A multi-scale enhanced boiling functional surface and composite preparation method

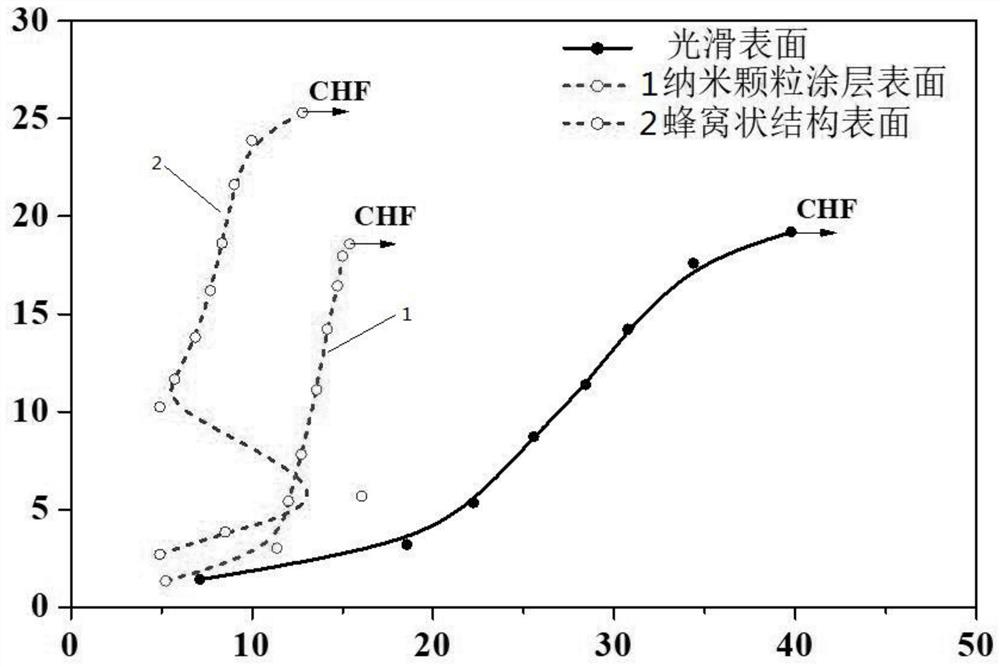

A technology to enhance boiling and heat transfer surfaces, applied in heat exchange equipment, lighting and heating equipment, coatings, etc., can solve the problems of stability, cost, and feasibility limitations of large-scale preparation, and achieve the improvement of critical heat flux density, preparation The method is simple and easy, and the effect of enhancing the liquid absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] (1) Metal surface treatment: select a copper block with a diameter of 12mm, and polish the surface with 220 mesh, 600 mesh, 1000 mesh, 1500 mesh and 2000 mesh sandpaper in sequence. It was then ultrasonically cleaned in acetone and ethanol, respectively, and finally rinsed with deionized water and dried.

[0025] (2) Preparation of nanoparticle solution: purchase copper-zinc alloy nanoparticles with a diameter of about 100 nm, bathe in an ultrasonic water bath for 5 hours according to the ratio, and fully mix the nanoparticles with deionized water to obtain a 20 mg / mL nanoparticle solution.

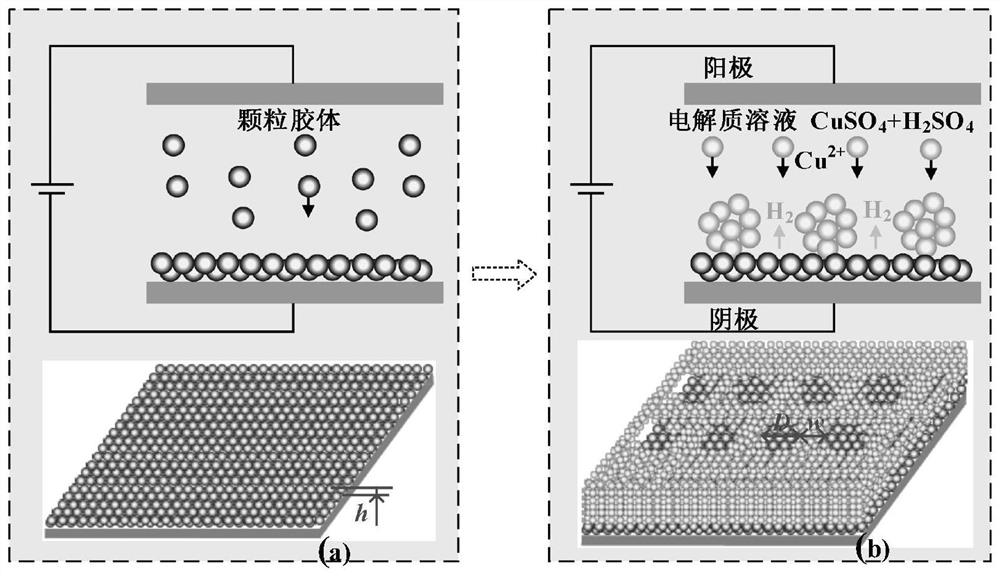

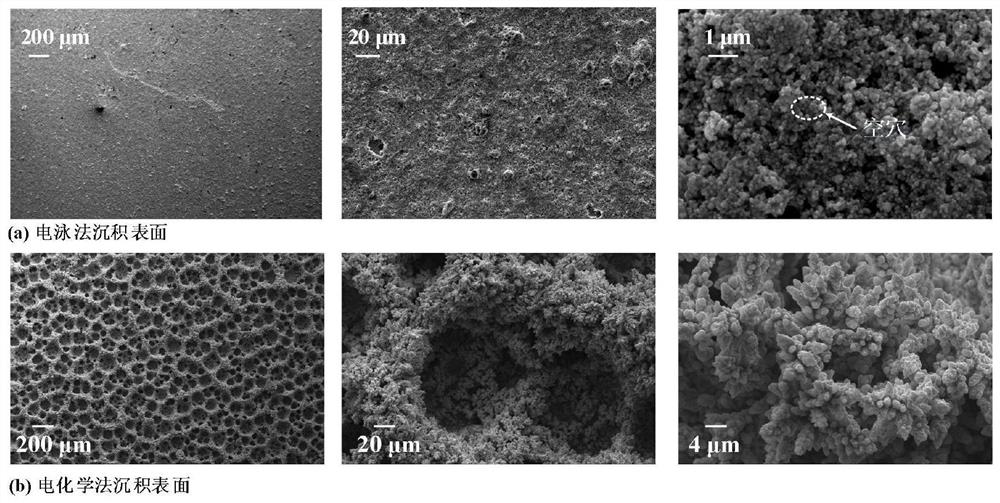

[0026] (3) Preparation of nanoparticle coating: copper-zinc alloy nanoparticles are positively charged, so the treated copper surface is used as a cathode and is paired with another anode. The distance between the two electrodes is about 5 cm, and the mid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com