Preparation method of nitrided iron nano-powder and high-pressure gas-solid reaction bed thereof

A high-pressure gas-solid reaction and nano-powder technology, which is applied in nanotechnology, nanotechnology, nitrogen-metal/silicon/boron binary compounds, etc., can solve the difficulty of airflow transporting nano-powders, small amount of plasma powder making, very high It is difficult to collect all of them, so as to achieve the effect of improving primary utilization rate, large batch output and improving reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

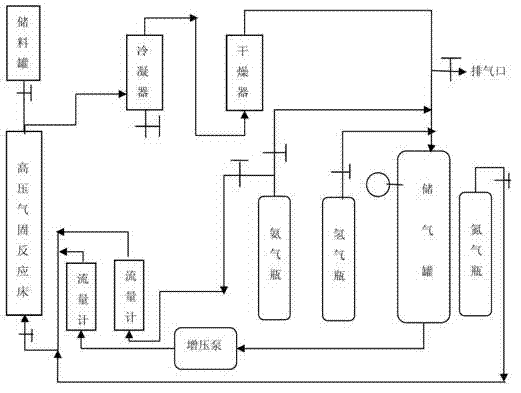

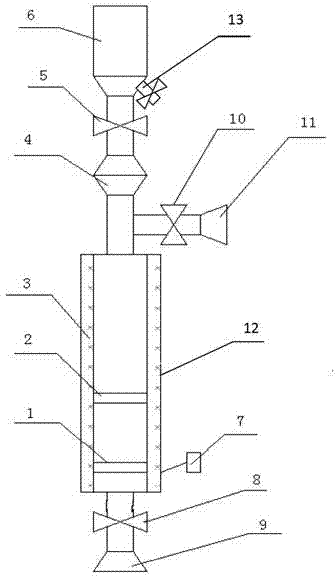

[0027] Such as figure 1 , figure 2 As shown, the product particle size is Fe with an average particle size of 50±5nm 4 The preparation method of N nano powder and the high-pressure gas-solid reaction bed device, the specific operation steps are as follows:

[0028] 1. Weigh 1692 grams of FeCl 3 ·6H 2 O is put into a container, and is mixed with 8L water and 2L absolute ethanol to prepare stable precursor solution A; Get 751.47 grams of sodium hydroxide, dissolve in 10L twice distilled water and prepare stable precursor solution B; Precursor solution A and B are quickly mixed and reacted in the reactor to obtain a precipitated precursor, which is filtered, washed and dried with deionized water to obtain dark red iron hydroxide powder.

[0029] 2. Put the precursor ferric hydroxide powder through the opening of the quick connector 4 through the pipeline above the heater 3, put it into the high-pressure gas-solid reaction bed, first pass the gas inlet 9 into the nitrogen cle...

Embodiment 2

[0032] Such as figure 1 , figure 2 As shown, Fe with an average particle size of 80±5nm 4 The preparation method of N nano powder and its high-pressure gas-solid reaction bed, the specific operation steps are as follows:

[0033] Step one, step two are the same as embodiment 1.

[0034]Step 3, the temperature of the high-pressure gas-solid reaction bed is raised to 380°C through the heater 3, and the other procedures are the same as in Example 1 to finally obtain Fe 4 N nano-powder, the average particle size of the product is 80±5nm. Such as Figure 5 shown, for Fe 4 TEM picture of N nanopowder (380°C).

Embodiment 3

[0036] Such as figure 1 , figure 2 As shown, Fe 3 The preparation method of N nano powder and its high-pressure gas-solid reaction bed, the specific operation steps are as follows:

[0037] Step one, step two are the same as embodiment 1.

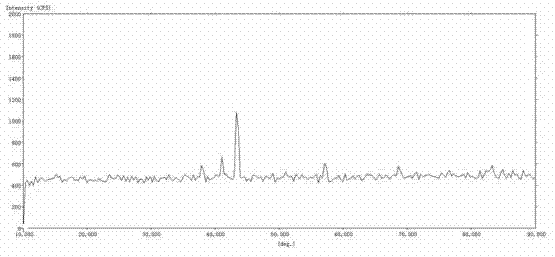

[0038] Step 3, use the exhaust valve of the circulation system to control and maintain the system pressure at 0.4-0.5MPa, and the other processes are the same as in Example 1 to finally obtain Fe 3 N nano powder. Such as Figure 6 Shown, for Fe 3 X-ray diffraction pattern of N nanopowder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com