Cave foundation reinforcing method

A technology of foundation reinforcement and karst caves, which is applied in the direction of infrastructure engineering, construction, soil protection, etc., can solve the problems of increasing construction difficulty, increasing construction cost, and large grouting range, so as to shorten the construction period, save construction cost, The effect of less disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

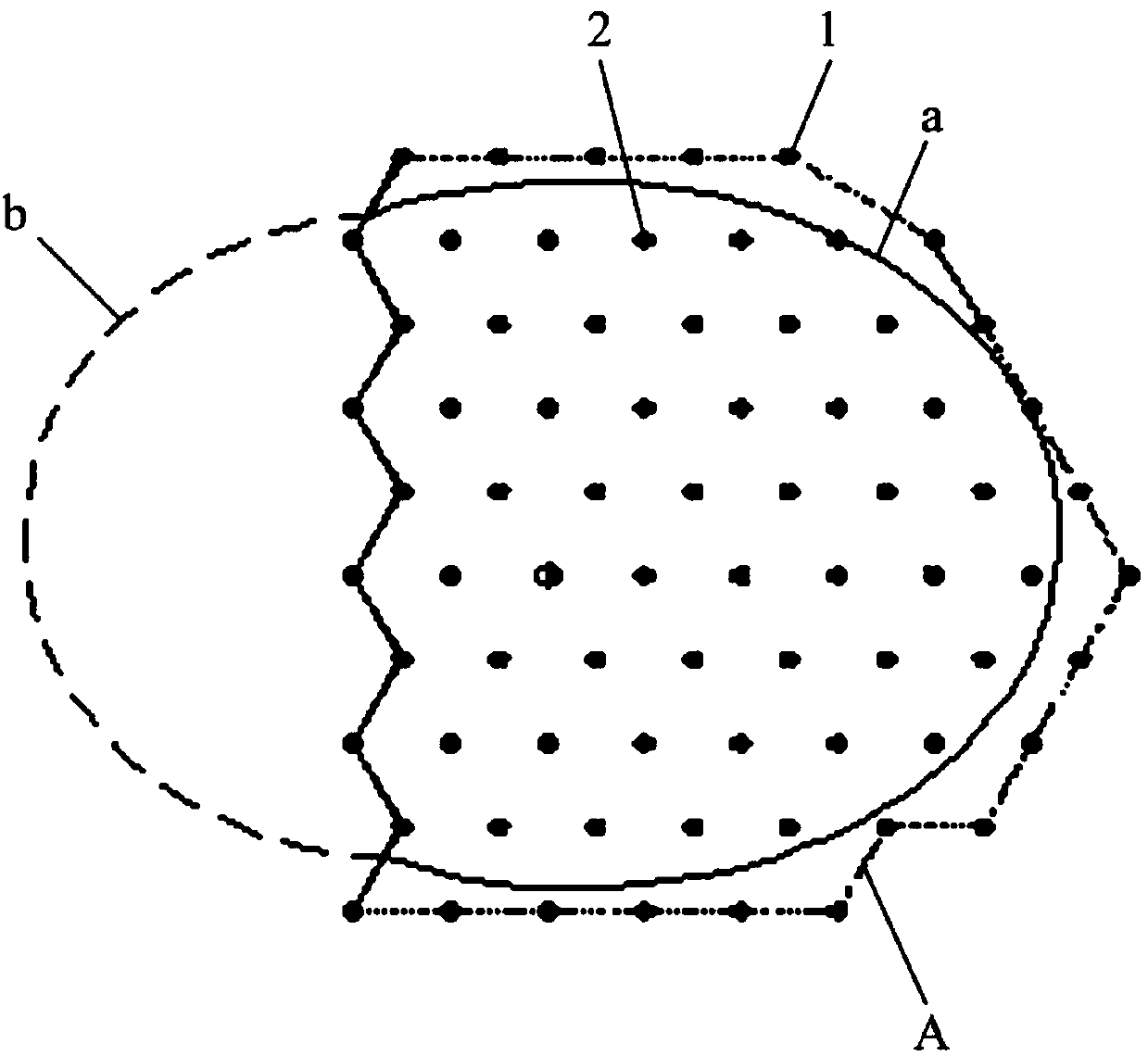

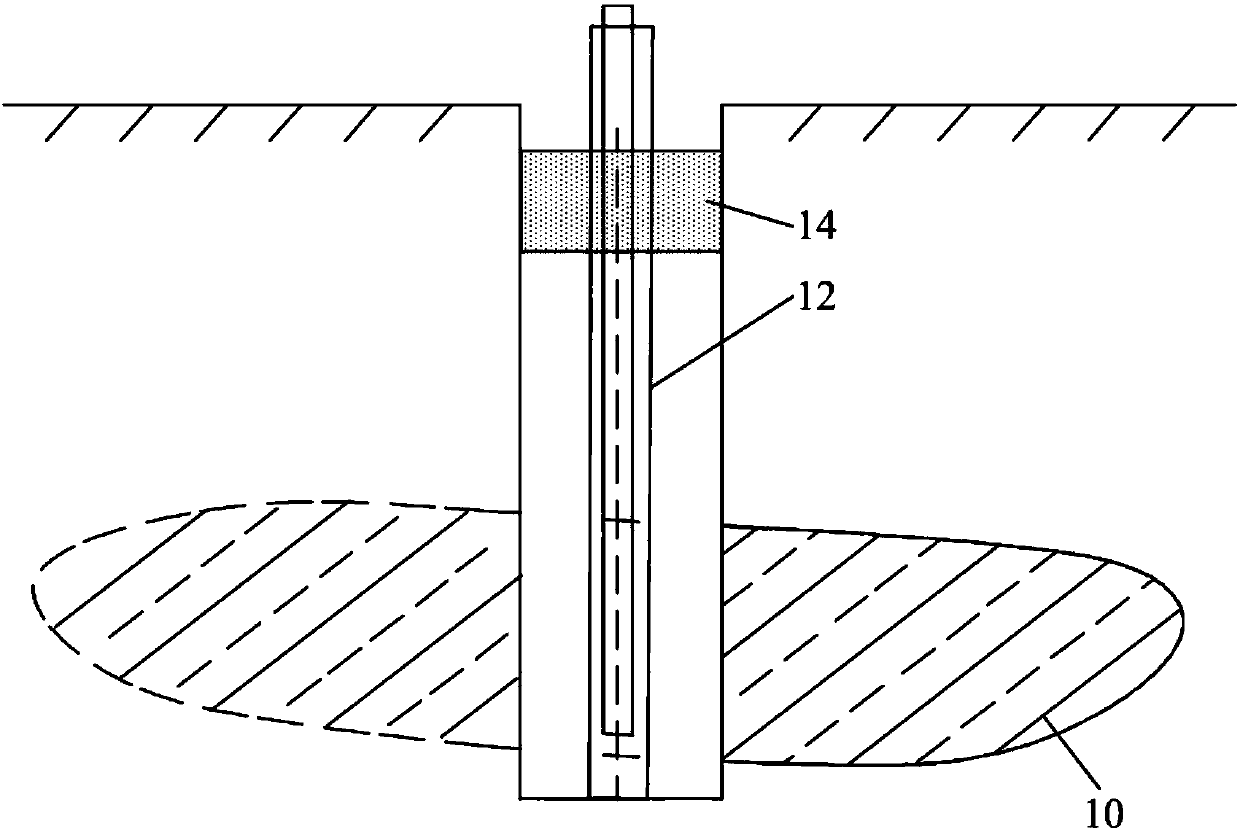

[0021] Embodiment 1: This embodiment takes a construction project located in a karst area as an example. There are irregular karst caves 10 that affect construction safety under the construction area of the underground comprehensive pipe gallery. Therefore, the underground karst caves 10 located under the foundation pit need to be reinforced. processing, combined below figure 1 and figure 2 Illustrate a kind of karst cave ground reinforcement method of the present invention, concrete steps are as follows:

[0022] S1: After the foundation pit excavation, support, and precipitation are completed, and before the construction of the main structure of the underground comprehensive pipe gallery starts, the geological survey method and geophysical prospecting are used on site to infer the distribution characteristics of the caves 10, including the size, scope, location and number of the caves 10, etc. The stability of karst cave 10 is evaluated by the roof collapse self-filling ...

Embodiment 2

[0033] Embodiment 2: different from Example 1, cement: water: water glass mixing ratio (mass ratio)=1:1:0.5, water glass modulus m=2.4, field test draws the initial setting time of double liquid slurry ( min)=30, fluidity (mm)=400.

Embodiment 3

[0034] Embodiment 3: Different from Embodiment 1 or 2, cement: water: water glass mix ratio (mass ratio)=1: 1.2: 0.4, water glass modulus m=3, field test draws initial setting time (min) =12, fluidity (mm) =360.

[0035] After the above-mentioned karst cave 10 foundation reinforcement treatment meets the design requirements, carry out slope support and install steel mesh sheets, and at the same time ensure that the foundation pit is in a stable state during construction. After the foundation pit foundation treatment is completed, lay waterproof membranes on the foundation and bind the bottom plate Reinforcement and pouring of concrete, and then installation of side wall and roof reinforcement and pouring of concrete to complete the construction of the underground comprehensive pipe gallery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com