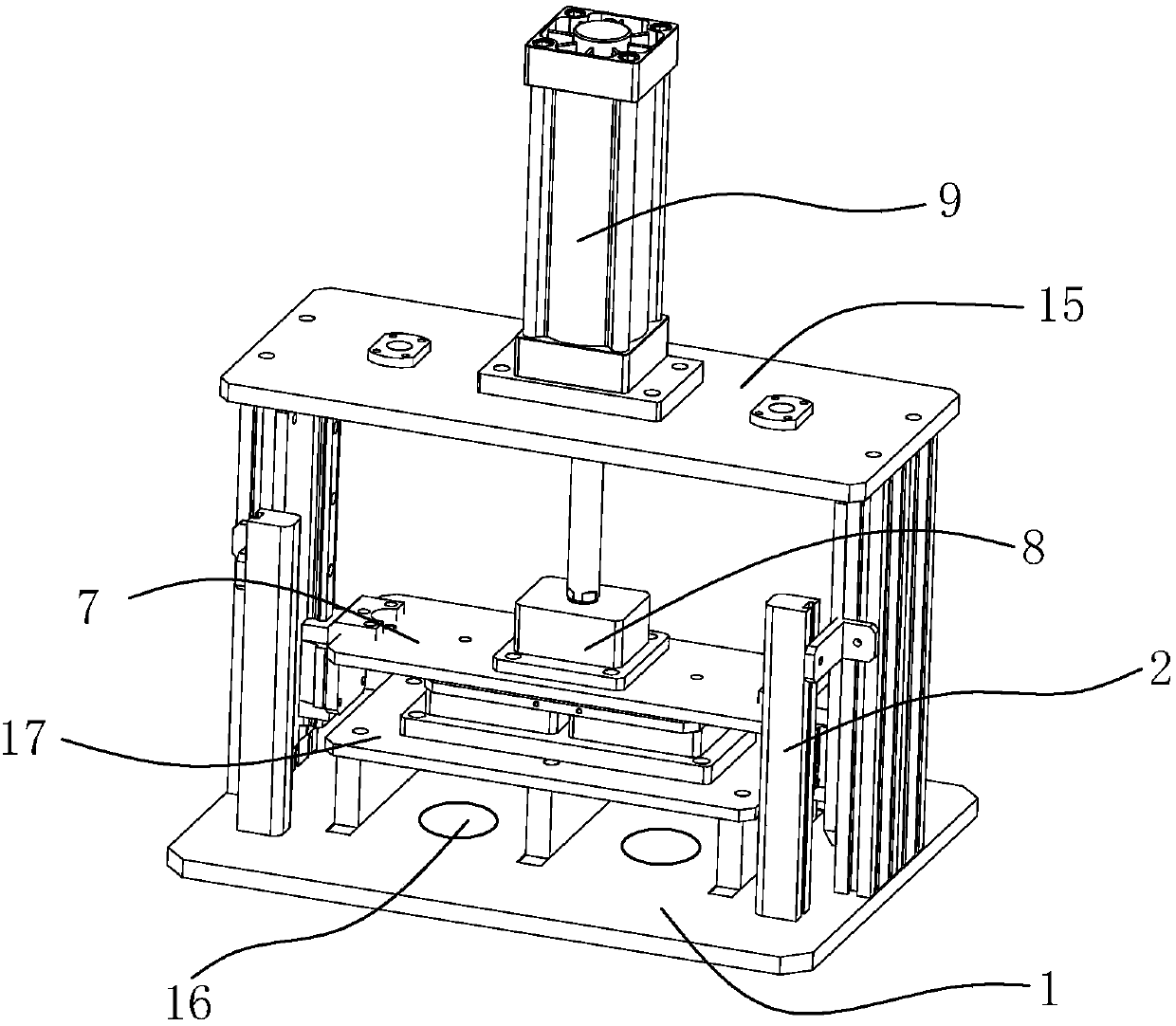

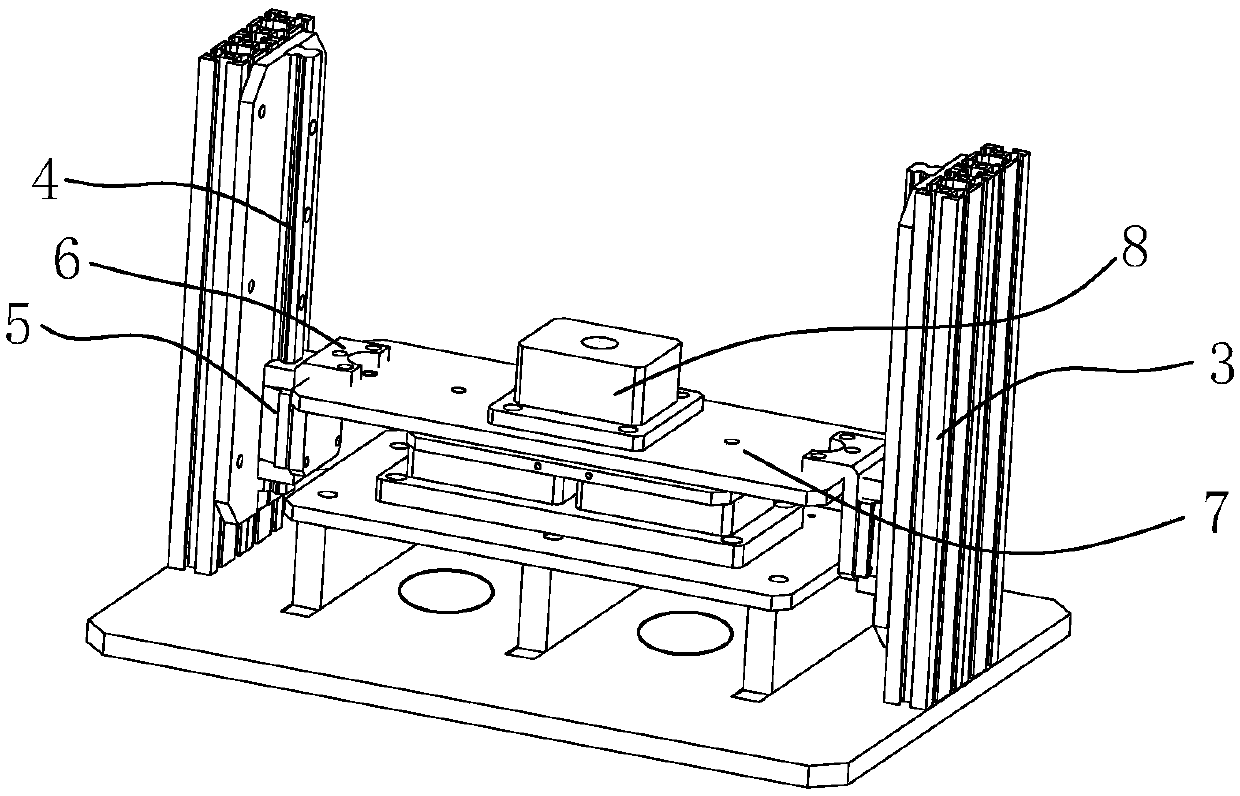

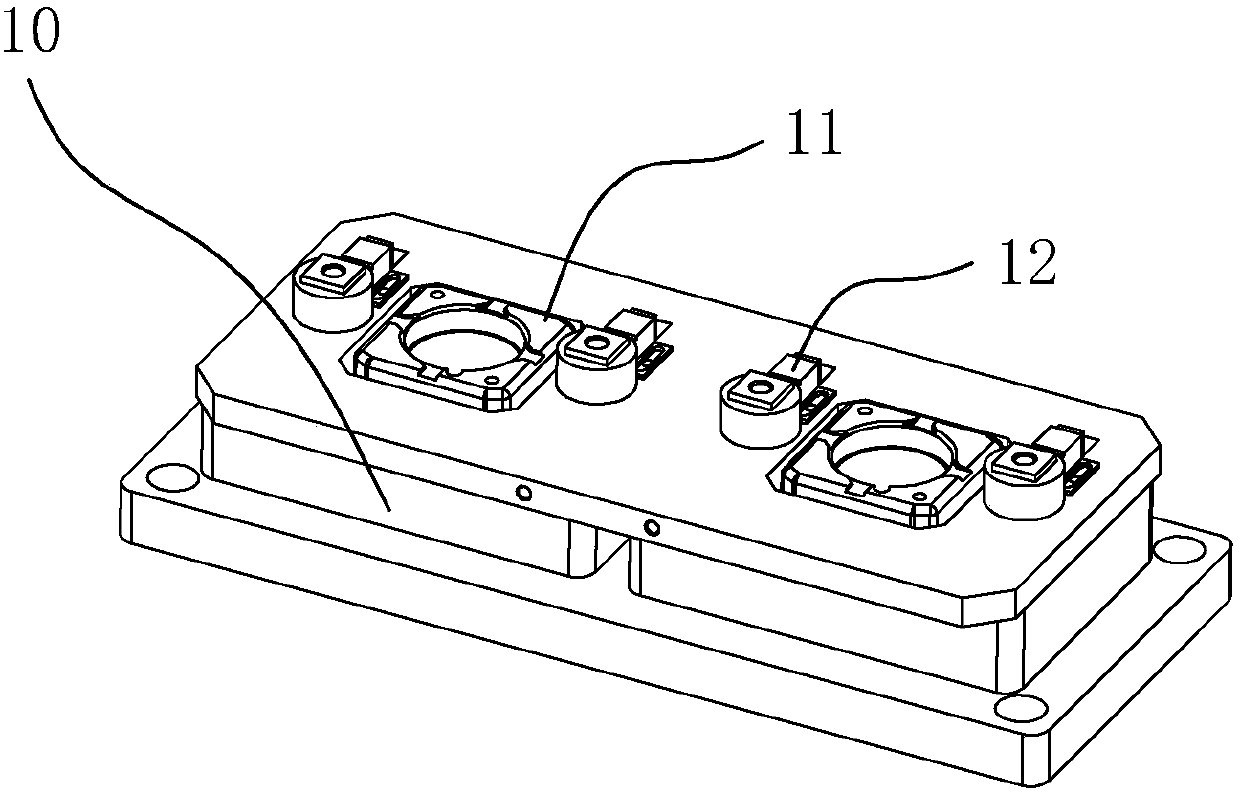

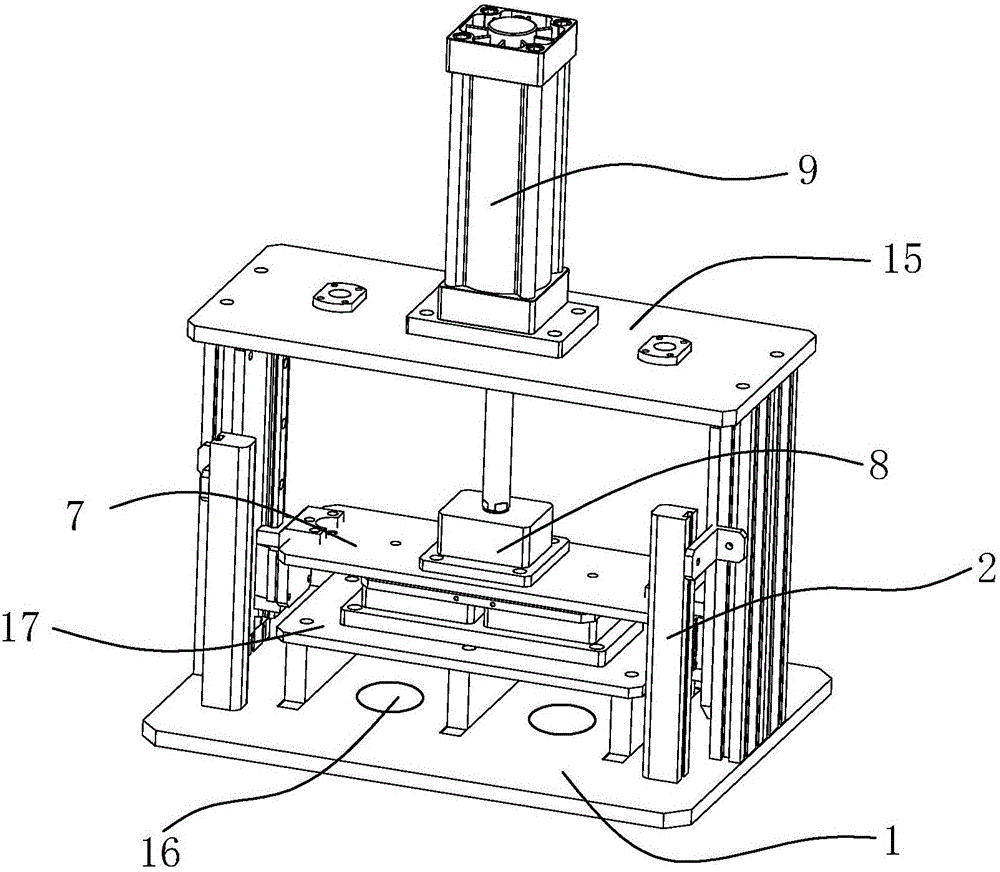

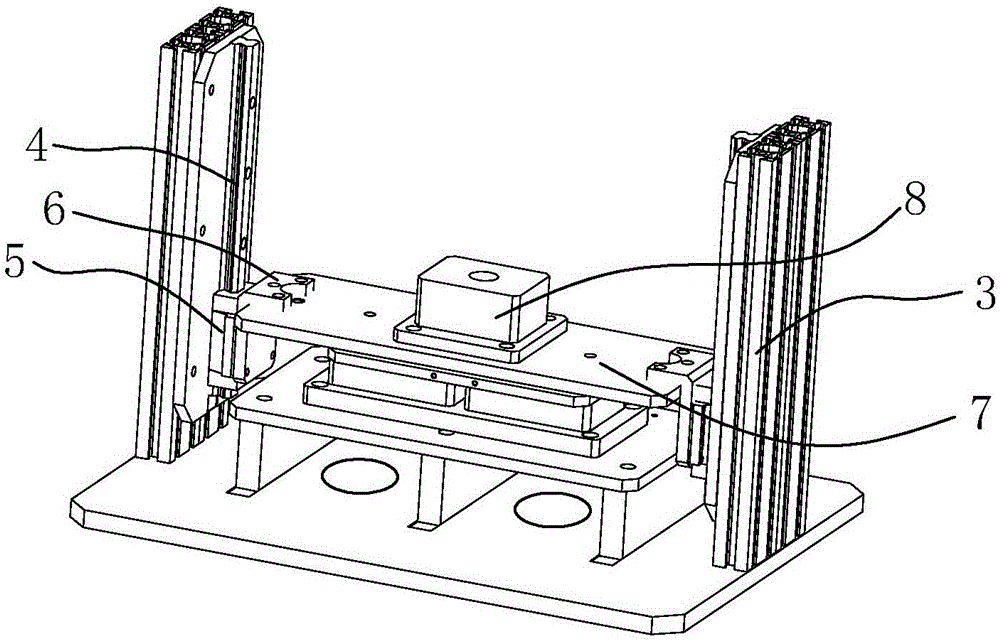

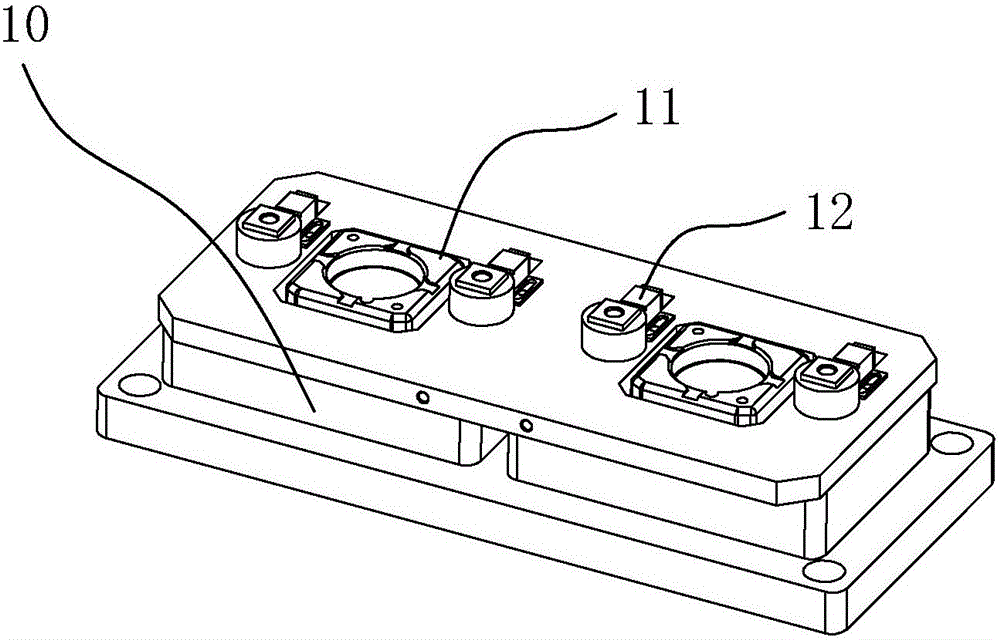

A cable head manufacturing device using electric control grating linkage

ActiveCN106786220BGood conductorAvoid accidents that pinch your handsApparatus for joining/termination cablesGratingEngineering

The invention relates to a manufacturing device of a cable connector employing electronically controlled grating linkage. A base plate and a top cover plate are fixedly supported through a vertical arm lever; a rail bar is fixed at the inner side of the vertical arm lever; a sliding block is erected on the rail bar and is fixed to a pressure plate through a connector; a soldering tin cavity is arranged at the center position of the pressure plate; an electric gas bar is arranged at the center position of the top cover plate; the tail end of a bar member of the electric gas bar is fixed on the soldering tin cavity; and a tin injection contact is fixed at the lower part of the pressure plate and runs through the soldering cavity through a metal conduit. Tin and a tin flux in the soldering tin cavity can automatically flow into a cable clamp easily through the gravity through the mode that the soldering tin cavity, the tin injection contact, a fixed hole and a tin outlet bath run through one another, so that the cable clamp, a cable chuck and a cable are fused into a whole; a good electric conductor is achieved; and by adopting the working mode that a grating is linked with the electric gas bar, an accident of hand injury caused by misoperation of an operator can be avoided.

Owner:安徽爱谱华顿电子科技有限公司

Manufacturing device of cable connector employing electronically controlled grating linkage

ActiveCN106786220AGood conductorAvoid accidents that pinch your handsApparatus for joining/termination cablesGratingEngineering

The invention relates to a manufacturing device of a cable connector employing electronically controlled grating linkage. A base plate and a top cover plate are fixedly supported through a vertical arm lever; a rail bar is fixed at the inner side of the vertical arm lever; a sliding block is erected on the rail bar and is fixed to a pressure plate through a connector; a soldering tin cavity is arranged at the center position of the pressure plate; an electric gas bar is arranged at the center position of the top cover plate; the tail end of a bar member of the electric gas bar is fixed on the soldering tin cavity; and a tin injection contact is fixed at the lower part of the pressure plate and runs through the soldering cavity through a metal conduit. Tin and a tin flux in the soldering tin cavity can automatically flow into a cable clamp easily through the gravity through the mode that the soldering tin cavity, the tin injection contact, a fixed hole and a tin outlet bath run through one another, so that the cable clamp, a cable chuck and a cable are fused into a whole; a good electric conductor is achieved; and by adopting the working mode that a grating is linked with the electric gas bar, an accident of hand injury caused by misoperation of an operator can be avoided.

Owner:上海河姆渡实业发展有限公司

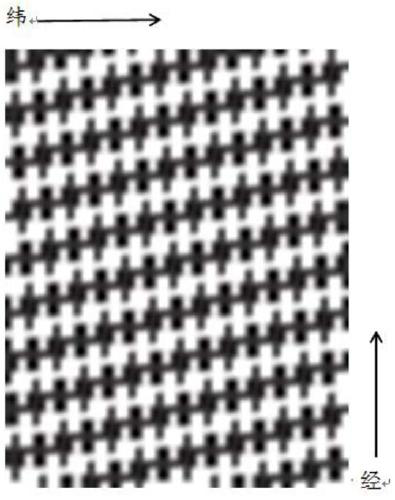

Binchotan fiber fabric, preparation method and application

InactiveCN111254547AComfortable to wearLarge specific surface areaMonocomponent cellulose artificial filamentOpen work fabricsYarnCarbon fibers

The invention discloses a binchotan fiber fabric, a preparation method and application. The binchotan fiber fabric is prepared from blended yarn of binchotan fiber and long stapled cotton fiber. The preparation method comprises the steps that warping beams are prepared, specifically, binchotan fiber blended warp yarn penetrates through a tentering reed on a high-speed warping machine, and then uniformly-arranged warping beams are formed in a lease warping method and to be used on the machine; the well sorted warping beams are subjected to drafting and denting, and then the warping beams are mounted on a 280cm high-speed rapier loom for spinning; the weft density of the machine is adjusted; a jacquard weaving program is well designed for an electronic jacquard machine to perform heald raising, and then weaving is performed based on porous composite structure regular adjusting and testing; woven greige cloth is subjected to dyeing treatment after being taken off the machine; and after passing inspection, the dyed greige cloth is sent to a finishing workshop for clipping, sewing, inspecting and packaging. The binchotan fiber finished product is rich in binchotan active substance, andcapable of effectively blocking electromagnetic waves from mobile phones, computers and televisions, thus preventing the human bodies from being hurt.

Owner:河北瑞春纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com