Binchotan fiber fabric, preparation method and application

A technology of long-staple charcoal and long-staple cotton fibers, which is applied in the field of textiles, and can solve the problems of unreasonable design of tissue structure, poor silky feeling and drapability, etc., and achieve good air permeability and softness. , strong adsorption capacity, strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The technical parameters table of the prepared carbon fiber fabric of the present embodiment is shown in Table 1.

[0042] Table 1

[0043]

[0044]

[0045] The specific production process is as follows:

[0046] (1) The preparation of the warp beams, on the high-speed warping machine, the density of 26 pieces / CM is used to put the long carbon fiber blended warp yarns through the fixed-width reed, and then the evenly arranged warp beams are produced according to the method of split-twisting warping, for supply Use on the machine;

[0047] (2) Put the finished warp beam, adopt the warp yarn density of 130 reed / 10CM, wear 1 warp yarn for each heddle, wear 2 warp yarns for each reed tooth, carry out drafting and reeding, and put it on the 280cm high-speed rapier machine ;

[0048] (3) Adjust the weft density of the machine according to the weft yarn density of 315 / 10CM;

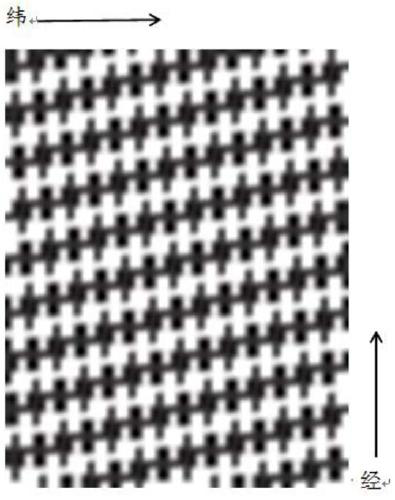

[0049](4) The jacquard program is designed to be heald-lifted by the electronic jacquard ma...

Embodiment 2

[0053] With embodiment 1, difference only is that long charcoal fiber is changed into bamboo fiber.

Embodiment 3

[0055] With embodiment 1, the only difference is that binchotan fiber is replaced by modal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com