Patents

Literature

32results about How to "Improve medium and high temperature strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

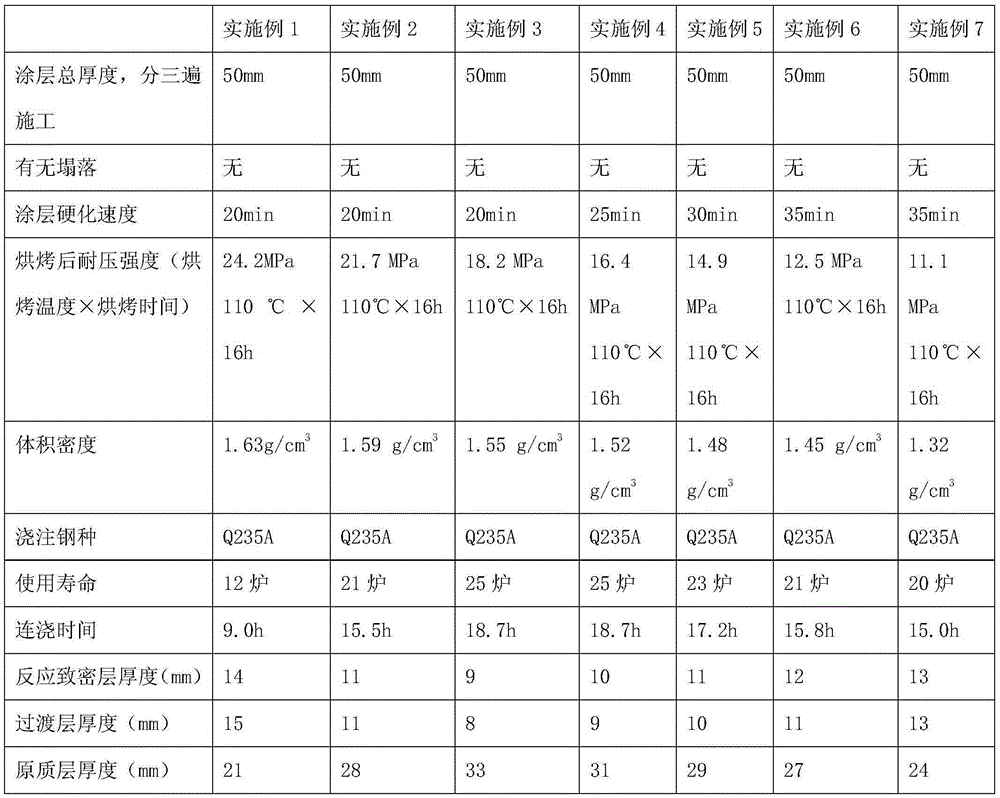

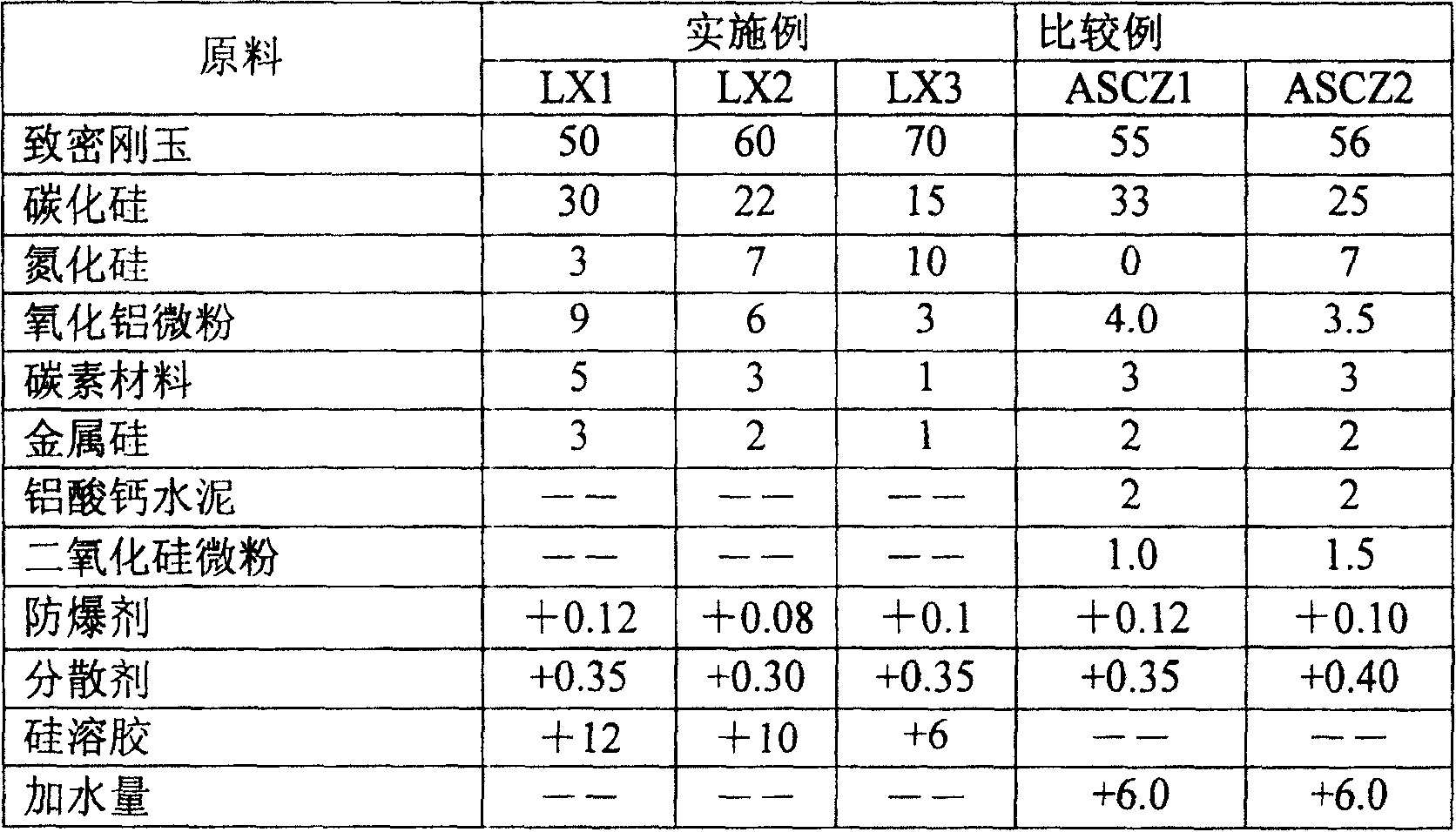

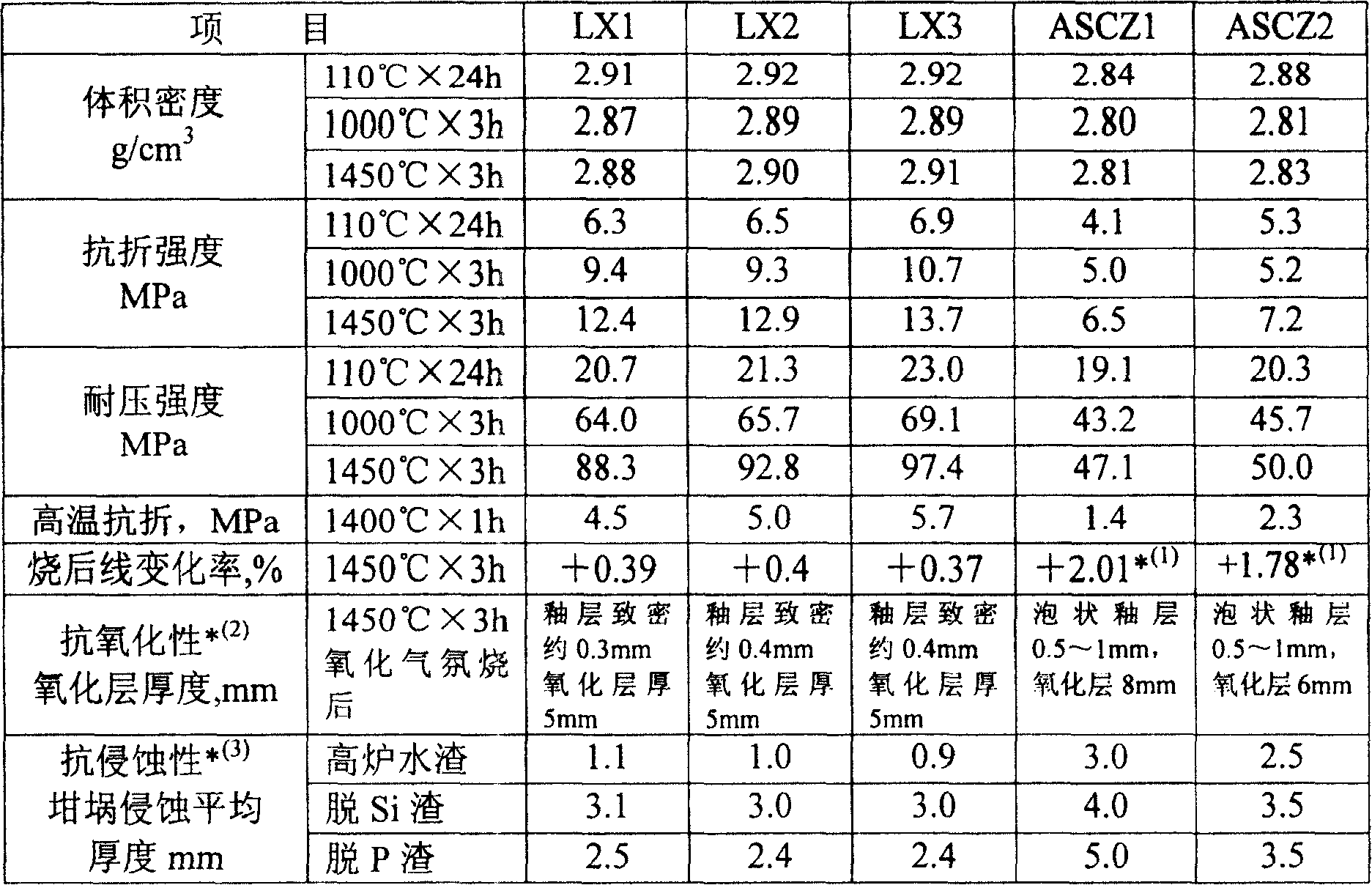

Non-oxide composite refractory materials for molten iron chute

The invention relates to a technology for preparation of refractory material, and especially to a composite refractory of non-oxidized substance used in a hot-metal launder of consecutive pre-processing. The composite refractory of non-oxidized substance used in a hot-metal launder is characterized in that it contains (wt %) 50-70 % of corundum material, 15-30 % of silicon carbide, 3-10 % of silicon nitride, 3-10 % of silicon nitride tiny powder, 1-5 % of charcoal material, 1-3 % of silicon anti-oxidization agent, 6-15 % of additional silicasol astringent, and a few additives containing anti-knock agent and dispersing agent with 0.15-1.5 % by wt. The refractory material of the said invention can resist the erosion of the hot-metal and the molten ash and is of strong erosion ability, uniform and high-integrity structure, high intensity at a medium-high-temperature, strong stability of resistance to heat shocks and of volume of material, and strong resistance to oxidation, so it adapts to the process requirement of the desired hot-metal launder of consecutive pre-processing.

Owner:BAOSHAN IRON & STEEL CO LTD

Poured material for foundry ladle bottom and its pouring process and mold

The present invention is poured material for foundry ladle bottom and its pouring process and mold. The poured material consists of high grade alumina clinker, white alundum, fine alumina powder, magnesite sand clinker and fine silica powder. The pouring process includes the following steps: cleaning and mounting mold, smearing grease, mixing the material in a stirrer, pouring, curing and demolding. The present invention has even poured thickness, compact structure, high strength at high temperature and high heat shock stability.

Owner:CHEMIAL PLANT GANGCHENG ENTERPRISE GENERAL PANZHIHUA IRON & STEEL GROUP

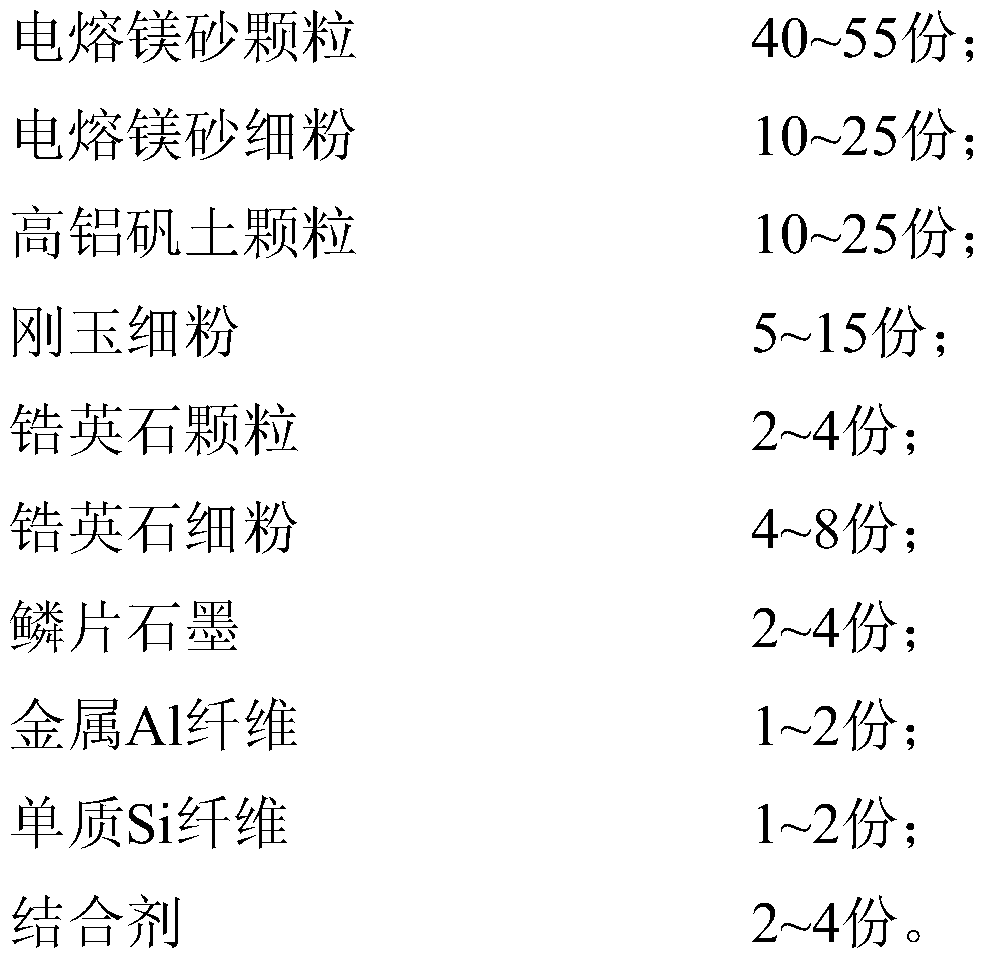

Low carbon magnesia-alumina-carbon brick combining ceramics at high temperature and preparation method thereof

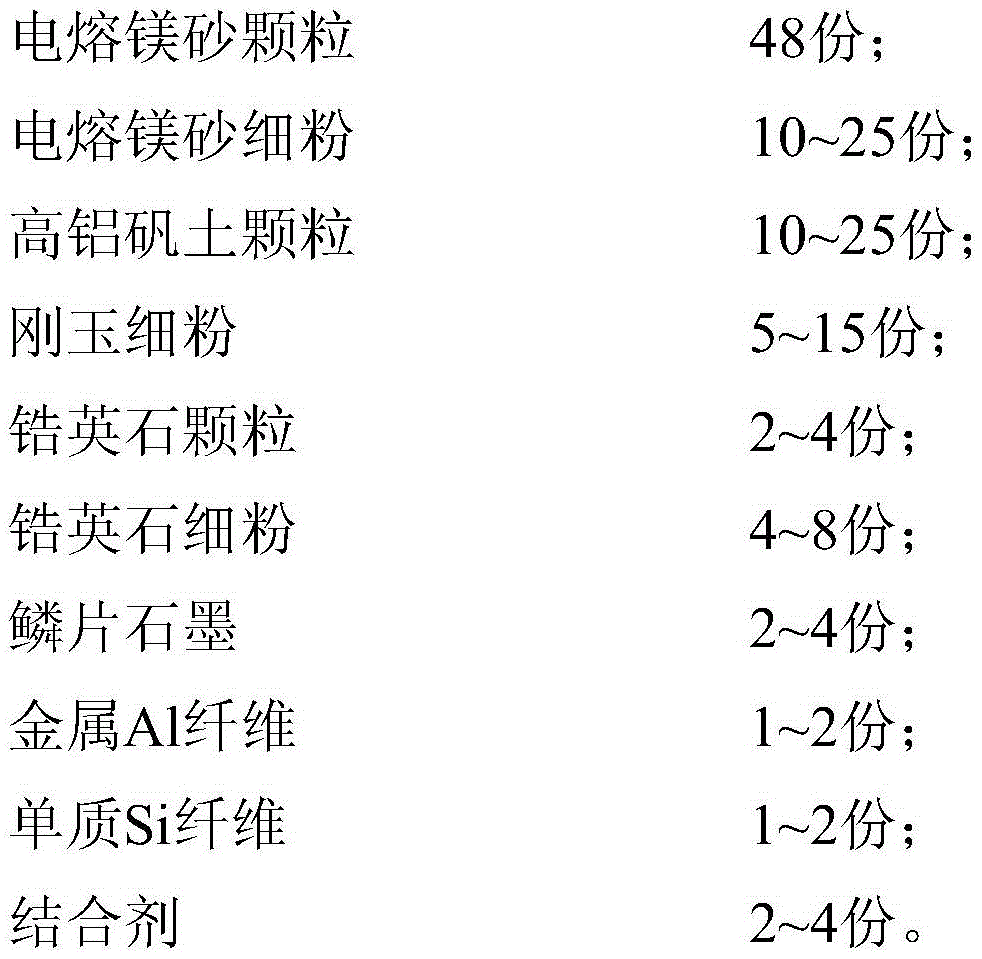

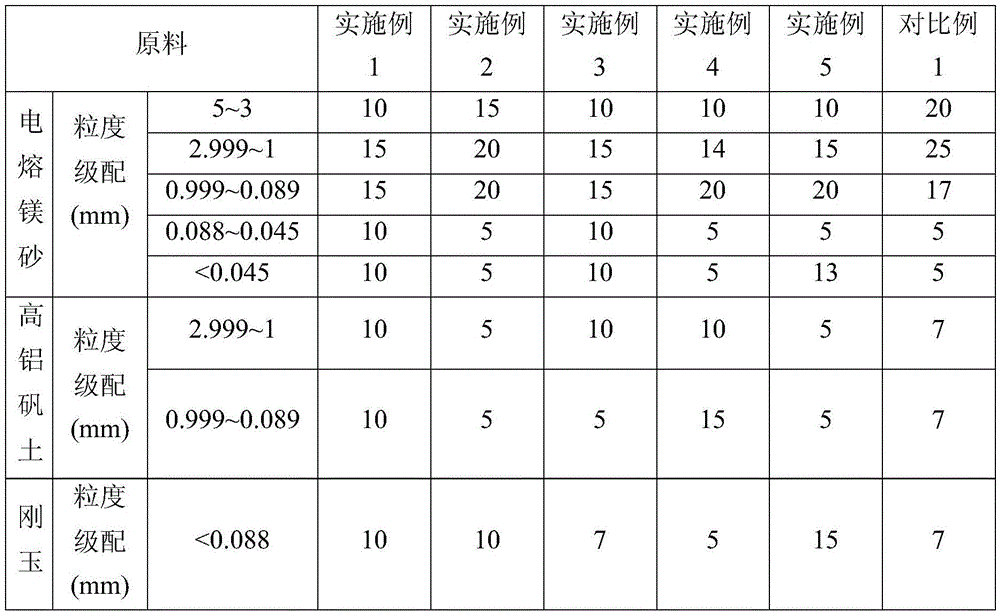

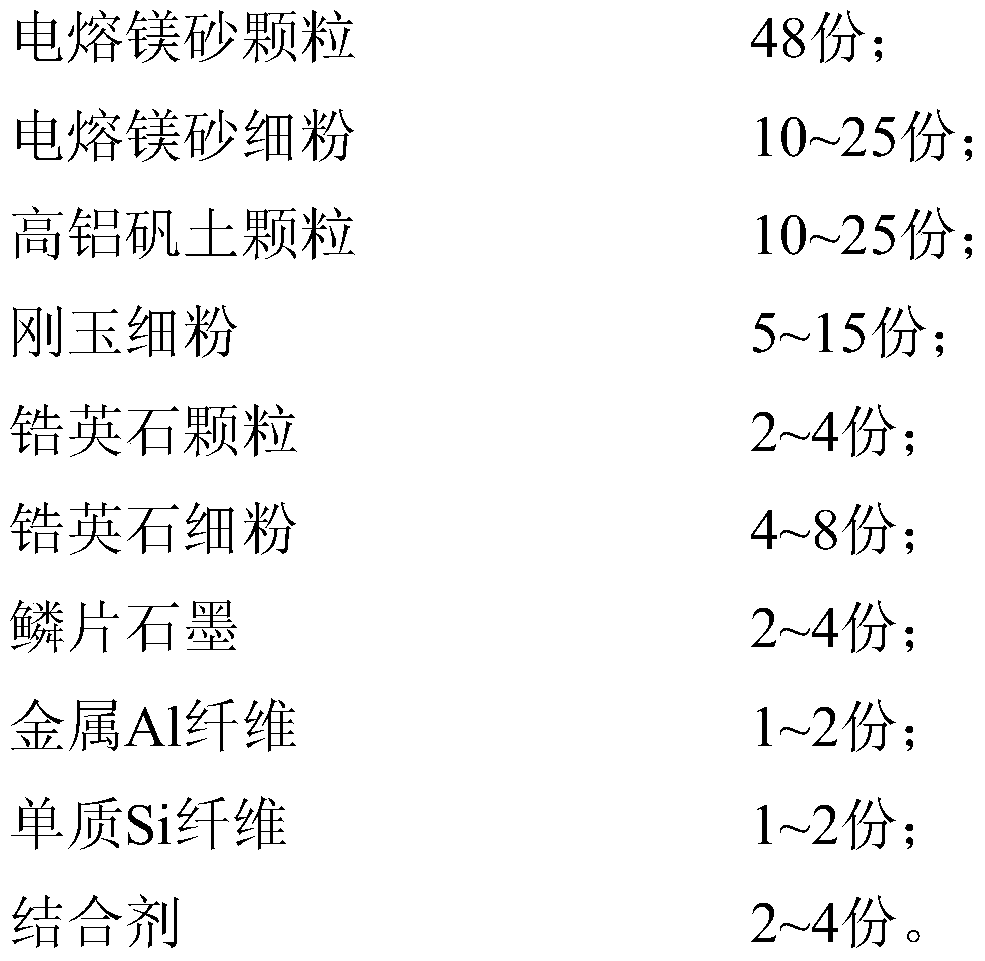

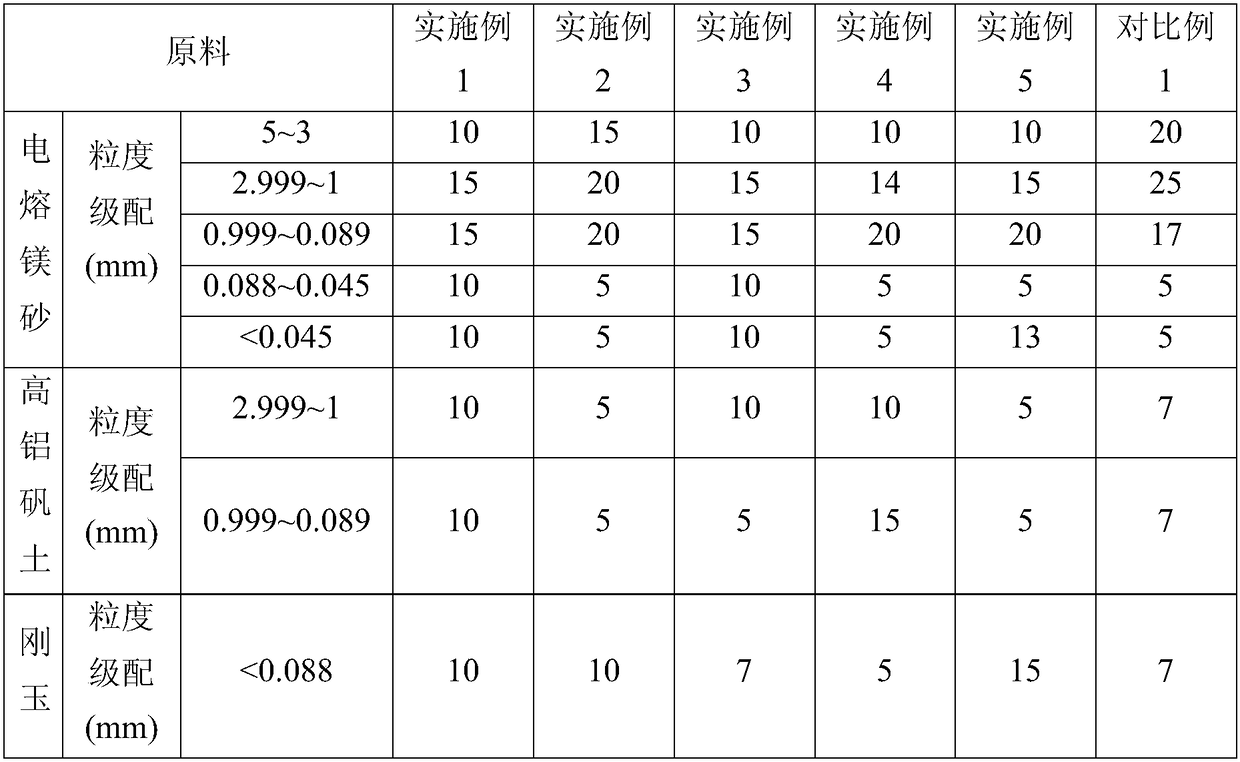

The invention discloses a low carbon magnesia-alumina-carbon brick combining ceramics at a high temperature and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing raw materials in the low-carbon magnesia-alumina-carbon brick, pressing to form a green body, and then baking the green body for 6 to 12 hours at 150 to 220 DEG C. The low carbon magnesia-alumina-carbon brick is prepared from the following raw materials in parts by weight: 40 to 50 parts of fused magnesite particles, 10 to 25 parts of fused magnesite fine powder, 10 to 25 parts of high-alumina bauxite particles, 5 to 15 parts of corundum fine powder, 2 to 4 parts of zirconite particles, 4 to 8 parts of zirconite fine powder, 2 to 4 parts of crystalline flake graphite, 1 to 2 parts of metal Al fibers, 1 to 2 parts of elementary substance Si fibers and 2 to 4 parts of binding agents. Compared with the traditional carbon-combined low carbon magnesia-alumina-carbon brick, the low carbon magnesia-alumina-carbon brick is excellent in medium-high-temperature strength, thermal shock resistance and oxidation resistance.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

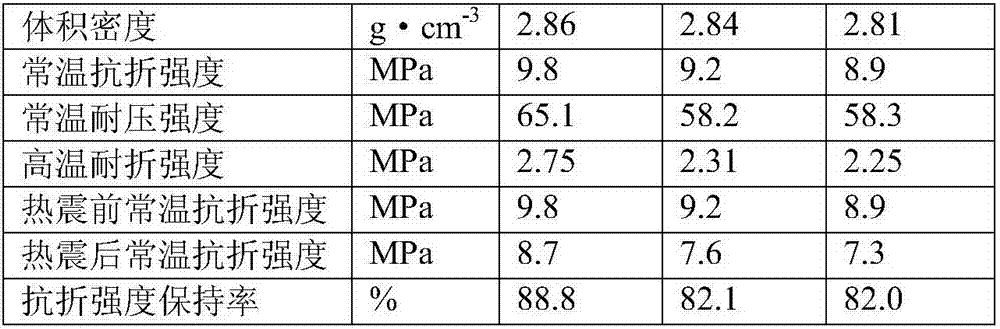

Light tundish working lining and method for preparing same

ActiveCN108530090AImprove corrosion resistanceObvious volume shrinkage (≤-4.0%) phenomenonCeramic materials productionClaywaresFiberBrick

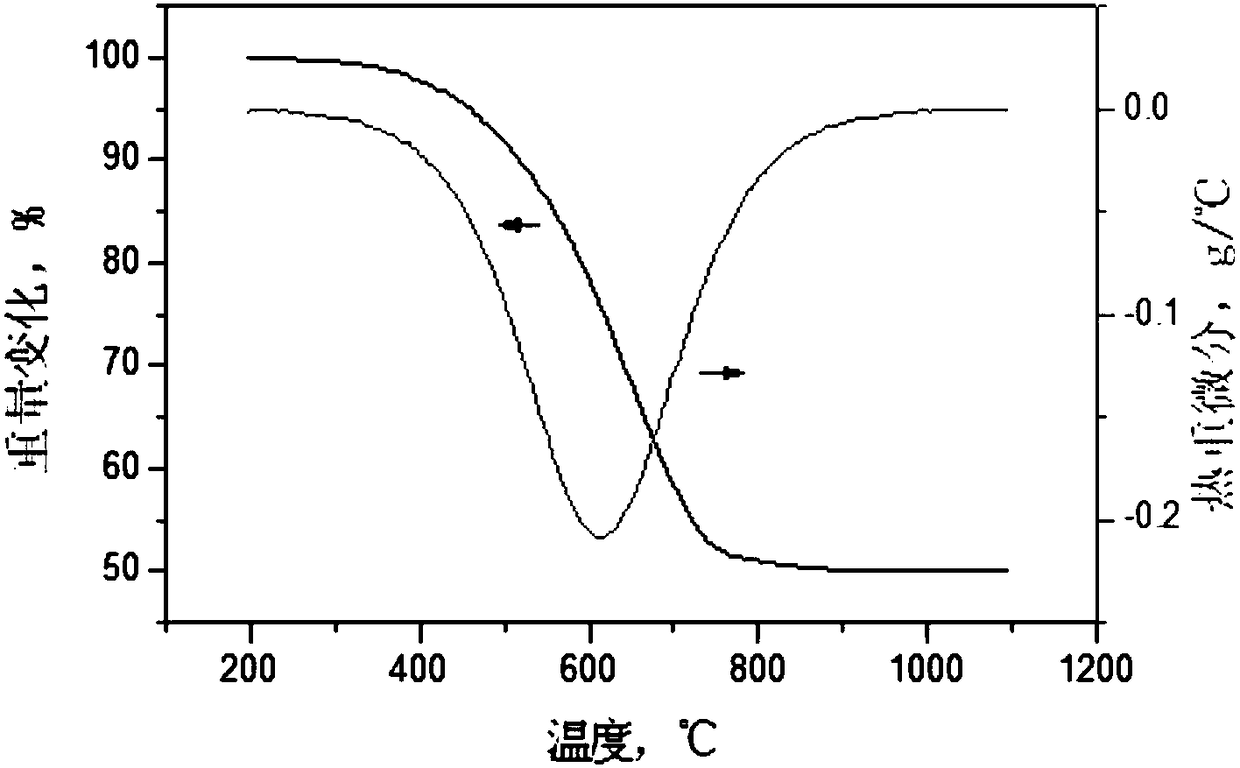

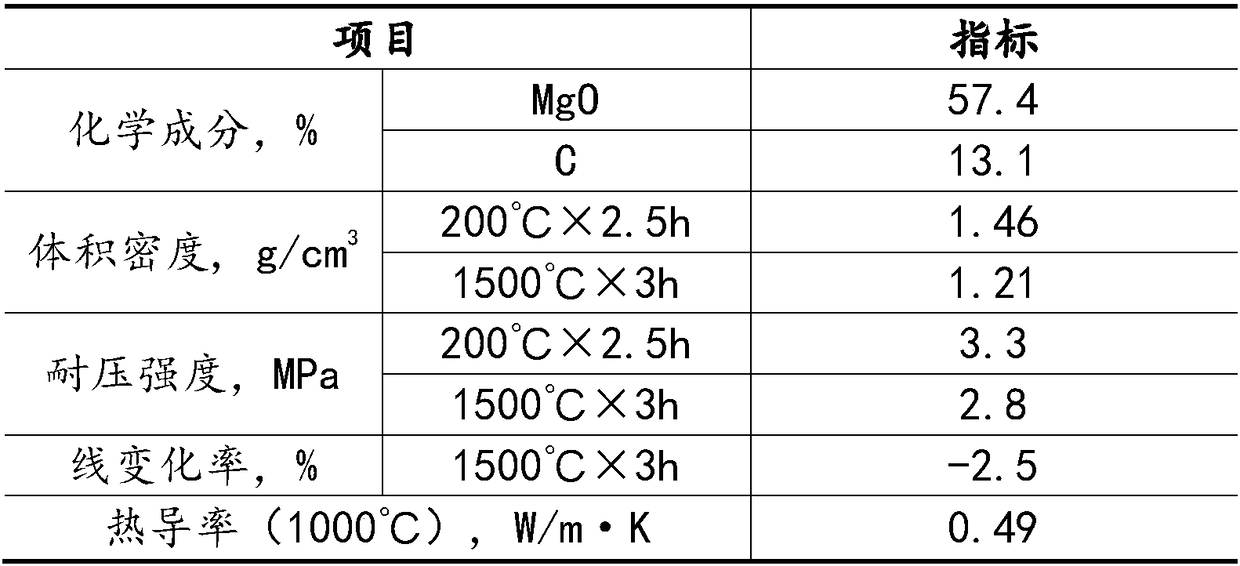

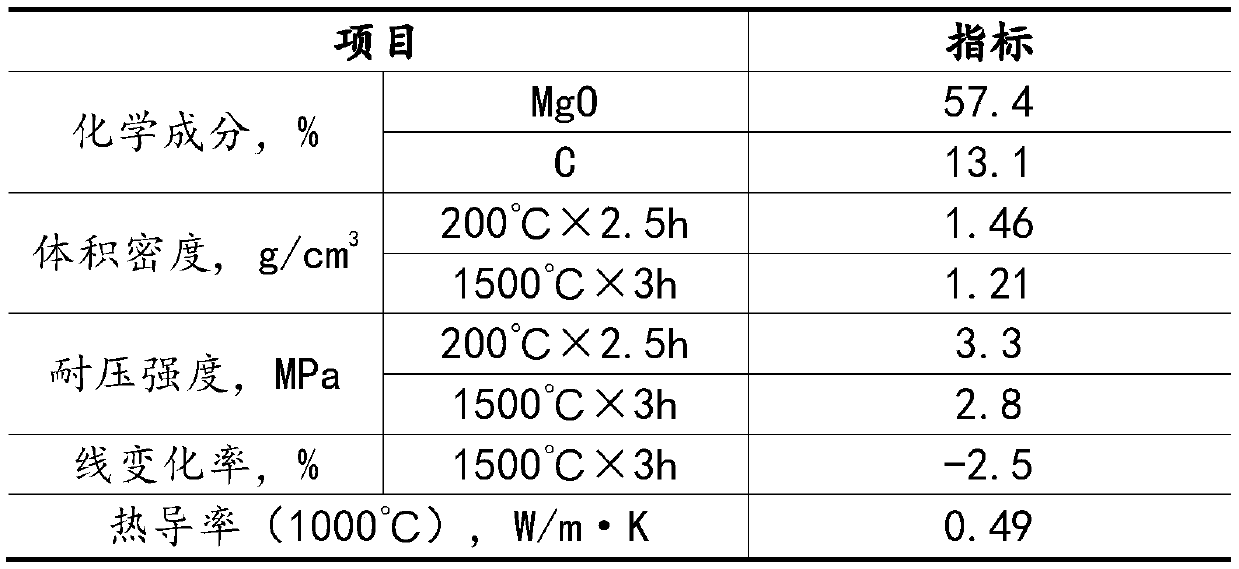

The invention discloses a light tundish working lining and a method for preparing the same. Ingredients for the light tundish working lining comprise waste magnesia-carbon bricks, magnesite tailing, aluminum oxide, fibers, compound bonding agents and additives. The method for preparing the light tundish working lining includes dry vibration forming or wet smearing forming. The light tundish working lining and the method have the advantages that the light tundish working lining prepared by the aid of the method is low in volume density, erosion rate, cost and consumption and long in service life, energy can be saved, and the like. Besides, the problem of excessive consumption of resources of existing refractory raw materials (including waste magnesia-carbon brick reclaimed materials and thelike), the problems in the aspects of energy conservation and heat preservation and the like can be solved by the aid of the light tundish working lining and the method.

Owner:PUYANG REFRACTORIES GRP CO LTD

Iron runner casting material for blast furnace for smelting vanadium titanium ore and preparation method thereof

The invention relates to an iron runner casting material for a blast furnace for smelting a vanadium titanium ore and a preparation method thereof. The method comprises the following steps of: firstly placing 1-4wt% of silicon dioxide micro-powder, 3-6wt% of active aluminum oxide micro-powder and 2-5wt% of silicon micro-powder in a conical stirring machine, externally adding metal aluminum powder accounting for 0.04-0.06wt% of raw materials and polycarboxylic acid type water reducer accounting for 0.3-0.5wt% of the raw materials, and stirring for 20-30min to prepare a premix; further stirring the premix, 10-150wt% of silicon carbide with the particle size of 0.088-1mm, 10-150wt% of silicon carbide with the particle size of not more than 0.088mm, 3-6wt% of CA-70 cement, 2-5wt% of ball asphalt and 50-70wt% of fused brown corundum particles by using a planetary stirring machine for 8-12min; and further preparing the iron runner casting material for the blast furnace for smelting the vanadium titanium ore. The graduation of the fused brown corundum particles is as follows: 8-5mm: 15-25wt%; 5-3mm: 15-20wt%; and 3-1mm: 20-25wt%. The iron runner casting material disclosed by the invention has the advantages of good scouring resistance, oxidation resistance, erosion resistance and thermal shock resistance, no slag adhesion, long service life and high one-time iron capacity.

Owner:WUHAN WINNING TECH

Thermal-state repair spray coating and preparation method thereof

The invention belongs to the technical field of spray coating, and particularly relates to thermal-state repair spray coating for quickly repairing a working lining in a thermal state and a preparation method of the thermal-state repair spray coating. The thermal-state repair spray coating is prepared from the following components in percentage by weight: 70-76% of brown aluminium oxide, 4.5-5.5%of Guangxi white mud, 4.5-5.5% of pure calcium aluminate 70 cement, 1.5-2.5% of boric acid, 4.5-5.5% of silicon metal, 1.5-2.5% of aluminum metal and 7-9% of silicon carbide. According to the thermal-state repair spray coating, in the thermal state, the conditions of severe local erosion, peeling or local damage occurring in the use process of the working lining are quickly repaired, a prepared finished product is good in bonding, high in strength and long in service life.

Owner:河南恒耐尔耐火材料有限公司

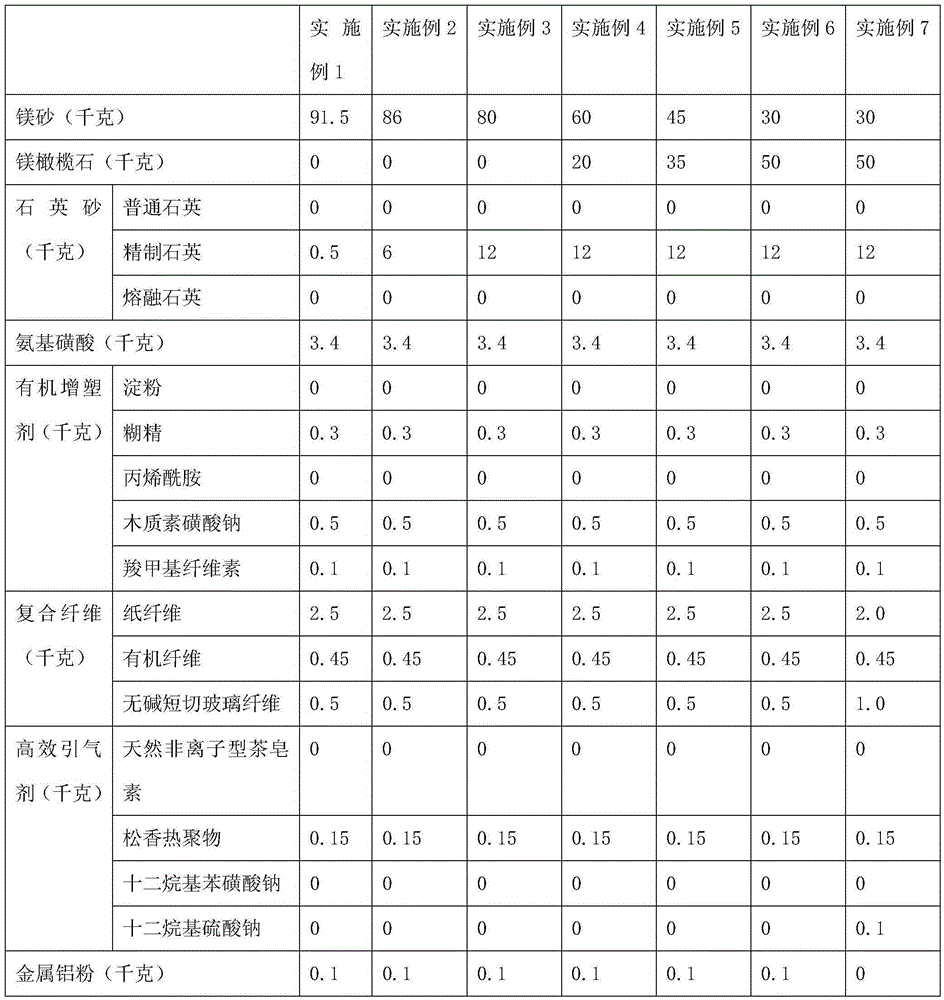

Anti-permeation type tundish light coating and preparation method thereof

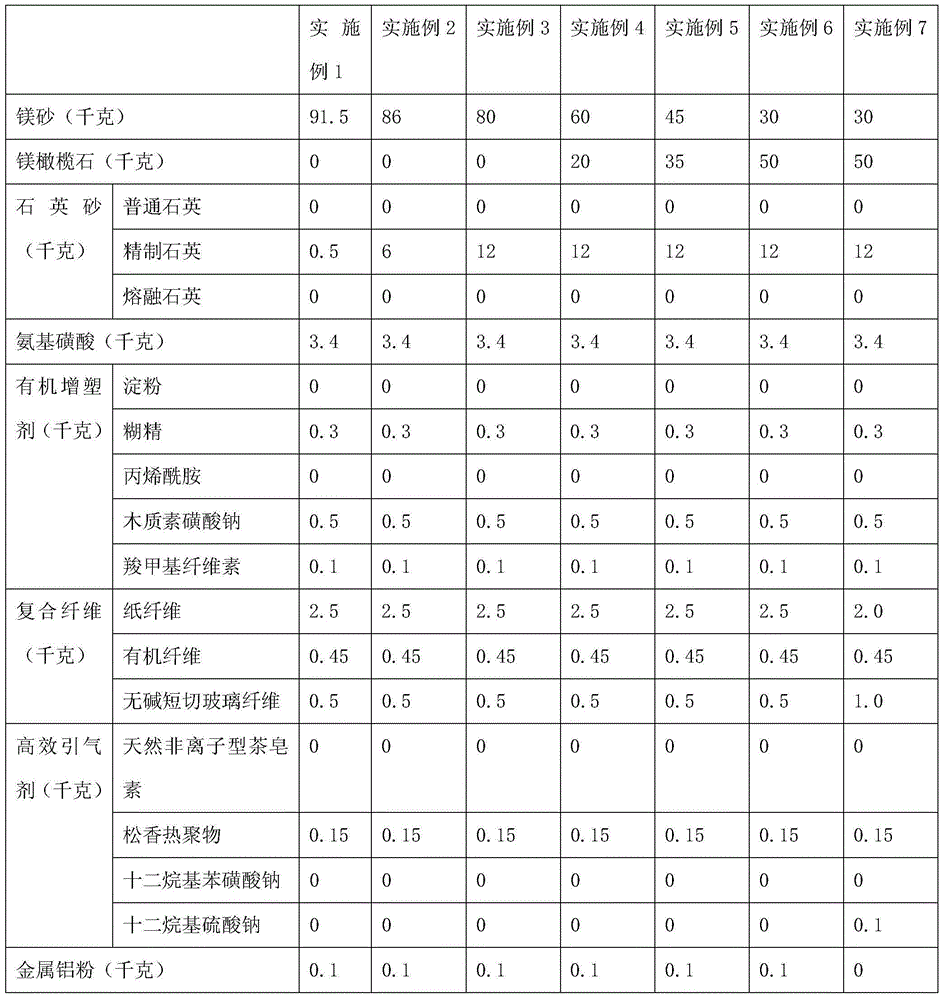

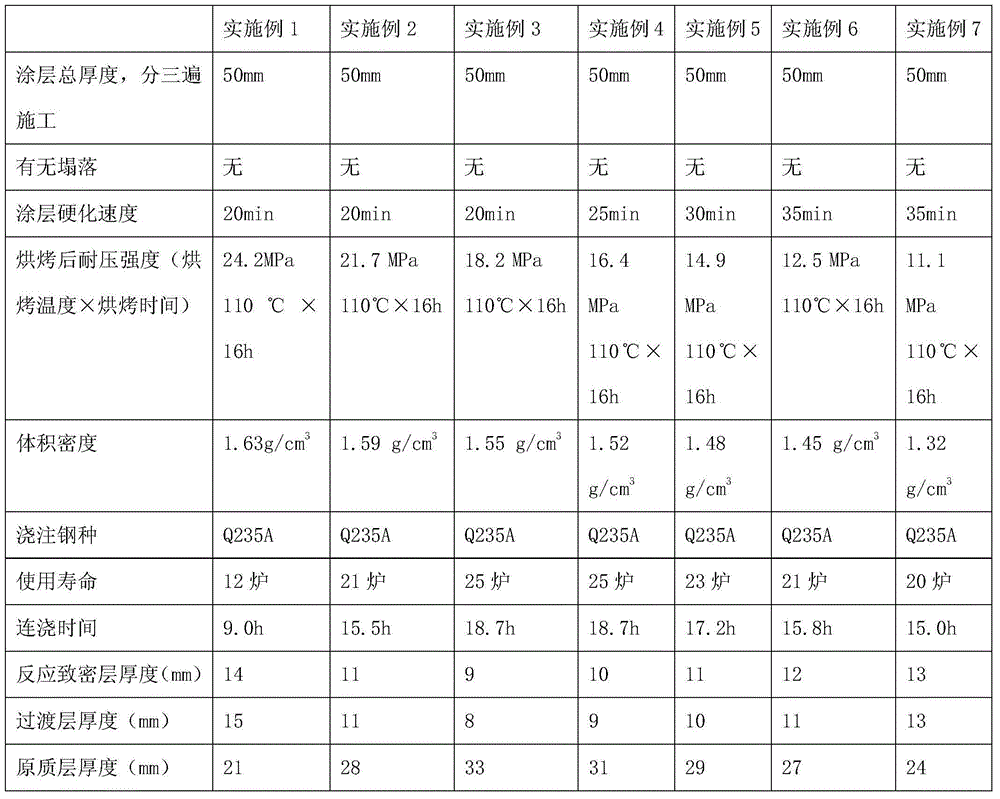

The invention discloses an anti-permeation type tundish light coating and a preparation method thereof. The anti-permeation type tundish light coating comprises the following components in parts by weight: 73-99 parts of magnesite and / or forsterite with the granularity less than or equal to 1mm, 0.1-15 parts of quartz sand, 0.2-4 parts of sulfamic acid, 0.1-3.0 parts of an organic plasticizer agent, 0.5-5 parts of composite fiber, 0.02-0.25 part of high-efficiency air entraining agent and 0.01-0.15 part of metal aluminum powder. The coating disclosed by the invention is small in volume density, high in pressure resisting intensity after being baked, small in low melt and capable of effectively preventing slag permeation and solving the problems of a conventional light coating in construction, baking and use.

Owner:PUYANG REFRACTORIES GRP CO LTD

Environment-friendly magnesian dry material and preparation process thereof

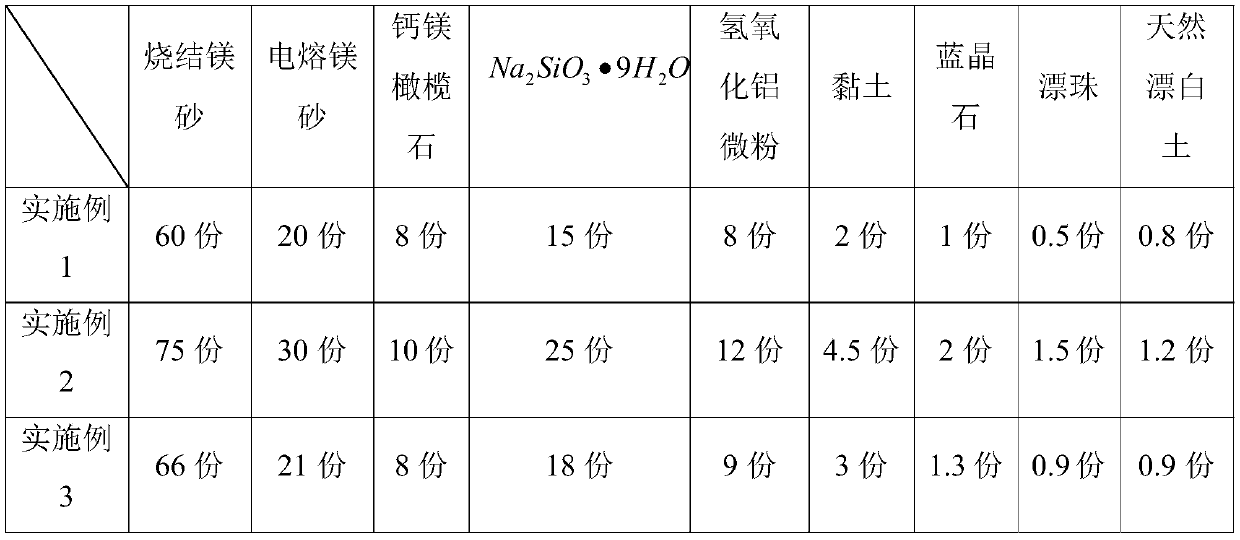

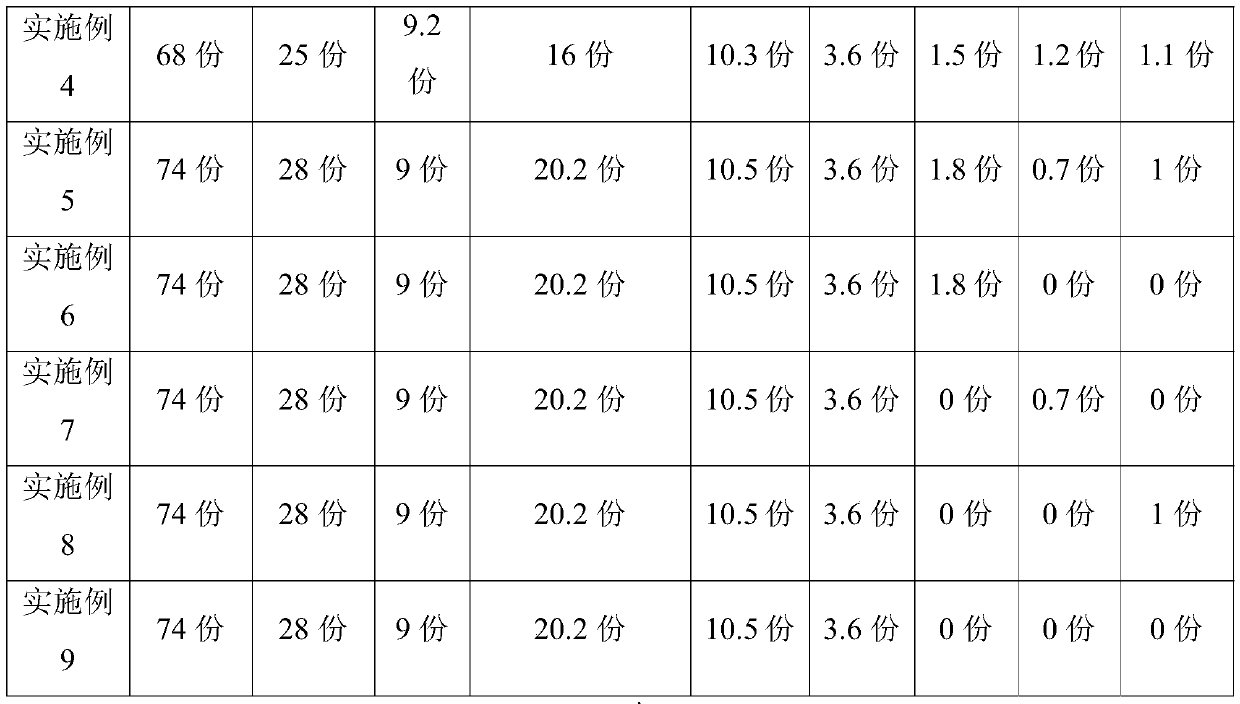

An environment-friendly magnesian dry material comprises sintered magnesia, fused magnesia, calcium forsterite, a binding agent, aluminum hydroxide micro powder, a high-temperature sintering agent, anexpanding agent, floating beads and bentonite in a mass ratio of (60-75): (20-30): (8-10): (15-25): (8-12): (2-4.5): (1-2): (0.5-1.5): (0.8-1.2). According to the invention, the proportion of each component of the dry material is optimized; by adopting the environment-friendly binding agent, the problem that the binding agent is decomposed into toxic and harmful substances under a high-temperature condition can be effectively solved, the dry material is more energy-saving and environment-friendly, the hardness requirement of the dry material in the using process can be ensured on the premisethat the dry material has no pungent smell in the using process and is more beneficial to the production environment, and the scouring resistance of the dry material is ensured.

Owner:浙江欣辉耐火材料股份有限公司

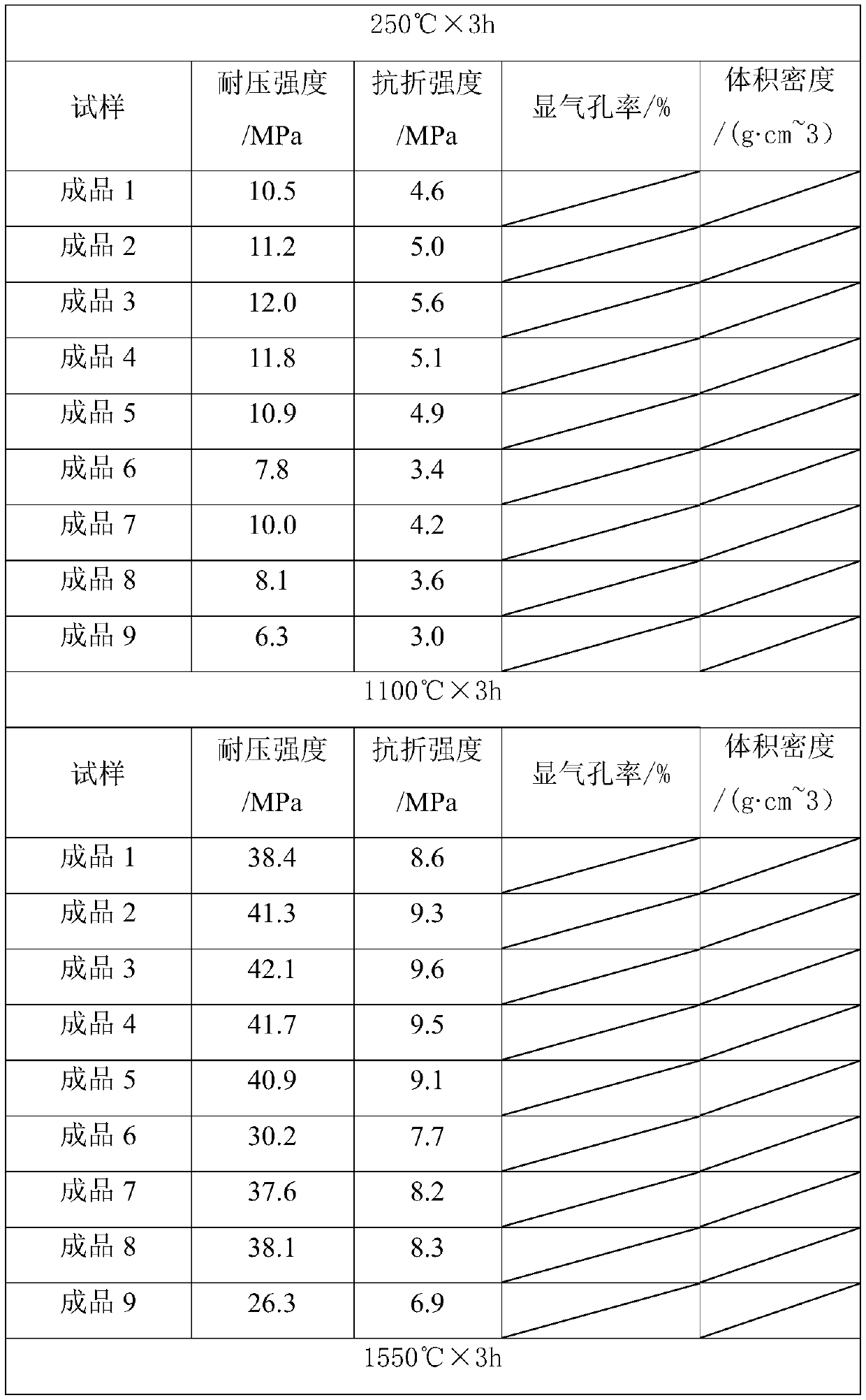

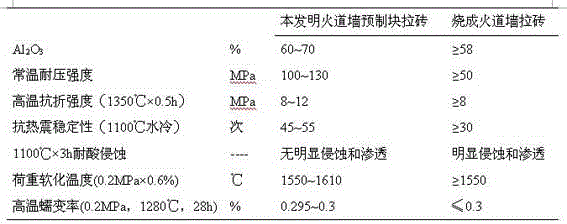

Carbon roaster flue wall guy brick precast block and production method thereof

The invention discloses a carbon roaster flue wall guy brick precast block and a production method thereof. The carbon roaster flue wall guy brick precast block is produced by subjecting a mixture and an additive to mixing, stirring with water, molding by casting, curing and roasting, wherein the mixture comprises, by weight, 60-80% of bauxite chamotte, 5-20% of silicon carbide, 3-10% of silica fume, 3-10% of alumina powder, 3-10% of fine kyanite powder, 3-10% of pure calcium aluminate cement and 3-10% of metallic silicon, and the mass ratio of the mixture to the additive is 100 to 0.2-2. The production method includes mixing the mixture with the additive with the water added, pouring a mixed material into a mould and casting for vibration molding; roasting for 24-48 hours at 110-300 DEG C after natural curing so as to obtain a finished product. The carbon roaster flue wall guy brick precast block is low in production cost and simple in technology, properties such as the high-temperature creep rate and refractoriness under load can reach the levels of fired guy bricks, and the strength, the thermal-shock-resistant stability and sulfide corrodibility are superior to those of the fired guy bricks.

Owner:河南鑫诚耐火材料股份有限公司

Application of spherical alumina micro-powder in refractory castable

The invention discloses application of spherical alumina micro-powder in a refractory castable, belonging to the technical field of refractory castables. The refractory castable is prepared from the following components in parts by weight: 64-70 parts of refractory aggregate, 18 parts of a cementing material, 0-7 parts of aluminum oxide micro-powder, 0-7 parts of spherical alumina micro-powder, 6parts of cement, 2 parts of kyanite, 0.03 part of citric acid, 0.05 part of 3p and 0.25 part of explosion-proof fibers, wherein the spherical alumina micro-powder contains aluminum oxide, silicon dioxide, ferric oxide and sodium oxide as main components; the content of the aluminum oxide is more than or equal to 99.5%; the content of the silicon dioxide is less than or equal to 1200 ppm; the content of the ferric oxide is less than or equal to 800 ppm; and the content of the sodium oxide is less than or equal to 3500 ppm. The problems that a conventional refractory castable is poor in high-temperature use performance, short in service life, poor in compactness and bad in flowability are solved in the invention.

Owner:天津泽希矿产加工有限公司

In-situ generated CM2A8 multiphase reinforced steel ladle casting material and preparation method thereof

The invention relates to an in-situ generated CM2A8 multiphase reinforced steel ladle casting material and a preparation method thereof. The technical scheme comprises that the composition and content of the steel ladle casting material comprise that 65-80 wt% of modified corundum particles is used as an aggregate, 6-10 wt% of a white corundum powder, 2-6 wt% of a magnesia fine powder, 6-8 wt% of an active alpha-Al2O3 micro-powder, 5-8 wt% of calcium aluminate cement and 0.5-3 wt% of a magnesium aluminate spinel fiber are used as a matrix material, and 0.05-0.06 wt% of organic fibers, 0.1-0.3 wt% of a water reducer, 0.02-0.04 wt% of an aluminum silicon alloy powder and 0.1-1 wt% of a rare earth oxide are added according to the sum of the amounts of the aggregate and the matrix material. The preparation method comprises the steps: firstly, dry-mixing the matrix material with the water reducer, the aluminum silicon alloy powder and the rare earth oxide, then adding the aggregate and the organic fibers, dry-mixing, finally, adding water, stirring, pouring and molding, drying, demoulding, and thus obtaining the in-situ generated CM2A8 multiphase reinforced steel ladle casting material. The prepared product has the characteristics of high medium-high temperature strength, good thermal shock stability and excellent slag resistance.

Owner:WUHAN UNIV OF SCI & TECH

Aluminum silicon refractory

InactiveCN107573082AImprove toughnessImprove medium and high temperature strengthClaywaresSlagMechanical property

The invention relates to an aluminum silicon refractory. The refractory comprises an aggregate, a powder material and an admixture, wherein the aggregate comprises a kaolin, xenotime, zircon and silicon carbide; the powder material comprises ooze and bauxite micropowder; the admixture comprises a composite binding agent and a composite mineralizer. The aluminum silicon refractory has good high temperature resistance, erosion resistance, wear resistance and low heat conductivity, has good mechanical properties, heat stability and heat shock resistance, reduces heat dissipation loss, is safe andnon-toxic, and is an environment-friendly material, so that the refractory has a good toughening effect, the medium temperature strength, the high temperature strength, the heat shock resistance andthe slag erosion resistance of the refractory are significantly improved, the service life is prolonged, and economic benefits are increased.

Owner:浙江攀盛冶金材料有限公司

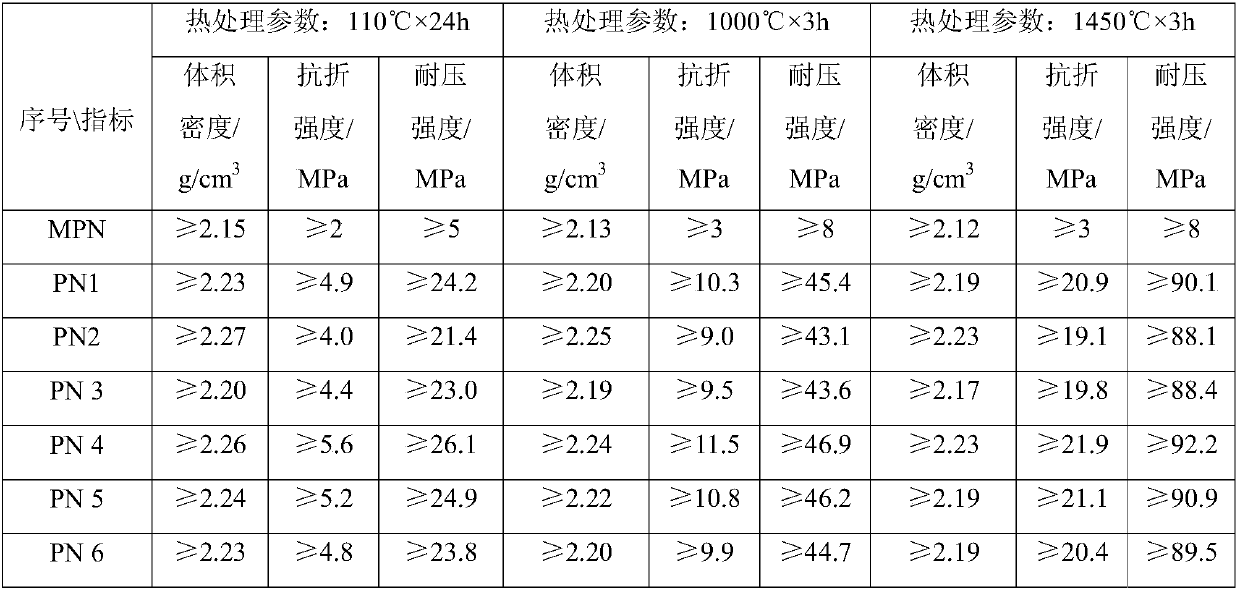

No-water stemming material for blast furnace taphole and its prepn

InactiveCN100453509CShorten the blasting timeExtend the tapping timeBlast furnace componentsBlast furnace detailsCarbide siliconSlag

The present invention relates to amorphous refractory material, and is especially one kind of no-water stemming material for blast furnace taphole and its preparation process. The no-water stemming material is prepared with coke powder 15-25 wt%, clay 10-20 wt%, bauxite corundum 20-36 wt%, silicon carbide 10-20 wt%, asphalt 8-16 wt%, sericite 5-9 wt%, additive 1-5 wt% and binding agent 12-22 wt%, and through crushing, sieving, pre-mixing, rolling, kneading and extruding. The no-water stemming material has excellent plasticity and sintering performance, high strength at high and middle temperature and high slag and molten iron flush resistance, and can meet the requirement of high strength smelting in blast furnace.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Quick baking castable containing SioxX Zero and application of quick baking castable in aluminum industry

PendingCN113511903AImprove utilization efficiencyImprove explosion-proof performanceCharge composition/stateCharge treatment typeFiberMullite

The invention belongs to the field of baking castable materials, and particularly discloses a quick baking castable material containing SioxX Zero and application of the quick baking castable material in the aluminum industry. The quick baking castable material is prepared from the following raw materials in parts by weight: 50-70 parts of mullite, 10-20 parts of bauxite, 5-10 parts of calcined alumina powder, 3-12 parts of silicon micro powder, 3-9 parts of water 1-3 parts of SioxX Zero, and 0.05-0.15 part of explosion-proof fiber. The rapid baking castable containing SioxX Zero disclosed by the invention has excellent high-temperature performance and excellent thermal shock resistance stability, can be rapidly baked, realizes rapid baking of aluminum melting furnace castable in the aluminum industry for the first time, can shorten the time by 2 / 3, greatly shortens the baking time, saves time cost and energy cost for customers, and has a remarkable effect.

Owner:SUZHOU NORETA NEW MATERIAL TECH

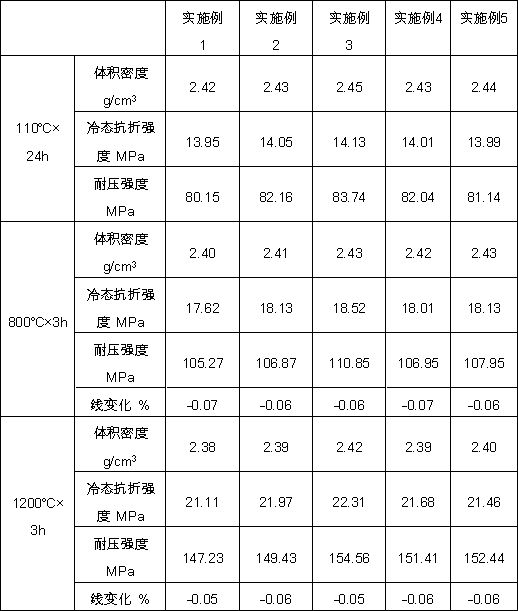

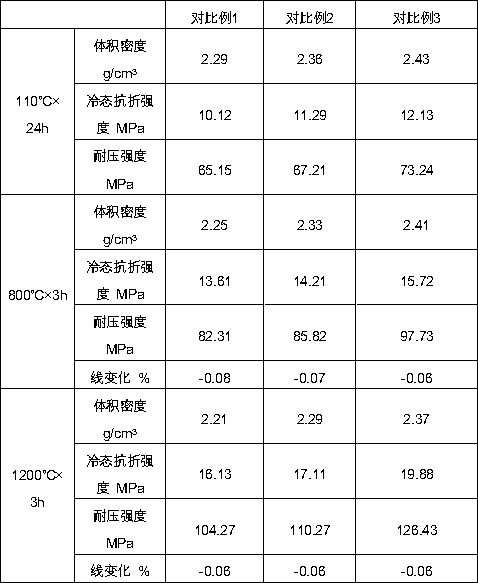

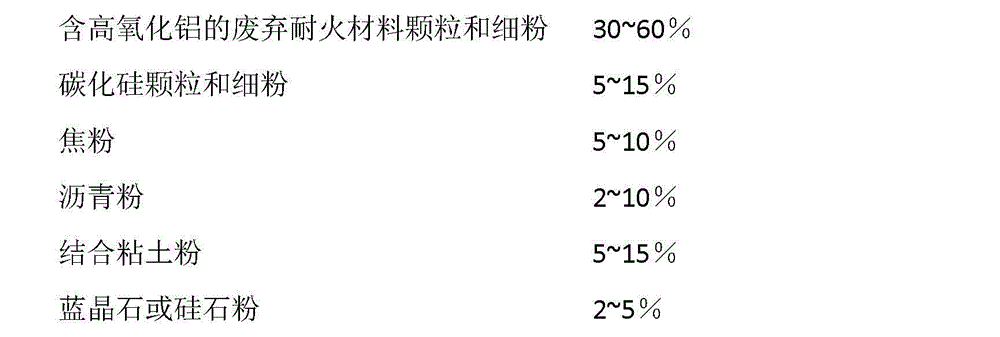

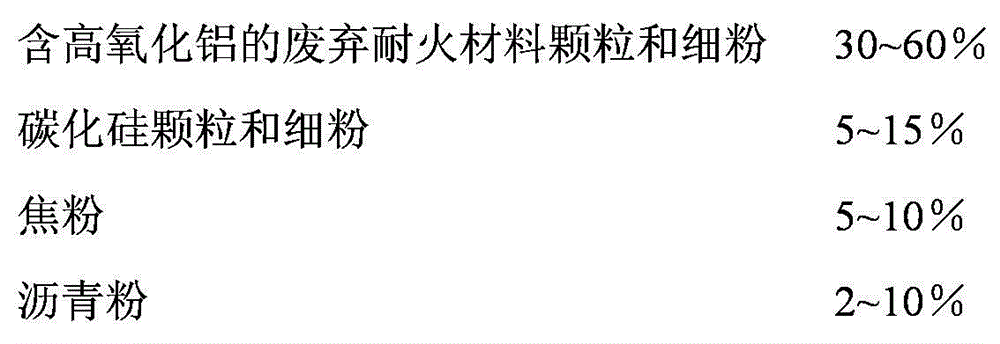

Method for producing waterless taphole mix for blast furnace from high-alumina waste refractory materials

The invention discloses a method for producing a waterless taphole mix for a blast furnace from high-alumina waste refractory materials. The produced low-cost waterless taphole mix can satisfy the operating requirements for plugging tapholes of large and medium blast furnaces. The method comprises the selection of raw materials for production, the processing of the raw materials for production, the proportioning of the raw materials for production, and the production process. The waterless taphole mix produced by the method has the characteristics of low cost, good plasticity and sintering property, high middle-and-high-temperature strength, favorable slag and iron erosion resistance and the like, and can completely satisfy the operating requirements of large and medium blast furnaces. Compared with the existing waterless taphole mix, the cost can be reduced by 40-60%; since a great amount of waste refractory materials are used, the emission of the solid waste can be decreased, and a great amount of high-quality refractory materials such as brown corundum, premium / extra grade alumina and the like can be saved; and meanwhile, the energy consumption and the emission of carbon dioxide gas during the smelting of brown corundum and premium / extra grade alumina can be decreased.

Owner:UNIV OF SCI & TECH LIAONING

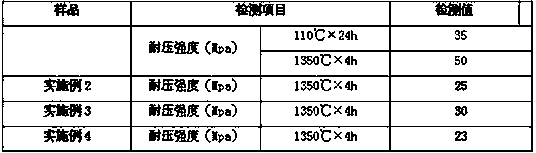

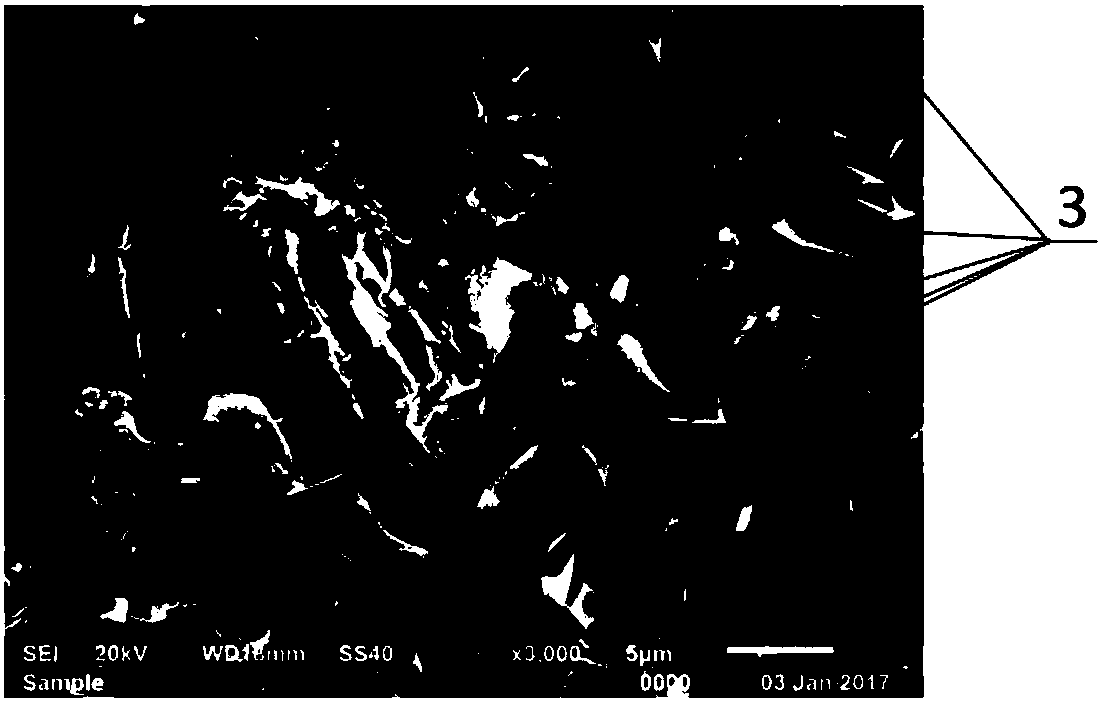

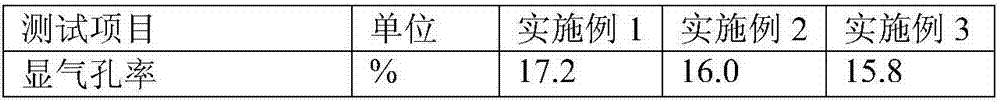

Aluminum nitride reinforced castable for CDQ coke oven chute column and preparation method thereof

ActiveCN108191441BImprove medium and high temperature strengthHigh thermal conductivityCarbide siliconPtru catalyst

The invention relates to an aluminum nitride reinforced pouring material for a chute column of a CDQ coke oven and a preparation method thereof. The technical solution is: 45-65wt% mullite, 15-35wt% silicon carbide, 2-8wt% inorganic-metal composite microcapsules, 4-6wt% α-alumina powder, 2-4wt% Silica powder and 4-6wt% calcium aluminate cement are used as raw materials, and 0.1-0.3wt% catalyst and 0.1-0.3wt% water reducer are used as additives. First mix the inorganic-metal composite microcapsules and the catalyst to obtain a premix; then mix the premix, water reducer and other raw materials, and stir evenly to obtain aluminum nitride reinforced CDQ oven chute castables . The aluminum nitride reinforced castable for CDQ coke oven chute column prepared by the invention has good hydration resistance, high production stability and good fluidity; the use results show that it has excellent mechanical properties at medium and high temperatures, wear resistance and thermal shock Good stability, long life, energy saving and environmental protection.

Owner:WUHAN UNIV OF SCI & TECH

High-thermal-conductivity unfired alumina-carbon sliding plate brick and preparation method thereof

ActiveCN114349523AGood thermal conductivityImprove thermal conductivityMelt-holding vesselsActivated aluminaSteel belt

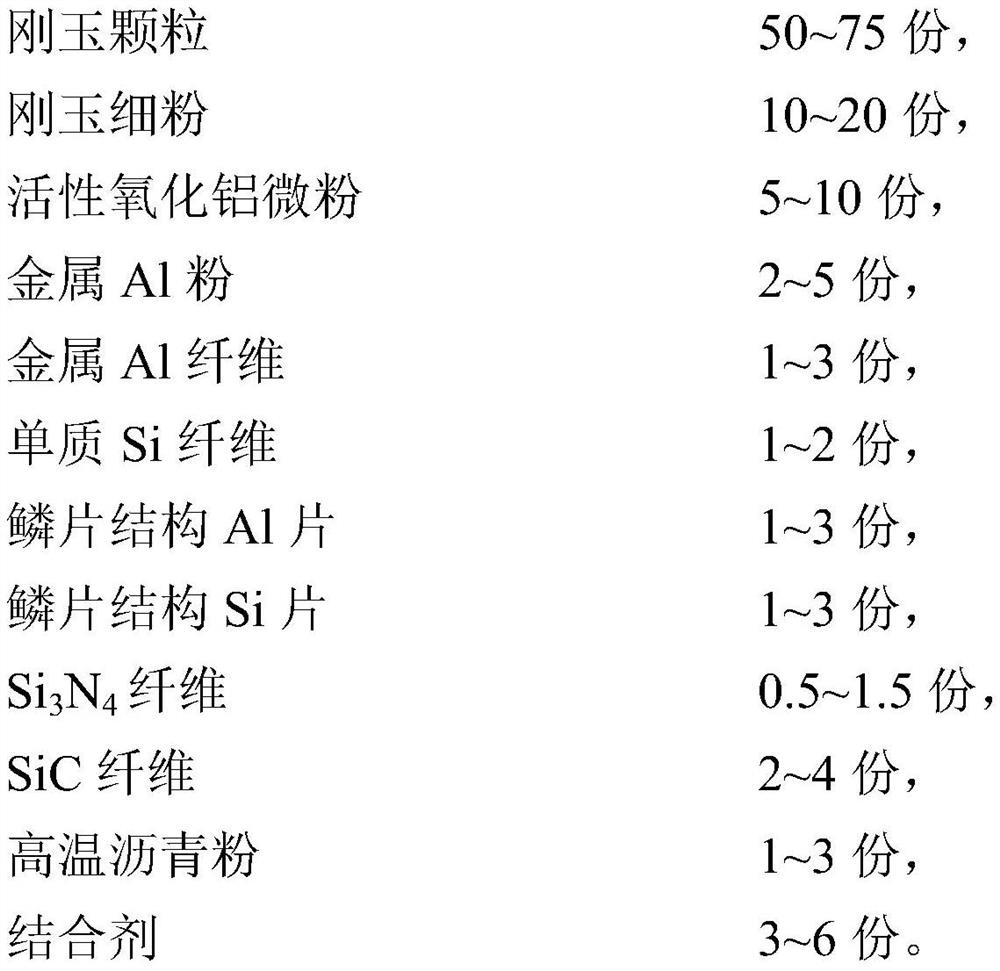

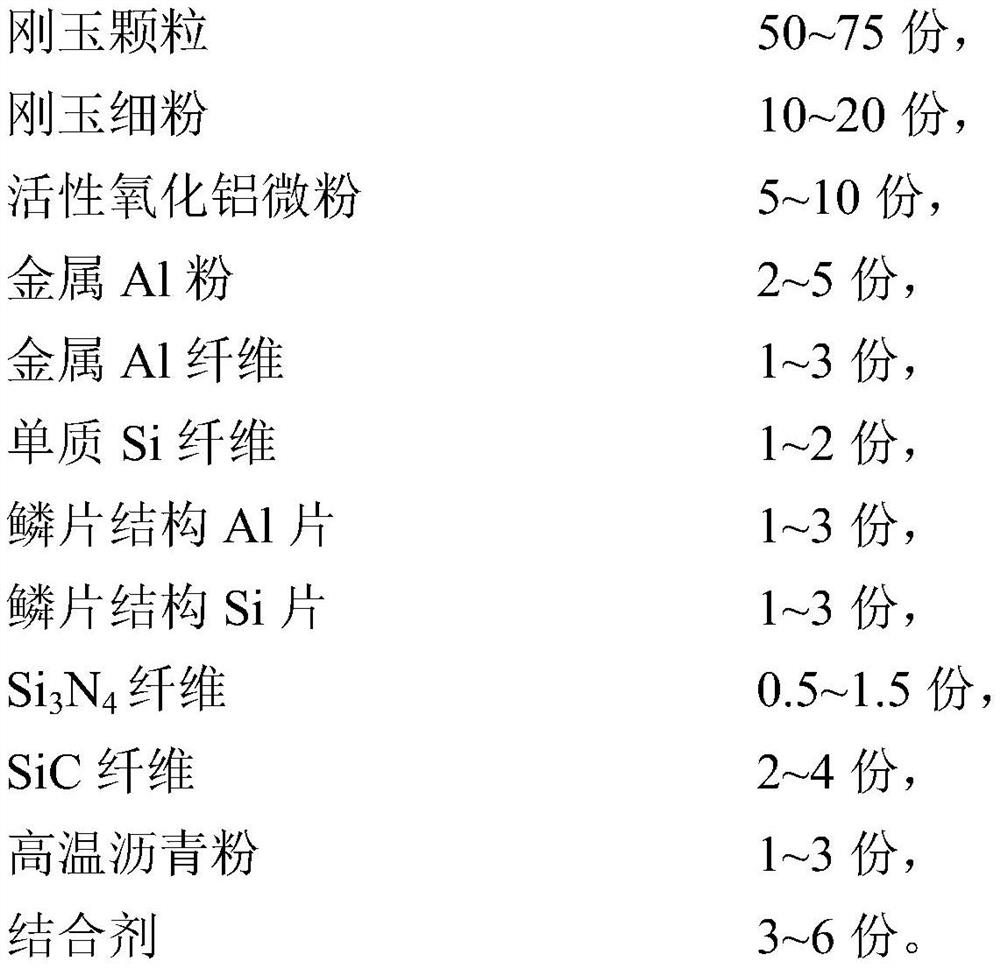

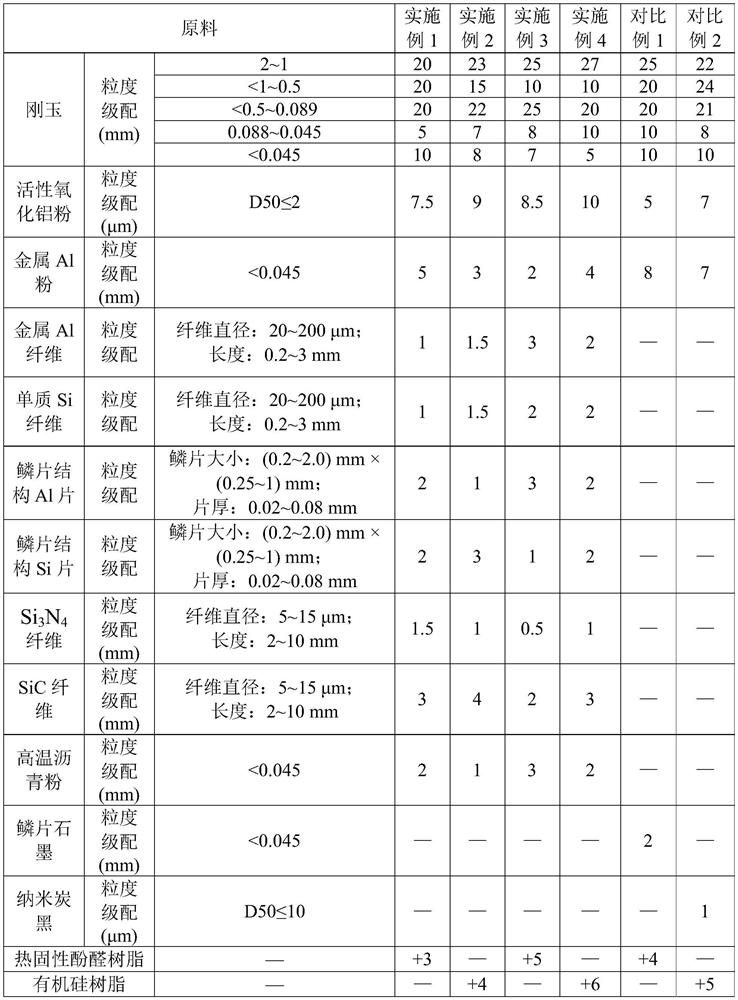

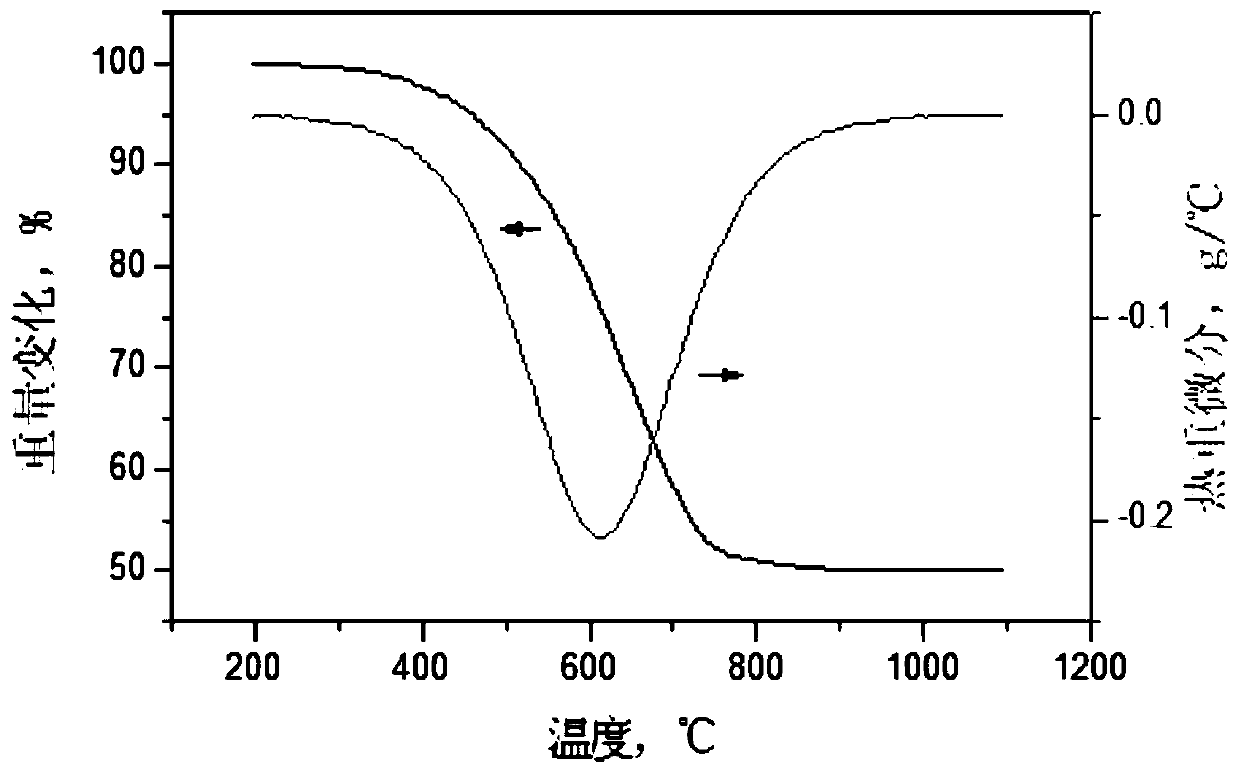

The invention discloses a high-thermal-conductivity unfired Al2O3-C sliding plate brick and a preparation method thereof. The sliding plate brick comprises the following raw materials in parts by mass: 50-75 parts of corundum particles, 10-20 parts of corundum fine powder, 5-10 parts of activated alumina micro powder, 2-5 parts of metal Al powder, 1-3 parts of metal Al fibers, 1-2 parts of elemental Si fibers, 1-3 parts of flake structure Al sheets, 1-3 parts of flake structure Si sheets, 0.5-1.5 parts of Si3N4 fibers, 2-4 parts of SiC fibers, 1-3 parts of high-temperature asphalt powder and 3-6 parts of a binding agent. The preparation method comprises the following steps: uniformly pre-mixing other raw materials except the corundum particles and the binding agent to prepare pre-mixed powder; the preparation method comprises the following steps: mixing and grinding corundum particles, a binding agent and premixed powder, ageing for more than 24 hours, then carrying out compression molding, baking for more than 24 hours at 180-260 DEG C, and directly sleeving a steel belt and a steel shell on the baked sliding plate brick, drilling, polishing and smearing a graphite coating to obtain the high-thermal-conductivity unfired Al2O3-C sliding plate brick.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

A kind of lightweight tundish working lining and preparation method thereof

ActiveCN108530090BRealize learning from each otherLow costCeramic materials productionClaywaresFiberBrick

The invention discloses a light tundish working lining and a method for preparing the same. Ingredients for the light tundish working lining comprise waste magnesia-carbon bricks, magnesite tailing, aluminum oxide, fibers, compound bonding agents and additives. The method for preparing the light tundish working lining includes dry vibration forming or wet smearing forming. The light tundish working lining and the method have the advantages that the light tundish working lining prepared by the aid of the method is low in volume density, erosion rate, cost and consumption and long in service life, energy can be saved, and the like. Besides, the problem of excessive consumption of resources of existing refractory raw materials (including waste magnesia-carbon brick reclaimed materials and thelike), the problems in the aspects of energy conservation and heat preservation and the like can be solved by the aid of the light tundish working lining and the method.

Owner:PUYANG REFRACTORIES GRP CO LTD

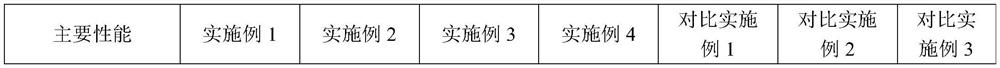

Phosphorus-free plastic refractory for casting and preparation method thereof

ActiveCN114180977AExtended storage lifeAvoid contamination and destructionProcess efficiency improvementCast ironPlastic materials

The invention belongs to the technical field of cast steel and cast iron smelting, and particularly relates to a phosphorus-free plastic refractory for casting and a preparation method thereof. According to the technical key points, the ceramic comprises the following chemical components in percentage by mass: 78%-88% of Al2O3, 6%-10% of SiO2, 2%-4% of ZrO2 and 2%-3% of C. According to the phosphorus-free plastic refractory for casting and the preparation method of the phosphorus-free plastic refractory, provided by the invention, the problems of harm and pollution to molten iron and molten steel in the using process of the phosphorus-containing plastic refractory in the current market are solved; meanwhile, the problems of low construction green body strength, easiness in cracking during use, short storage life and the like of the plastic material combined by other binding agents in the use process are solved, and the plastic material has the advantages of excellent construction, long storage life, good high-temperature strength and the like.

Owner:ZHENJIANG SINO FOUNDRY REFRACTORY

High-strength heat-insulating fiber composite spraying material and preparation method thereof

The invention belongs to the technical field of spraying materials, and particularly relates to a high-strength heat- insulation fiber composite spraying material capable of quickly repairing heat damaged parts, prolonging service life and saving cost and a preparation method thereof. The high-strength heat- insulation fiber composite spraying material comprises the following components in percentage by weight: 50-54% of a mullite light material, 23-27% of spherical fiber wool, 4-6% of Guangxi white mud, 1.5-3% of guar gum, 6-9% of aluminum dihydrogen phosphate liquid, 4-6% of pure calcium aluminate 70 cement and 4-6% of silica micropowder. The invention aims to provide the high-strength heat- insulation fiber composite spraying material which can effectively solve the repair of heat damaged parts, prolong the service life and save cost and a preparation method thereof with simple process and low cost.

Owner:河南恒耐尔耐火材料有限公司

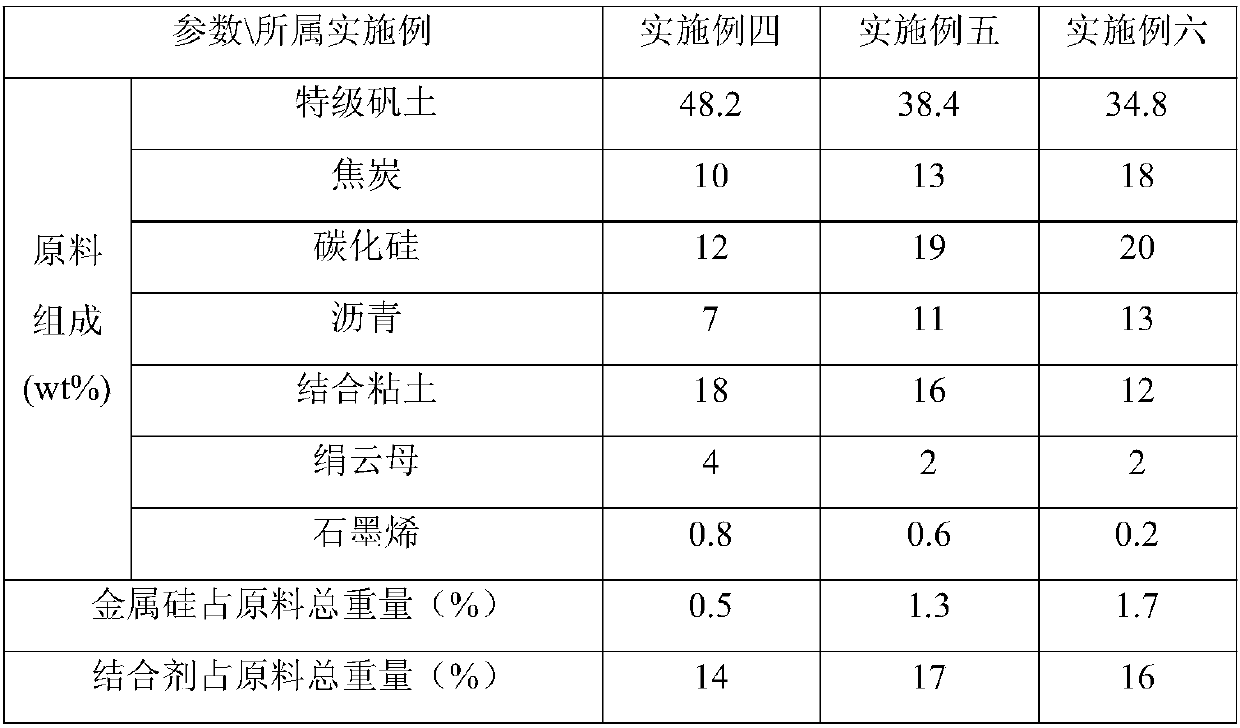

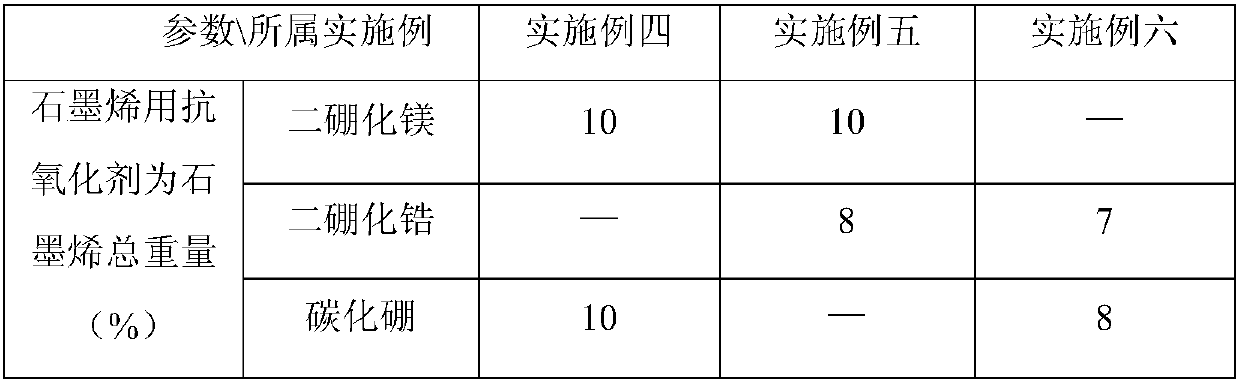

High performance anhydrous stemming containing graphene and preparation method of high-performance anhydrous stemming

InactiveCN107867867ASimple manufacturing process stepsProcess parameters are easy to controlMixed materialsThermal shock

The invention provides high-performance anhydrous stemming containing graphene and a preparation method of the high-performance anhydrous stemming. The preparation method comprises: step 1, preparingmaterials, which includes weighing required raw materials including super-grade bauxite, coke, silicon carbide, asphalt, combined clay, sericite and graphene, and additives including metallic siliconand an anti-oxidant used for graphene; step 2, fully mixing the weighed materials with a binder; and step 3, making the uniformly mixed material into final products via an extruder and bagging the final products for storage. According to the technical scheme, the anhydrous stemming has the following effect: (1) the preparation method is simplified in steps and suitable for industrial production; (2) graphene is added to reduce the consumption of conventional carbonaceous materials including coke and asphalt and can reduce production of toxic carcinogenic flue gas during high-temperature usage;and (3) graphene is extremely high in structural strength and is added to resist washing, thermal shock and corrosion.

Owner:湖南永盛高新耐火材料有限公司 +1

A kind of anti-penetration type tundish lightweight coating and preparation method thereof

The invention discloses an anti-permeation type tundish light coating and a preparation method thereof. The anti-permeation type tundish light coating comprises the following components in parts by weight: 73-99 parts of magnesite and / or forsterite with the granularity less than or equal to 1mm, 0.1-15 parts of quartz sand, 0.2-4 parts of sulfamic acid, 0.1-3.0 parts of an organic plasticizer agent, 0.5-5 parts of composite fiber, 0.02-0.25 part of high-efficiency air entraining agent and 0.01-0.15 part of metal aluminum powder. The coating disclosed by the invention is small in volume density, high in pressure resisting intensity after being baked, small in low melt and capable of effectively preventing slag permeation and solving the problems of a conventional light coating in construction, baking and use.

Owner:PUYANG REFRACTORIES GRP CO LTD

High-alumina castables for permanent layers of torpedo tanks

Owner:WUGANG REFRACTORY CO LTD

T91 water wall tube row welding process

ActiveCN104801834BImprove medium and high temperature strengthStrong anti-porosityArc welding apparatusMaterials preparationTime range

Owner:JIANGSU GREENLEAVES BOILER

Environment-friendly magnesia-alumina-carbon brick

InactiveCN112079628AImprove antioxidant capacityImprove medium and high temperature strengthCarbide siliconAdhesive

The invention relates to an environment-friendly magnesia-alumina-carbon brick which is mainly prepared from the following components in parts by mass: 35-45 parts of magnesia particles, 5-10 parts ofmagnesia fine powder, 10-20 parts of aluminum-zinc metal composite powder, 2-5 parts of silicon dioxide micro powder, 1-3 parts of colorless corundum fine powder, 2-4 parts of a complex magnesia-alumina adhesive, 0.1-0.2 part of wash oil, 3-5 parts of carbon black and 2-3 parts of silicon carbide micro powder. According to the magnesia-alumina-carbon brick, the oxidation resistance can be remarkably improved by adding a small amount of wash oil, and the medium-high temperature strength of a magnesia-alumina-carbon brick product can be improved through compatibility of colorless corundum finepowder and silicon carbide; meanwhile, the magnesia-alumina-carbon brick has the advantages of low carbon content and low apparent porosity.

Owner:常州宇达耐火材料有限公司

A kind of y-psz reinforced refractory material and its preparation process

The invention relates to a Y-PSZ strengthened fireproof material and a preparation process thereof. The fireproof material is prepared from the following raw materials in percentage by weight: 28 to 30 percent of high-purity fine magnesia, 27 to 30 percent of high-purity crude magnesia, 17 to 21 percent of fused magnesia, 15 to 20 percent of aluminum magnesium spinel, 1.5 to 4 percent of monatomicsilicon, 1.5 to 3 percent of carbon nano-tube and 0.5 to 1.0 percent of an additive. The product has high mechanical property, heat stability and thermal shock resistance, has high medium-temperatureand high-temperature strength, is safe and non-toxic, and is an environment-friendly material; the use requirement of a binding agent is avoided and the preparation process is environmentally friendly and clean; the Y-PSZ is added, so that the toughening effect is achieved, and the medium-temperature and high-temperature strength, the thermal shock resistance and the slag corrosion resistance ofthe material are obviously improved.

Owner:营口宏远耐火材料有限公司

Non-oxide composite refractory materials for molten iron chute

The invention relates to a technology for preparation of refractory material, and especially to a composite refractory of non-oxidized substance used in a hot-metal launder of consecutive pre-processing. The composite refractory of non-oxidized substance used in a hot-metal launder is characterized in that it contains (wt %) 50-70 % of corundum material, 15-30 % of silicon carbide, 3-10 % of silicon nitride, 3-10 % of silicon nitride tiny powder, 1-5 % of charcoal material, 1-3 % of silicon anti-oxidization agent, 6-15 % of additional silicasol astringent, and a few additives containing anti-knock agent and dispersing agent with 0.15-1.5 % by wt. The refractory material of the said invention can resist the erosion of the hot-metal and the molten ash and is of strong erosion ability, uniform and high-integrity structure, high intensity at a medium-high-temperature, strong stability of resistance to heat shocks and of volume of material, and strong resistance to oxidation, so it adapts to the process requirement of the desired hot-metal launder of consecutive pre-processing.

Owner:BAOSHAN IRON & STEEL CO LTD

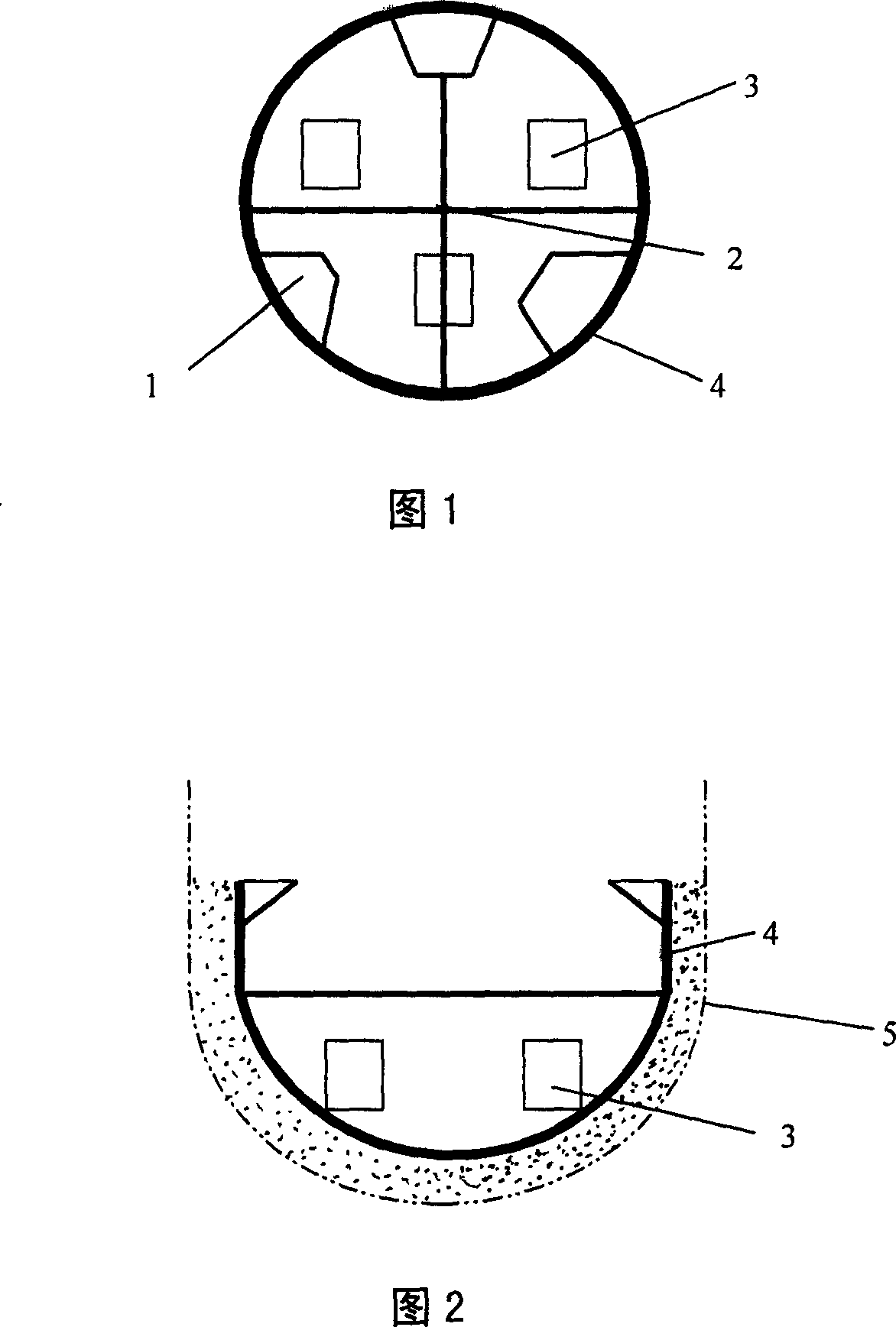

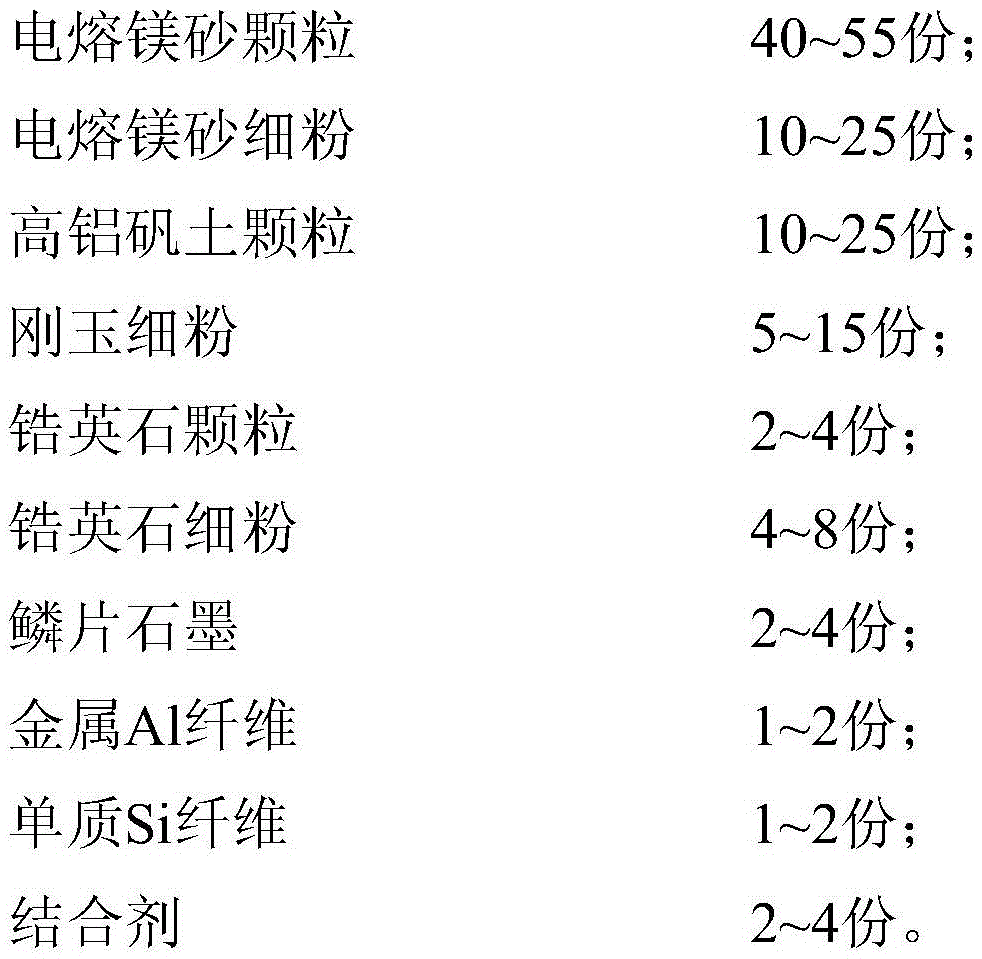

A kind of low-carbon magnesia-alumina-carbon brick bonded with ceramics at high temperature and preparation method thereof

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

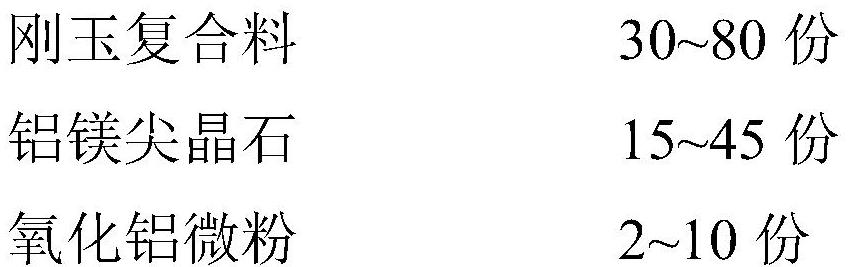

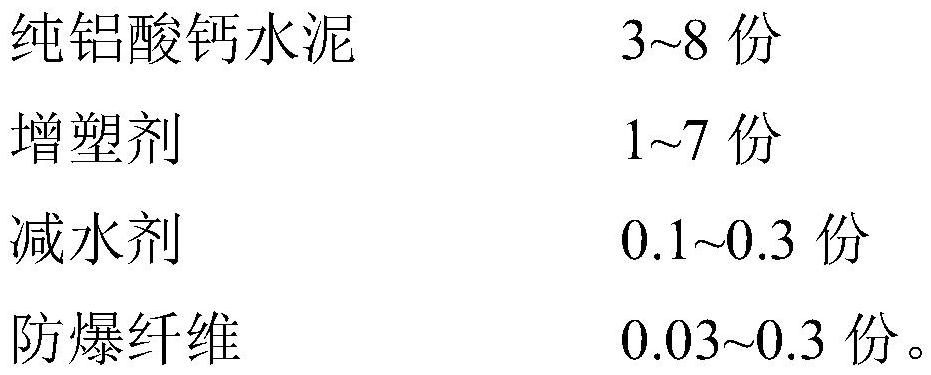

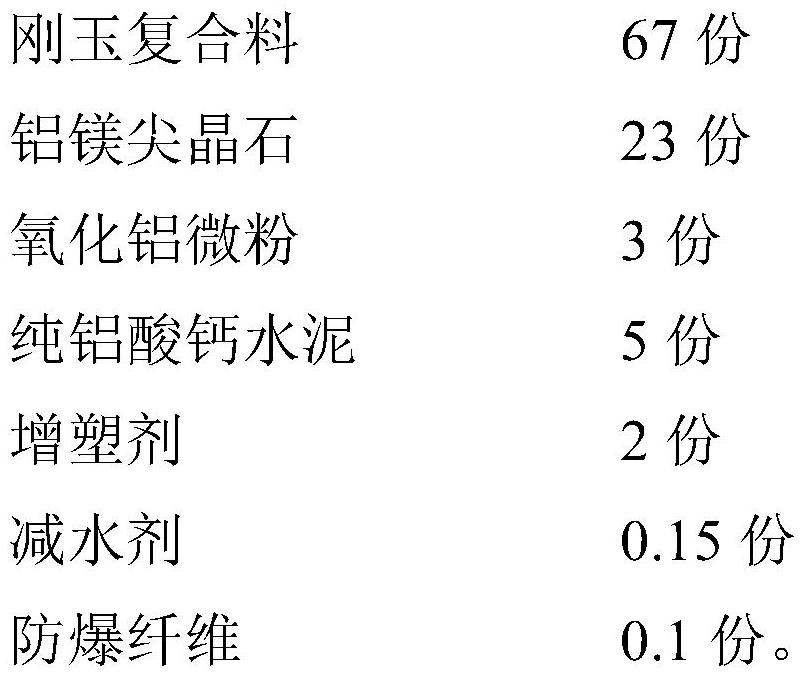

Corundum spinel repair material for carbonless steel ladle working lining and preparation method thereof

ActiveCN112960974BProtect resourcesEmission reductionProcess efficiency improvementFiberWater reducer

The invention discloses a corundum-spinel repair material for carbon-free steel ladle working lining and a preparation method thereof. The repair material includes the following components in parts by mass: 30-80 parts of corundum composite material, 15 parts of aluminum-magnesium spinel ~45 parts, 2-10 parts of alumina micropowder, 3-8 parts of pure calcium aluminate cement, 1-7 parts of plasticizer, 0.1-0.3 parts of water reducing agent, 0.03-0.3 parts of explosion-proof fiber. The corundum-spinel repair material for carbon-free ladle working lining of the invention has good adhesion performance, appropriate spreading performance, high medium and high temperature strength, good overall performance, excellent anti-scour and anti-erosion performance, long service life, and economical resources and reduce carbon emissions.

Owner:WUGANG REFRACTORY CO LTD

High-strength wear-resistant castable for rotary hearth furnace and preparation method thereof

ActiveCN110156445BEasy constructionImprove medium and high temperature strengthMulliteWear resistance

The invention discloses a high-strength wear-resistant castable for a rotary hearth furnace and a preparation method thereof. It is composed of aggregate, fine powder and mixed powder. The aggregate is high-alumina bauxite homogenized material, brown corundum, white corundum and mullite any one or several of stones; the fine powder is any one or several of brown corundum, white corundum, plate corundum and mullite; the mixed powder is composed of SiC powder, fine powder, binder, and Composition of agents and dispersants. The high-strength wear-resistant castable for kilns with a strong reducing atmosphere such as rotary hearth furnaces for direct reduced iron of the present invention has good CO cracking resistance, low requirements on raw materials, and excellent thermal shock resistance and wear resistance.

Owner:PUYANG REFRACTORIES GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com