A kind of anti-penetration type tundish lightweight coating and preparation method thereof

A tundish and anti-permeation technology, which is applied in the field of monolithic refractory materials, can solve the problems of poor erosion resistance, lower coating refractoriness, serious coating sintering, etc., and achieve excellent sintering resistance and disintegration performance, and service life The effect of long, low melt and less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

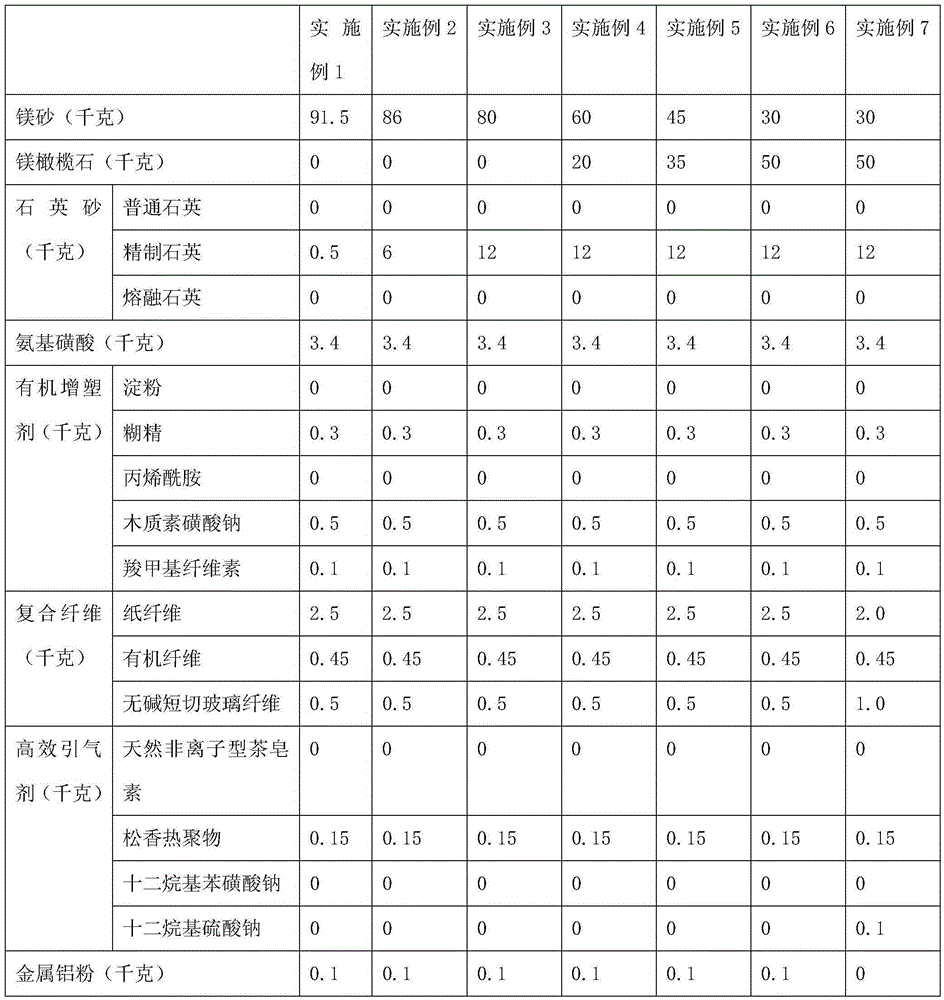

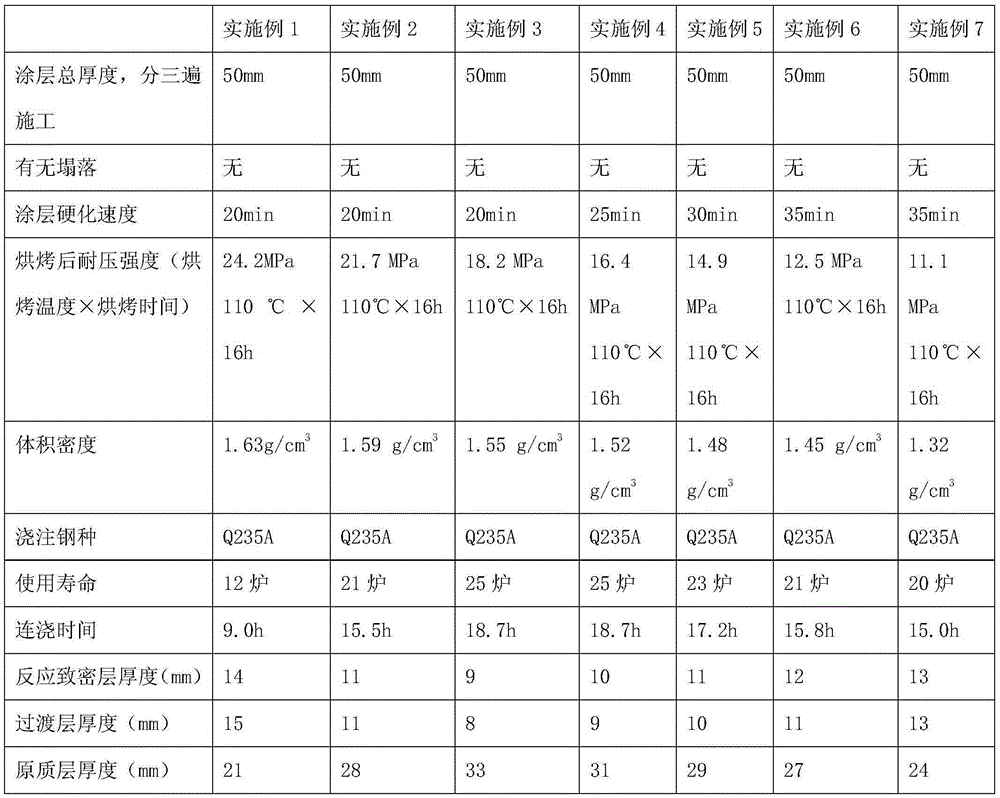

[0028] The preparation method of the anti-penetration type tundish lightweight coating in embodiment 1-embodiment 7 comprises the steps:

[0029] (1) Embodiment 1-embodiment 7 prepares raw material according to table 1;

[0030] (2) Add composite fibers to the main raw materials of magnesia and / or forsterite, and stir vigorously in a forced mixer for 5-10 minutes to eliminate fiber clumping;

[0031] (3) Then add quartz sand, sulfamic acid, organic plasticizer, high-efficiency air-entraining agent and metal aluminum powder and mix and grind for 10-15 minutes;

[0032] (4) During on-site construction, directly add 25wt% water of the total mass of the raw materials in step (1) and stir evenly, then manually apply or machine spray, and can also be combined with other coatings for internal and external composite construction as required.

Embodiment 1

[0035] In Example 1:

[0036] The particle gradation composition of the magnesia is: 24.705 kg of particles with a particle size greater than 0.5 mm and less than or equal to 1 mm, 21.045 kg of particles with a particle size greater than 0.2 mm and less than or equal to 0.5 mm, and 21.045 kg of particles with a particle size greater than 0.088 mm and less than or equal to 0.2mm particles are 16.47 kg, and particles with a particle size less than or equal to 0.088 mm are 29.28 kg. The weight percentage of MgO in the magnesia is 93wt%.

[0037]The particle gradation composition of the quartz sand is: 0.125 kg of particles with a particle size greater than 0.2 mm and less than or equal to 0.5 mm, 0.15 kg of particles with a particle size greater than 0.088 mm and less than or equal to 0.2 mm, and 0.15 kg of particles with a particle size of less than or equal to 0.088 mm The pellets are 0.225 kg.

[0038] In the sulfamic acid: the mass of particles with particle size less than ...

Embodiment 2

[0039] In Example 2:

[0040] The particle gradation composition of the magnesia is: 23.22 kg of particles with a particle size greater than 0.5 mm and less than or equal to 1 mm, 19.78 kg of particles with a particle size greater than 0.2 mm and less than or equal to 0.5 mm, and 19.78 kg of particles with a particle size greater than 0.088 mm and less than or equal to 0.2mm particles are 15.48 kg, and particles with a particle size less than or equal to 0.088 mm are 27.52 kg. The weight percentage of MgO in the magnesia is 93wt%.

[0041] The particle gradation composition of the quartz sand is as follows: 1.5 kg of particles with a particle size greater than 0.2 mm and less than or equal to 0.5 mm, 1.8 kg of particles with a particle size greater than 0.088 mm and less than or equal to 0.2 mm, and 1.8 kg of particles with a particle size of less than or equal to 0.088 mm The pellets are 2.7 kg.

[0042] In the sulfamic acid: the mass of particles with particle size less th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com