Intelligent foam metal reinforced boiling heat transfer cooling device

A foamed metal, enhanced boiling technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problem of not having a good solution, reducing heat exchange area and thermal conductivity, increasing bubble flow resistance, etc. The effect of condensation, reducing surface energy and improving heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

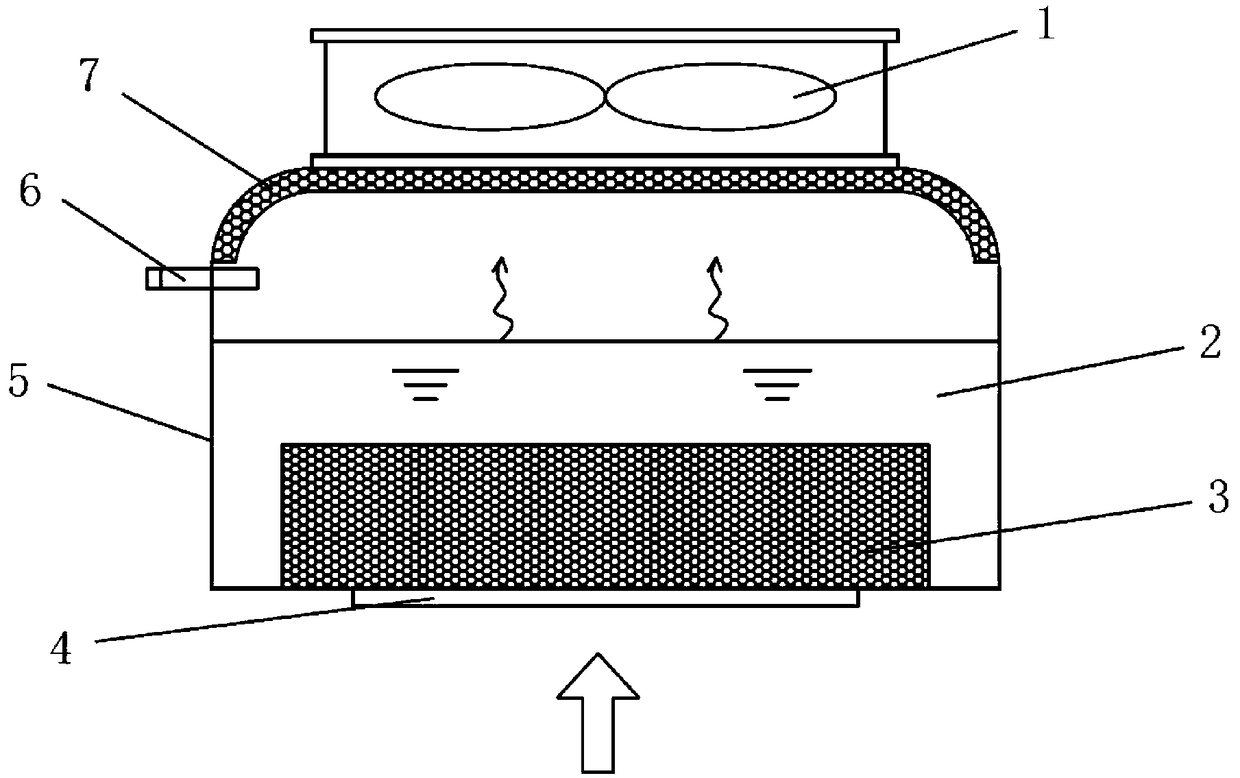

[0031] An intelligent foamed metal enhanced boiling heat exchange cooling device, comprising a sealed cavity 5 containing a refrigerant 2 inside the sealed cavity 5, the underlying smart foamed metal 3 is fixed on the inner surface of the bottom of the sealed cavity 5 and immersed in the cooling In the working fluid 2, a top layer of metal foam 7 is fixed on the inner surface of the top of the sealed cavity 5, a conduit 6 is arranged on the upper end of the side wall of the sealed cavity 5, and a fan 1 is arranged on the outer surface of the top of the sealed cavity 5.

[0032] Such as figure 1 As shown, the sealed cavity 5 is a square cavity, the top corner of the sealed cavity 5 exists in the form of a curved surface, and the bottom surface of the sealed cavity 5 is a plane; the sealed cavity 5 is welded by a metal plate, and the metal plate material can be copper, aluminum or other metals; the sealed chamber 5 is 50-200mm long, 50-200mm wide, and 50-80mm high.

[0033] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com