High-efficiency evaporation and condensation casing heat exchanger

An evaporative and condensing, casing-type technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of not easy to clean, large flow resistance on the water side, increased energy consumption, etc., to improve evaporation heat transfer Effect, enhanced condensation heat transfer, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and examples, but this example is not intended to limit the present invention, any similar structures and similar changes of the present invention, especially the various deformations of the casing heat exchanger, All should be included in the protection scope of the present invention.

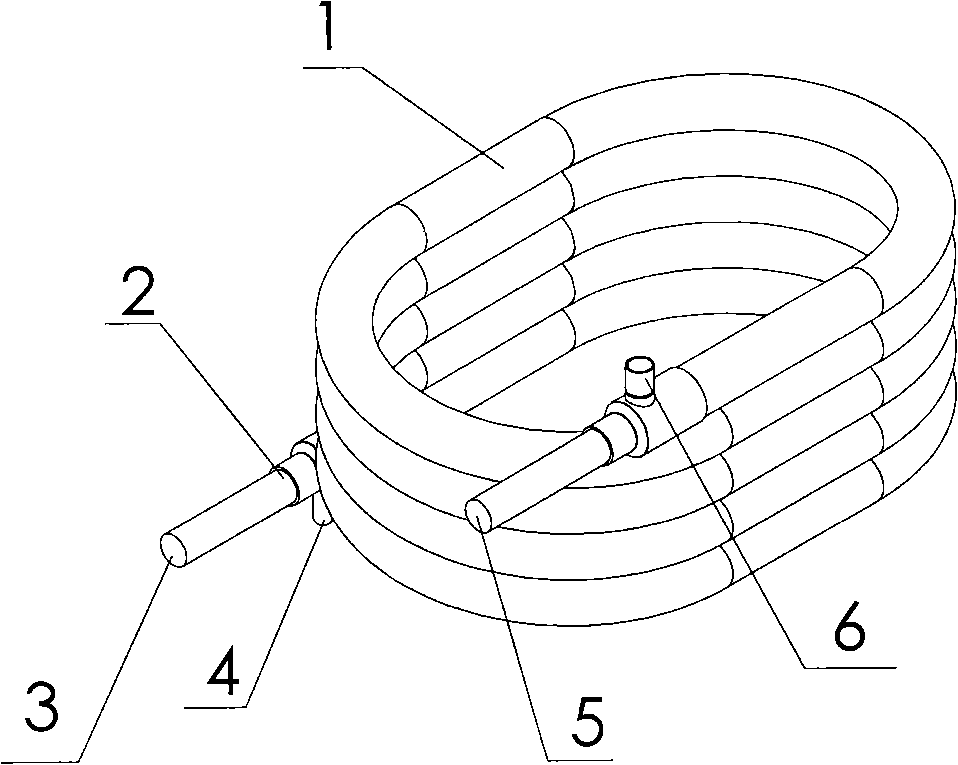

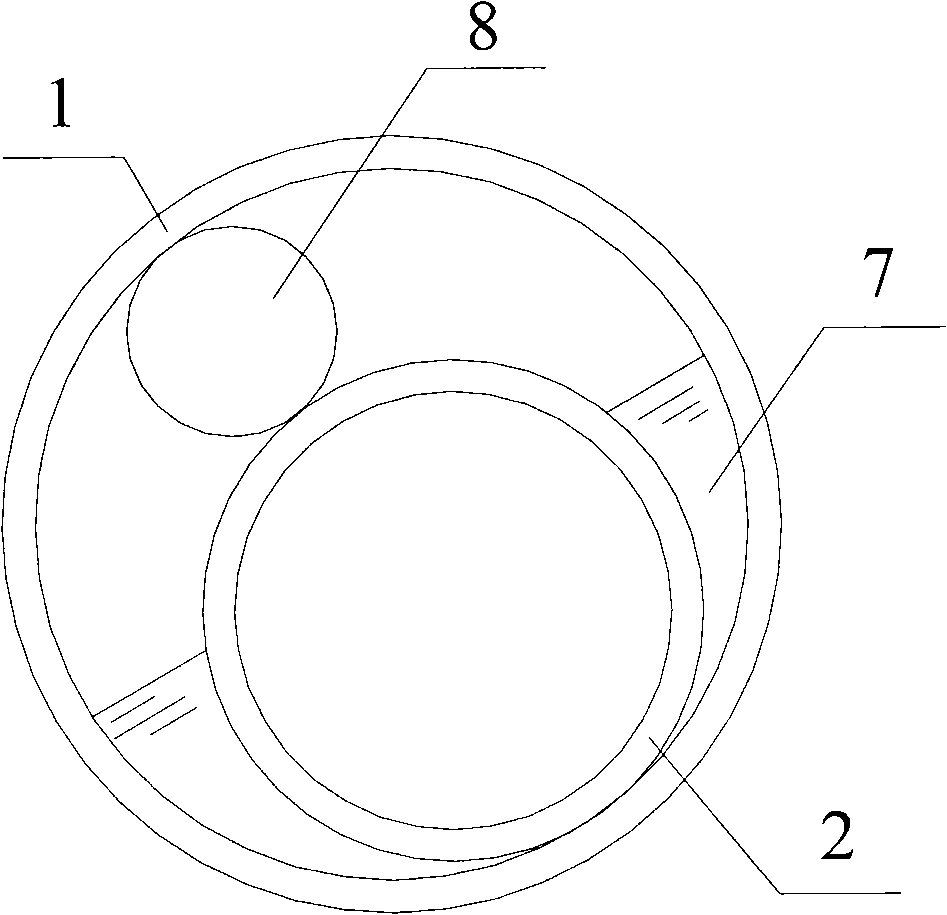

[0013] The evaporating and condensing casing heat exchanger of the present invention is as figure 1 As shown, when the air-water air-conditioning heat pump unit is cooling, the high-temperature and high-pressure refrigerant gas enters the inner and outer tube jackets of the sleeve-and-tube heat exchanger from port 6 on the refrigerant pipeline, and connects with the secondary water pipeline in the inner tube 2 The water flowing into the lower port 3 performs heat exchange, the refrigerant gas condenses into liquid and flows out from the lower port 4 of the refrigerant pipeline, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com