Odorless anti-static carpet gum composition, gum, preparation method thereof and carpet

An anti-static carpet and composition technology, applied in the direction of carpets, rubber-derived adhesives, conductive adhesives, etc., can solve problems such as inconvenience in carpet preparation, and achieve enhanced conductive performance and antistatic performance, improved waterproof performance, and rubber surface. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

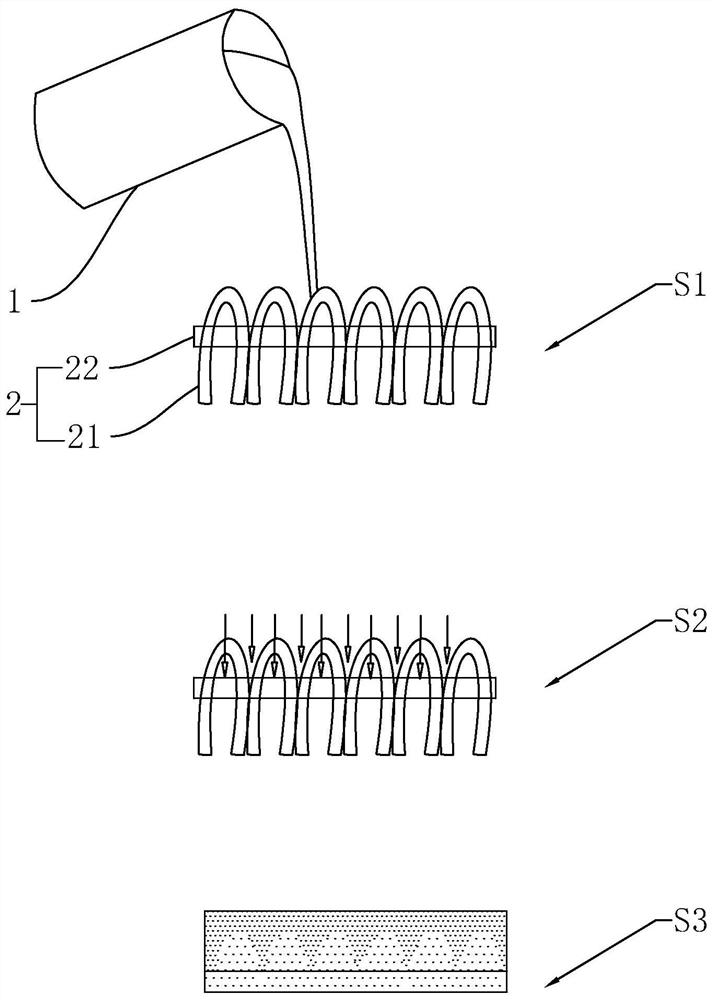

[0127] Yet another embodiment of the present invention discloses a method for preparing odor-free antistatic carpet back glue in the above scheme, comprising the following steps:

[0128] adding the raw materials of the auxiliary agent into water and mixing to obtain a fluid preform a;

[0129] Mix the raw materials of the latex part evenly to obtain the pre-product b, and control the pH value of the pre-product b at 8-10;

[0130] Grinding the conductive carbon black with a sand mill;

[0131] Mix preform a and preform b evenly to form preform c, add ground conductive carbon black and other raw materials of the functional additive part to preform c and mix evenly, and adjust the pH to 8-10.

[0132] Mix the raw materials of the latex part evenly to obtain the pre-product b step, add 1% emulsifier of the total weight of the latex part.

[0133] The preparation method of this embodiment is simple, and the adhesive force of the carpet back glue can be greatly improved by "glue...

Embodiment 1

[0162] The particle size of the conductive carbon black in Example 1 is 100 μm, and the particle size of the conductive carbon black in other examples is 20 μm.

[0163] The present invention has also done comparative example to carpet adhesive composition, and the weight parts of concrete component and component are shown in following table 2:

[0164] Concrete components and components by weight in Table 2 Comparative Examples 1-11

[0165]

[0166] The preparation method of the carpet back glue of embodiment 1-16 and comparative example 1-11, comprises the following steps:

[0167] adding the raw materials of the auxiliary agent into water and mixing to obtain a fluid preform a;

[0168] Mix the raw materials of the latex part evenly to obtain the pre-product b, and control the pH value of the pre-product b at 8-10;

[0169] Grinding the conductive carbon black with a sand mill;

[0170] Mix preform a and preform b evenly to form preform c, add ground conductive carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com