A block-type enhanced boiling heat transfer microstructure and its manufacturing method

A technology of enhancing boiling and partitioning, applied in indirect heat exchangers, lighting and heating equipment, semiconductor devices, etc., to achieve the effect of dense internal microstructure, high heat flux density, and improved heat exchange performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

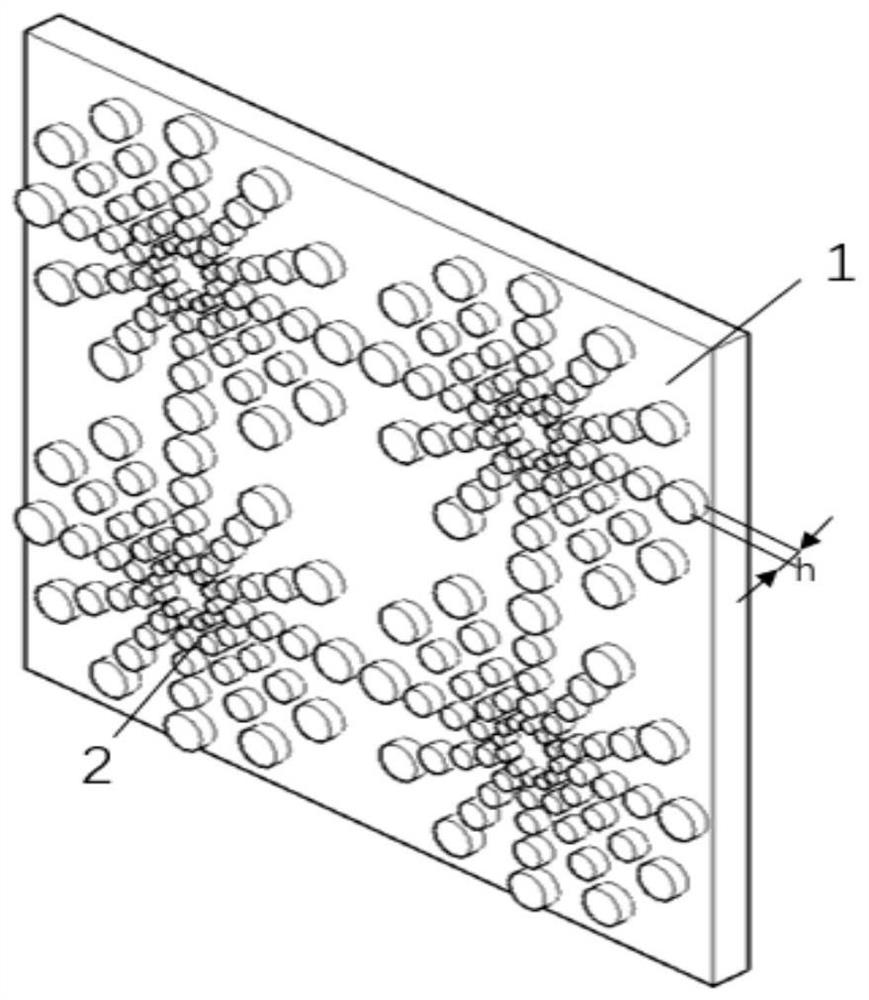

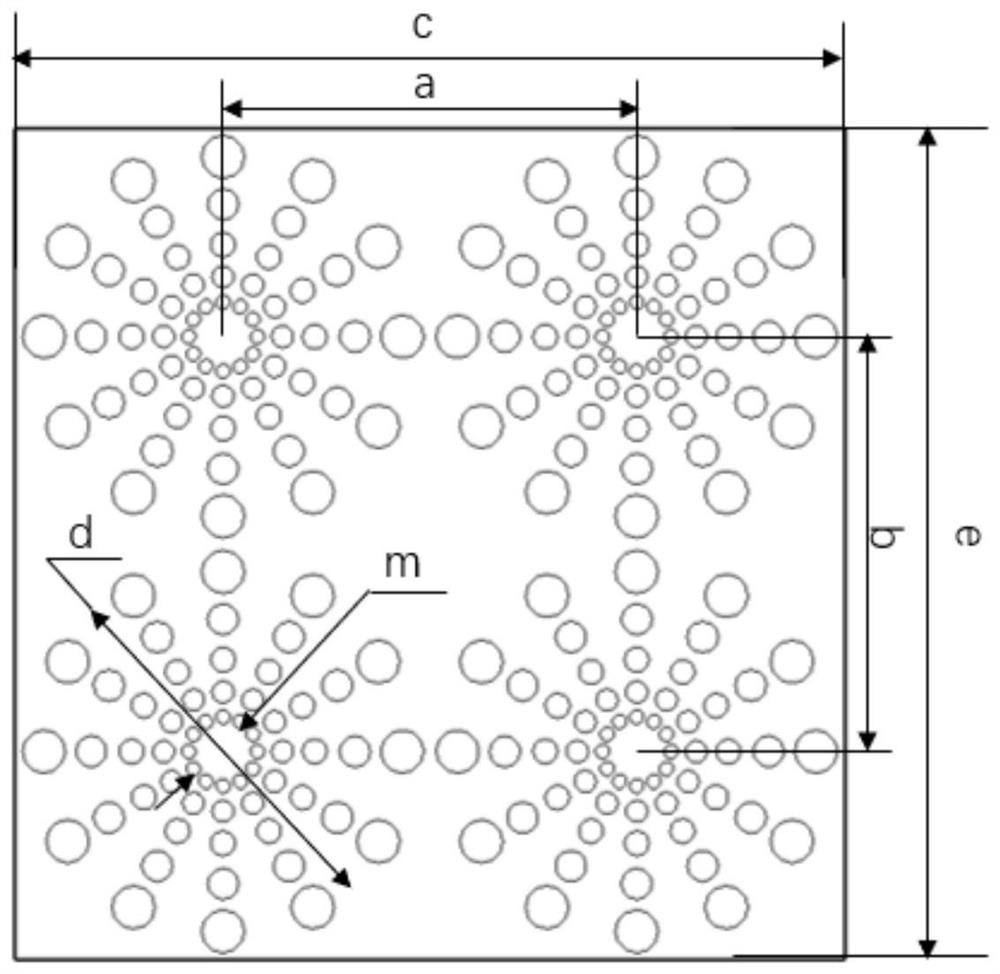

[0029] see figure 1 and figure 2 , a block-type enhanced boiling heat transfer microstructure, including a heat dissipation plate 1 on the heat exchange surface, a plurality of circular block units 2 are arranged on the heat dissipation plate 1, and each circular block unit 2 is composed of several circles of microstructures. Composed of pillars, the block units 2 are distributed on the cooling plate 1 in a square array, and the length c of the cooling plate 1 is equal to the width e. Each block unit 2 is exactly the same as an element of the array, and the number of rows and columns of the array are equal, the spacing between adjacent block units 2 is equal, and the array can be filled with the cooling plate 1, wherein the block unit 2 The number ranges from 4 to 16, the diameter d of each block unit 2 is 0.25mm-10mm, the distance between adjacent block units 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com