In-situ generated CM2A8 multiphase reinforced steel ladle casting material and preparation method thereof

A technology of ladle pouring and in-situ generation, which is applied in the field of ladle castables, can solve the problems of slag resistance and strength, influence of castable strength, loss of bonding strength, etc., to improve medium and high temperature strength and slag resistance, enhance thermal Good shock stability and thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

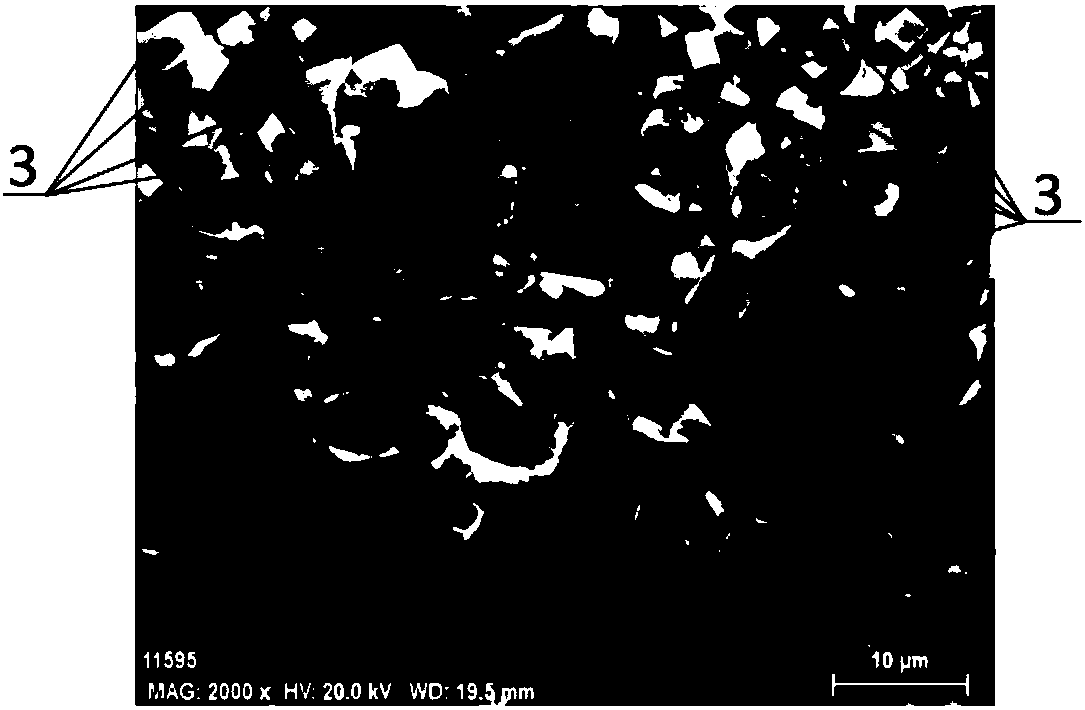

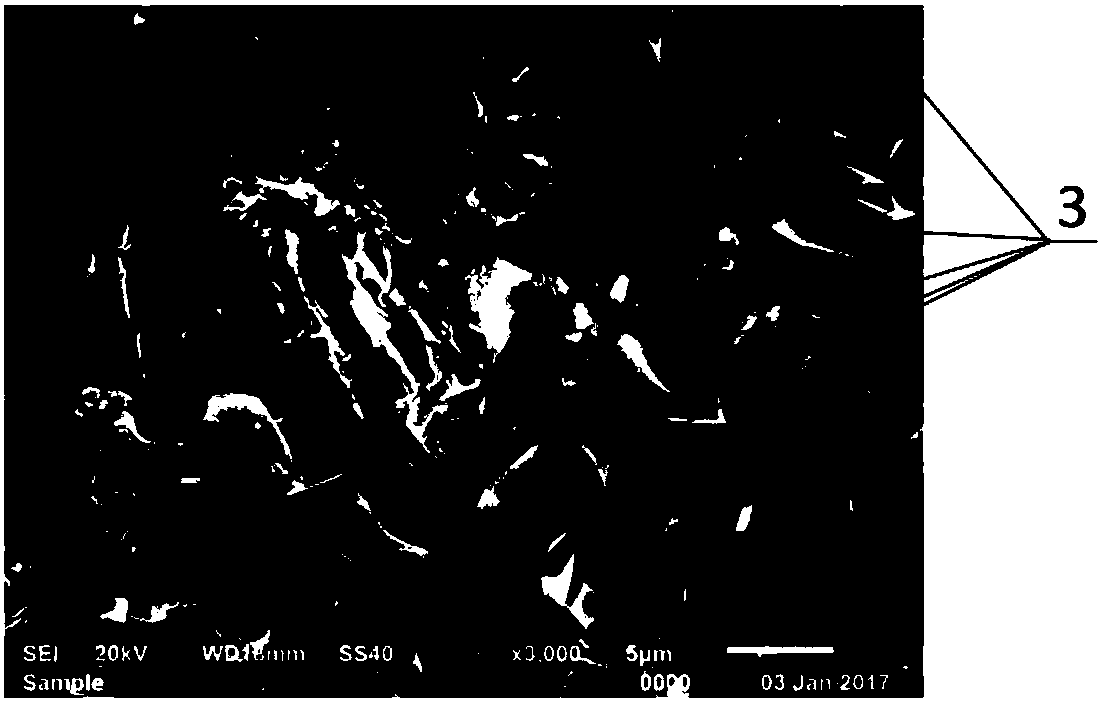

[0037] An in situ generation of CM 2 A 8 Multi-phase reinforced ladle castable and preparation method thereof.

[0038] The in situ generation of CM 2 A 8 The chemical composition and content of the multi-phase reinforced ladle castable are: 65-72wt% modified corundum particles as aggregate, 8-10wt% white corundum powder, 4-6wt% magnesia fine powder, 6-6wt% 8wt% active α-Al 2 o 3 Micropowder, 7-8wt% calcium aluminate cement and 2-3wt% magnesia-aluminum spinel fibers are used as the matrix material, plus 0.05-0.06wt% organic fiber and 0.1-0.15wt% of the sum of the aggregate and the matrix material % water reducing agent, 0.02-0.04wt% aluminum-silicon alloy powder and 0.1-0.4wt% rare earth oxide.

[0039] Generate CM in situ according to the 2 A 8 For the chemical composition and content of the multi-phase reinforced ladle castable, first dry mix the base material with the water reducing agent, aluminum-silicon alloy powder and rare earth oxide for 3-8 minutes to obtain ...

Embodiment 2

[0042] An in situ generation of CM 2 A 8 Multi-phase reinforced ladle castable and preparation method thereof.

[0043] The in situ generation of CM 2 A 8 The chemical composition and content of the multi-phase reinforced ladle castable are: 68-75wt% modified corundum particles as aggregate, 7-9wt% white corundum powder, 3-5wt% magnesia fine powder, 6-5wt% 8wt% active α-Al 2 o 3 Micropowder, 7-8wt% calcium aluminate cement and 1-2wt% magnesia-aluminum spinel fiber are used as the base material, plus 0.05-0.06wt% organic fiber and 0.15-0.20wt% of the sum of the aggregate and the base material % water reducing agent, 0.02-0.04wt% aluminum-silicon alloy powder and 0.3-0.6wt% rare earth oxide.

[0044] Generate CM in situ according to the 2 A 8 For the chemical composition and content of the multi-phase reinforced ladle castable, first dry mix the base material with the water reducing agent, aluminum-silicon alloy powder and rare earth oxide for 3-8 minutes to obtain a mix...

Embodiment 3

[0047] An in situ generation of CM 2 A 8 Multi-phase reinforced ladle castable and preparation method thereof.

[0048] The in situ generation of CM 2 A 8 The chemical composition and content of the multi-phase reinforced ladle castable are: 71-78wt% modified corundum particles as aggregate, 7-9wt% white corundum powder, 2-4wt% magnesia fine powder, 6- 8wt% active α-Al 2 o 3 Micropowder, 6-7wt% calcium aluminate cement and 0.5-1wt% magnesia-aluminum spinel fiber are used as the matrix material, plus 0.05-0.06wt% organic fiber and 0.20-0.25wt% of the sum of the aggregate and the matrix material % water reducing agent, 0.02-0.04wt% aluminum-silicon alloy powder and 0.5-0.8wt% rare earth oxide.

[0049] Generate CM in situ according to the 2 A 8 For the chemical composition and content of the multi-phase reinforced ladle castable, first dry mix the base material with the water reducing agent, aluminum-silicon alloy powder and rare earth oxide for 3-8 minutes to obtain a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com