Control system of full-automatic chemical nickel-palladium-gold production equipment

A technology of automatic chemistry and production equipment, applied in liquid chemical plating, printed circuit manufacturing, metal material coating process, etc., can solve problems such as affecting normal production, slow response, and abnormal detection in time, to improve product quality , Improve product quality, increase the effect of traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

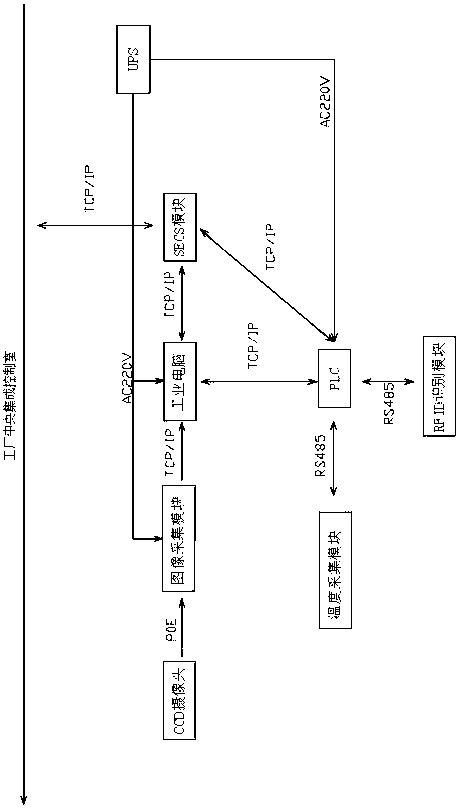

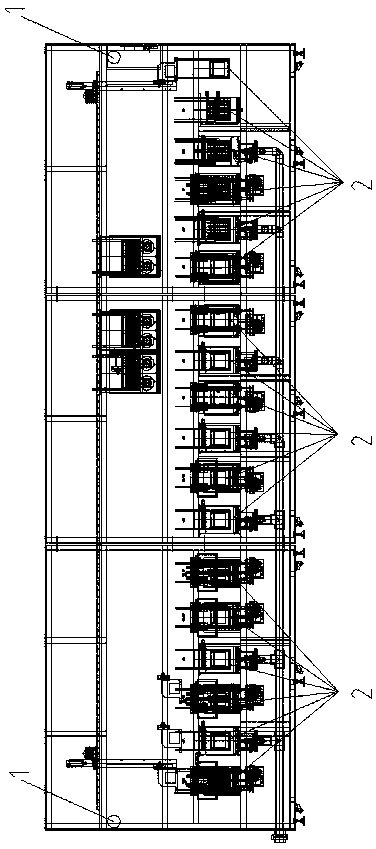

[0024] Such as figure 1 , 2 As shown, the fully automatic chemical nickel palladium gold production equipment control system, its structure includes CCD high-definition camera, industrial computer (integrated), temperature acquisition module, PLC and RFID identification module, in which the signal input terminal of the industrial computer and the image acquisition module The signal output ends are connected, the first signal input / output end of the industrial computer is connected with the first signal output / input end of the PLC, the second signal input / output end of the industrial computer is connected with the first signal output / input end of the SECS module Connected, the signal input end of the image acquisition module is connected with the signal output end of the CCD high-definition camera, the second signal output / input end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com