Thermal-state repair spray coating and preparation method thereof

A technology for repairing and spraying paint in a hot state, applied in the field of spray paint, can solve the problems of lack of spray paint spray paint preparation method, affecting normal use, large loss and waste, etc. The effect of weak knot and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

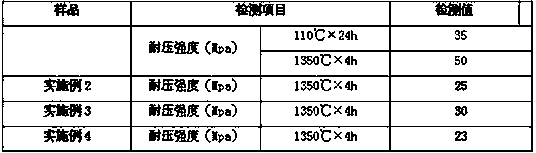

Embodiment 1

[0026] The proportion by weight of the components is: brown corundum 73%, Guangxi white mud 5%, pure calcium aluminate 70 cement 5%, boric acid 2%, metal silicon 5%, metal aluminum 2%, silicon carbide 8%.

Embodiment 2

[0028] The proportion by weight of the components is: brown corundum 73%, Guangxi white mud 5%, pure calcium aluminate 70 cement 5%, boric acid 0.5%, metal silicon 2%, metal aluminum 0.5%, silicon carbide 8%.

Embodiment 3

[0030] The proportion by weight of the components is: brown corundum 73%, Guangxi white mud 5%, pure calcium aluminate 70 cement 5%, boric acid 1%, metal silicon 3%, metal aluminum 1%, silicon carbide 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com