High-efficiency gravity heat pipe and manufacturing method thereof

A gravity heat pipe, high-efficiency technology, applied in the field of gravity tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

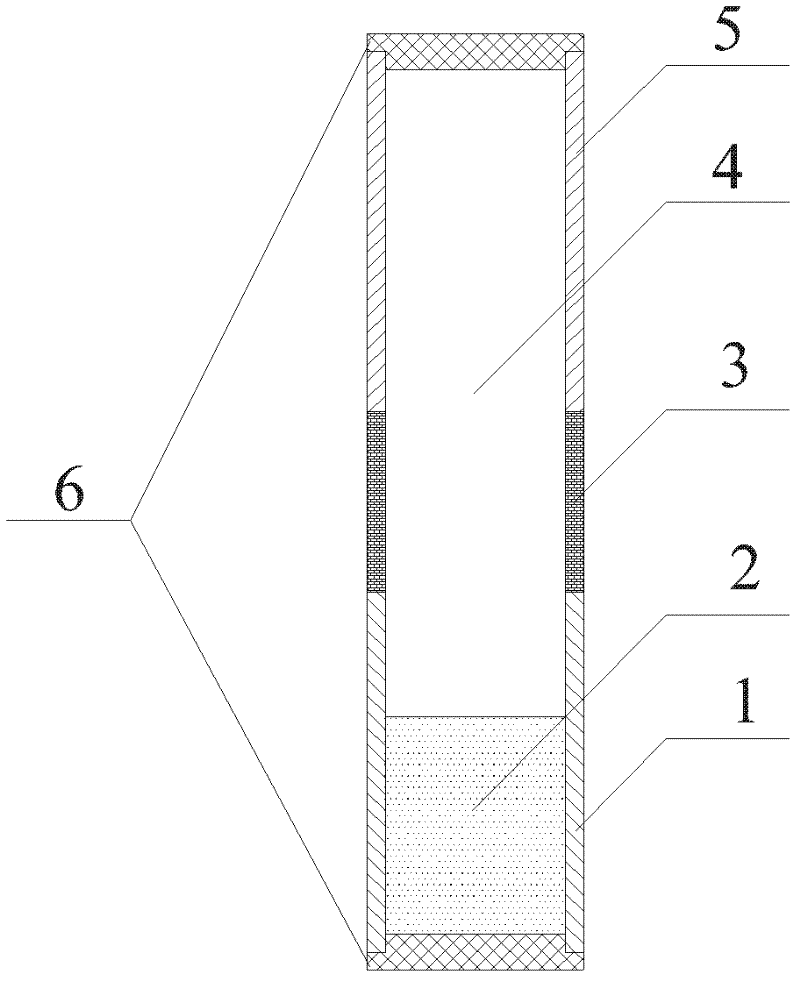

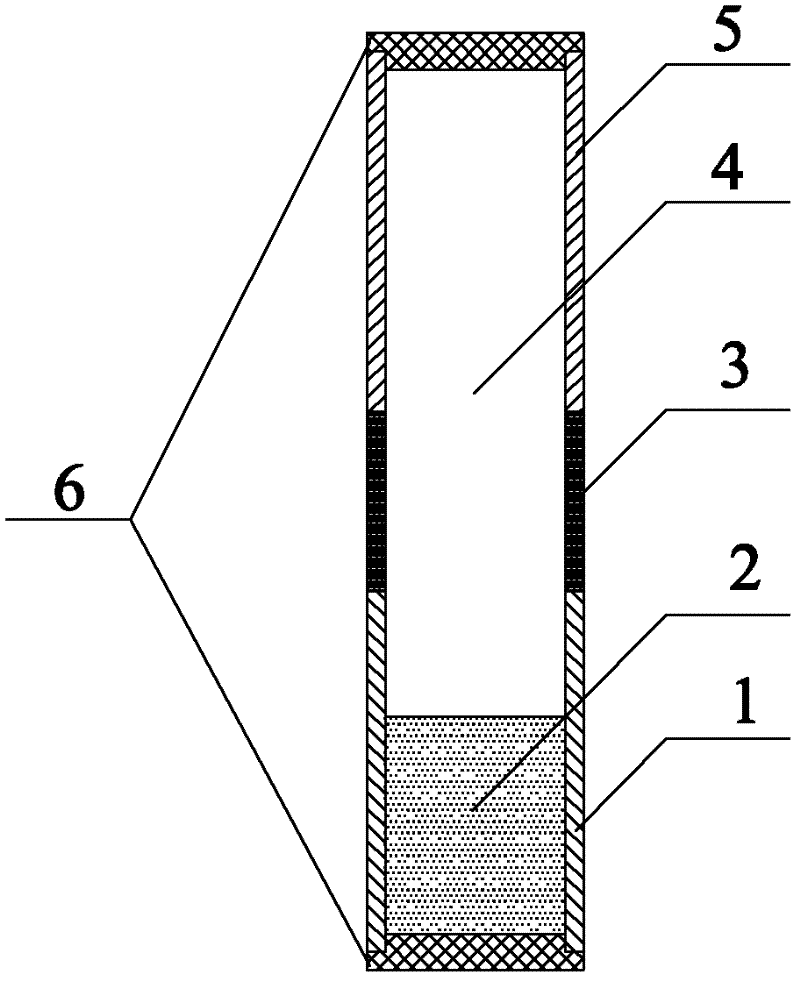

[0023] Please see attached figure 1 and 2 , a high-efficiency gravity heat pipe, which includes three parts: an evaporating section 1, an adiabatic section 3 and a condensing section 5, and the adiabatic section 3 is located between the evaporating section 1 and the condensing section 5.

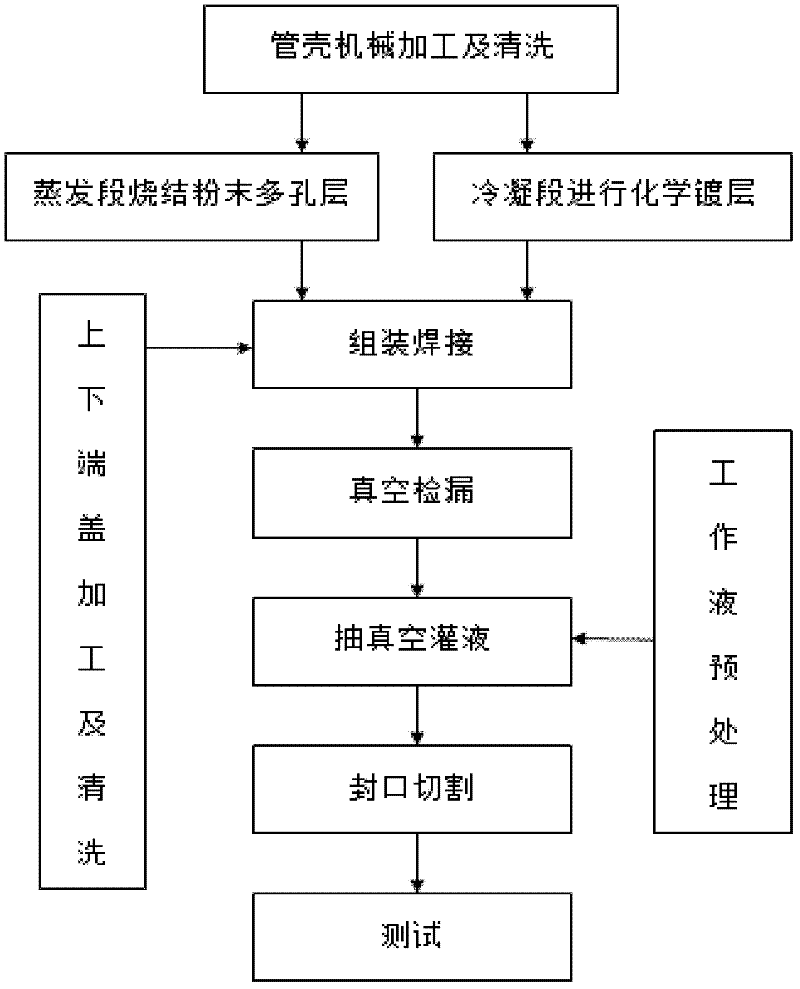

[0024] A high-efficiency gravity heat pipe is a closed structure consisting of a shell and an end cap 6. The inside of the pipe is under negative pressure and filled with a working medium 2. A porous layer of metal powder is sintered on the inner surface of the heat pipe evaporation section and chemically carried out in the condensation section. Plating, the specific steps are:

[0025] (1) Coat the mixed slurry of metal powder and binder on the inner wall of the heat pipe evaporation section, dry it, enter it into a high-temperature sintering furnace for sintering, and take it out of the furnace after cooling, that is, the inner surface of the heat pipe evaporation section is a porous laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com