Machining method and device for gold and platinum jewelry and combined type jewelry structure

A technology of processing method and processing equipment, which is applied in the field of jewelry product structure, processing method and processing equipment, can solve the problems of high production cost, unsuitable varieties, difficult processing, etc., achieve low production cost, many varieties, and save production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

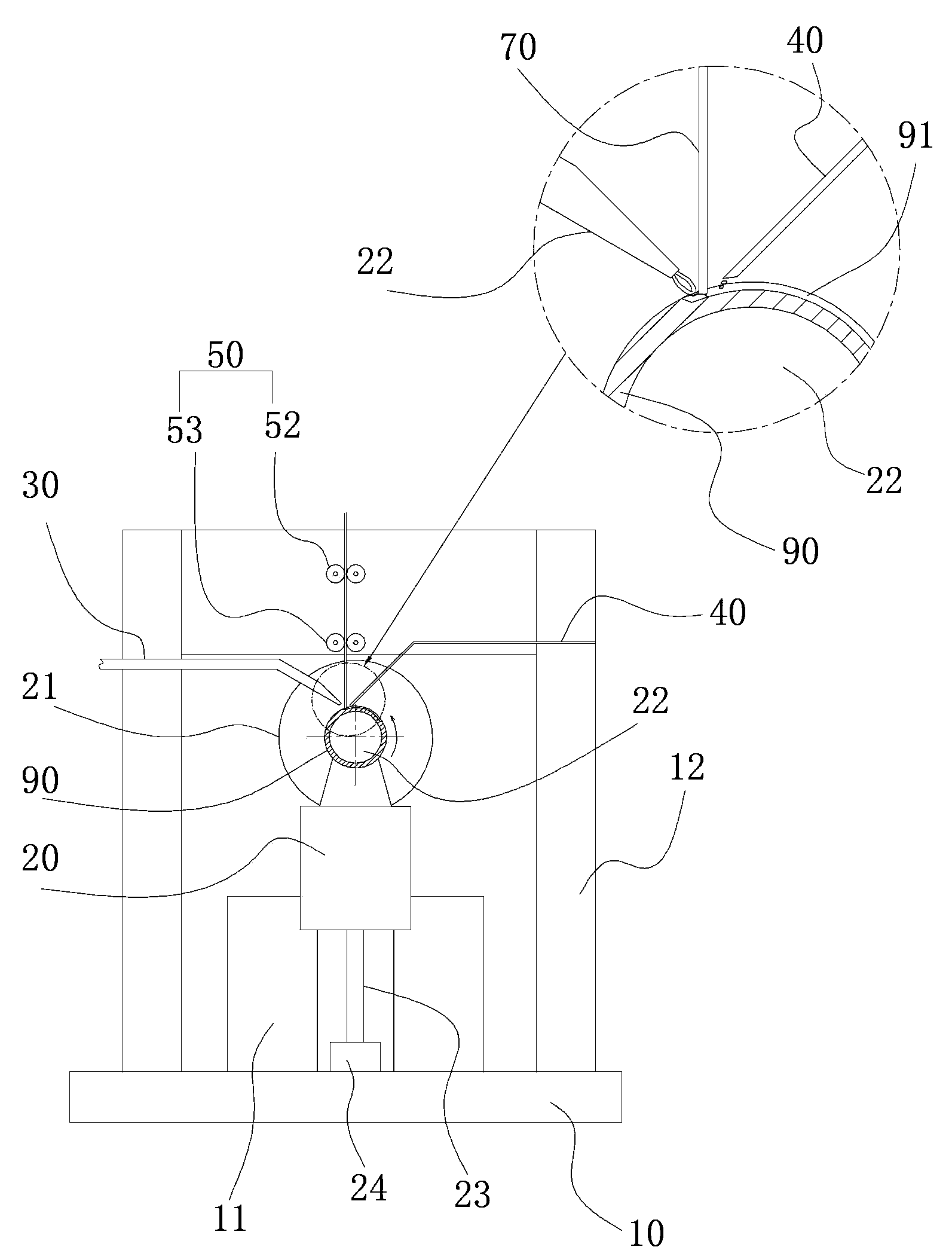

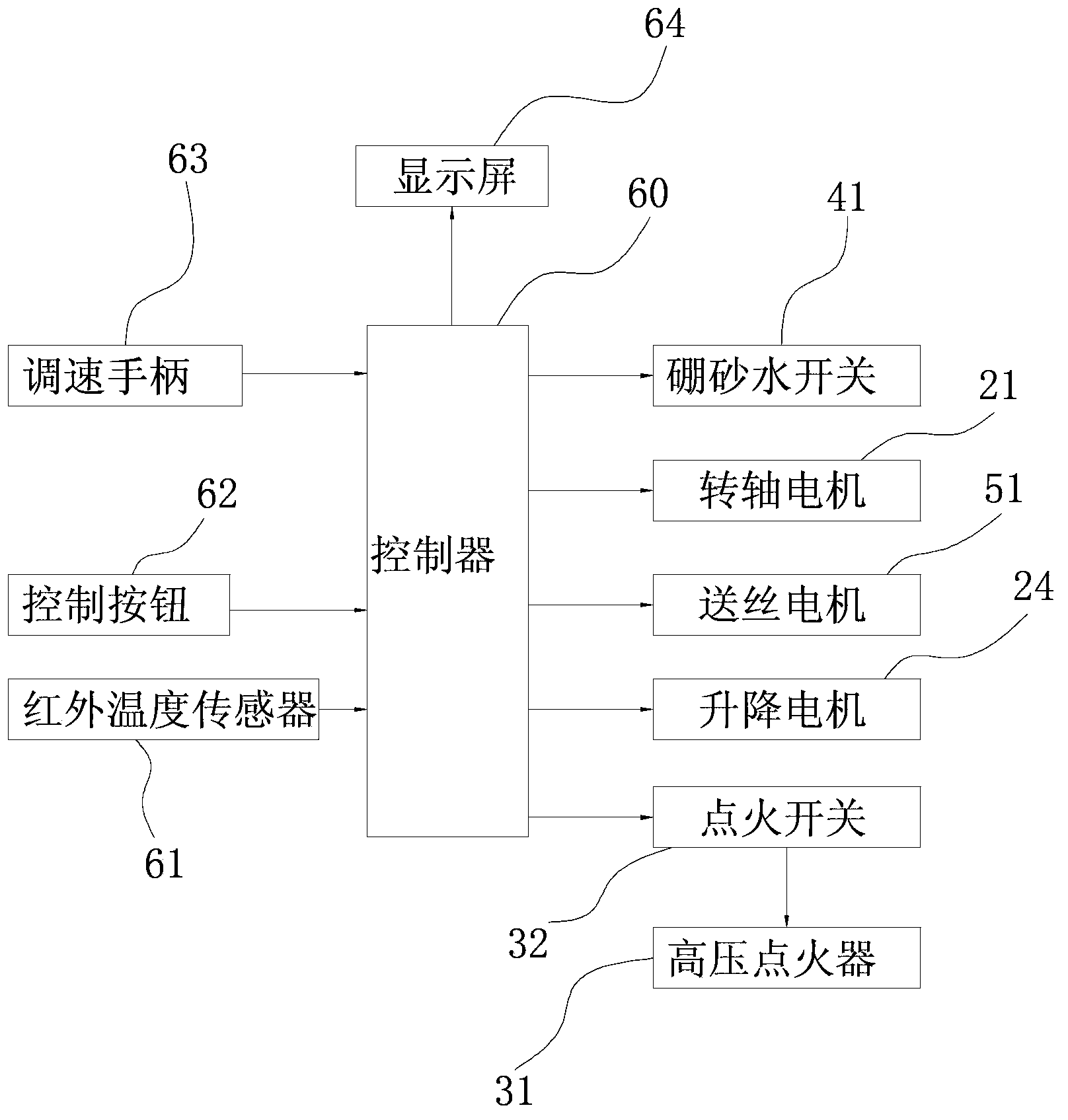

[0036] The processing method of yellow platinum jewelry of the present invention comprises the following steps:

[0037] 1) Platinum material is used, and the jewelry body is formed or cut according to the shape of the jewelry;

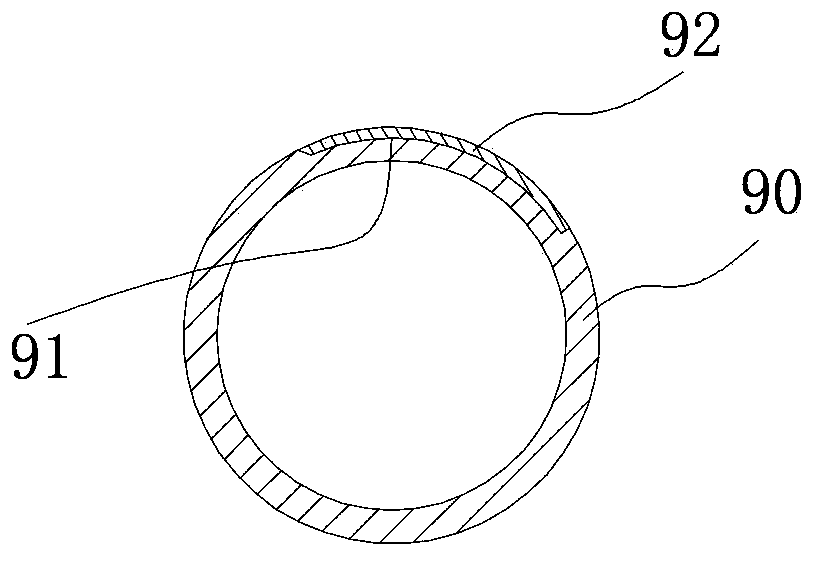

[0038] 2) Process grooves on the surface of the jewelry body, at least one groove; it can also be two, three, or four;

[0039] 3) Melt the gold material in the groove of the jewelry body at high temperature;

[0040] 4) Surface grinding treatment: grinding the surface of gold and platinum;

[0041] 5) Electrolytic electro-gold treatment on the surface of the jewelry: first apply oil to the gold surface, and then perform electrolysis and electro-gold after air-drying;

[0042] 6) Polishing treatment.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com