Enhanced condensation heat transfer tube

A technology of heat transfer tubes and regular changes, applied in the field of heat transfer tubes, can solve the problems of low heat transfer performance of condensers, achieve the effects of weakening the tube bundle effect, enhancing heat transfer performance, and accelerating dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

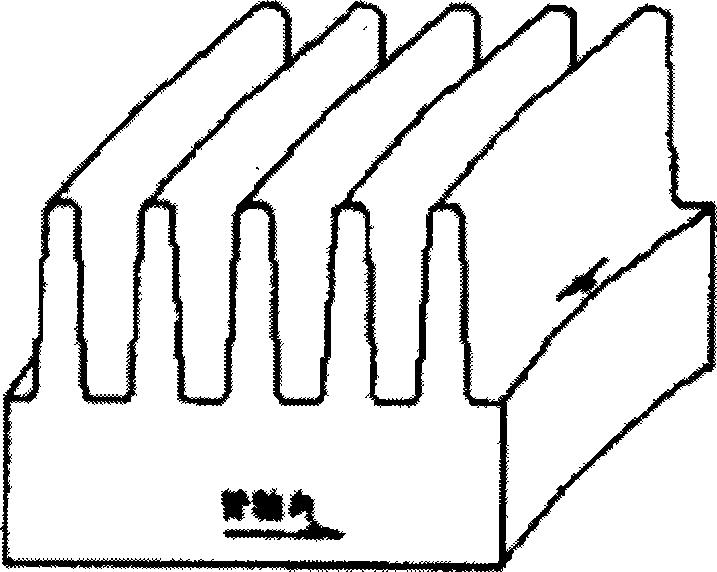

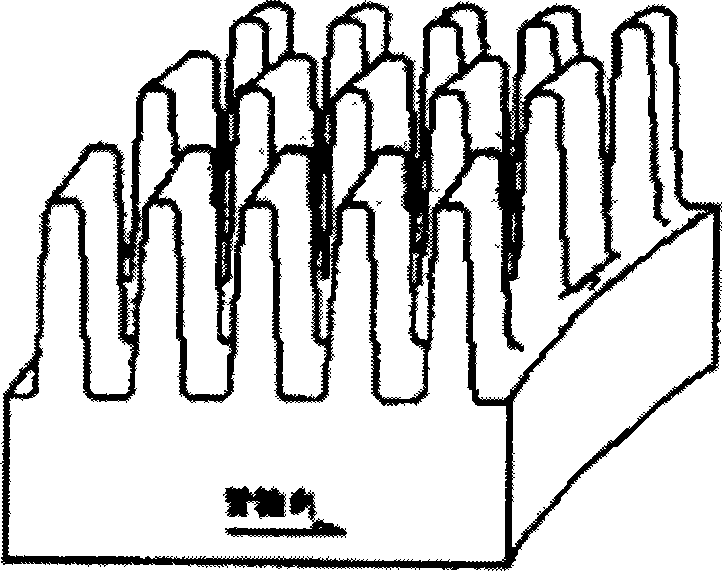

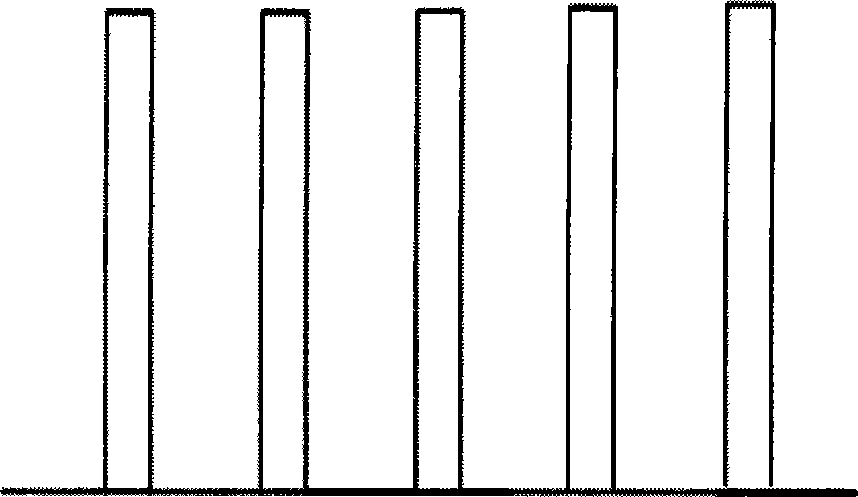

[0025] refer to Figure 4 , shows the front projection view of the first embodiment of the enhanced condensation heat transfer tube of the present invention. In this preferred embodiment, the outer surface of the heat transfer tube has spiral fins, and the distance between the fins is one along the axial direction. The changing law of width and narrowness; among them, the helical fins are provided with 26-60 fins per inch along the axial direction, the spacing between the axial fins is 0.4-1mm, the thickness of the fins is 0.1-0.4mm, and the helix angle range of the helical fins It is 0.3~1.5°, and the fin height ranges from 0.4~1.5mm; in addition, the spiral fin can be smooth, or it can be a slotted fin that is grooved on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com