A parallel small-diameter heat pipe enhanced heat exchange device for recovering waste heat of medium and low temperature flue gas and its preparation method

A technology of low-temperature flue gas and enhanced heat transfer, which is applied in steam generation methods using heat carriers, heat exchange equipment, indirect heat exchangers, etc., can solve the waste heat waste of flue gas, achieve enhanced reflux, and improve waste heat recovery efficiency , Increase the effect of heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples of implementation.

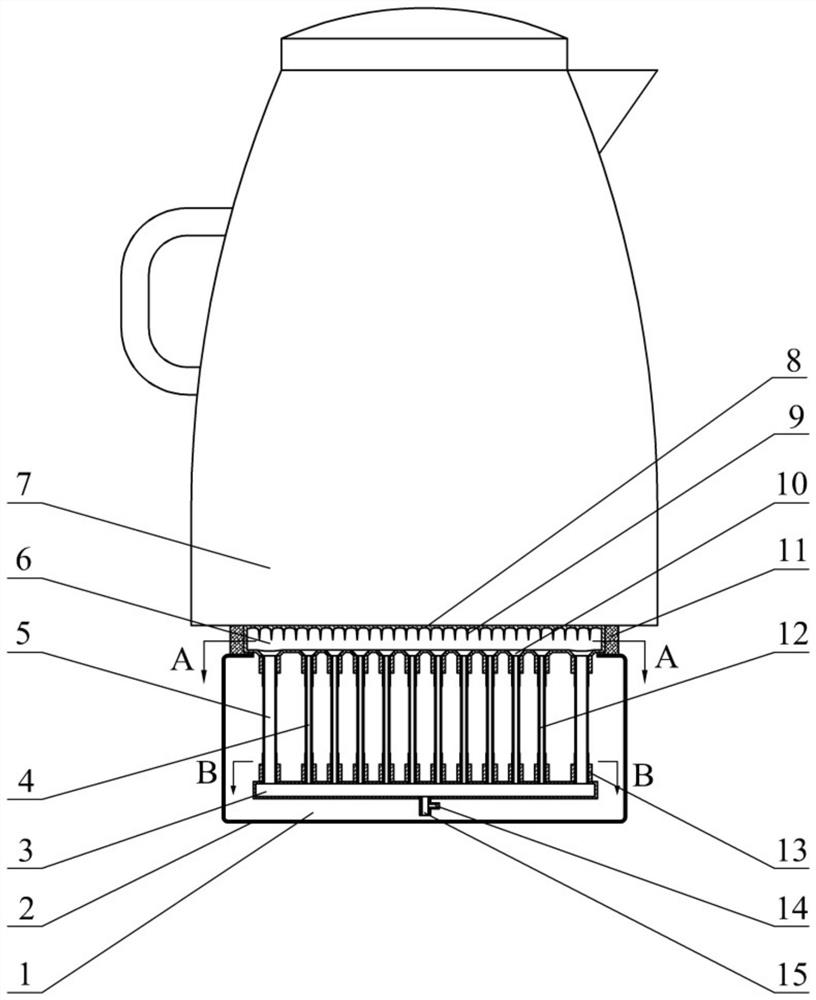

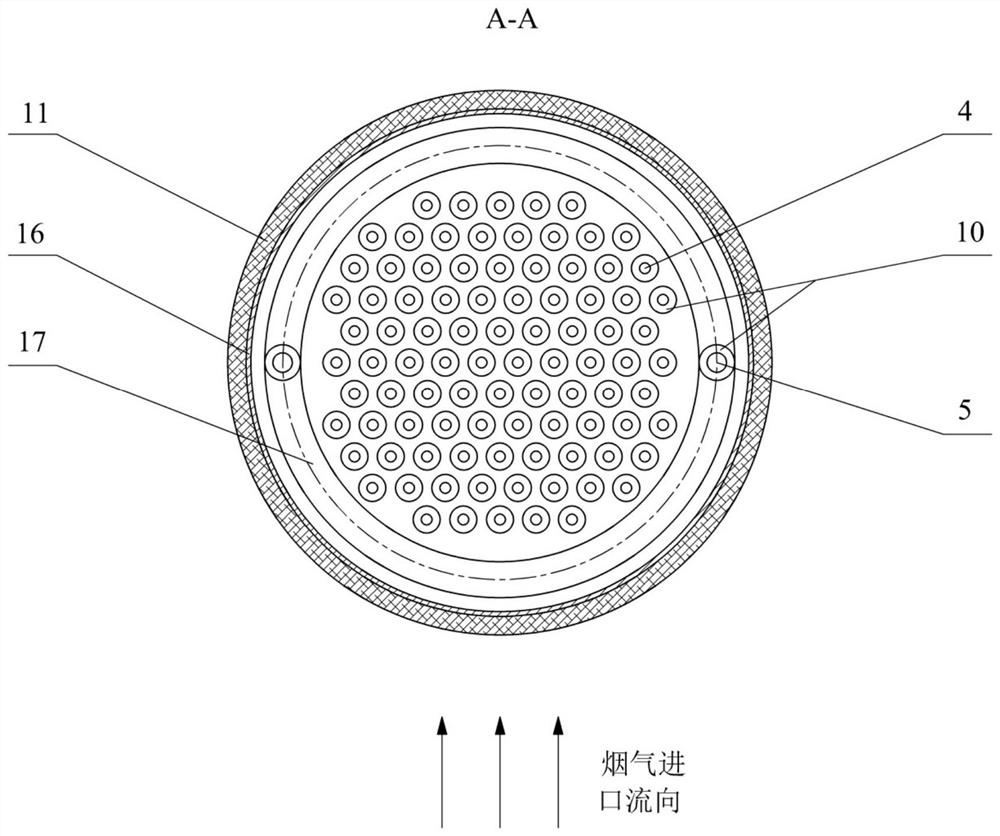

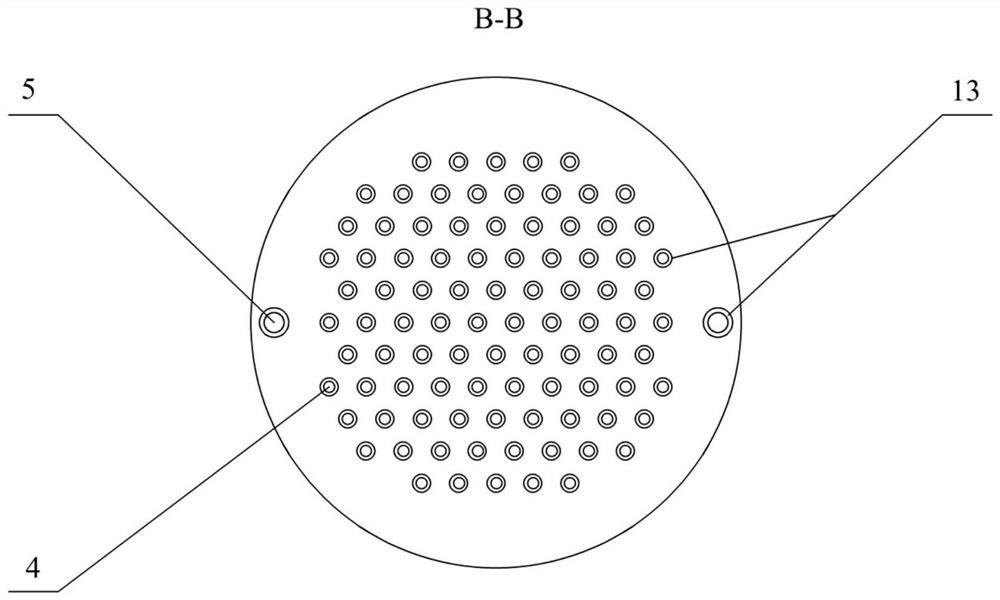

[0046] Such as Figure 1 to Figure 16 , the flue gas passage 1 is a rectangular passage, the flue gas flows in from one side of the passage, and flows out from the other side, and the heat exchange main body of the parallel small-diameter heat pipe heat exchange device is arranged in the flue, that is, the multiple parallel small diameter heat exchange devices of the heat exchange device Diameter heat pipe 4 and liquid accumulation cavity 3, when the flue gas flows through multiple parallel small-diameter heat pipes 4 at a certain flow rate, the flue gas transfers heat from the flue gas to the heat pipe in the liquid-absorbing core on the inner wall of the small-diameter heat pipe through convection and heat conduction Working fluid.

[0047] The flue wall 2 isolates the flue gas from the environment, and at the same time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com