Full-automatic cleaning control method

A fully automatic cleaning and control method technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of manual cleaning, cleaning control that cannot be fully automatic, and unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

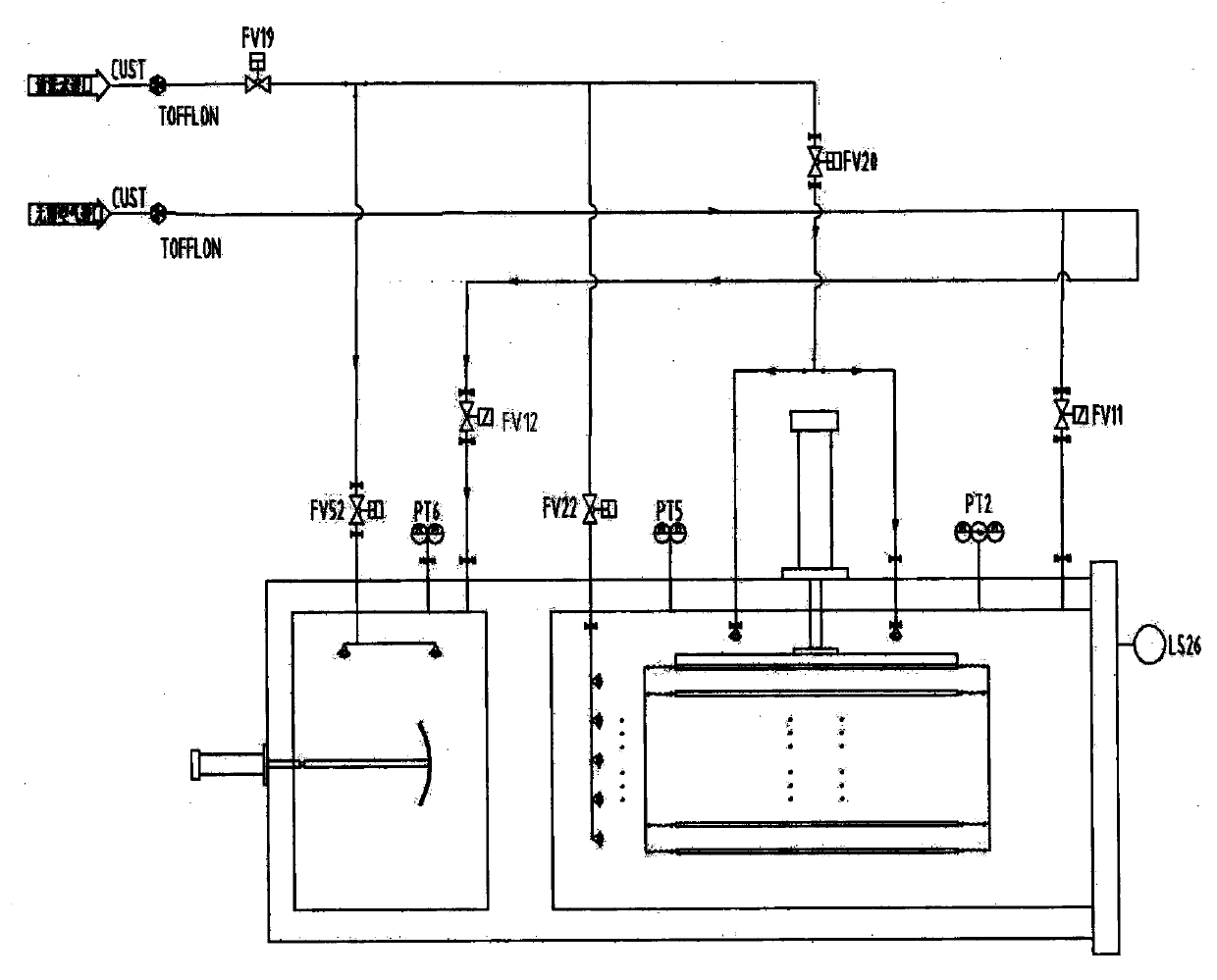

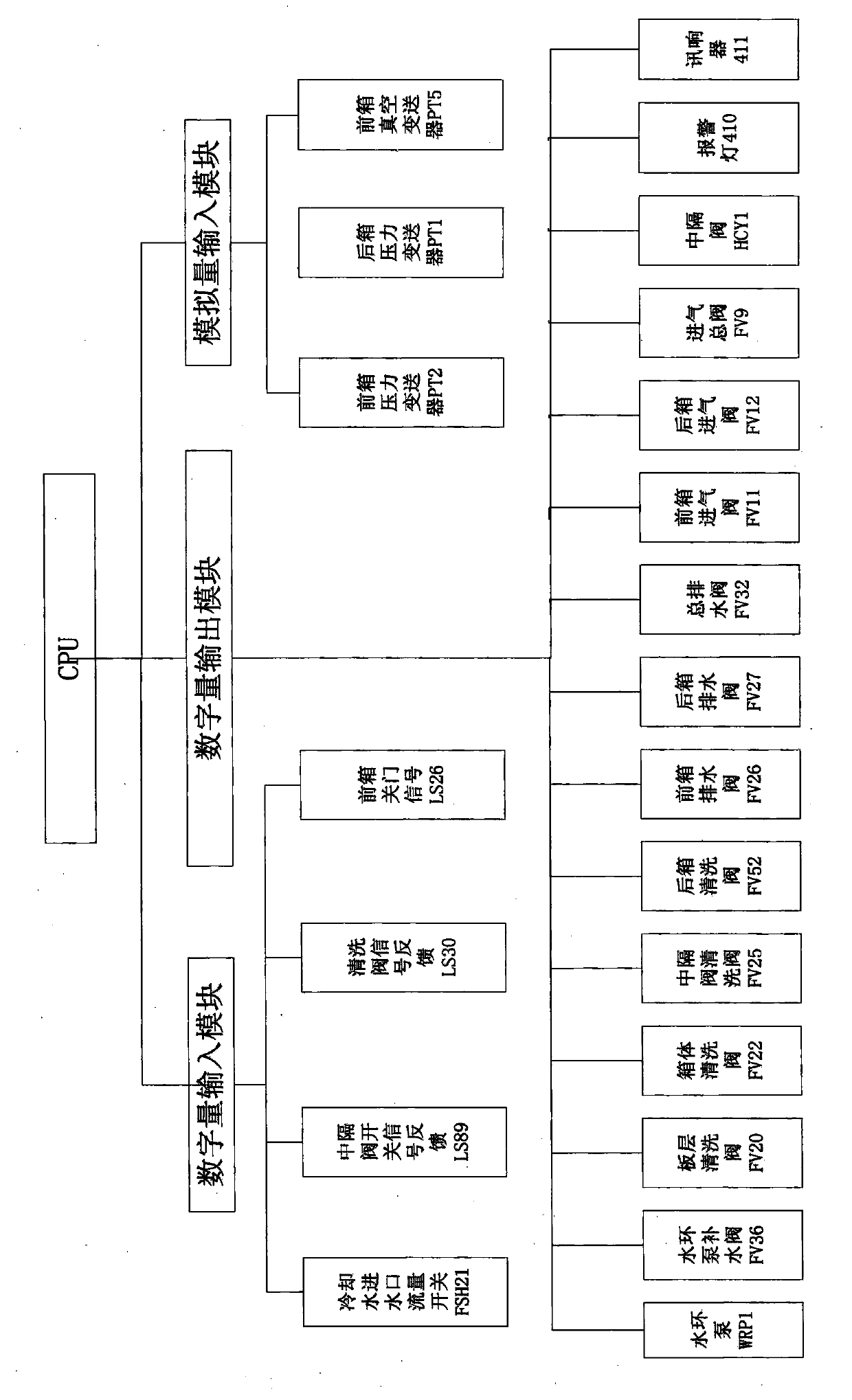

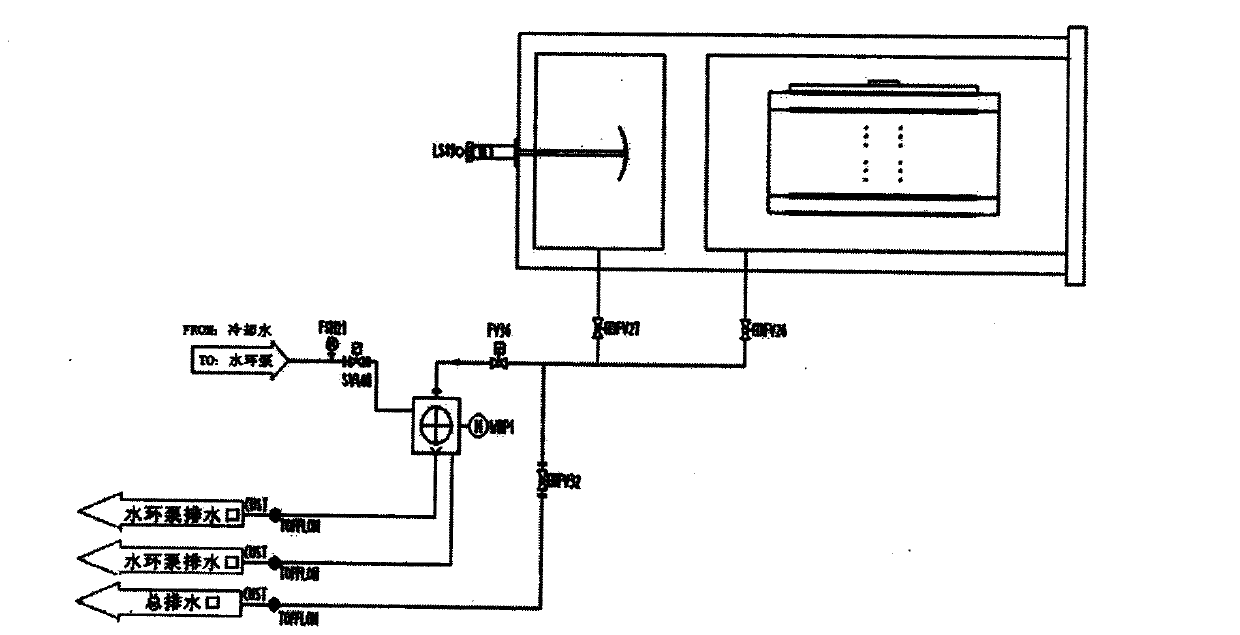

[0024] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings. The following examples use as figure 1 and figure 2 A cleaning control device is shown, which includes a main cleaning valve FV19, a front box water inlet valve FV20 connected in series with the main cleaning valve FV19, a rear box water inlet valve FV52, and a front box air inlet valve FV11, rear box intake valve FV12, front box is equipped with front box pressure transmitter PT2, front box vacuum transmitter PT5 (vacuum gauge is used), and rear box is equipped with pressure transmitter PT6. It also includes the front box drain valve FV26, the rear box drain valve FV27, and the main drain valve FV32 and the water ring pump WRP1 connected in series with the front box drain valve FV26 and the rear box drain valve FV27, and the water ring pump replenishment valve SV401, water ring Pump isolation valve FV36.

[0025] combine imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com