High performance anhydrous stemming containing graphene and preparation method of high-performance anhydrous stemming

A technology of anhydrous taphole clay and graphene, which is applied in the field of blast furnace taphole clay, can solve the problems of inconspicuous increase in high-temperature strength, strengthening, etc., achieve the effects of reducing toxic and carcinogenic fumes, simplifying the preparation process steps, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A high-performance anhydrous taphole clay containing graphene and its preparation method, adding 15% of super-grade alumina, 19.9% of coke, 25% of silicon carbide, 15% of asphalt, and 20% of combined Clay, 5% sericite and 0.1% Graphene form the raw material, adding an additional material that accounts for 2% of the metal silicon of the raw material gross weight and 12% of the Graphene gross weight of the Graphene. 13% of binder was added based on the total weight of the raw materials.

[0034] The antioxidant for graphene is magnesium diboride, and the binding agent is tar.

[0035] The mass content of aluminum oxide in the super-grade bauxite is greater than or equal to 85%, and its particle size is less than or equal to 3mm; the mass content of carbon in the coke is greater than or equal to 80%, and its particle size is less than or equal to 3mm; the silicon carbide The mass content of silicon carbide is greater than or equal to 97%, and its particle size is less t...

Embodiment 2

[0042] A high-performance anhydrous gunpowder containing graphene and its preparation method, adding 50% of super-grade alumina, 10% of coke, 15% of silicon carbide, 9.99% of asphalt, and 10% of combined Clay, 5% sericite and 0.01% Graphene form the raw material, adding an additional material that accounts for 1% of the total weight of the raw material and 10% of the Graphene with an antioxidant that accounts for the total weight of the graphene. Add 20% of binder based on the total weight of the raw materials.

[0043] The antioxidant for graphene is zirconium diboride, and the binding agent is anthracene oil.

[0044] The preparation method specifically comprises the following steps:

[0045] Step 1: Prepare materials, specifically: weigh the raw materials and external materials according to their mass, and place them separately for use;

[0046] Step 2: Mixing materials, specifically: first add super-grade bauxite, coke, silicon carbide, and asphalt into a mixer with heat...

Embodiment 3

[0050] A high-performance anhydrous gunpowder containing graphene and its preparation method, adding 36.5% of super-grade alumina, 15% of coke, 20% of silicon carbide, 10% of asphalt, and 15% of combined Clay, 3% sericite and 0.5% Graphene form the raw material, adding an additional material that accounts for 1.4% of the metal silicon of the raw material gross weight and 16% of the Graphene by the graphene gross weight. 16% of binder was added based on the total weight of the raw materials.

[0051] The antioxidant for graphene is boron carbide, and the binding agent is tar.

[0052] The preparation method specifically includes the same steps as in Example 2.

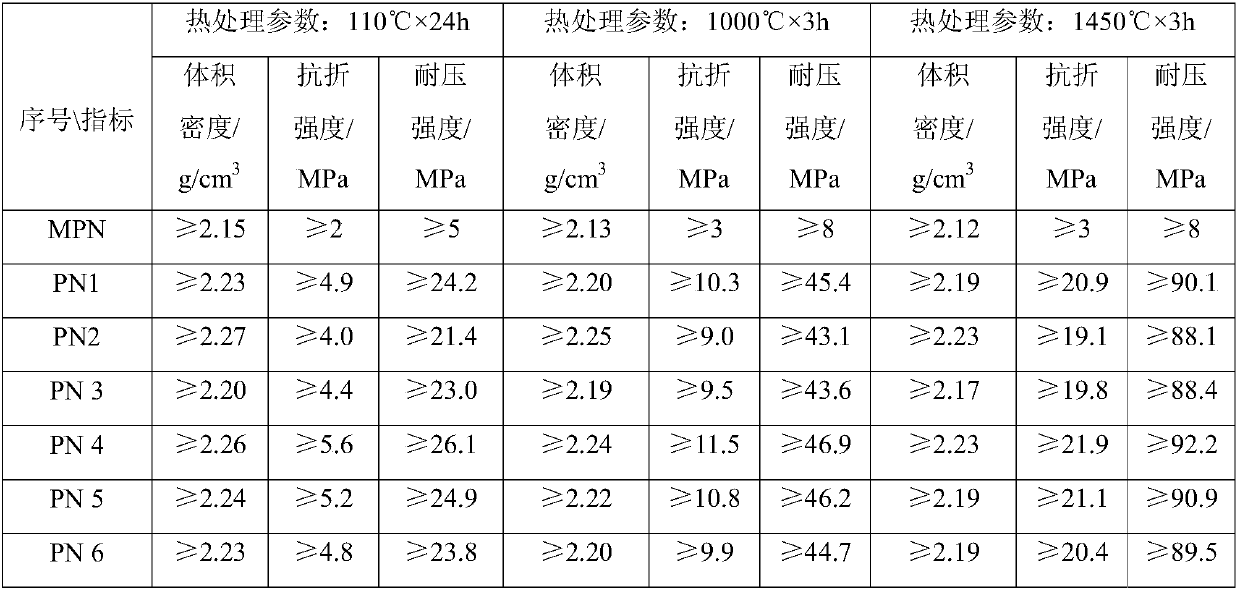

[0053] The anhydrous taphole mud of this embodiment is marked as PN3, and its physical and chemical indicators are shown in Table 4.

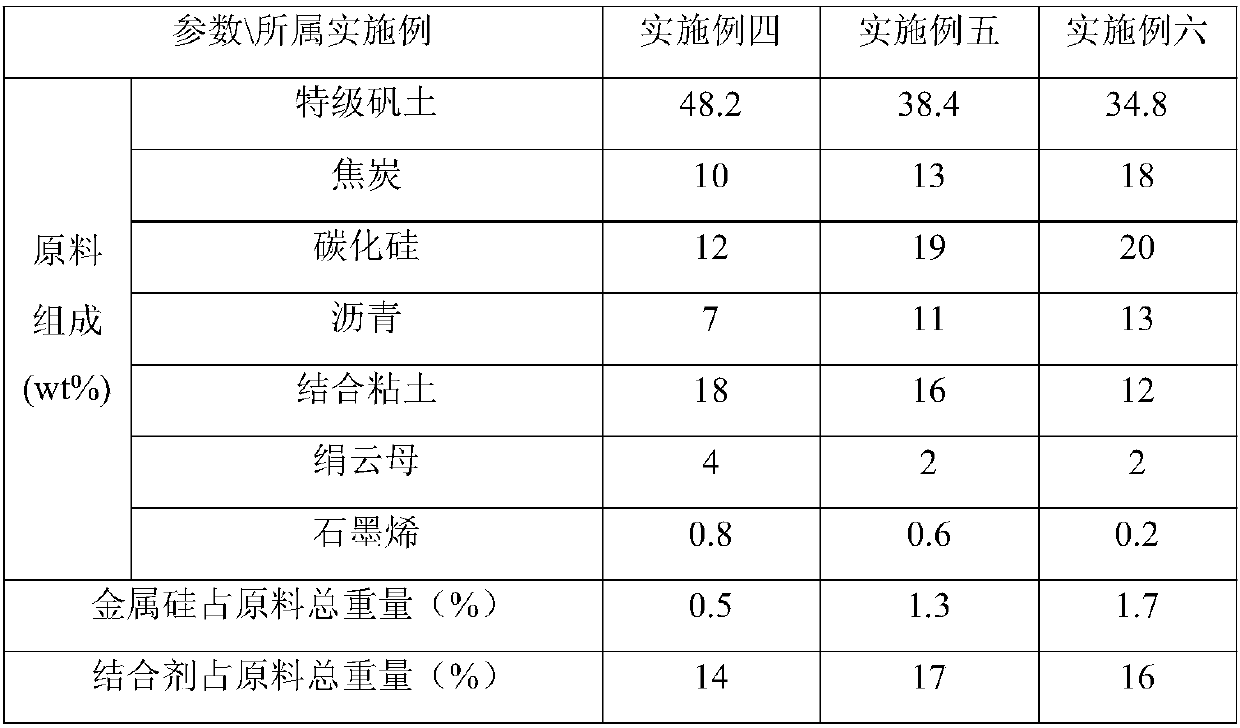

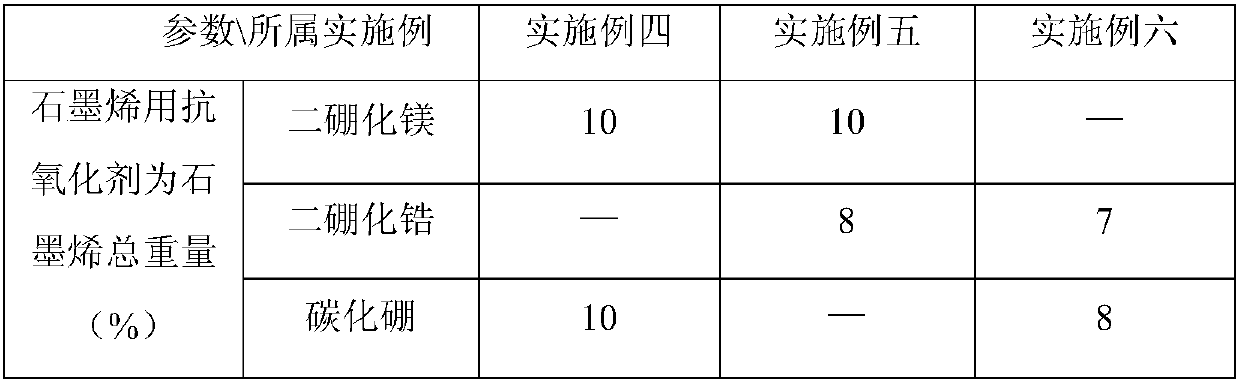

[0054] The following Examples 4-6 use the same preparation method as Example 1 to Example 3, and the specific composition of each component is shown in Table 1.

[0055] Table 1 embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com