Fuel cell bipolar plate based on carbon nanotube film composite material and preparation method and application thereof

A carbon nanotube film and fuel cell technology, which is applied in fuel cells, applications, and other household appliances, can solve the problems of difficult promotion, long process cycle, and high production cost, and achieve excellent electrical conductivity, improved corrosion resistance, and air tightness Sexuality and mechanical performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] This example is used to illustrate the preparation of carbon nanotube films by floating catalytic method.

[0083] The main devices used are as follows: carrier gas system, including gas circuit and flow controller; carbon source / catalyst propulsion system, including micro injection pump and carbon source / catalyst mixed solution; high temperature tube furnace, equipped with 99 pure corundum tubes, the maximum The temperature is 1600°C, the length of the constant temperature zone is 20cm; and exhaust gas system.

[0084] Under the protection of argon, the mixed system of carbon source ethanol, thiophene and catalyst ferrocene (the molar ratio of ethanol, thiophene and ferrocene is 1:1:0.05) is mixed at a speed of 0.15ml / min through the carbon source / catalyst propulsion system Inject into a high temperature tube furnace at 1300°C. At the other end of the high-temperature tube furnace, a winding device is used to collect the formed carbon nanotube airgel, and 70% ethanol ...

Embodiment 2

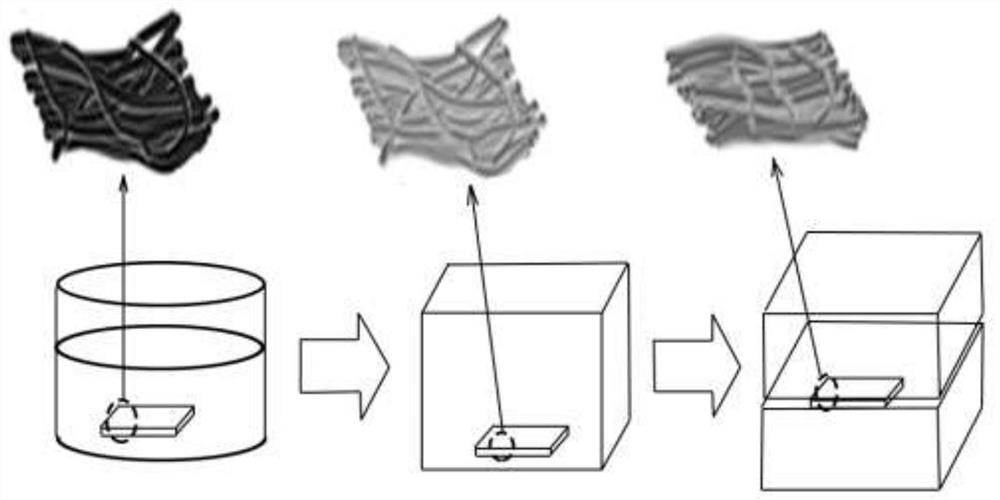

[0087] refer to figure 1 , which shows the fabrication process flow of bipolar plates for fuel cells.

[0088] (1) preparation concentration is the N,N-dimethylformamide dilution of the E51 type epoxy resin of 5% by weight;

[0089] (2) Place the carbon nanotube film prepared in Example 1 in the N,N-dimethylformamide dilution of E51 type epoxy resin and immerse for 2 hours;

[0090] (3) Take out the carbon nanotube film and suck off the excessive diluent on both sides of the carbon nanotube film with a breathable tetrafluorocloth, then place it in a vacuum oven, and perform a vacuum treatment at 80° C. for 0.5 hour, wherein the degree of vacuum is 0.5KPa;

[0091] (4) the carbon nanotube membrane material obtained in step (3) is placed between two flat polytetrafluoroethylene membranes, and placed in a press and cold-pressed under a pressure of 5MPa to obtain cold-pressed carbon The nanotube film material layer has a thickness of about 0.01mm, wherein the cold pressing tempe...

Embodiment 3

[0095] refer to figure 1 , which shows the fabrication process flow of bipolar plates for fuel cells.

[0096] (1) Using polyvinylidene fluoride with a trade name of SOLEF PVDF 5130 purchased from Solvay in the United States to prepare a N,N-dimethylformamide dilution of polyvinylidene fluoride with a concentration of 2% by weight;

[0097] (2) Place the carbon nanotube film prepared in Example 1 in the N,N-dimethylformamide dilution of polyvinylidene fluoride and immerse for 0.5 hours;

[0098] (3) Take out the carbon nanotube film and suck off the excessive diluent on both sides of the carbon nanotube film with a breathable tetrafluorocloth, then place it in a vacuum oven, and perform a vacuum treatment at 50°C for 1 hour, wherein the degree of vacuum is 0.2KPa;

[0099] (4) the carbon nanotube membrane material obtained in step (3) is placed between two flat polytetrafluoroethylene membranes, and placed in a press and cold-pressed under a pressure of 10MPa to obtain the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com