A liquid separation phase change plate heat exchanger and its application

A plate heat exchanger and phase change technology, applied in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems of not being able to thin the condensate film in time, low heat transfer coefficient, and low condensation effect , to achieve the effect of improving condensation heat transfer effect, reducing steam dryness, reasonable and reliable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

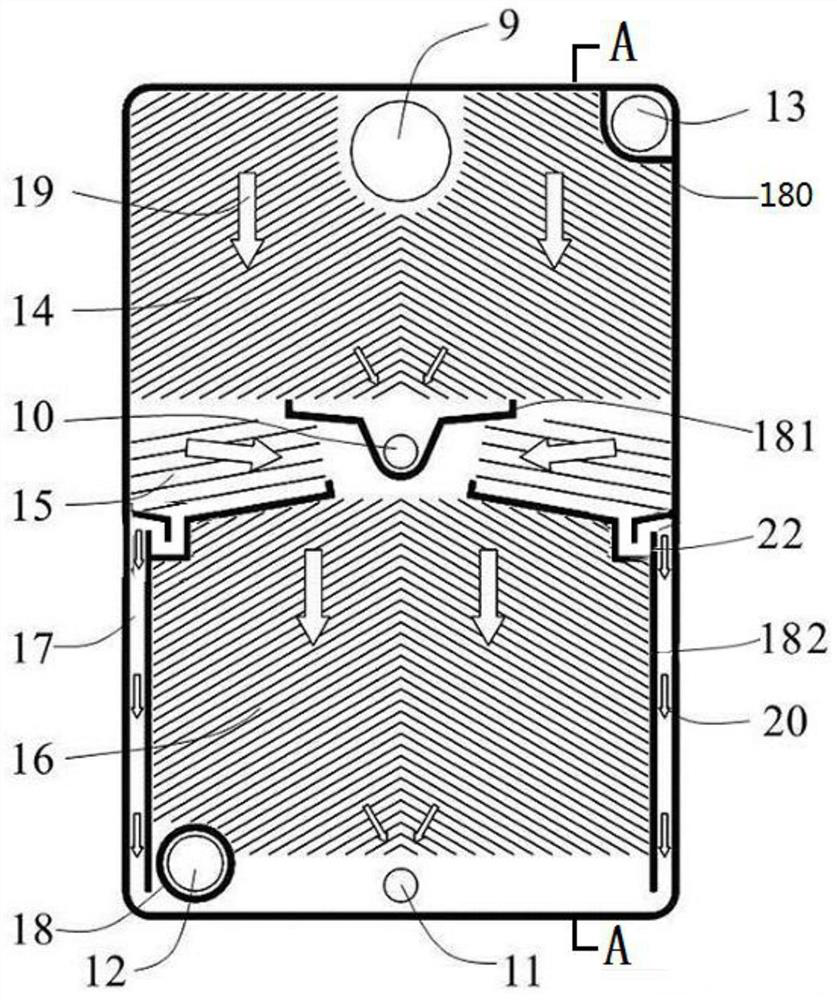

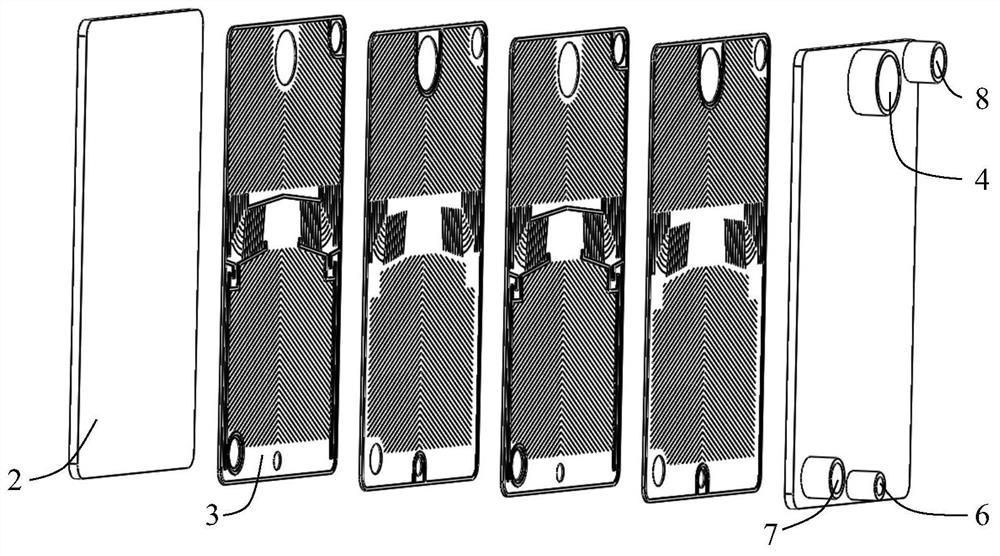

[0064] A liquid phase change plate heat exchanger 101, such as Figure 1-5 , which includes a movable pressing plate 1, a fixed pressing plate 2, at least one heat exchange plate 3 and several sealing gaskets. The heat exchange plate 3 is arranged between the movable compression plate 1 and the fixed compression plate 2, and a sealing gasket is arranged between the movable compression plate 1 and the heat exchange plate 3 to form a heat exchange channel; A sealing gasket is provided between the fixed pressing plate 2 and the heat exchange plate 3 to form a heat exchange flow channel. The heat exchange flow channels are the working fluid flow channel 24 and the cold and heat source fluid flow channel 25 respectively.

[0065] The movable compression plate 1 and the fixed compression plate 2 are respectively installed on the front and rear sides of the heat exchange plate 3; the movable compression plate 2 is provided with a steam working medium nozzle 4, a second liquid workin...

Embodiment 2

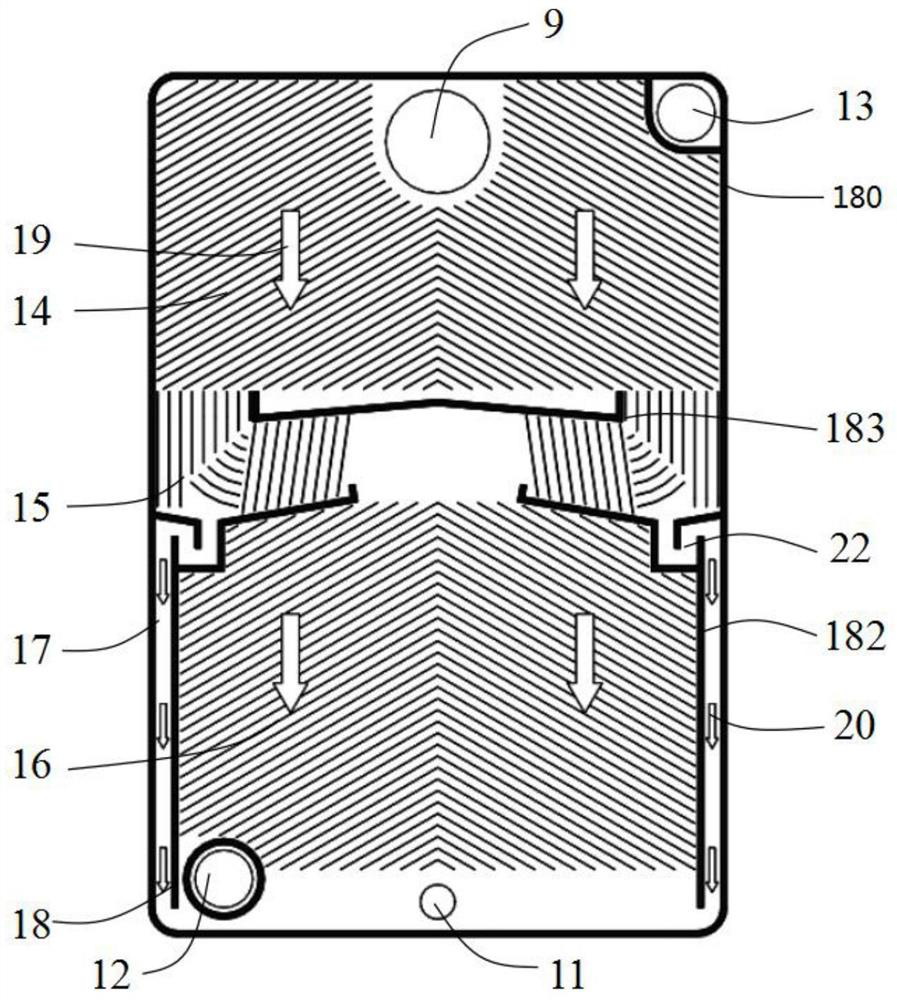

[0076] A liquid phase change plate heat exchanger 101, such as Figure 6-7 , on the basis of the structure of Example 1, the movable compression plate 2 is provided with a first liquid working medium nozzle 5; the heat exchange plate 3 is provided with a first liquid working medium corner hole 10, the The first liquid working medium corner hole 10 communicates with the first liquid working medium nozzle 5 . The first liquid working medium corner hole 10 may be disposed in the middle of the middle zone 15 . The first liquid working medium corner hole 10 may be arranged at the lowest end of the second sealing gasket 181 . In this embodiment, the second sealing gasket 181 replaces the fourth sealing gasket 183 . A concave portion is provided in the middle of the second sealing gasket 181 , and the corner hole 10 of the first liquid working medium is disposed in the concave portion.

[0077] The middle zone 15 is provided with oblique corrugations on both sides of the first liq...

Embodiment 3

[0079] A liquid phase change plate heat exchanger 101, such as Figure 8 As shown, on the basis of the structure of Embodiment 1 and Embodiment 2, the middle area of the surface above the second sealing gasket 181 in the first heat exchange region 14 is a vertical corrugation, which is convenient for the condensed liquid film to flow down , both sides of the middle area are oblique corrugations and one end close to the middle area is higher than the other end; the second heat exchange area 16 is a herringbone corrugation.

[0080] After passing through the gas-liquid separation zone in the middle zone 15, the mass flow rate of the gas entering the second heat exchange zone 16 will decrease. The mass flow rate of the gas, so that the mass flow rate meets the design requirements.

[0081] Therefore, if Figure 15 The flow channel on the refrigerant side of the first heat exchange zone 14 shown is the same as that on the water side; Figure 16 The refrigerant side of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com