Method for enabling condensed liquid drops to be spontaneously expelled in horizontal direction

A horizontal direction, condensate technology, applied in the direction of coating, etc., can solve the problem of poor droplet repelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

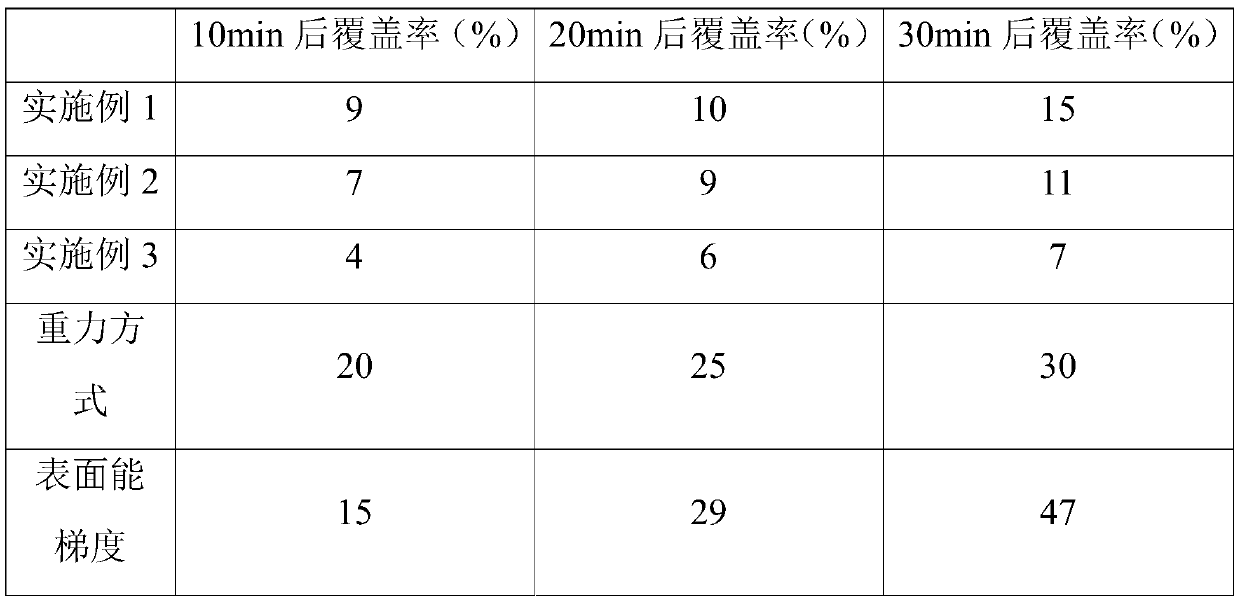

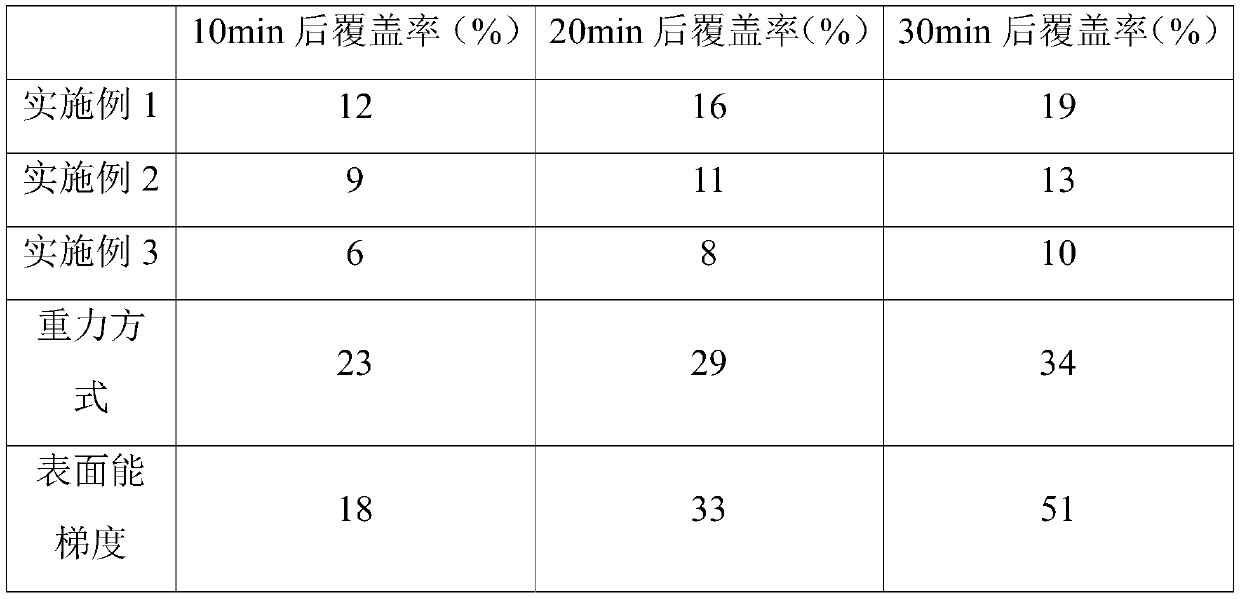

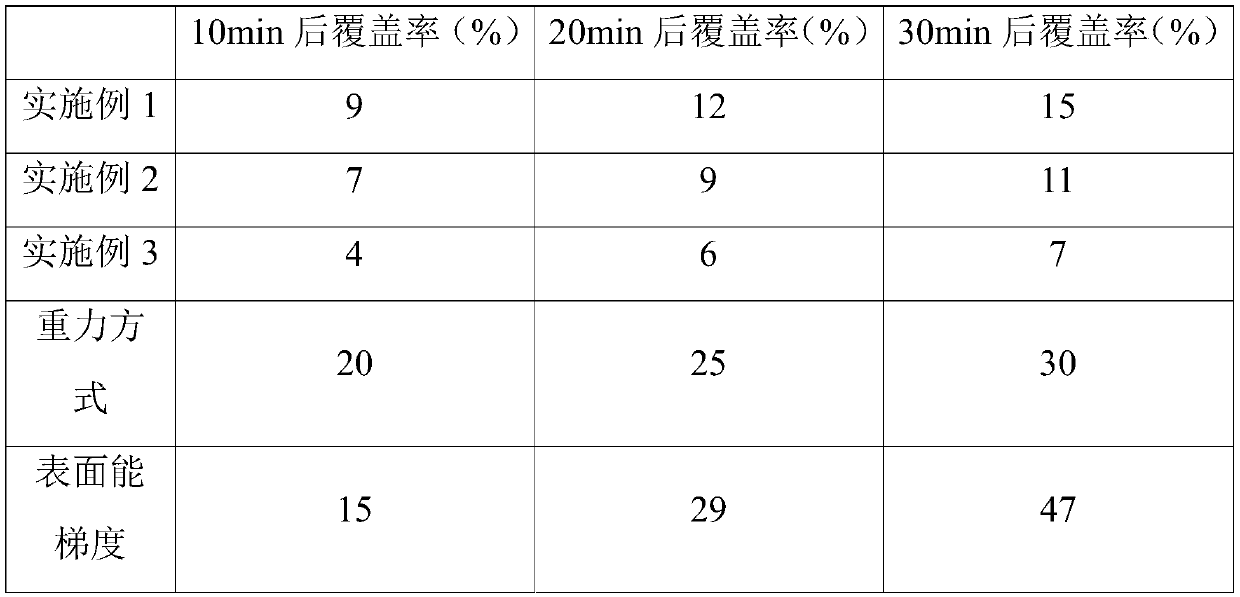

Embodiment 1

[0031] A method for spontaneously dispelling condensate droplets in a horizontal direction, comprising the steps of:

[0032] (1) Place a glass sheet with an area of 27*5mm on a candle flame for 30 seconds, then place the glass sheet, 4ml tetraethyl orthosilicate and 4ml ammonia solution in a dry container, vacuum and let it stand for 20 hours ;

[0033] (2) annealing the glass sheet treated in step (1) at 500° C. for 1.5 h;

[0034] (3) Use O 2 The glass sheet after the annealing in the plasma treatment step (2), the treatment time is 10min, wherein, O 2 The proportion is 70%, and the rest is Ar. Then place the glass sheet and 100 μl perfluorooctyltrichlorosilane in a dry container, vacuumize and let stand for 1 hour to obtain the base layer;

[0035] (4) Charge the base layer in step (3) for 1 min at a voltage of 8kV to inject a gradient electric field into the base layer, and then place the base layer horizontally in a condensation environment to achieve the effect of ...

Embodiment 2

[0037] A method for spontaneously dispelling condensate droplets in a horizontal direction, comprising the steps of:

[0038] (1) Place a glass sheet with an area of 27*5mm on a candle flame for 30 seconds, then place the glass sheet, 4ml tetraethyl orthosilicate and 4ml ammonia solution in a dry container, vacuum and let it stand for 26 hours ;

[0039] (2) annealing the glass sheet treated in step (1) at 600° C. for 3 hours;

[0040] (3) Use O 2 The glass sheet after the annealing in the plasma treatment step (2), the treatment time is 10min, wherein, O 2 The proportion is 80%, and the rest is Ar, then place the glass sheet and 100 μl perfluorooctyltrichlorosilane in a dry container, vacuumize and let stand for 3 hours to obtain the base layer;

[0041] (4) Charge the base layer in step (3) for 3 minutes at a voltage of 12kV to inject a gradient electric field into the base layer, and then place the base layer horizontally in a condensation environment to achieve the ef...

Embodiment 3

[0043] A method for spontaneously dispelling condensate droplets in a horizontal direction, comprising the steps of:

[0044] (1) Place the glass sheet with an area of 27*5mm on the candle flame for 30s, then place the glass sheet, 4ml tetraethyl orthosilicate and 4ml ammonia solution in a dry container, vacuumize and let stand for 24h ;

[0045] (2) annealing the glass sheet treated in step (1) at 550° C. for 2 hours;

[0046] (3) Use O 2 The glass sheet after the annealing in the plasma treatment step (2), the treatment time is 10min, wherein, O 2The proportion is 75%, and the rest is Ar. Then place the glass sheet and 100 μl perfluorooctyltrichlorosilane in a dry container, vacuumize and let stand for 2 hours to obtain the base layer;

[0047] (4) Charge the base layer in step (3) for 1.5 minutes under the condition of 10kV voltage, inject a gradient electric field into the base layer, and then place the base layer horizontally in a condensation environment to achieve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com