Preparation method of high-performance contact material

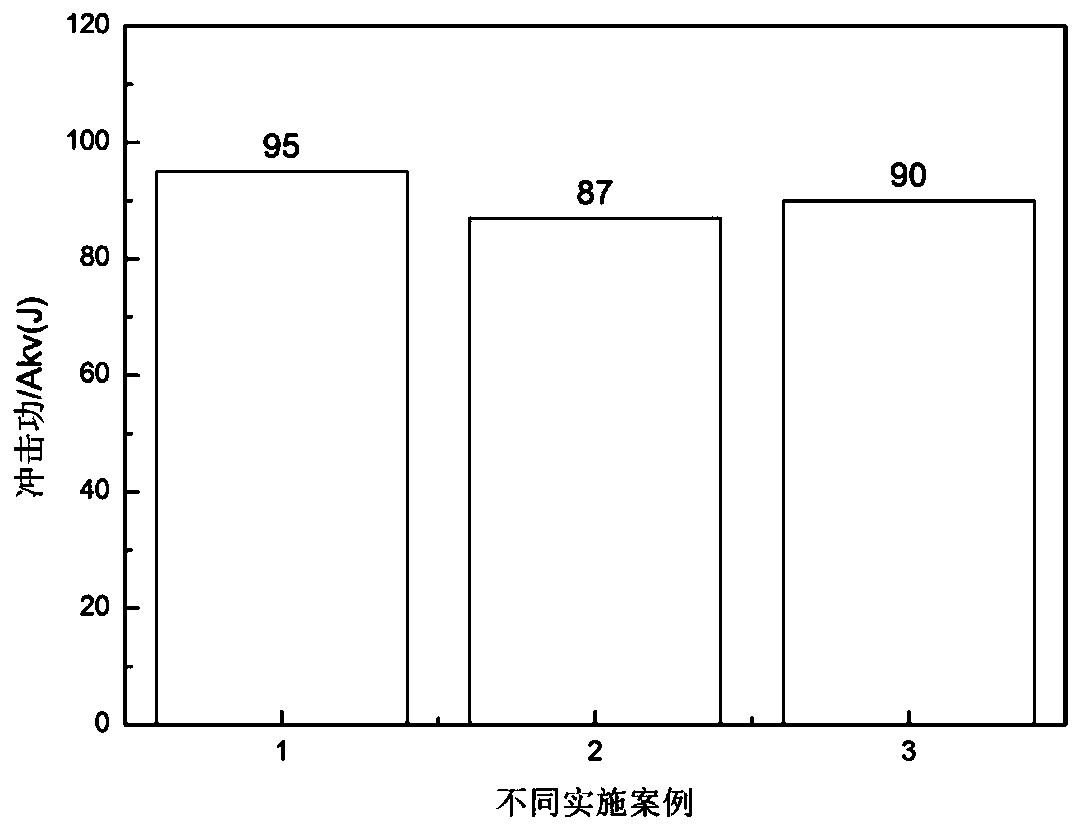

A contact material, high-performance technology, applied in the direction of improving energy efficiency, additive manufacturing, additive processing, etc., can solve the problems of short life, poor wear resistance, low strength of contact materials, etc., to achieve long service life, internal structure The effect of uniform density and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

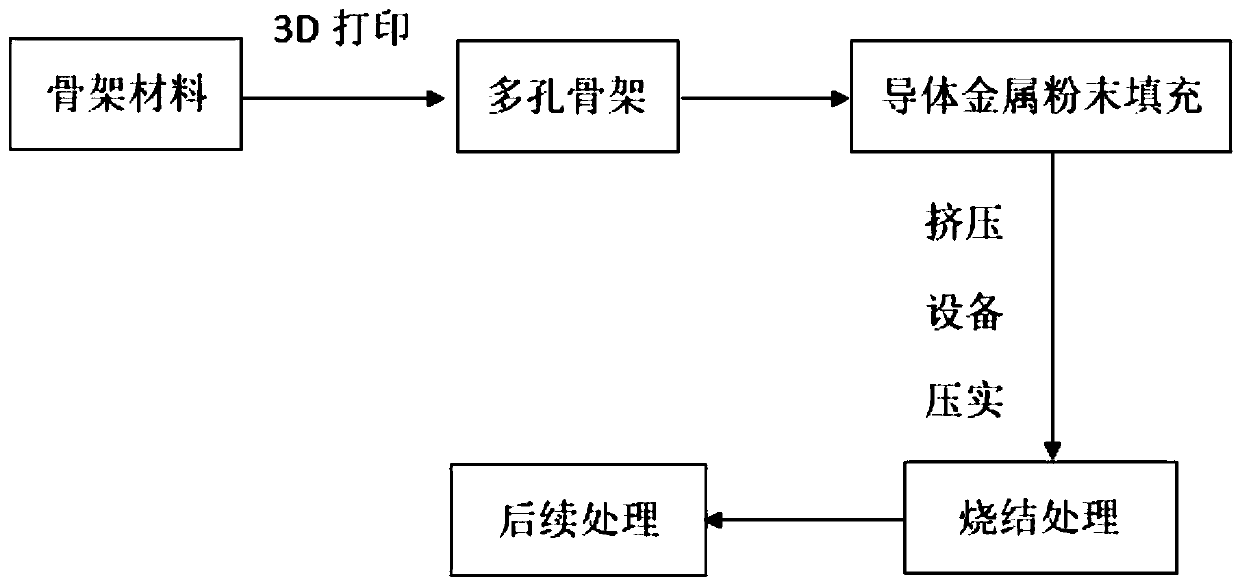

[0025] Such as figure 1 As shown, a preparation method of a high-performance contact material, the main structure of the high-performance contact material is a porous skeleton, comprising the following steps:

[0026] (1) Preparation of porous skeleton; the skeleton material is nickel alloy with high hardness and high strength, and the skeleton material is prepared into a porous skeleton by laser 3D printing technology; among them, the laser power P is 1500W, the scanning speed V is 100mm / min, and the spot The diameter D is 0.8mm, the focal length H is 180mm, and the protective airflow L is 4L / min; the hole shape of the porous skeleton is a regular square, and the thickness of the skeleton wall is 1.5mm; the height range is 5mm; the width range is 10mm;

[0027] (2) Conductive metal powder filling and compaction; the porous skeleton prepared in step (1) is filled with conductive metal powder, and the filled conductive metal powder is copper alloy powder, which is compacted by ...

Embodiment 2

[0033] Such as figure 1 As shown, a preparation method of a high-performance contact material, the main structure of the high-performance contact material is a porous skeleton, comprising the following steps:

[0034] (1) Preparation of porous skeleton; the skeleton material is made of titanium alloy with high hardness and high strength, and the skeleton material is prepared into a porous skeleton by laser 3D printing technology; among them, the laser power P is 2000W, the scanning speed V is 500mm / min, and the spot The diameter D is 3mm, the focal length H is 220mm, and the protective air flow L is 15L / min; the hole shape of the porous skeleton is a regular arc shape, and the thickness of the skeleton wall is 8mm; the height range is 100mm; the width range is 500mm;

[0035] (2) Conductive metal powder filling and compaction; the porous skeleton prepared in step (1) is filled with conductive metal powder, and the filled conductive metal powder is copper alloy powder, which is...

Embodiment 3

[0040] Such as figure 1 As shown, a preparation method of a high-performance contact material, the main structure of the high-performance contact material is a porous skeleton, comprising the following steps:

[0041] (1) Preparation of porous skeleton; the skeleton material is made of tungsten-titanium with high hardness and high strength, and the skeleton material is prepared into a porous skeleton by laser 3D printing technology; wherein, the laser power P is 3000W, and the scanning speed V is 100mm / min. The spot diameter D is 0.5mm, the focal length H is 190mm, and the protective airflow L is 5L / min; the hole shape of the porous skeleton is irregular, and the thickness of the skeleton wall is 7mm; the height range is 50mm; the width range is 100mm;

[0042] (2) Conductive metal powder filling and compaction; the porous skeleton prepared in step (1) is filled with conductive metal powder, and the filled conductive metal powder is copper alloy powder, which is compacted by e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com