Aluminum silicon refractory

A refractory material, aluminum-silicon technology, applied in the field of refractory materials, can solve the problems of easy flocculation of lime milk solution, insufficient fineness of iron oxide particle size, poor effect of mineralizer, etc., to improve life and economic benefits, low thermal conductivity, good The effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

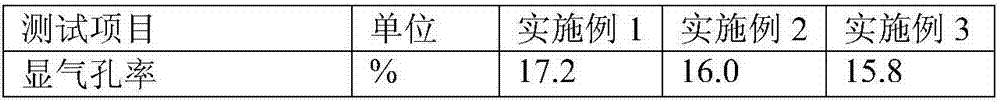

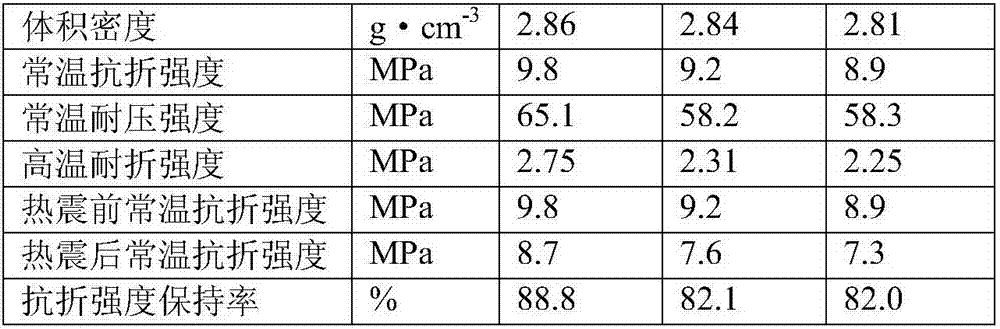

Embodiment 1

[0033] An aluminosilicate refractory material, the refractory material includes aggregate, powder and additives, the aggregate includes kaolin, xenotime, zircon and silicon carbide; the powder includes ooze and alumina fine powder; The admixture includes a composite binder and a composite mineralizer, and the components of the raw materials in the aggregate include: 75 parts of kaolin, 5 parts of xenotime, 10 parts of zircon, and 20 parts of silicon carbide; The components of each raw material in powder include: 12 parts of bauxite micropowder, 2 parts of ooze; the mass ratio of the aggregate, powder and admixture is: 5:3:0.5.

[0034] The composite binder is made of the following raw materials by weight: 12 parts of phenolic resin powder, 5 parts of nano europium modified resin, 3 parts of absolute ethanol, H 2 N-CH 2 -CH 2 -SO 32 parts of H and 0.25 parts of sodium decaborate.

[0035] The preparation steps of described nano-nickel modified resin are as follows:

[0036...

Embodiment 2

[0046] An aluminosilicate refractory material, the refractory material includes aggregate, powder and additives, the aggregate includes kaolin, xenotime, zircon and silicon carbide; the powder includes ooze and alumina fine powder; The admixture includes a composite binder and a composite mineralizer, and the components of the raw materials in the aggregate include: 100 parts of kaolin, 8 parts of xenotime, 12 parts of zircon, and 23 parts of silicon carbide; The components of each raw material in powder include: 18 parts of bauxite micropowder, 3 parts of ooze; the mass ratio of the aggregate, powder and admixture is: 6:4:1.

[0047] The composite binder is made of the following raw materials in parts by weight: 13 parts of phenolic resin powder, 7 parts of nano europium modified resin, 4 parts of absolute ethanol, H 2 N-CH 2 -CH 2 -SO 3 3 parts of H and 0.3 parts of sodium decaborate.

[0048] The preparation steps of described nano-nickel modified resin are as follows: ...

Embodiment 3

[0059] An aluminosilicate refractory material, the refractory material includes aggregate, powder and additives, the aggregate includes kaolin, xenotime, zircon and silicon carbide; the powder includes ooze and alumina fine powder; The admixture includes a composite binder and a composite mineralizer, and the components of the raw materials in the aggregate include: 125 parts of kaolin, 10 parts of xenotime, 15 parts of zircon, and 25 parts of silicon carbide; The components of each raw material in powder include: 25 parts of bauxite micropowder, 5 parts of ooze; the mass ratio of the aggregate, powder and admixture is: 10:4:1.2.

[0060] The composite binder is made of the following raw materials in parts by weight: 15 parts of phenolic resin powder, 8 parts of nano europium modified resin, 5 parts of absolute ethanol, H 2 N-CH 2 -CH 2 -SO 3 3.5 parts of H and 0.4 parts of sodium decaborate.

[0061] The preparation steps of described nano-nickel modified resin are as fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com