Quick baking castable containing SioxX Zero and application of quick baking castable in aluminum industry

A castable and fast technology, applied in the direction of charge, charge composition/state, charging treatment type, etc., can solve the problems of poor erosion resistance and erosion, low high temperature strength, harsh baking system, etc., to save costs and improve resistance. Thermal shock performance, effect of excellent thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

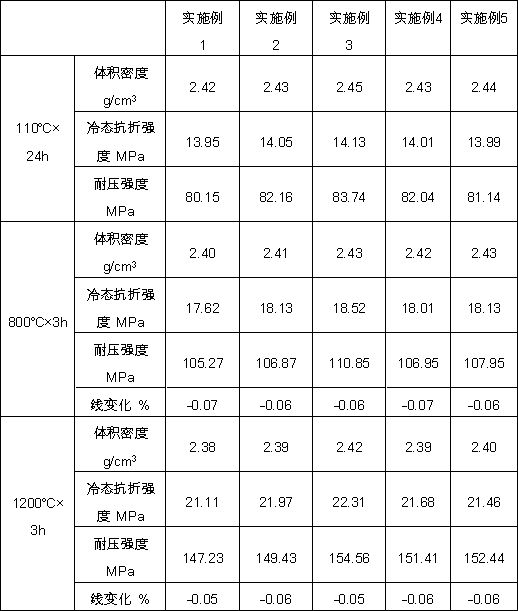

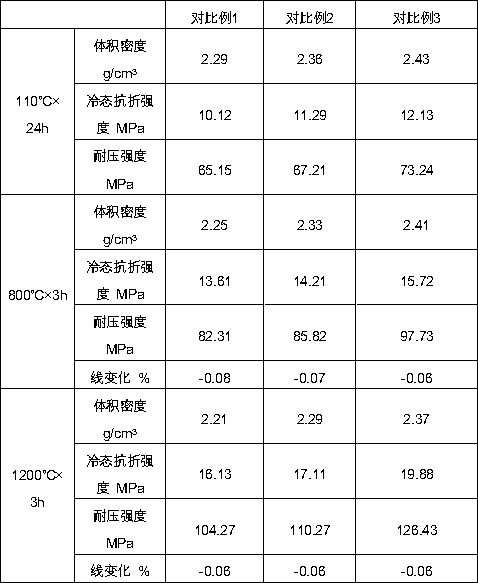

Embodiment 1

[0035] A quick-baking castable containing Sek Z, prepared from the following raw materials in parts by weight: 50 parts of mullite, 10 parts of bauxite, 5 parts of calcined alumina powder, 3 parts of silicon micropowder, and 3 parts of water , 1 part of Sek Z, 0.05 part of explosion-proof fiber;

[0036] The preparation process includes the following steps:

[0037] S1 Preparation of mixture A: Add the mullite and alumina in the formula amount into the mixer, and stir for 5 minutes, the mixer speed is 80r / min, and mix well to prepare mixture A;

[0038] S2 Preparation of mixture B: add calcined alumina powder and silicon micropowder in the prescribed amount to mixture A in sequence, and stir for 5 minutes, the speed of the mixer is 80r / min, and mix well to prepare mixture B;

[0039] S3 Preparation of quick-baking castables: Add the water in the formula amount, Seike Z and explosion-proof fiber to the mixture B in sequence, and stir for 3 minutes, the speed of the mixer is 50...

Embodiment 2

[0041] A quick-baking castable containing Sek Z, prepared from the following raw materials in parts by weight: 55 parts of mullite, 12 parts of bauxite, 6.5 parts of calcined alumina powder, 5 parts of silicon micropowder, and 4 parts of water , Seke Z 1.5 parts, explosion-proof fiber 0.075 parts;

[0042] The preparation process includes the following steps:

[0043]S1 Preparation of mixture A: Add the mullite and alumina in the formula amount into the mixer, and stir for 5 minutes, the mixer speed is 80r / min, and mix well to prepare mixture A;

[0044] S2 Preparation of mixture B: add calcined alumina powder and silicon micropowder in the prescribed amount to mixture A in sequence, and stir for 5 minutes, the speed of the mixer is 80r / min, and mix well to prepare mixture B;

[0045] S3 Preparation of quick-baking castables: Add the water in the formula amount, Seike Z and explosion-proof fiber to the mixture B in sequence, and stir for 3 minutes, the speed of the mixer is 5...

Embodiment 3

[0047] A quick-baking castable containing Sek Z, prepared from the following raw materials in parts by weight: 60 parts of mullite, 15 parts of bauxite, 7.5 parts of calcined alumina powder, 8 parts of silicon micropowder, and 5 parts of water , Seke Z 2 parts, explosion-proof fiber 0.1 part;

[0048] The preparation process includes the following steps:

[0049] S1 Preparation of mixture A: Add the mullite and alumina in the formula amount into the mixer, and stir for 6.5 minutes, the mixer speed is 100r / min, and mix well to prepare the mixture A;

[0050] S2 Preparation of mixture B: add calcined alumina powder and micro-silica powder in the prescribed amount to mixture A in sequence, and stir for 6.5 minutes, the speed of the mixer is 100r / min, and mix well to prepare mixture B;

[0051] S3 Preparation of quick-baking castable: add the water in the formula amount, Seike Z and explosion-proof fiber into the mixture B in sequence, and stir for 4.5 minutes, the speed of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com