Refrigerating condenser without refrigerant superheating section and refrigerating method thereof

A condenser and refrigerant technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of increased investment cost, large volume, and reduced refrigerant flow rate, and achieve low cost, low processing difficulty, Effect of improving heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

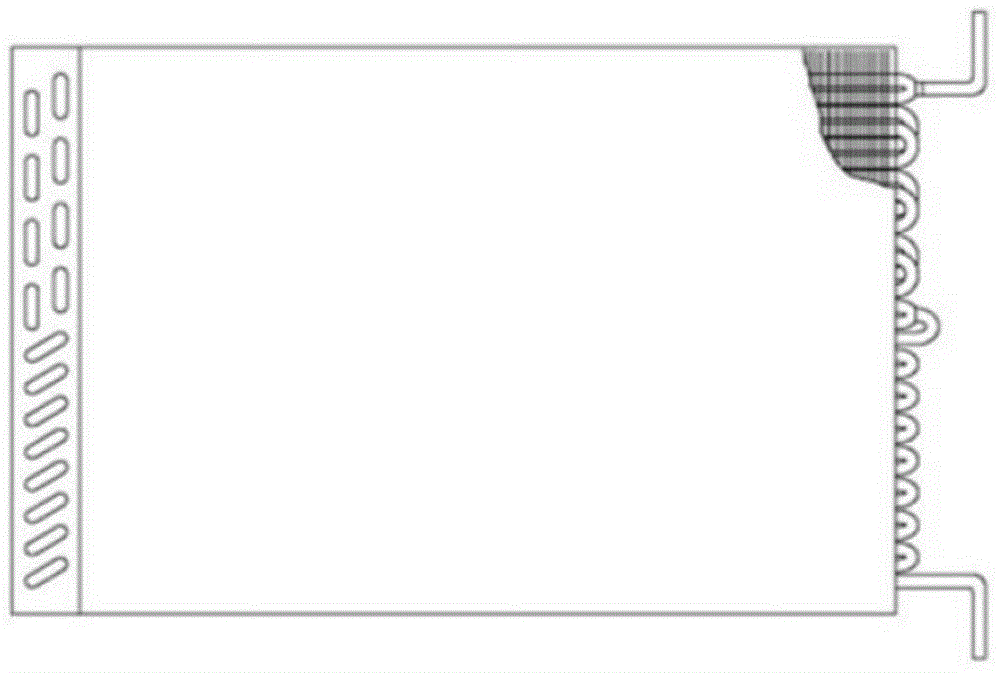

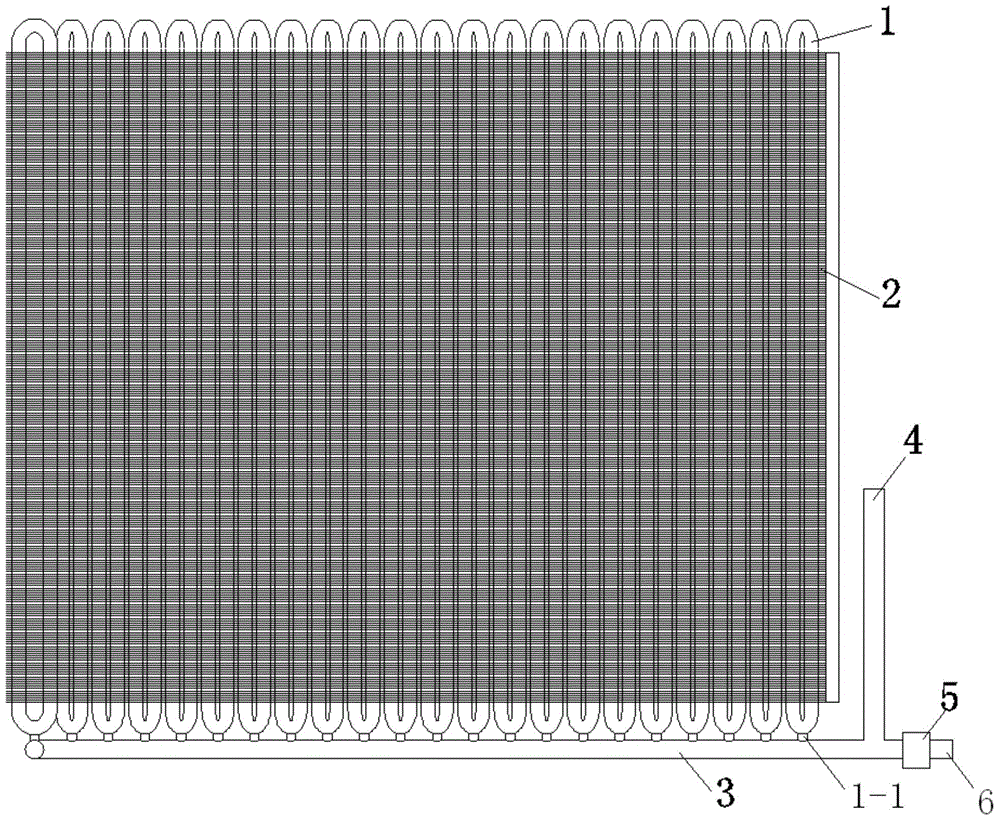

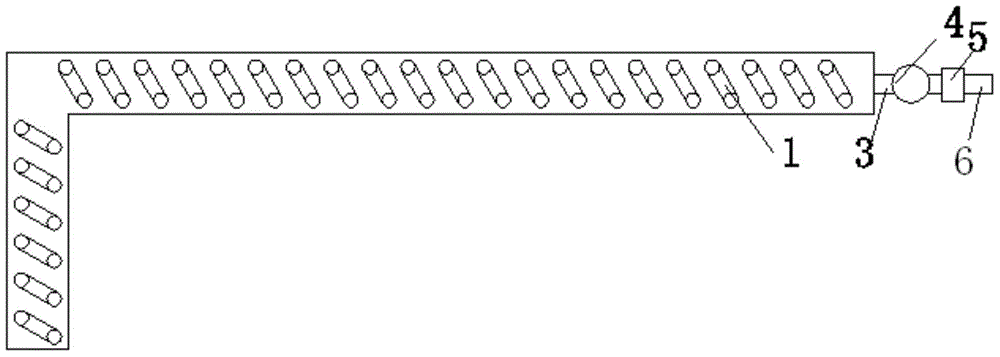

[0026] Such as Figures 1 to 5 shown. The refrigeration condenser without refrigerant superheating section of the present invention includes a horizontal lower liquid pipe 3, and multiple sets of vertical heat exchange tubes 1 vertically arranged on the horizontal lower end liquid pipe 3, and each set has two vertical heat exchange tubes 1; wherein, the upper and lower ends of the two vertical heat exchange tubes 1 in each group are respectively connected through elbows to form an independent circuit;

[0027] An inlet pipe 4 and a liquid outlet pipe 6 are arranged on one end pipeline of the liquid pipe 3 at the lower horizontal end, and a liquid sealing device 5 is arranged on the pipeline between the air inlet pipe 4 and the liquid outlet pipe 6. The inlet pipe 4 and the liquid outlet pipe 6 are separated.

[0028] The lower elbows of the two vertical heat exchange tubes 1 in each group communicate with the horizontal lower liquid tube 3 through the communication tube 1-1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com