A microchannel heat exchanger with staggered inner groove structure and its manufacturing method

A technology of micro-channel heat exchanger and manufacturing method, applied in the direction of heat exchanger type, indirect heat exchanger, heat exchange equipment, etc., to achieve the effect of increasing heat transfer area, enhancing heat transfer, and enhancing boiling heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below through specific embodiments.

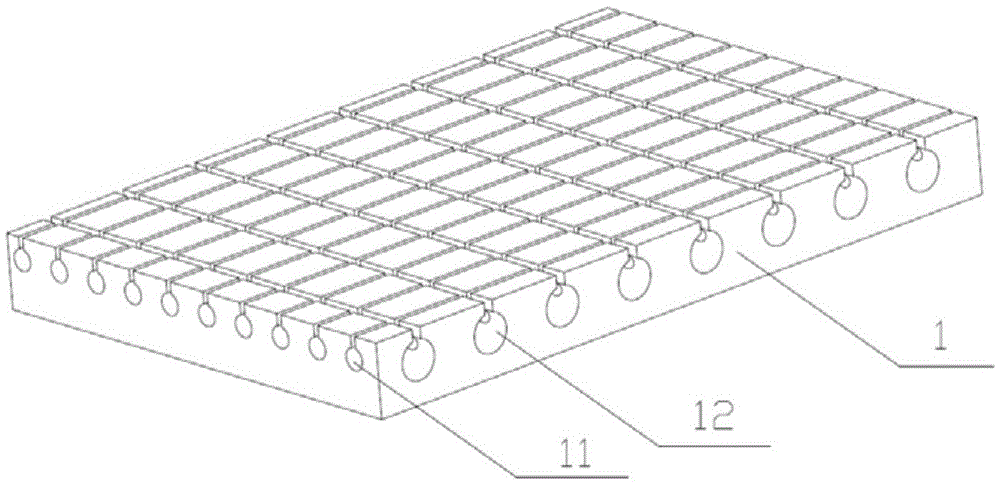

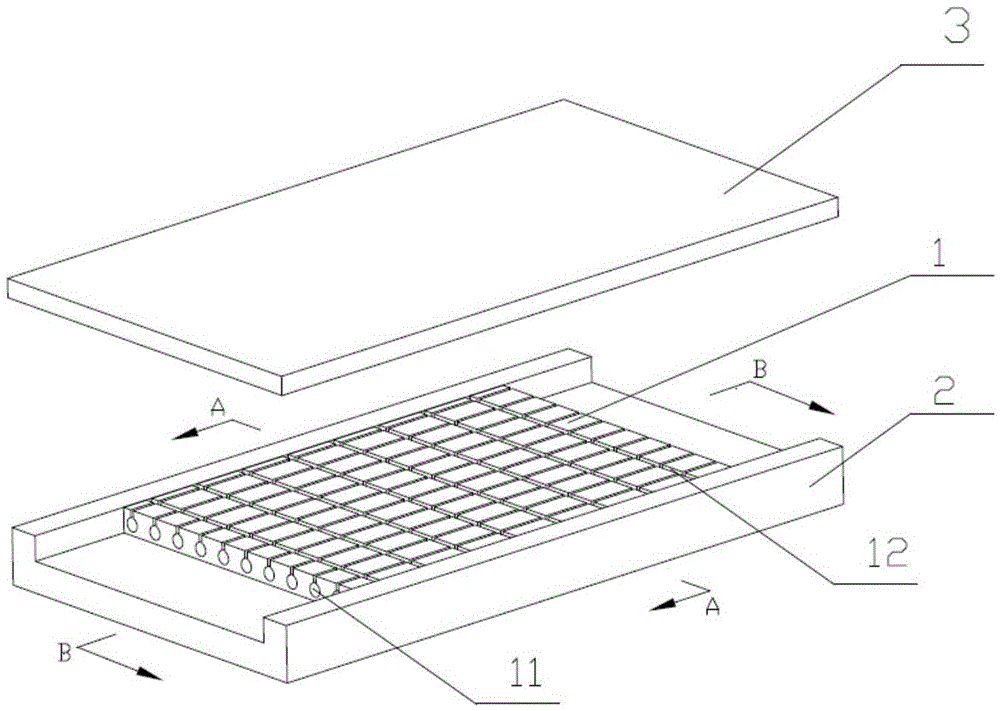

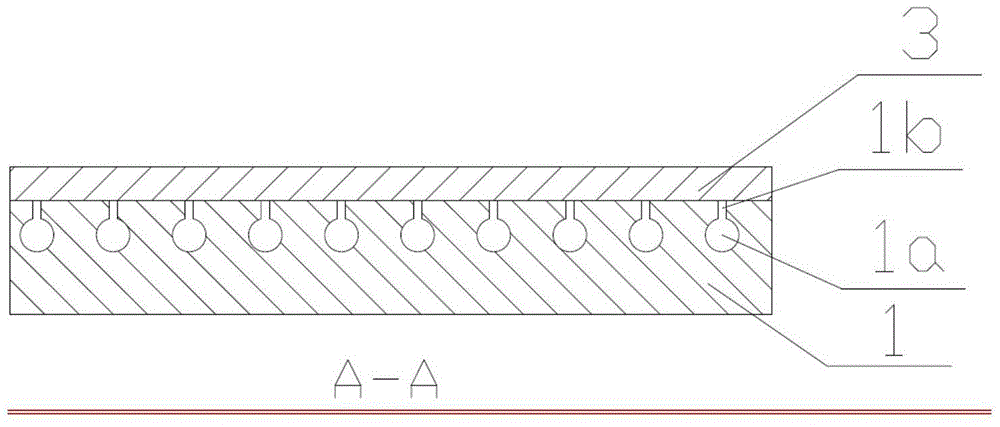

[0032] A microchannel heat exchanger with staggered inner groove microchannel structure, such as Figure 1 to Figure 4 As shown, it includes a metal microchannel substrate 1 , inlet and outlet channel chambers 2 and heat-resistant glass 3 . The substrate 1 includes a plurality of longitudinal microchannels 11 parallel to the flow direction of the coolant and spaced apart from each other, and a plurality of transverse microchannels 12 perpendicular to the longitudinal microchannels 11 and spaced apart from each other. The longitudinal microchannels 11 and the transverse microchannels 12 form a criss-cross microchannel array. Both the longitudinal microchannel 11 and the transverse microchannel 12 are in the shape of inner grooves, which include an embedded groove body 1a located inside the substrate 1 and a slit 1b forming the opening of the substrate 1, the embedded groove body 1a and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com