Composite phase change heat sink with micro-groove group

A composite phase transition and micro-groove technology, applied in electric solid devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of short lifespan, low heat dissipation efficiency, uneven heat dissipation, etc. Light, compact device, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

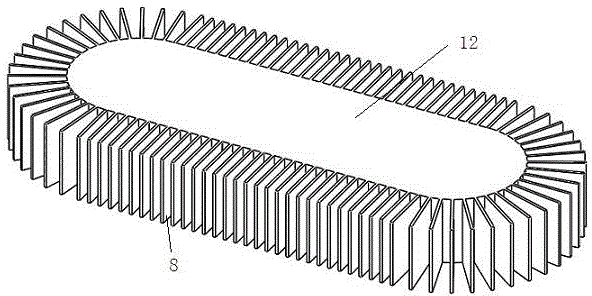

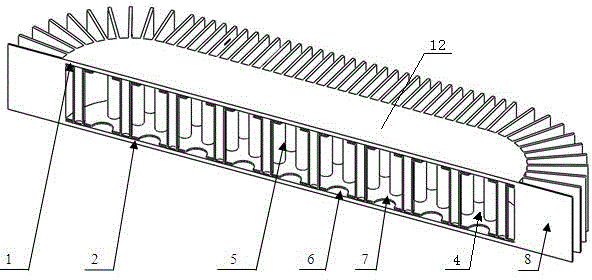

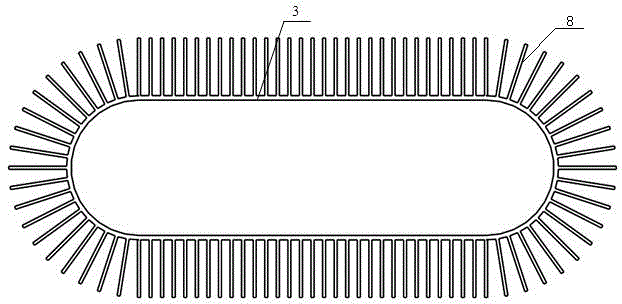

[0038] Such as Figure 1-Figure 8 As shown, the radiator of the present invention includes a radiating surface and a condensing surface oppositely arranged. The radiating surface 1 and the condensing surface 2 are connected by a side wall 3 to form a closed inner cavity 4 . In the inner cavity 4, a plurality of connecting and conveying pipelines 5 are set; on the heat dissipation surface 11 in the inner cavity, a micro-groove group structure composed of a plurality of micro-scale micro-grooves 6 is set for accommodating the heat-taking medium. In the inner cavity 4 , the voids between the delivery lines 5 are filled with porous core material. The end of the delivery pipeline 5 in contact with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com