Flat-plate heat tube with nanometer structure

A flat heat pipe and nanostructure technology, applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of increased heat transfer resistance, large energy consumption, difficult control of sintering quality, etc., and achieve enhanced boiling heat transfer capacity , Improve heat transfer performance, speed up the effect of working medium circulation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

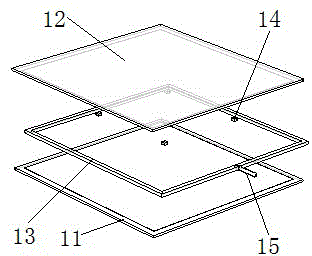

[0020] Such as figure 1 , figure 2 As shown, a nanostructured flat heat pipe of the present invention includes a bottom plate 11, a top plate 12, a support plate 13 between the top plate 12 and the bottom plate 11, and the bottom plate 11, the top plate 12, and the support plate 13 are sealed and connected to form a hollow airtight Cavity; the body of the bottom plate 11 as the evaporation surface of the flat heat pipe is a brass plate, and the inner surface of the bottom plate 11 is covered with a copper oxide film formed by electrochemical replacement with super-hydrophilic properties of nanostructure; as the condensation of the flat heat pipe The body of the top plate 12 is a brass plate. The inner surface of the bottom plate 12 is covered with a nanostructured electroplated nickel layer with superhydrophobic properties. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com