Compound fertilizer generation system

A technology for generating a system and compound fertilizer, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of difficult control of the reaction process, uneven particles, and low product strength, and achieve easy control of the reaction process, uniform particle size, one-time The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

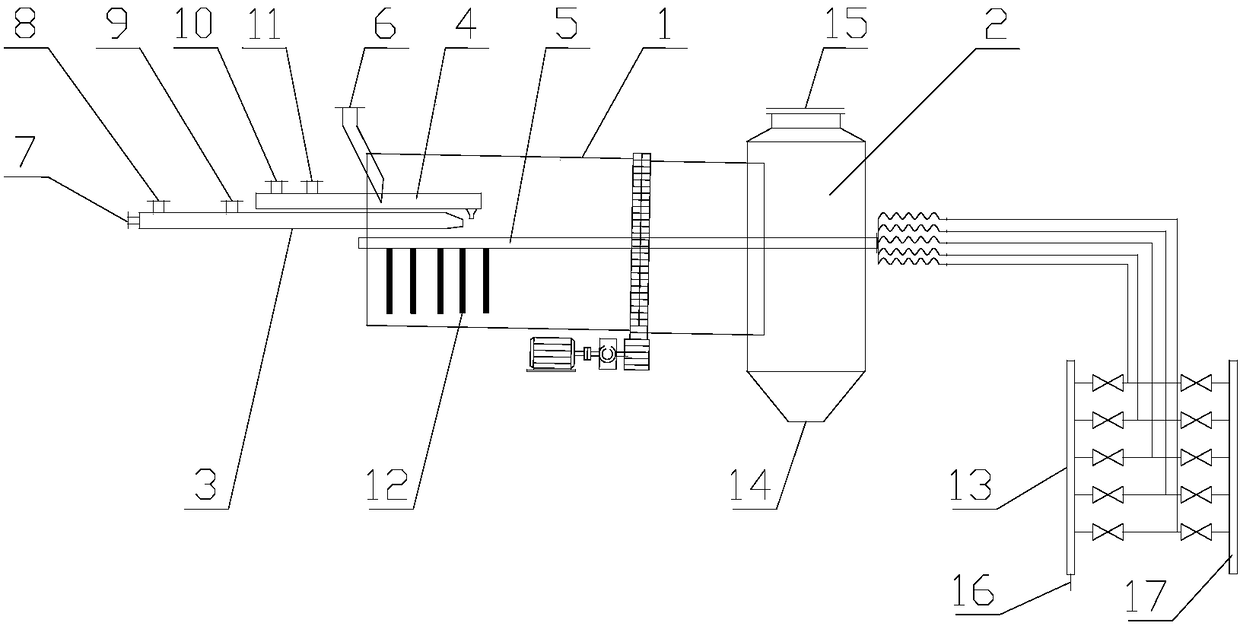

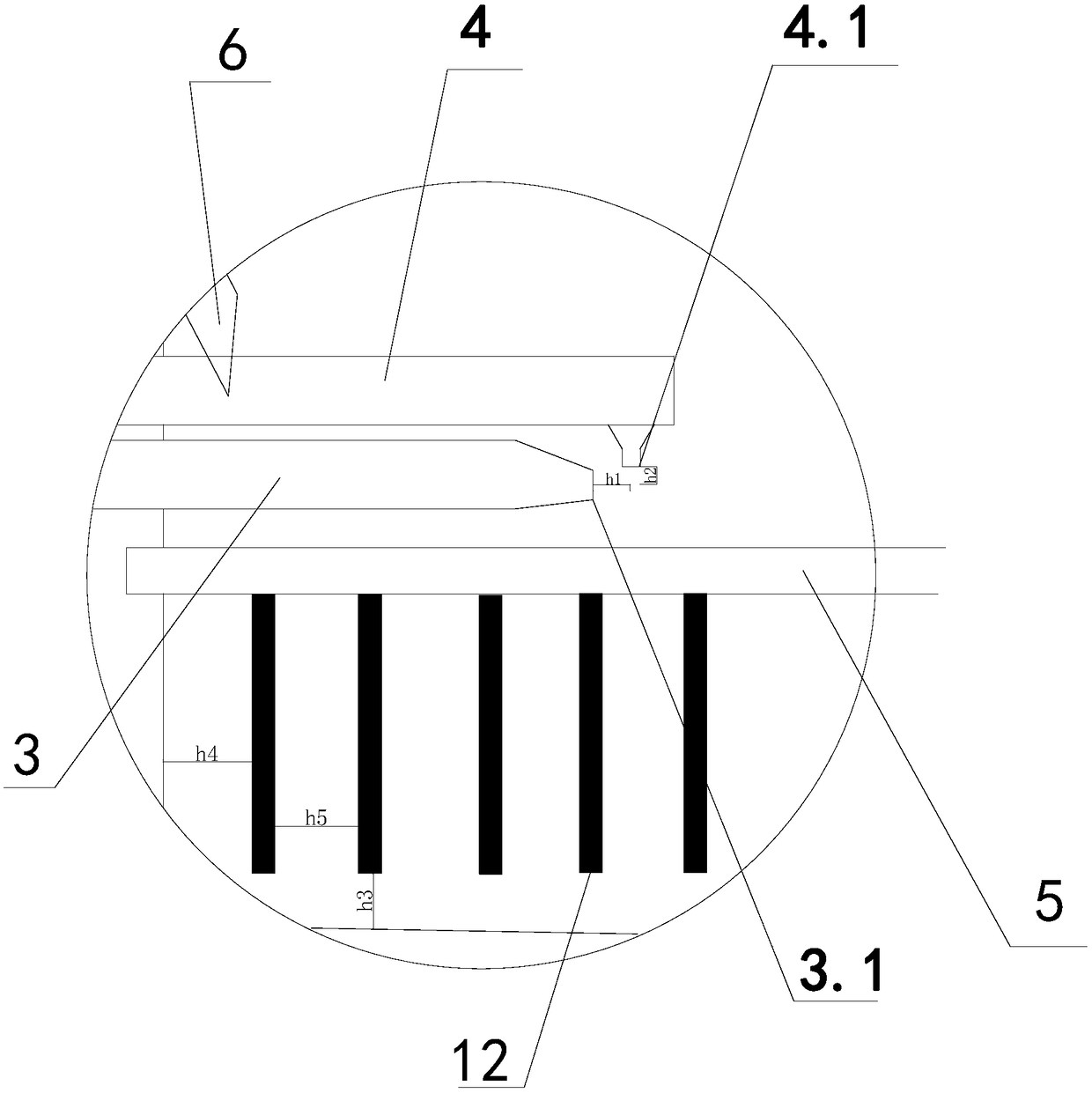

[0030] Below in conjunction with accompanying drawing, the present invention will be further explained:

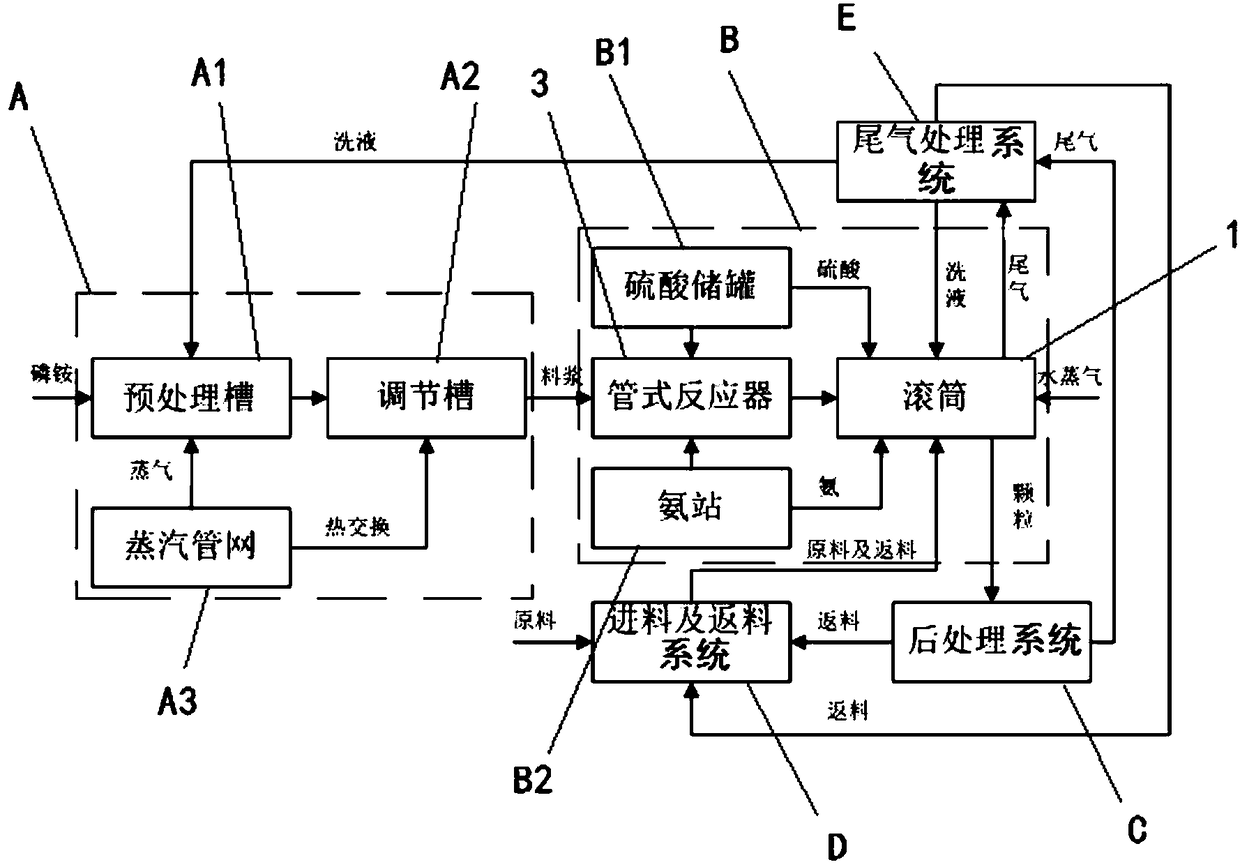

[0031] see figure 1 , the embodiment of the present invention provides a compound fertilizer production system, the system includes a pretreatment system A, a granulation system B, a post-treatment section C, a feed and return system D, and an exhaust gas treatment system E, wherein the pretreatment system A, granulation system B, post-processing system C and feed and return system D are sequentially connected, the granulation system B and post-processing system C are also connected to the tail gas treatment system E, and the generated tail gas is uniformly sent to the tail gas treatment System E does the processing.

[0032] The connection relationship and process flow of each equipment in the post-processing section C, the feeding and returning system D, and the tail gas treatment system E are the same as those of the prior art, and those skilled in the art can also rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com