Preparation method of lanthanum oxide/lithium lanthanite-coated lithium-rich manganese-based anode material

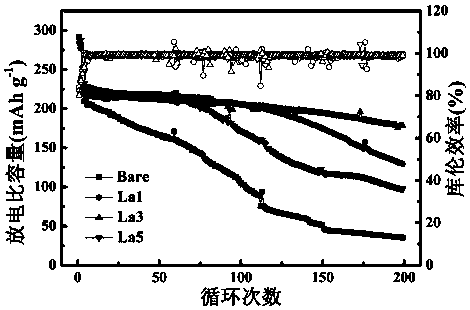

A lithium-rich manganese-based, cathode material technology, applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of poor cycle stability of lithium-rich manganese-based cathode materials, improve cycle stability, improve electrical conductivity, The effect of good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

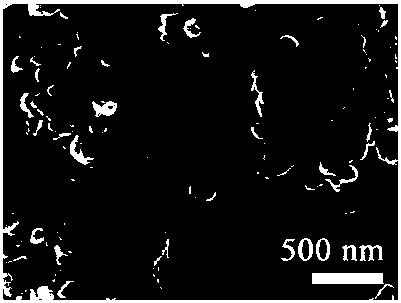

[0040] The preparation method of lanthanum oxide / lithium lanthanate coated lithium-rich manganese-based positive electrode material comprises the following steps:

[0041] (1) Preparation of lithium-rich manganese-based cathode materials

[0042] Weigh 0.0840mol lithium-rich manganese-based precursor Mn 4 / 6 Ni 1 / 6 co 1 / 6 CO 3 With 0.1302molLiOH. h 2 O was hand-milled and mixed (the amount of lithium was 5%), and the grinding time was 2h; then the above-mentioned raw materials were put into a crucible, placed in a muffle furnace, and heated to 500°C at a heating rate of 5°C / min in an air atmosphere Pre-sintering for 6h, then heating up to 900°C at a heating rate of 5°C / min and sintering for 10h, and then grinding for 1h after the furnace temperature was naturally cooled to room temperature to obtain a lithium-rich manganese-based positive electrode material 0.5Li 2 MnO 3 0.5Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 , with a particle size of about 10 μm.

[0043] (2) Preparatio...

Embodiment 2

[0048] The preparation method of lanthanum oxide / lithium lanthanate coated lithium-rich manganese-based positive electrode material comprises the following steps:

[0049] (1) Preparation of lithium-rich manganese-based cathode materials

[0050] Weigh 0.1680mol lithium-rich manganese-based precursor Mn 4 / 6 Ni 1 / 6 co 1 / 6 CO 3 with 0.1302molLi 2 CO 3 Carry out hand-grinding and mixing (the amount of excess lithium is 5%), and the grinding time is 3 hours; then put the above-mentioned raw materials into a crucible, put them in a muffle furnace, and in an air atmosphere, first raise the temperature to 500°C at a heating rate of 5°C / min for pre-treatment. Sinter for 6h, then heat up to 900°C for 10h at a heating rate of 5°C / min, and grind for 1.5h after the furnace temperature cools to room temperature to obtain a lithium-rich manganese-based positive electrode material 0.5Li 2 MnO 3 0.5Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 , and its particle size is about 10 μm.

[0051] (2)...

Embodiment 3

[0055] The preparation method of lanthanum oxide / lithium lanthanate coated lithium-rich manganese-based positive electrode material comprises the following steps:

[0056] (1) Preparation of lithium-rich manganese-based cathode materials

[0057] Weigh 0.0840mol lithium-rich manganese-based precursor Mn 4 / 6 Ni 1 / 6 co 1 / 6 CO 3 With 0.1302molLiOH. h 2 O was hand-milled and mixed (the amount of excess lithium was 5%), and the grinding time was 2h; then the above-mentioned raw materials were put into a crucible, placed in a muffle furnace, and the temperature was raised to 500°C at a heating rate of 5°C / min for 5h pre-sintering, and then Heat up to 900°C at a heating rate of 5°C / min and sinter for 10 hours, and then grind for 1 hour after the furnace temperature cools to room temperature to obtain a lithium-rich manganese-based positive electrode material 0.5Li 2 MnO 3 0.5Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 , and its particle size is about 10 μm.

[0058] (2) Preparation of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com