A cable head manufacturing device using electric control grating linkage

A technology for manufacturing devices and cable heads, which is applied in the direction of equipment for connecting/terminating cables, etc. It can solve problems such as increased working current, interrupted production, scientific research, medical operations, fires, etc., and achieves the effect of a good conductor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

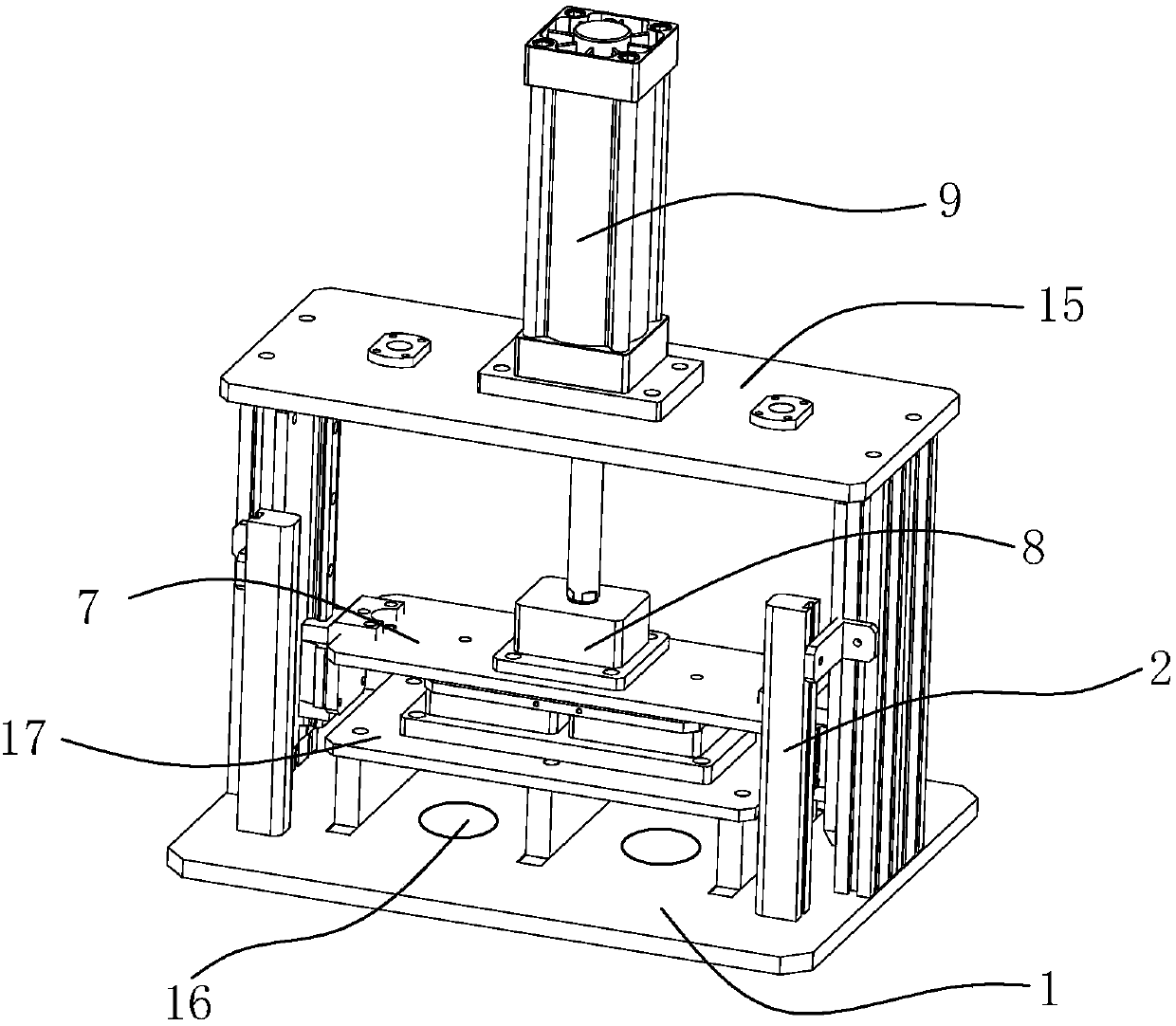

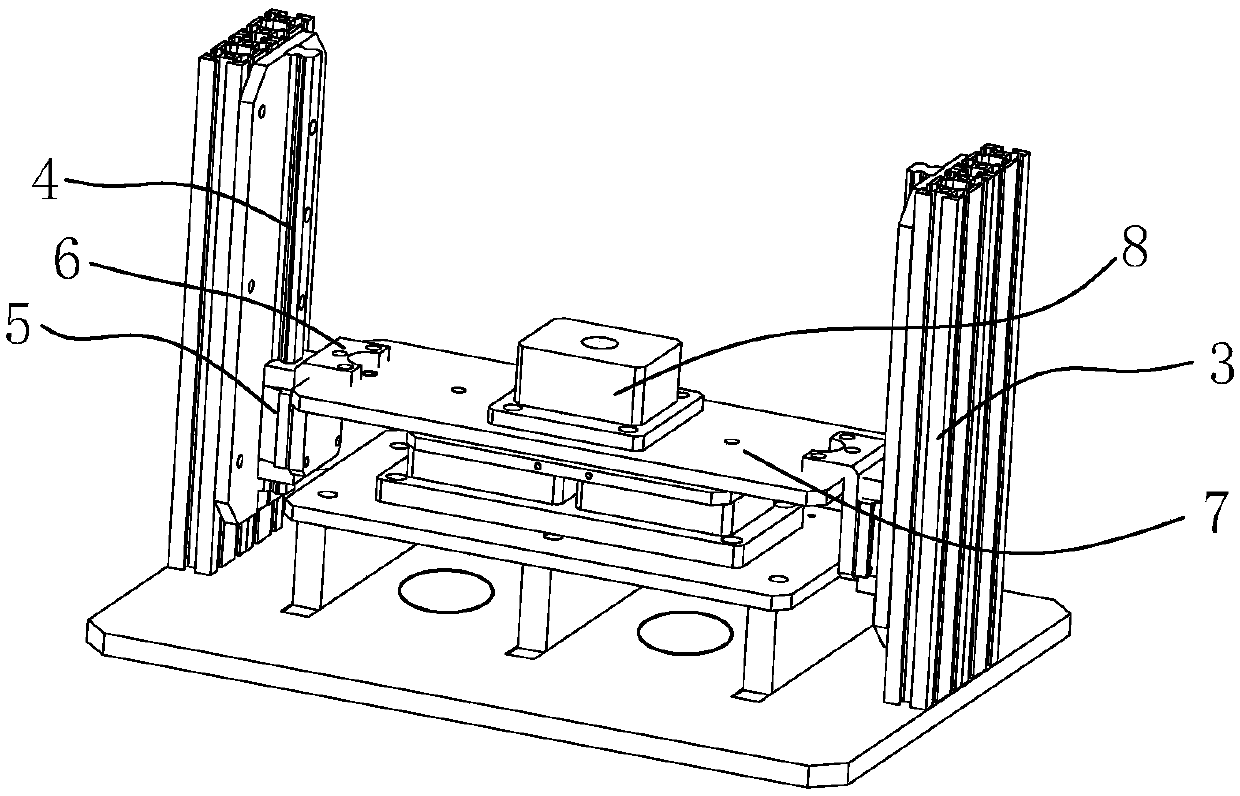

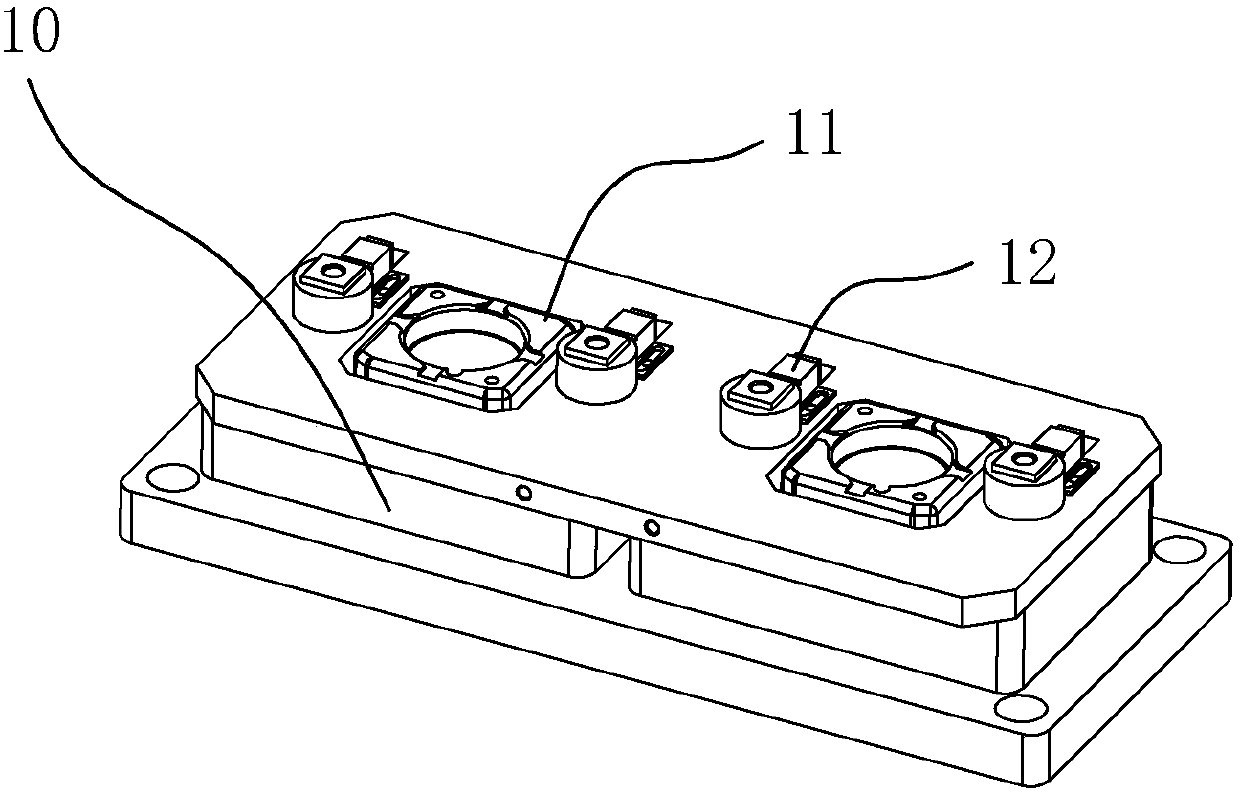

[0019] Embodiment: A cable head manufacturing device that adopts electronic control grating linkage, its main structure includes: base plate 1, grating 2, vertical arm rod 3, rail 4, slider 5, connector 6, pressure plate 7, solder cavity 8. Electric air rod 9, mold box 10, cable clamp 11, tin injection contact 12, tin outlet 13, cable harness ring 14, top cover plate 15, cable channel 16, platform plate 17, the The base plate 1 and the top cover plate 15 are fixed and supported by the vertical arm rod 3; the inner side of the vertical arm rod 3 is fixed with a rail 4, and a slider 5 is mounted on the rail 4, and the slider 5 and the pressure plate 7 pass through the connecting piece 6 Phase fixed;

[0020] The central position of the pressing plate 7 is provided with a solder chamber 8; the central position of the top cover plate 15 is provided with an electric air rod 9, and the end of the electric air rod 9 is fixed on the solder chamber 8; 7 is fixed with a tin-injected co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com