Kaolin-based curing agent as well as preparation method and application thereof

A kaolin and curing agent technology, applied in the field of inorganic chemical industry, can solve the problems of limited application and promotion, high manufacturing and use costs, and achieve the effects of fewer types of raw materials, improved mechanical properties, and improved bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides the preparation method of kaolin-based solidifying agent described in above-mentioned technical scheme, comprises the following steps:

[0034] (1) Preheating after mixing kaolin and water to obtain a suspension;

[0035] (2) Mix the suspension obtained in the step (1) with the phosphoric acid solution to react to obtain a kaolin-based curing agent.

[0036] In the invention, kaolin and water are mixed and then preheated to obtain a suspension.

[0037] In the present invention, when the particle size of the kaolin does not meet the requirement, the present invention preferably ball mills the kaolin before mixing. In the present invention, there is no special limitation on the specific operation of the ball milling. It is sufficient to adopt the conventional ball milling process in the field to make the particle size of the kaolin meet the requirements.

[0038] In the present invention, the mixing is preferably performed under stirring co...

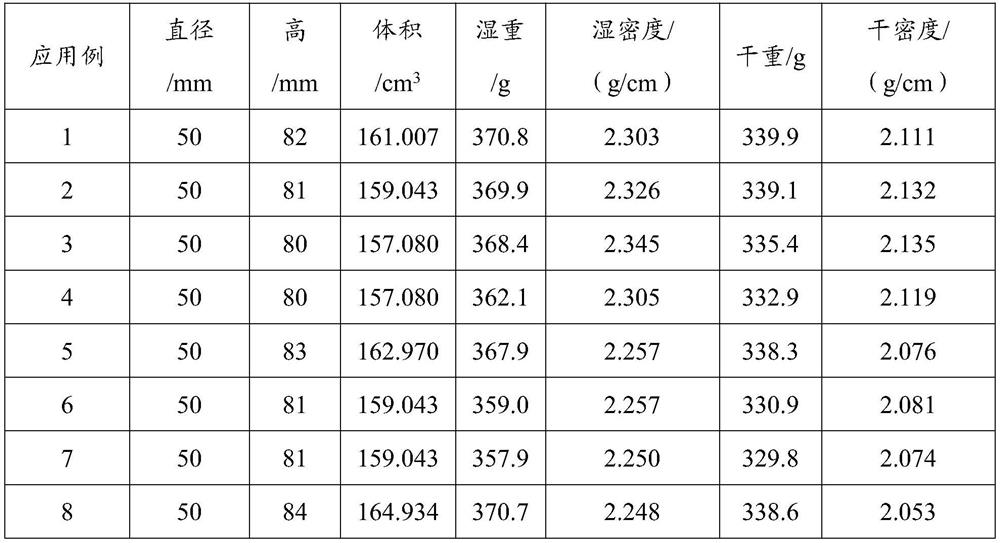

Embodiment 1

[0062] A kaolin-based curing agent, prepared from the following raw materials in parts by mass: 100 parts of kaolin, 80 parts of phosphoric acid solution, and 150 parts of water; the kaolin is kaolin concentrate, and the Al 2 o 3 Grade ≥ 35%; the mass percentage of the kaolin with a particle size of -0.074mm ≥ 95%; the mass concentration of the phosphoric acid solution is 72%;

[0063] The preparation method of described kaolin-based curing agent consists of the following steps:

[0064] (1) After kaolin and water are stirred and mixed, preheat to 110°C by means of electromagnetic heating to obtain a suspension;

[0065] (2) Heating the phosphoric acid solution to 50°C by means of pipeline heating, and then adding the phosphoric acid solution dropwise to the suspension in the step (1) under stirring conditions to react to obtain a kaolin-based curing agent; the reaction The temperature is 110°C, and the reaction time is 75-90min.

Embodiment 2

[0067] A kaolin-based curing agent, prepared from the following raw materials in parts by mass: 100 parts of kaolin, 95 parts of phosphoric acid solution, 150 parts of water, and other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com