Containment built-in efficient heat exchanger adopting double-wheel double-blade hybrid power air suction

A composite power and containment technology, applied in the field of high-efficiency heat exchangers built into containment, can solve problems such as the large influence of condensation heat transfer capacity, and achieve the effects of ensuring integrity, strengthening condensation heat transfer capacity, and rapidly reducing temperature and pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

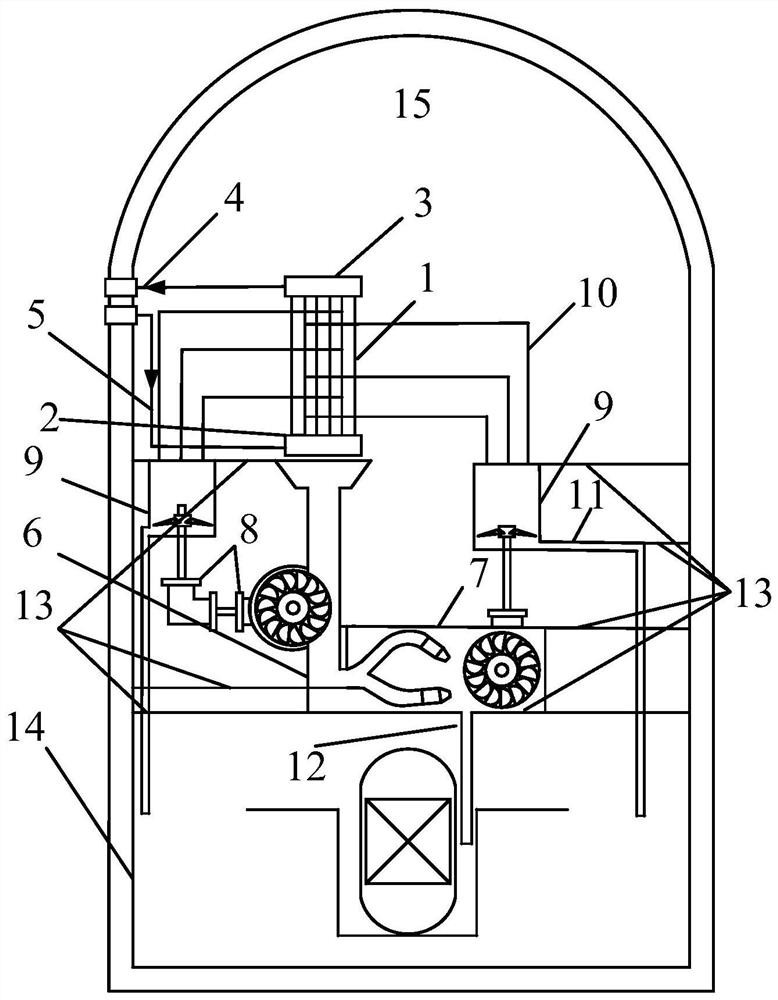

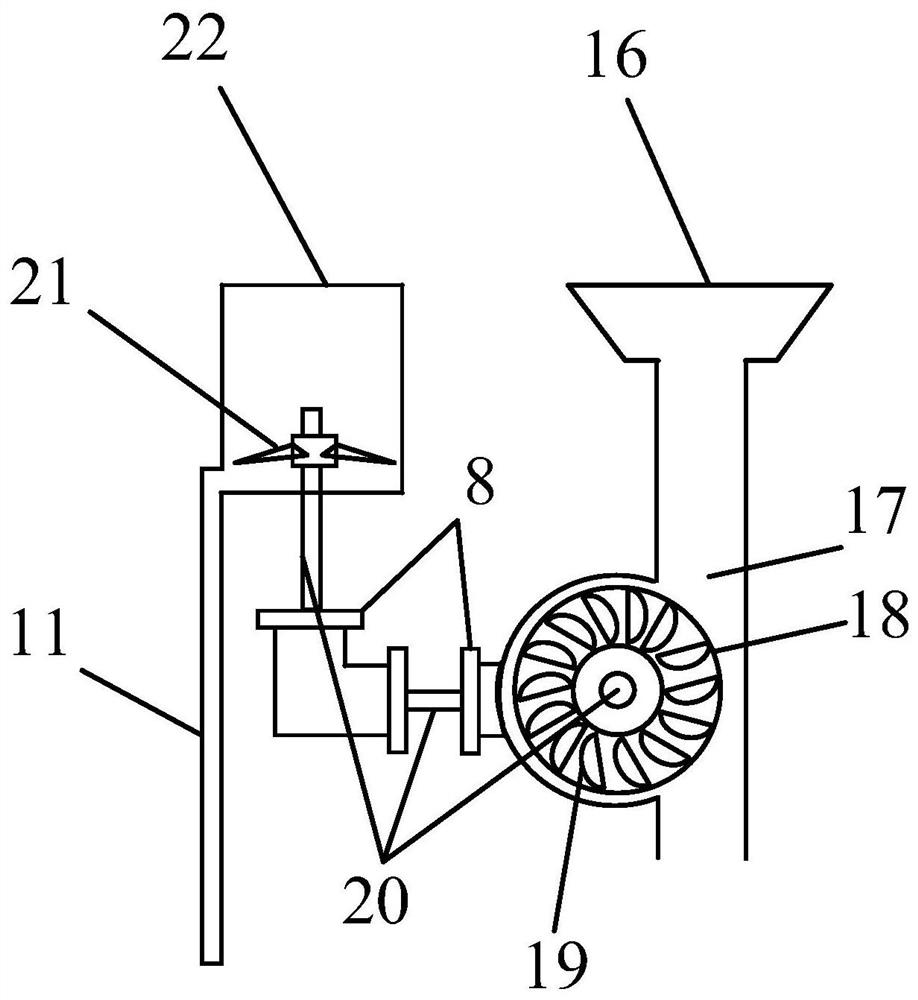

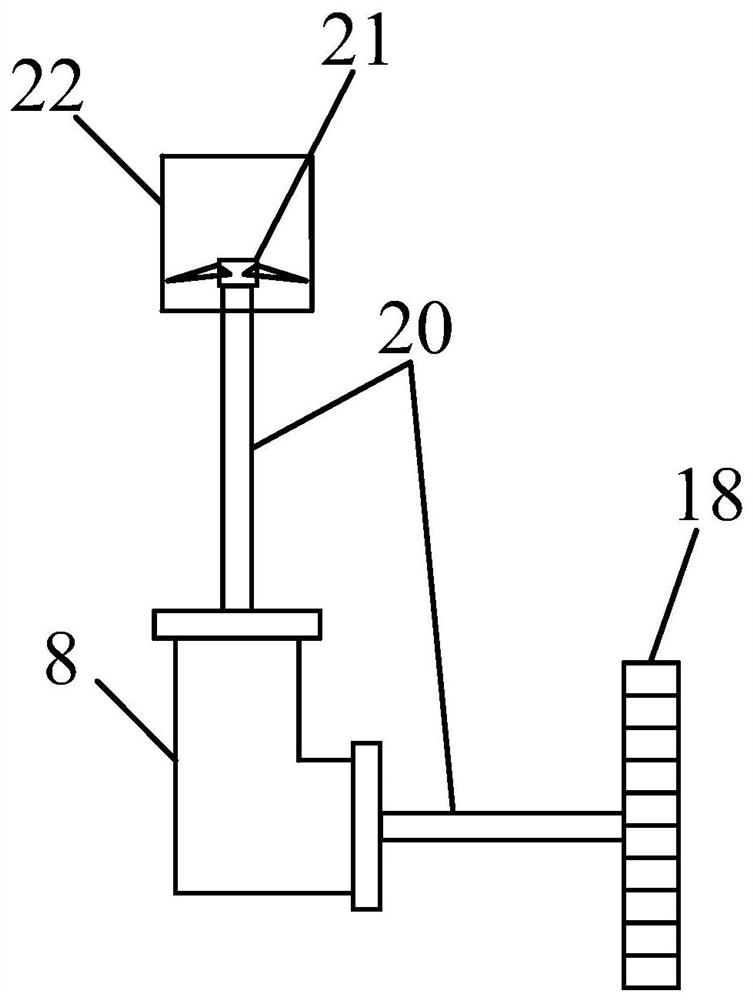

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] to combine figure 1 -7. The present invention provides a high-efficiency heat exchanger built into the containment using a double-wheel and double-blade composite power suction type. Mainly include containment built-in heat exchanger 1, heat exchanger inlet header 2, heat exchanger outlet header 3, upper pipe section 4, lower pipe section 5, water delivery structure 6, jet flow structure 7, gear steering box 8, suction gas structure 9 , suction pipe 10 , exhaust pipe 11 , exhaust pipe 12 , support column 13 , containment inner wall surface 14 , and containment gas space 16 .

[0026] The invention adopts a double-wheel and double-blade composite power suction type containment built-in high-efficiency heat exchanger, including a heat exchanger inlet header, a heat exchange tube, a heat exchanger outlet header, a self-flowing ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com