Heat conduction PA6/water three-phase flow closed type gravity-assisted heat pipe

A gravity heat pipe and flow closed technology, which is applied in the field of new-type three-phase flow closed gravity heat pipes, can solve the problems of wall scaling and heat transfer performance decline, and achieves prevention of scaling, less equipment investment, and major social benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

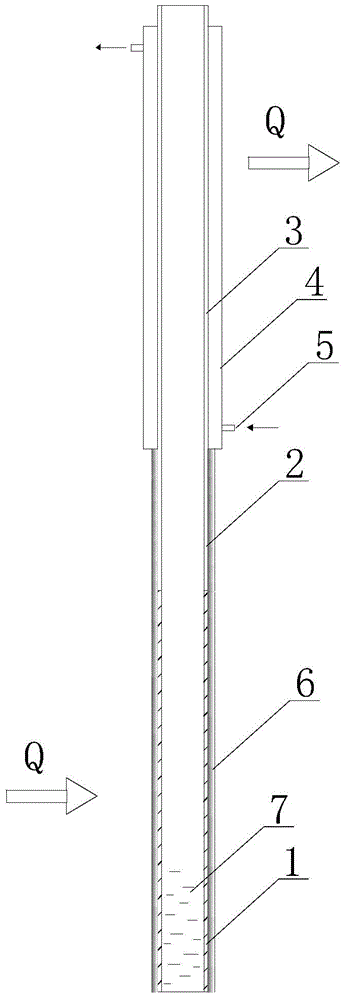

[0020] Such as figure 1 As shown, this embodiment discloses a new type of heat-conducting PA6 / water three-phase flow closed gravity heat pipe with a new type of working fluid. It consists of three parts. The outer diameter of the gravity heat pipe is 42.3mm, the wall thickness is 3.5mm, and the total length is 1635mm. The length of the evaporation section 1 is 665mm, the length of the adiabatic section 2 is 235mm, and the length of the condensation section 3 is 735mm. The evaporating section 1 is heated by resistance wire, the evaporating section 1 and the adiabatic section 2 are wrapped with an insulating layer 6 , the condensing section 3 is cooled by a cooling water jacket 4 , and is provided with a cooling water inlet 5 .

[0021] The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com