Production method of alloy oxide thin-film transistor

An oxide thin film and transistor technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of device integration, reliability and lifespan, leakage current and high power consumption, etc., and achieve excellent deposition uniformity and consistency, improved flatness, and high deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

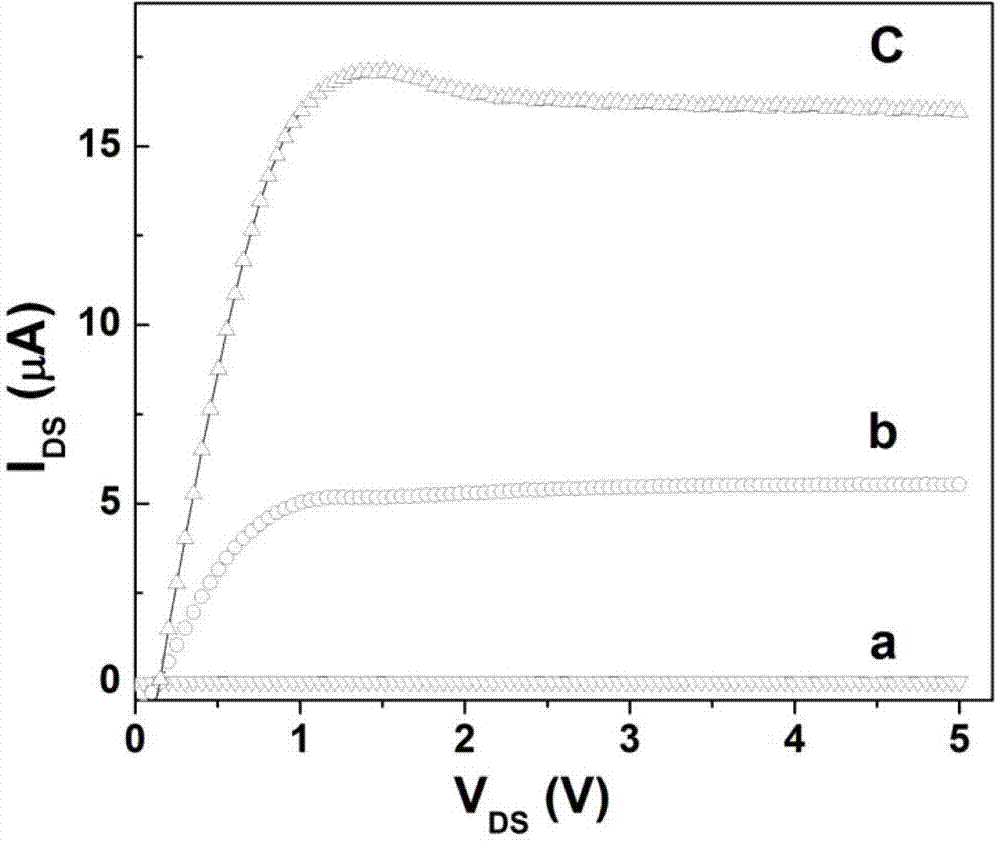

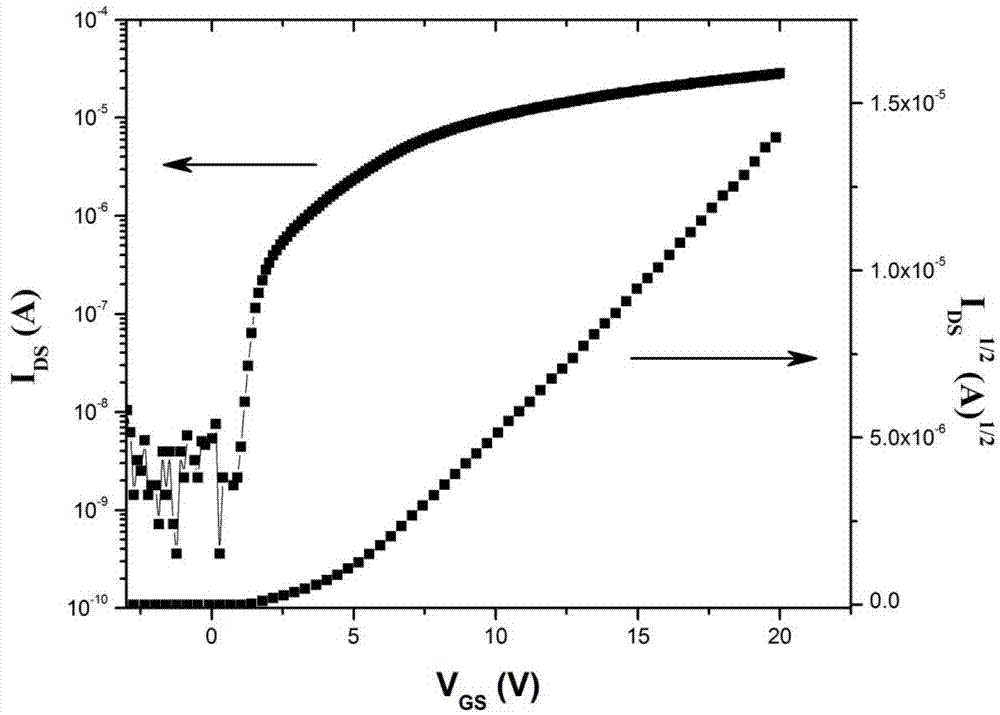

Examples

Embodiment

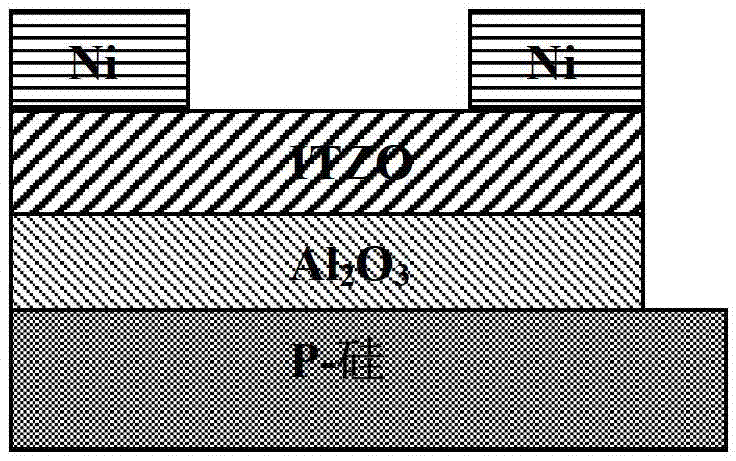

[0024] This embodiment prepares a bottom gate structure based on Al 2 o 3 The quaternary alloy oxide thin film transistor, the specific process is:

[0025] (1) Preparation of Al by pulsed laser deposition (PLD) 2 o 3 High-k dielectric film:

[0026] Step 1: Select P-type silicon (100) as the substrate, wash it with acetone with a purity greater than 99% and alcohol with a purity greater than 99% for 5 minutes, then rinse with deionized water repeatedly, and dry it with high-purity nitrogen;

[0027] Step 2: Put the P-type silicon substrate and the alumina ceramic target into the pulsed laser (PLD) reaction chamber, adjust the distance between the alumina ceramic target and the substrate to 40mm, and wait to be pumped to a high vacuum (10 -5 After Pa), high-purity oxygen is introduced, and the working pressure of the reaction chamber is kept at 60mTorr to perform pulsed laser ablation on the alumina target for 5 minutes, and the laser ablation energy density is 1J / cm 2 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com