Method for producing waterless taphole mix for blast furnace from high-alumina waste refractory materials

A technology of waste refractory materials and anhydrous taphole mud, which is applied in the field of blast furnace anhydrous taphole mud, which can solve the problems of inability to ensure the smooth operation of the blast furnace, leakage of molten iron from the melting of blast furnace mud, and reduce the cost of blast furnace mud, so as to achieve excellent slag resistance, Emission reduction and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

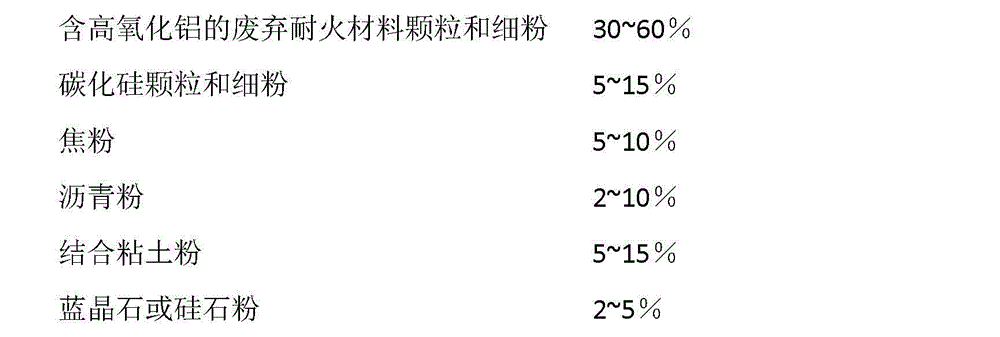

[0032] The waste refractories used are used blast furnace iron channel materials, which are processed into granules and fine powders. The mass ratio content of used blast furnace iron channel materials is 70.32% for alumina, 14.47% for silicon carbide and 2.85% for carbon. . It completely replaces the brown corundum and Youte bauxite raw materials in the original gun mud. Because it contains silicon carbide and carbon, it partially replaces silicon carbide and coke powder. The mass percentage ratio of each component is as follows:

[0033]

[0034] After accurately weighing various ingredients, add a special wet mill with heating function for gun mud and mix for 5 minutes until all raw materials are evenly distributed. First, add a binder with a mass ratio of 80%, and mill the mud within the range of 70°C. 20 minutes, then add the remaining binder with a mass ratio of 20%, and continue to grind the mud for 15 minutes to discharge; after discharging, put it into a high-press...

Embodiment 2

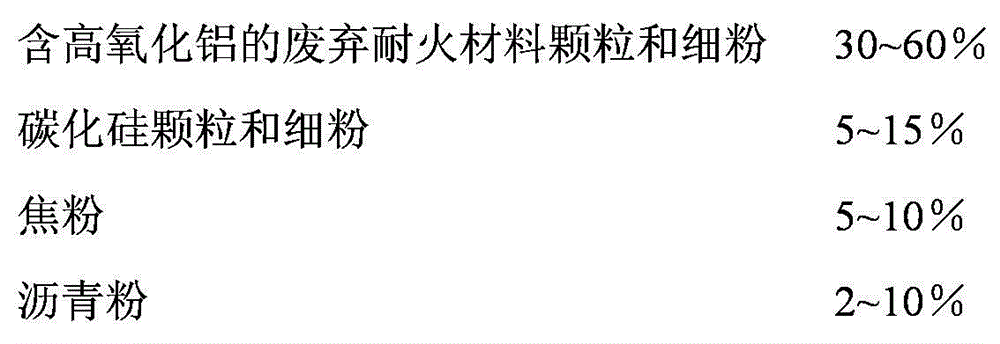

[0039] The waste refractory material used is the used ladle slide, which is processed into granules and fine powder. The used ladle slide has a mass ratio of alumina of 65.27% and a carbon content of 6.85%. Most of it replaces brown corundum, and part of it replaces coke powder. The mass percentage ratio of each component is as follows:

[0040]

[0041] After accurately weighing various ingredients, add a special wet mill with heating function for gun mud and mix for 7 minutes until all raw materials are evenly distributed. First, add a binder with a mass ratio of 85%, and mill the mud within the range of 70 ° C. 20 minutes, then add the remaining binder with a mass ratio of 20%, and continue to grind the mud for 15 minutes to discharge; after discharging, put it into a high-pressure extruder to form a cylinder with a diameter of 180mm and a length of 200mm, and seal it with a plastic bag. Put it in a special box or a big bag for clay.

[0042] The physical and chemical tec...

Embodiment 3

[0046] The waste refractory material used is a combination of used ladle seat bricks and used ladle breathable bricks. The used ladle seat bricks have an alumina mass ratio of 88.38%, and the used ladle breathable bricks have an alumina mass ratio of 90.67%. The two are processed into granules and fine powder, all of which replace the raw materials of brown corundum and Youte bauxite in the gun clay, and the mass percentage ratio of each component is as follows:

[0047]

[0048] The added binder is a composite binder, accounting for 12% of the total mass of the ingredients. The composite binder is used after mixing thoroughly with anthracene oil and phenolic resin in a ratio of 4:1.

[0049] After accurately weighing various ingredients, add them to a special wet mill with heating function for gun mud and mix for 6 minutes until all raw materials are evenly distributed. First, add a binder with a mass ratio of 80%, and mill the mud at 60 ° C. The mud milling time is 20 Min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com