A Passive Safety System to Suppress Water Hammer Induced by Steam Condensation

A safety system and steam condensation technology, applied in the fields of heat transfer and fluid mechanics, can solve problems such as steam condensation water hammer, achieve the effect of eliminating water hammer, broadening the application range, and eliminating water hammer induced by steam condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

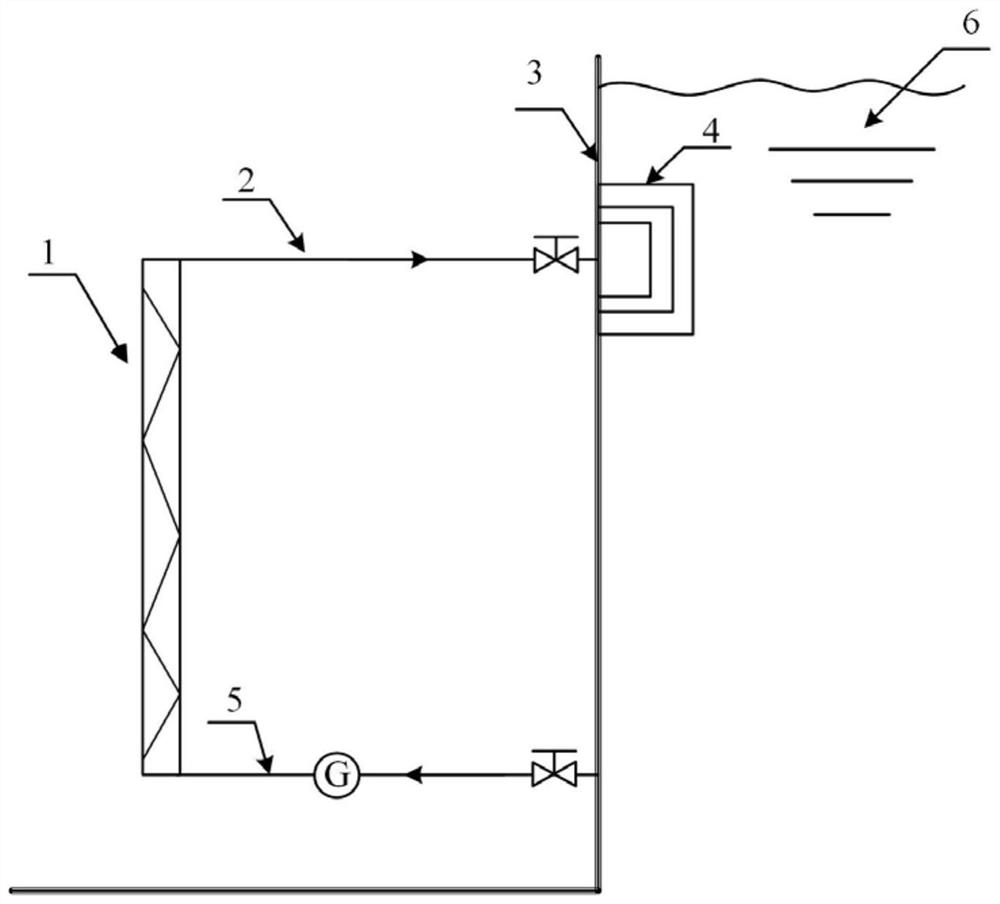

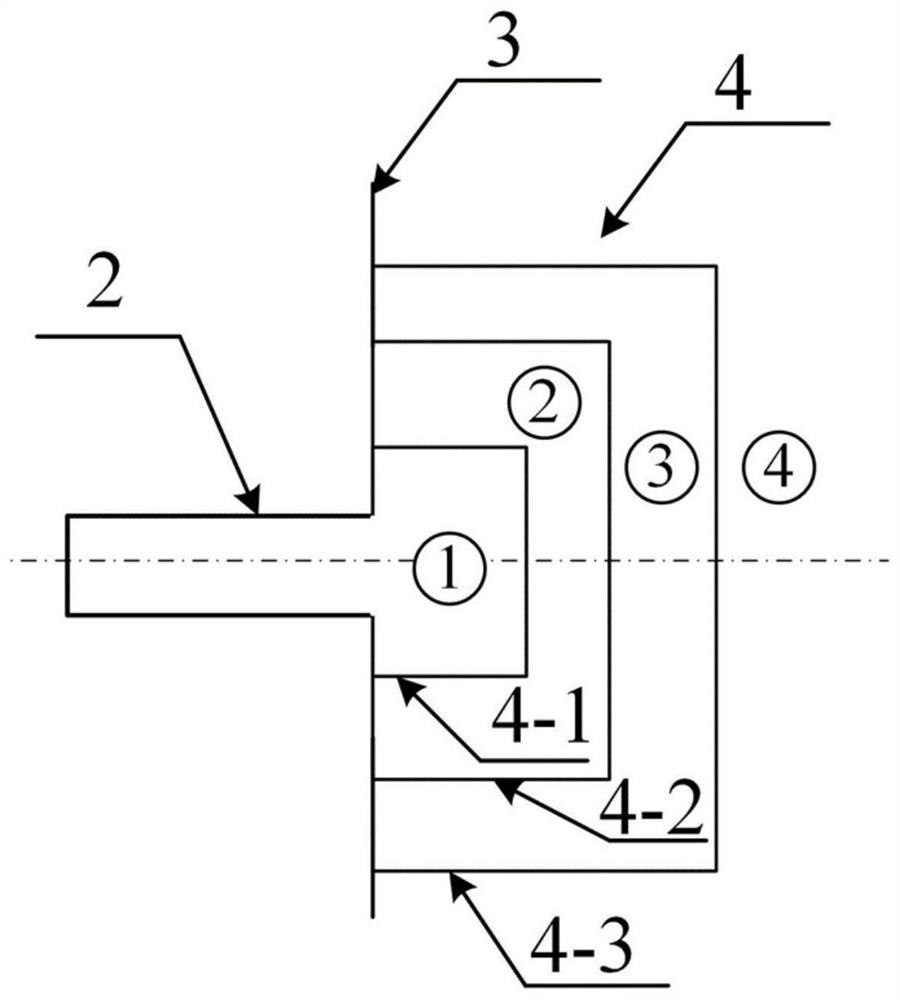

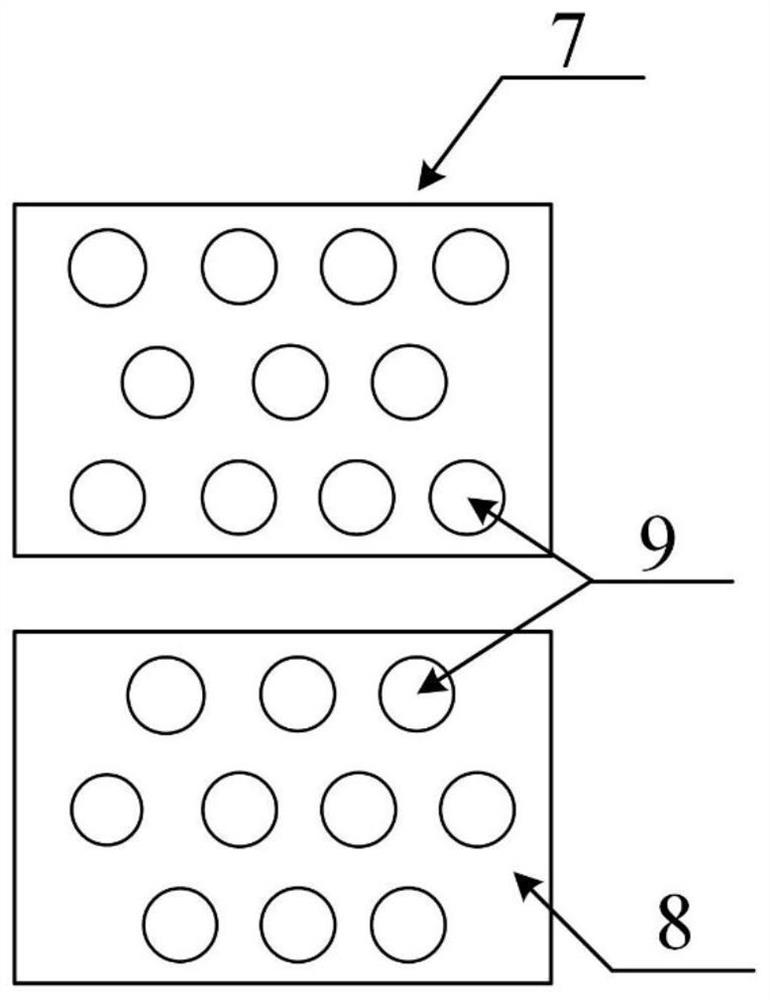

[0021] The invention includes a heat exchanger 1, a heat pipe section 2, a floating platform wall 3, an orifice compartment 4, a cold pipe section 5, and an ocean 6. It is characterized in that: the orifice compartment 4 is located in the ocean 6 and welded on the wall 3 of the floating platform. The orifice compartment 4 is a three-layer square structure formed by splicing the orifice 7 and the orifice 8, and forms four sections together with the wall 3 of the floating platform. Wherein the first layer of square body 4-1 is spliced by orifice plate 7, the second layer of square body 4-2 is spliced by orifice plate 8, and the third layer of square body 4-3 is spliced by orifice plate 7. The outlet nozzle of the heat pipe section 5 is located at the center of the projection of the three-layer orifice plate to the wall 3 of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com