Phase separation micro-channel condenser

A micro-channel and condenser technology, applied in indirect heat exchangers, cooling/ventilation/heating transformation, lighting and heating equipment, etc., can solve the problems of uncontrollable two-phase flow pattern, and reduce flow resistance and flow instability The effects of stability, thinning liquid film thickness, and improving condensation heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

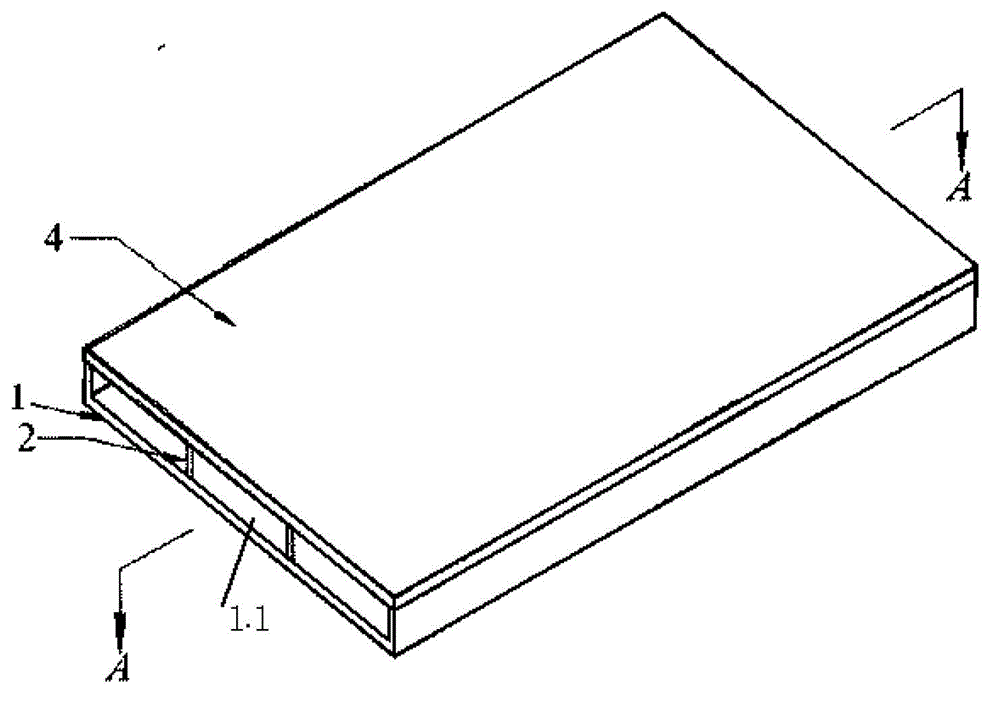

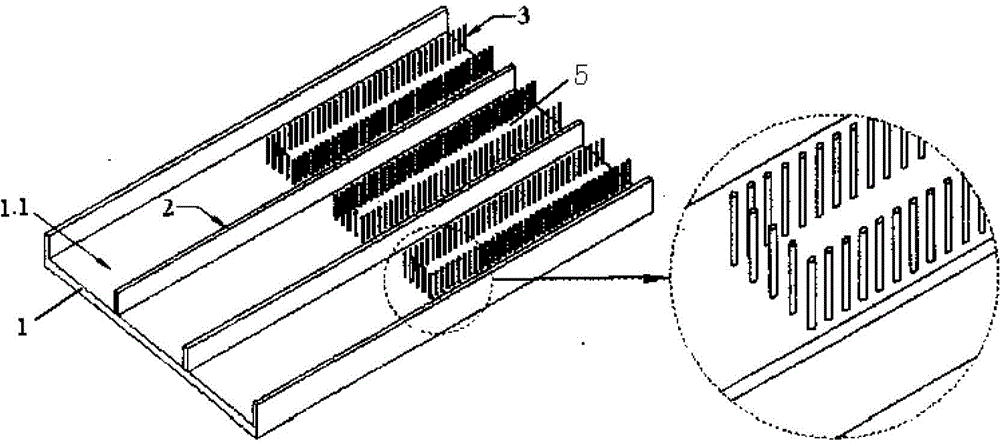

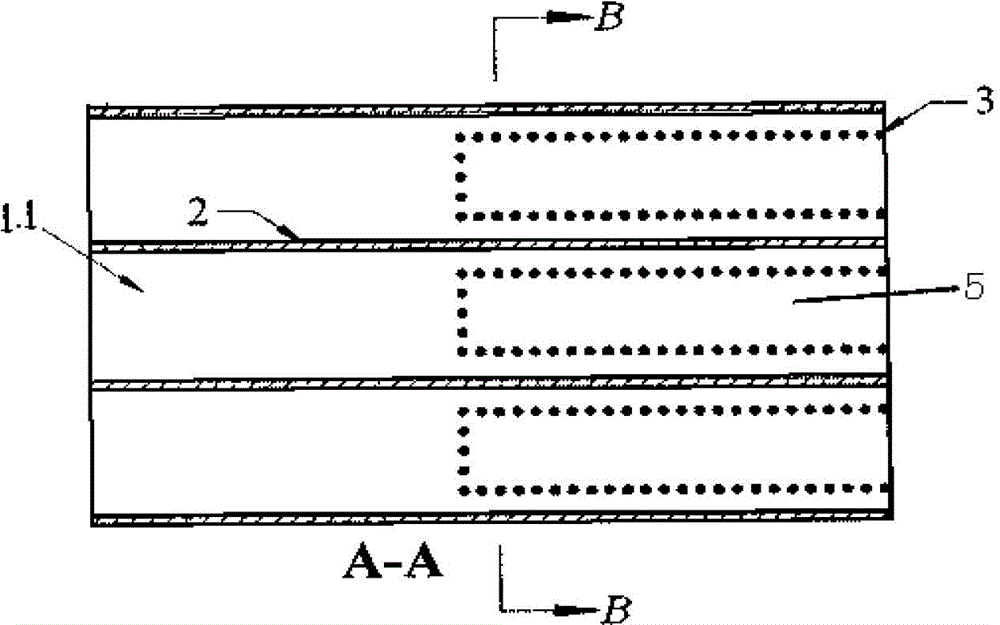

[0021] figure 1 , figure 2 Shown is a schematic structural view of the phase separation microchannel condenser of the present invention. The phase-separated microchannel condenser shown in the figure is to etch a plurality of parallel microchannels 1.1 on the silicon substrate 1, and the microchannels are separated by ribs 2; a large amount of microchannels are etched in the downstream area 5 of the microchannels Ribs 3, and surround openings towards the rib network downstream; the top of the microchannel is encapsulated by a cover plate 4; the external structure of the phase-separated microchannel condenser is as follows figure 1 As shown, the internal structure is as figure 2 , image 3 and Figure 4 shown. The phase-separated micro-channel condenser first processes a plurality of parallel micro-channels 1.1 on a semiconductor silicon substrate 1 through an etching process, and the silicon substrate 1 is a cooling surface at the bottom of the micro-channels. The widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com