A kind of lightweight tundish working lining and preparation method thereof

A tundish and working lining technology, applied in the field of refractory materials, can solve the problems of excessive consumption of resources, slow erosion of volume density, etc., and achieve the effect of improving anti-erosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

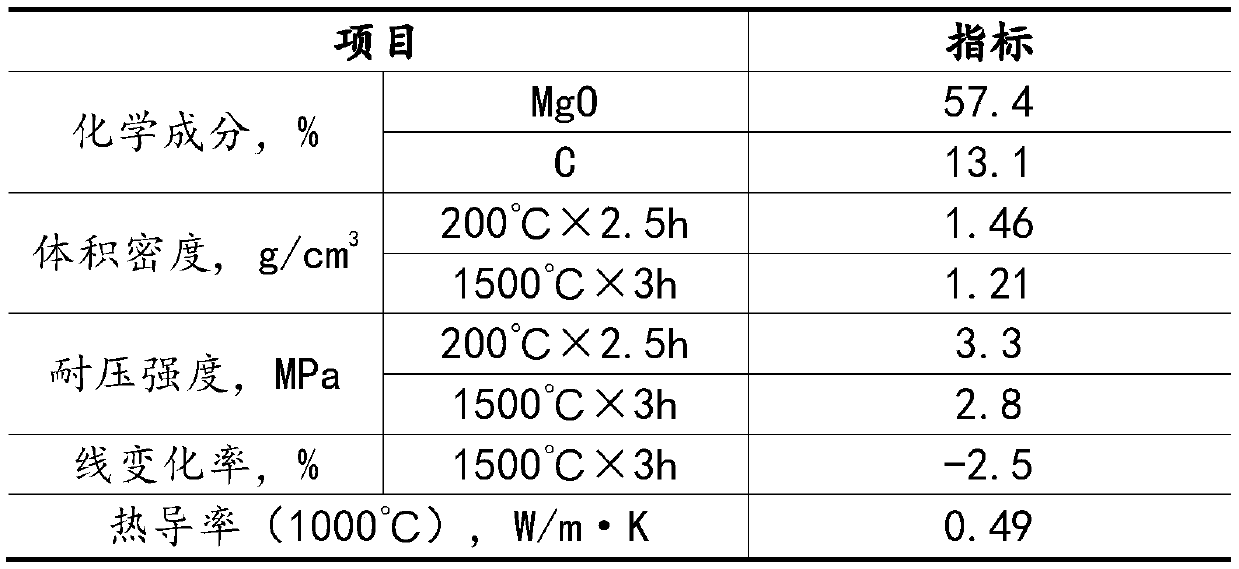

[0051] The intermediate working lining ingredients are composed of the following components: 60 kg of waste magnesite carbon bricks, 25 kg of magnesite tailings, 5 kg of sintered corundum, 1.1 kg of newspaper fiber, 5.3 kg of phenolic resin, and pentahydrate silica The sodium is 1.5 kg, the silicon powder is 0.7 kg, and the metal aluminum powder is 1.4 kg.

[0052] The said waste magnesia carbon brick particle size gradation is: the waste magnesia carbon brick with a particle size greater than or equal to 0.2mm and less than or equal to 0.5mm contains 45wt% of the total mass of the waste magnesia carbon brick, and the waste with a particle size greater than 0 and less than 0.2mm The content of magnesia-carbon bricks is 55wt% of the total mass of the waste magnesia-carbon bricks; in the waste magnesia-carbon bricks: the content of MgO≥70.0wt% of the total mass of the waste magnesia-carbon bricks, and the content of C≥the total mass of the waste magnesia-carbon bricks 10.0wt%, Al 2...

Embodiment 2

[0066] The intermediate working lining ingredients are composed of the following components: 70 kg of waste magnesite carbon bricks, 13 kg of magnesite tailings, 6.5 kg of fused white corundum, 1.9 kg of newspaper fiber, and 0.3 of alkali-free chopped glass fiber Kg, phenolic resin is 1.0 kg, magnesium sulfate heptahydrate is 0.5 kg, silica powder is 3.0 kg, aluminate cement is 1.7 kg, and metal aluminum powder is 2.1 kg.

[0067] The said waste magnesia carbon brick particle size gradation is: the waste magnesia carbon brick with a particle size greater than or equal to 0.2mm and less than or equal to 0.5mm contains 60wt% of the total mass of the waste magnesia carbon brick, and the waste with a particle size greater than 0 and less than 0.2mm The content of magnesia-carbon bricks is 40wt% of the total mass of waste magnesia-carbon bricks; in the said waste magnesia-carbon bricks: the content of MgO≥70.0wt% of the total mass of the waste magnesia-carbon bricks; the content of C≥t...

Embodiment 3

[0082] The intermediate working lining ingredients are composed of the following components: In this example, on the basis of the ingredients of Example 1, an admixture is added. The addition amount of the admixture is 1.5wt% of the total mass of the ingredients in Example 1. With a particle size of 1-50nm, the additive is a composite of zircon tailings, waste chrome bricks and potash feldspar. The mass ratio of zircon tailings, waste chrome bricks and potash feldspar is 4:2:1.

[0083] In this embodiment, the light-weight tundish working lining is prepared by dry vibration molding, which specifically includes the following steps:

[0084] ① Prepare raw materials according to the above-mentioned light-weight tundish working lining;

[0085] ②Pour the waste magnesite carbon bricks, the magnesite tailings, and the sintered corundum into a forced mixer according to the raw material ratio in ① to mix evenly;

[0086] ③Add the newspaper fiber according to the ratio of raw materials in ①, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com