Heat exchange tube of efficient liquid nitrogen heat exchanger and heat exchanger

A technology of heat exchange tubes and heat exchangers, which can be used in heat transfer modification, heat exchange equipment, lighting and heating equipment, etc., and can solve the problems of low boiling heat exchange efficiency of heat exchange tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with reference to the drawings and specific embodiments.

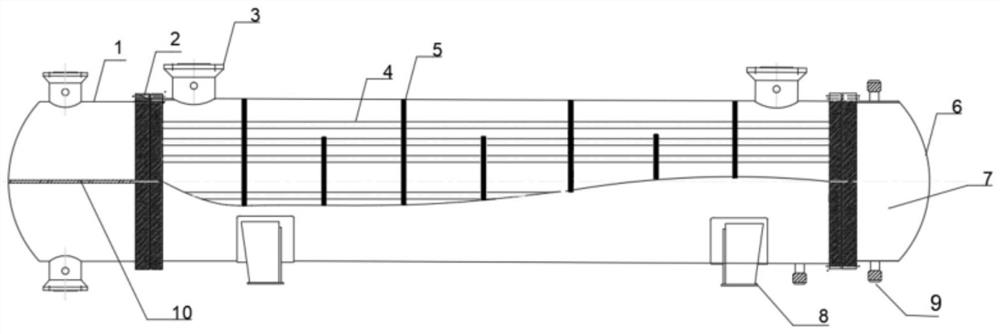

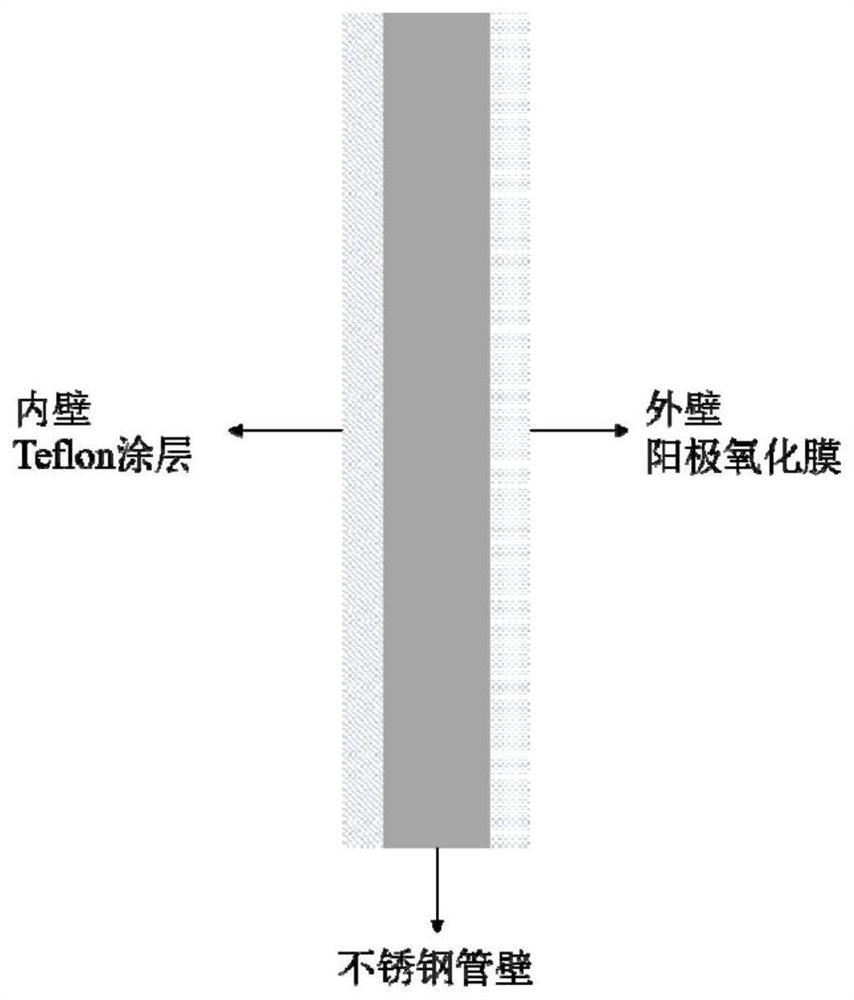

[0039] Such as figure 1 As shown, the shell and tube heat exchanger provided by the present invention includes: a shell 1, a tube box flange 2, a connecting flange 3, a heat exchange tube 4, a baffle 5, a convex head 6, and a head tube box 7. Movable saddle parts 8. Air vent / drain 9 and split-range partition plate 10, with liquid nitrogen through the tube side and cooling medium through the shell side. Among them, the inner surface of the heat exchange tube 4 has a thin thermal resistance layer, and the outer surface has a hydrophobic anodic oxide film, such as figure 2 Shown.

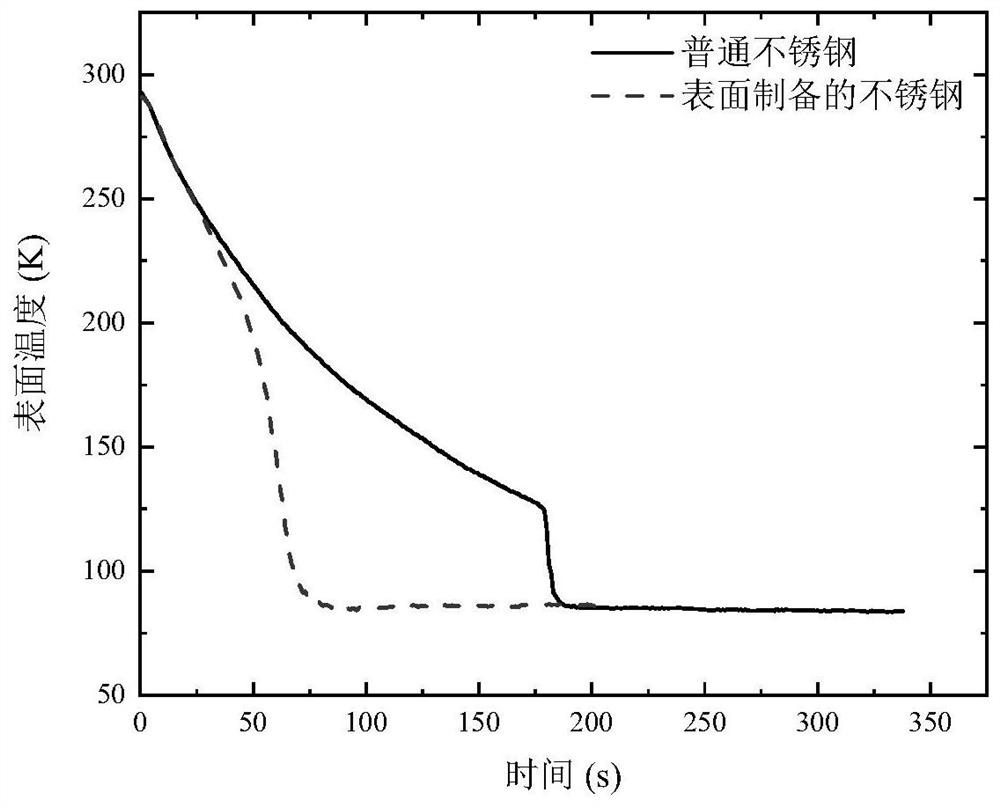

[0040] The characteristic of the hydrophobic surface of the heat exchange tube in this embodiment is that the droplets are difficult to spread on the surface, but form bead-like condensation and quickly fall off, and it is not easy to form a thick frost layer; the characteristic of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com